Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

135results about How to "Improve weather resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Halogen-free anti-flaming transparent unsaturated polyester insulated dope and preparation method thereof

InactiveCN101186779AImprove weather resistanceTransparent appearancePolyester coatingsPolyesterChemistry

The invention discloses insulating paint of non-toxic fire retardant transparent unsaturated polyester and process for preparation. The paint is composed of the following components which are based on quanlified latex, including 50-80 parts of unsaturated polyester, 5-30 parts of methyl phenylsilicone resin, 5-30 parts of phosphate flame retardant, 5-30 parts of etherified amino resins and 0.5-4 parts of evocating agent. The insulating paint of non-toxic fire retardant transparent unsaturated polyester can be achieved by stirring and mixing the components for 0.5-3 hours under 10 DEG C to 40 DEG C. The external appearance of the insulating paint of fire retardant unsaturated polyester of the invention is transparent, the oxygen index of the solidifying product can be increased to 27% from 19%, and the vertical flame passes UL-94 V-0 level. The heat-resistant property and the weather ability of the paint are remarkably improved, and the paint can be used for the insulating treatment of various dry-type transformer windings and machine windings.

Owner:SOUTH CHINA UNIV OF TECH

Exterior wall dope and preparation method of exterior wall dope

ActiveCN102732079AImprove weather resistanceImprove mold and algae resistanceAntifouling/underwater paintsPaints with biocidesSolventChemistry

The invention discloses an exterior wall dope for building. The exterior wall dope comprises an emulsion binder, a pigment, paddings, a solvent, a film-forming assistant and an auxiliary material and further comprises a water glass and a viscosity stabilizer. The exterior wall dope has good weather resistance, good mold-algae resistance, excellent performance and good compatibility with base materials as well as is stable to store. Moreover, the invention further discloses a preparation method of the exterior wall dope. The preparation method is simple to operate and convenient to realize.

Owner:NIPPON PAINT GUANGZHOU

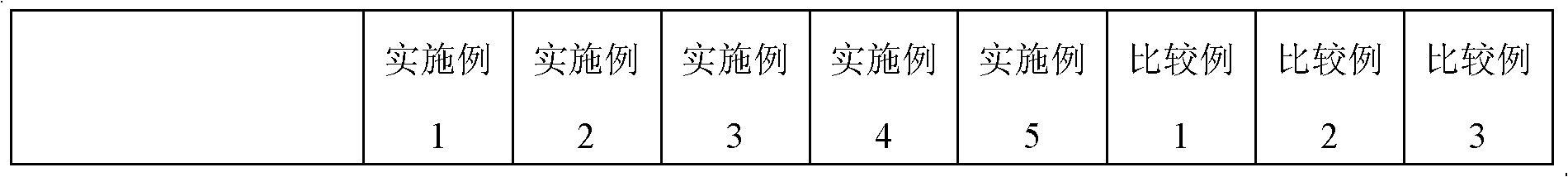

Weather-resistant, flame retardant and impact-resistant polystyrene material, and preparation method

InactiveCN103146090AGood flame retardancyImprove weather resistanceWeather resistanceFlame resistance

The invention belongs to the field of polymer material modification and processing technology, and relates to a polystyrene material and a preparation method. The polystyrene material is composed by the components of, by weight, 100 parts of a polystyrene resin, 20-35 parts of a toughening agent, 8-25 parts of a filler, 1-2.8 parts of an antioxidant, 0.2-1.0 parts of a light stabilizer, 8-15 parts of a flame retardant, 1-6 parts of a flame retardant synergist and 2.5-4 parts of a lubricant. The weather-resistant, flame retardant and impact-resistant polystyrene material provided by the invention has relatively high impact strength, relatively high tensile strength, good weather resistance and flame retardance, easy processing, stable performance and long service life, so that the application scope of the polystyrene material is expanded, and the polystyrene material can replace engineering plastics in some fields, can be used for electrical and mechanical parts, and has broad market application prospects.

