Waterborne energy-saving building coating and preparation method thereof

A technology for building energy-saving and coatings, applied in antifouling/underwater coatings, reflective/signal coatings, polyurea/polyurethane coatings, etc. Coefficient data and other issues, to achieve the effect of thermal insulation heating energy consumption, saving heating energy consumption, and excellent use effect in winter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

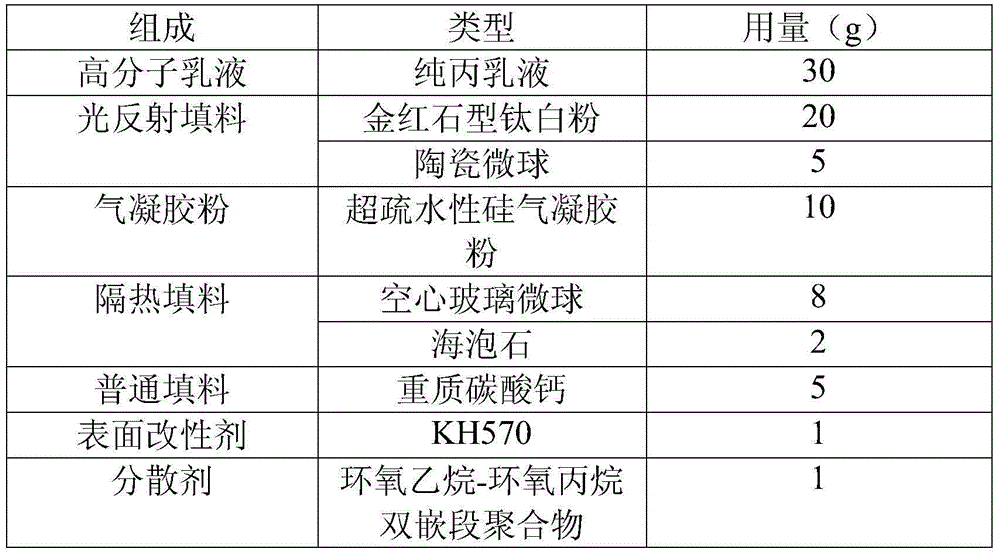

[0050] The formula composition of multi-functional high-efficiency and energy-saving coatings is shown in the following table:

[0051]

[0052]

[0053] (1) Preparation of airgel dispersion slurry: Add water, dispersant, and surface modifier into the dispersion tank according to the formula, and after mixing evenly, slowly add superhydrophobic airgel powder at a stirring rate of 500 rpm (The thermal conductivity is 0.018w / (m k), the density is 120kg / m 3 , the specific surface area is 400m 2 / g, the average particle diameter is 8 μm), and after all the airgel powders are added, disperse for 15 to 17 minutes at a speed of 1900 rpm to obtain a viscous airgel dispersion slurry;

[0054] (2) Preparation of energy-saving slurry: add water, dispersant, antifreeze and defoamer to the paint dispersion tank according to the above formula, and add titanium dioxide (TiO 2 Component mass fraction 96%, rutile phase content 99.5%, average particle size 200nm), ceramic microspheres (...

Embodiment 2

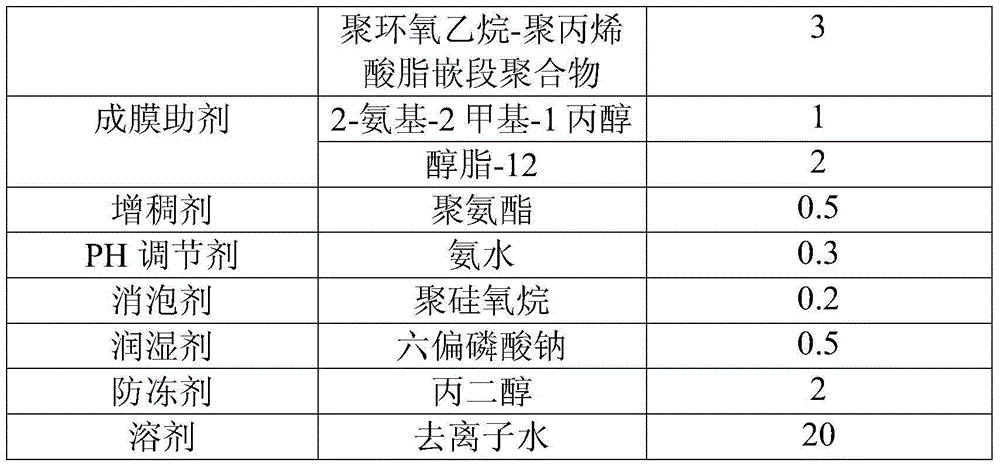

[0058] The formula composition of multi-functional high-efficiency and energy-saving coatings is shown in the following table:

[0059]

[0060]

[0061] Preparation of multifunctional high-efficiency and energy-saving coatings:

[0062] (1) Preparation of airgel dispersion slurry: Add water, dispersant, and surface modifier into the dispersion tank according to the formula, and after mixing evenly, slowly add superhydrophobic airgel powder at a stirring rate of 500 rpm (The thermal conductivity is 0.018w / (m k), the density is 120kg / m 3 , the specific surface area is 400m 2 / g, the average particle diameter is 8 μm), and after all the airgel powders are added, disperse for 15 to 17 minutes at a speed of 1900 rpm to obtain a viscous airgel dispersion slurry;

[0063] (2) Preparation of energy-saving slurry: add water, dispersant, antifreeze and defoamer to the paint dispersion tank according to the above formula, and add titanium dioxide (TiO 2 Component mass fraction ...

Embodiment 3

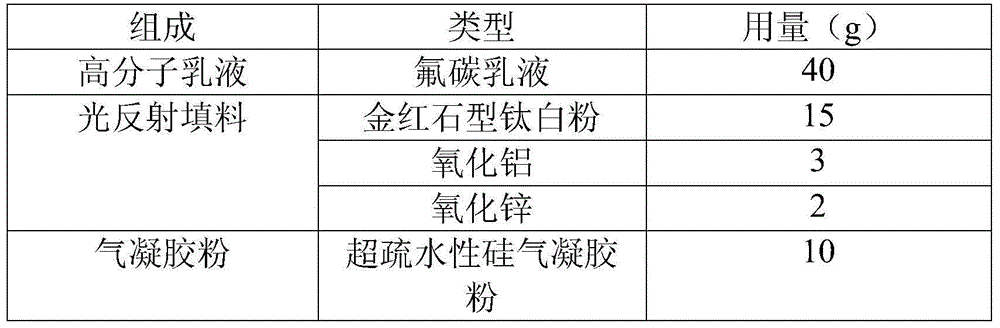

[0067] The formula composition of multi-functional high-efficiency and energy-saving coatings is shown in the following table:

[0068]

[0069]

[0070] Preparation of multifunctional high-efficiency and energy-saving coatings:

[0071] (1) Preparation of airgel dispersion slurry: Add water, dispersant, and surface modifier into the dispersion tank according to the formula, and after mixing evenly, slowly add hydrophilic airgel powder at a stirring rate of 500 rpm (The thermal conductivity is 0.025w / (m k), the density is 300kg / m 3 , the specific surface area is 280m 2 / g, the average particle diameter is 8 μm), and after all the airgel powders are added, disperse for 15 to 17 minutes at a speed of 1900 rpm to obtain a viscous airgel dispersion slurry;

[0072] (2) Preparation of energy-saving slurry: add water, dispersant, antifreeze and defoamer to the paint dispersion tank according to the above formula, and add titanium dioxide (TiO 2 Component mass fraction 96%, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com