Owner:滁州格美特科技有限公司

Heavy-duty coating of engineering machinery

ActiveCN102888187AImprove weather resistanceExcellent performanceAnti-corrosive paintsPrepolymerSolvent

The invention relates to an epoxy-modified organosilicone heavy-duty coating added with nano metal powder. The heavy-duty coating is composed of component A, component B and component C, wherein the component A is the epoxy-modified organosilicone which comprises the following components by mass percent: 25 to 40 % of matrix resin, that is, the epoxy-modified organosilicone, 20 to 40 % of pigment filler and auxiliary agents, and 20 to 40 % of a solvent; The component B is self-made titanium alloy nano powder in an amount of 0.5 to 2 % of the amount of the matrix resin; and the component C is aminosilane in an amount of 10 to 20% of the amount of matrix resin. According to the heavy-duty coating, the epoxy-modified organosilicone solution is prepared through the epoxy resin modification for prepolymer of organosilicone intermediate, the self-made titanium alloy nano powder is used to improve properties such as weather resistance, corrosion resistance, abrasion resistance, high strength and the like, of the heavy-duty coating of engineering machinery, and the aminosilane is used as a curing agent for normal-temperature curing. A cured film can be obtained through placing in an environment with the air humidity of 50% or more for seven days; and the obtained film is good in weather resistance, excellent in corrosion resistance, strong in adhesion and good in mechanical property, and is suitable for the field of the heavy duty of the engineering machinery, especially for the corrosion protection in the sun, salt atmosphere, acid, alkali and other environment.

Owner:广东四方威凯新材料有限公司

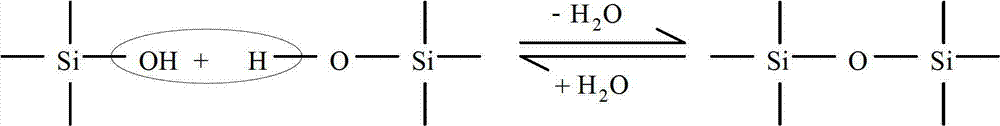

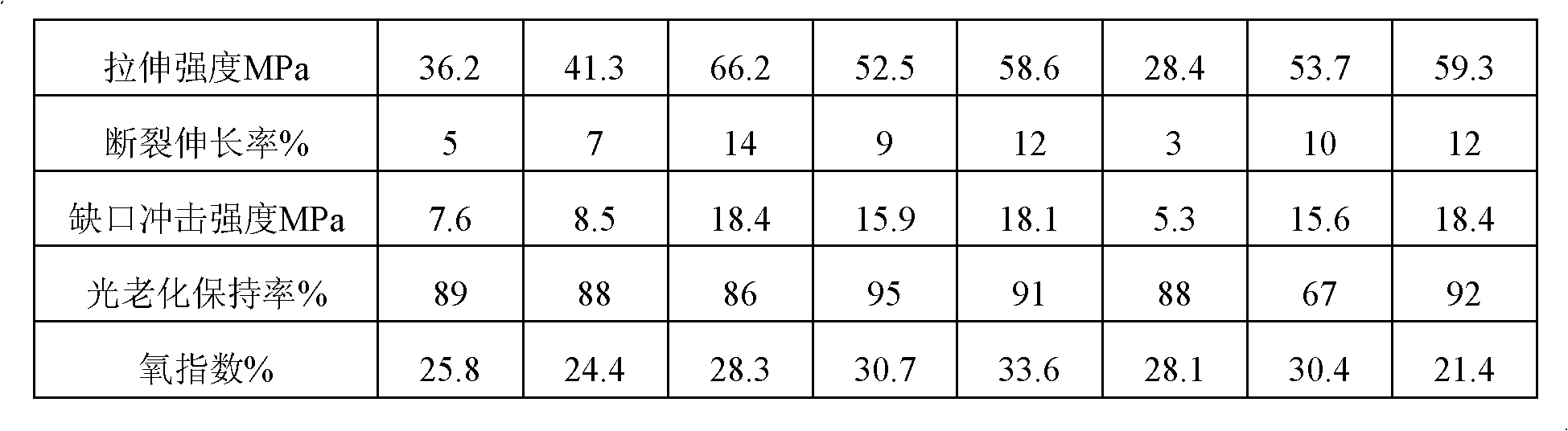

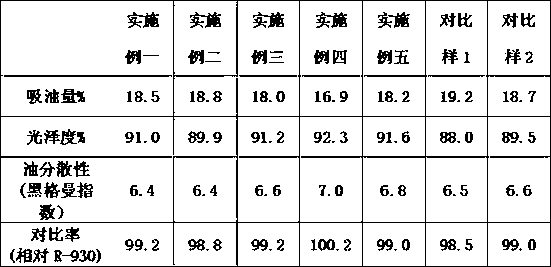

Preparation method of special titanium dioxide for oily system

InactiveCN103131212AImprove weather resistanceLow oil absorptionPigment treatment with organosilicon compoundsPigment physical treatmentHigh contrastWeather resistance

The invention discloses a preparation method of a special titanium dioxide for an oily system. The method comprises the following steps: 1, pulping to prepare a titanium dioxide suspension slurry, adding a dispersant, dispersing, and grinding; 2, diluting the ground titanium dioxide suspension slurry, and filtering; 3, adding a zirconium compound, curing, and depositing; 4, adding an aluminum compound, curing, and depositing; 5, adjusting the pH value, and curing; and 6, washing, drying, and carrying out airflow crushing. The method allows the surface of a titanium dioxide particle to be respectively coated with a zirconium oxide film and an alumina film inside out and a silane coupling agent hydrolysate to be adopted to carry out organic treatment, so the special titanium dioxide has the advantages of substantially-increased weather resistance, lipophilicity and luster, low oil absorption, good dispersity, realization of the hiding capability same to import titanium dioxide, high contrast rate, good temperature resistance, and no ink layer yellowing.

Owner:江苏镇钛化工有限公司

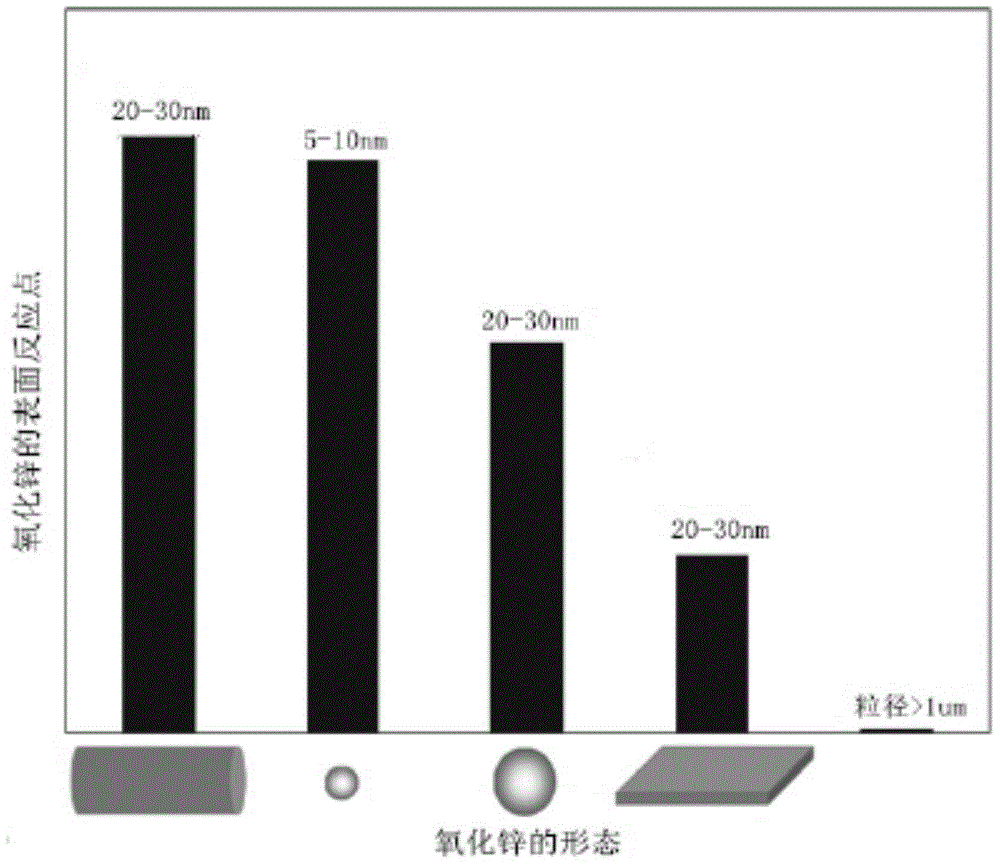

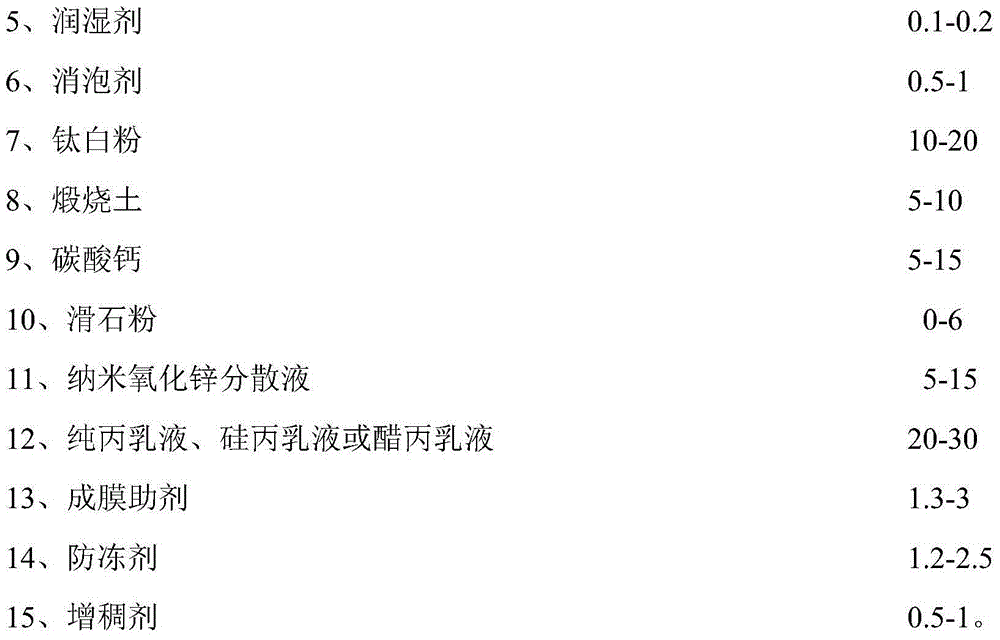

Inorganic antibacterial formaldehyde-removing paint and preparation method thereof

InactiveCN104592841AEasy constructionImprove weather resistanceAntifouling/underwater paintsPaints with biocidesEmulsionCalcium carbonate

The invention relates to an inorganic antibacterial formaldehyde-removing paint. The antibacterial formaldehyde-removing paint is prepared by using an emulsion as a binding agent and an inorganic antibacterial functional material nanometer zinc oxide as a functional material. The inorganic antibacterial formaldehyde-removing paint comprises the following components: water, emulsion, nanometer zinc oxide, titanium dioxide, calcined clay, calcium carbonate, talcum powder, a wetting agent, a dispersant, an anti-foaming agent, a film-forming agent, an antifreezer and a thickener. Compared with traditional regular organic antiseptic and anti-mildew agents, the inorganic nanometer zinc oxide antibacterial and antiviral paint has the functions of safeness, no toxicity, long-term antisepsis and formaldehyde removal.

Owner:SKSHU PAINT

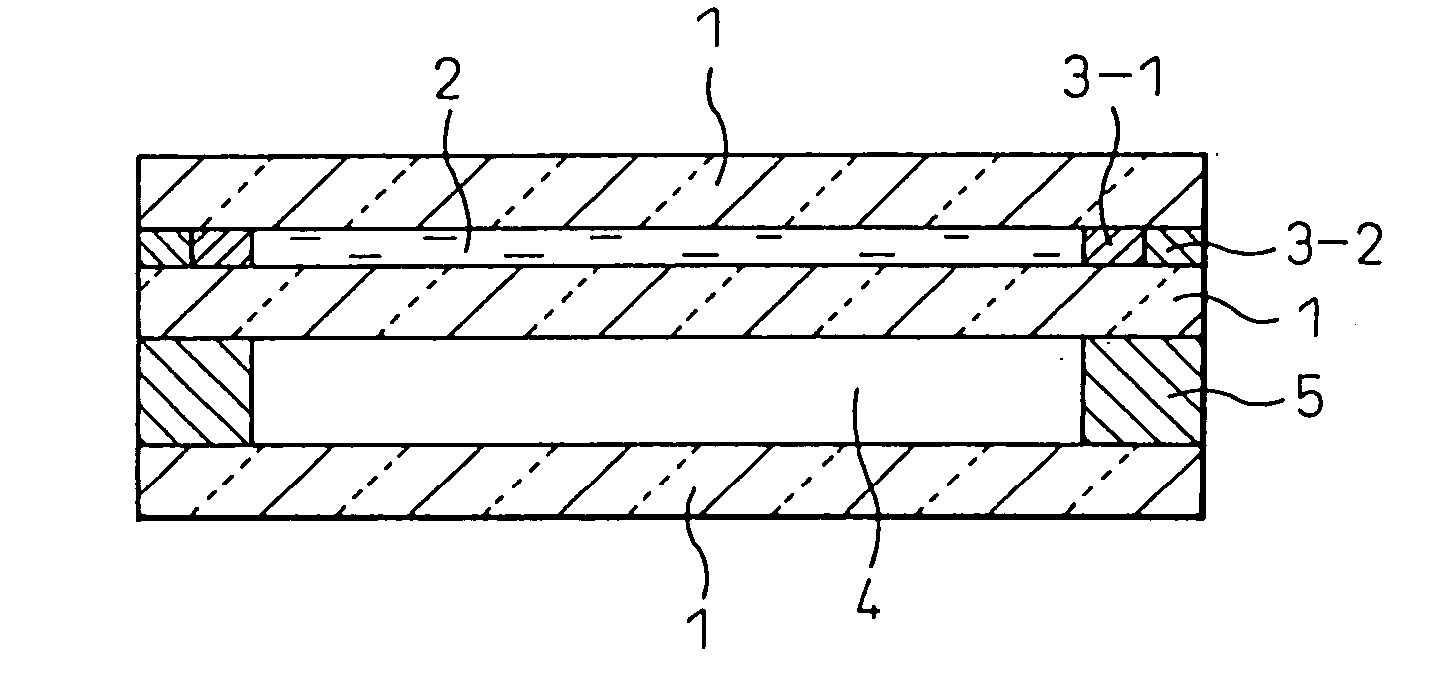

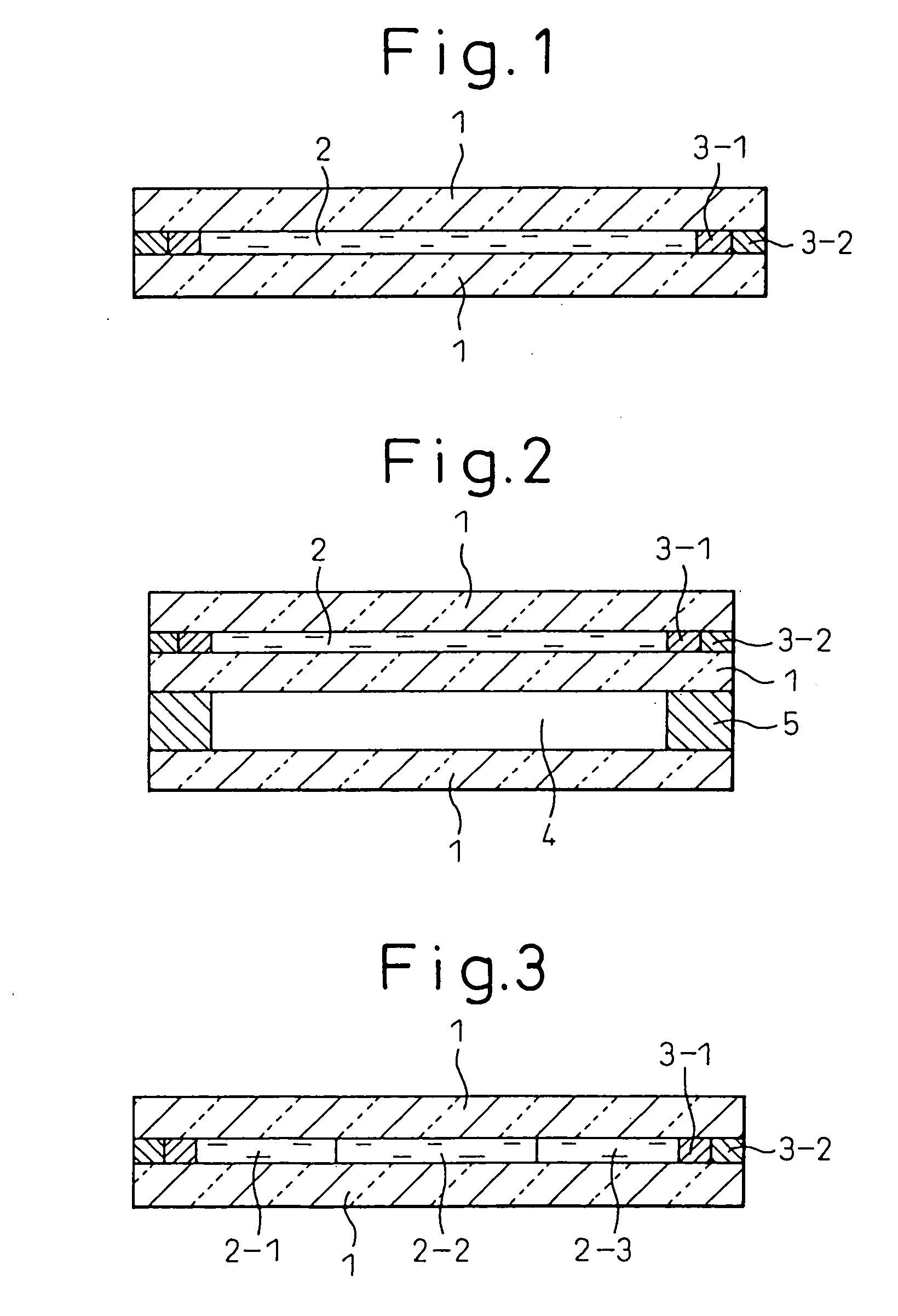

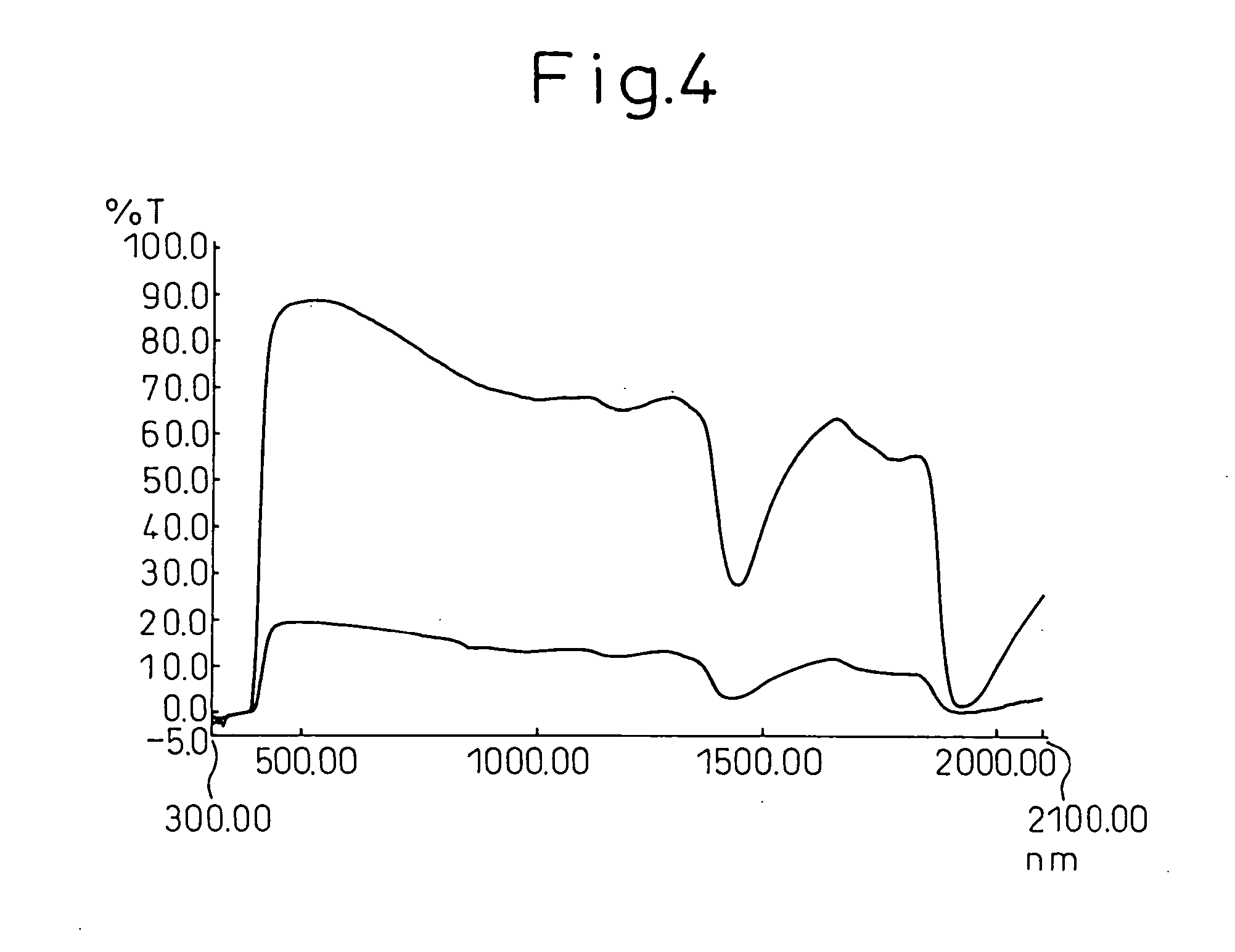

Laminate-controlling light autonomously and window using the same

InactiveUS20060057312A1Stable reversible changeImprove weather resistanceSynthetic resin layered productsCellulosic plastic layered productsWeather resistanceWater soluble

There are provided laminated bodies or laminated body-containing windows, which comprise isotropic aqueous solutions obtained by dissolving a water-soluble polysaccharide derivative having nonionic amphipathic functional groups in an aqueous medium composed of water and an amphipathic substance, laminated between plates that are at least partially transparent and allow direct vision of the isotropic aqueous solutions, wherein there are added to the isotropic aqueous solutions in appropriate amounts ultraviolet absorbers comprising nonionic or ionic benzophenone derivatives or benzotriazole derivatives which are highly weather resistant and uniformly dissolve in the isotropic aqueous solutions. The isotropic aqueous solutions are transparent and become opaque upon irradiation with light, and exhibit stable reversible change, in order to provide vastly improved weather resistance to the laminated bodies against exposure to sunlight rays over prolonged periods of time.

Owner:AFFINITY CO LTD

Flame-retardant wear-resisting modified polypropylene material and preparation method thereof

InactiveCN104371162AImprove weather resistanceElimination of antagonismPolypropylenePolymer chemistry

The present invention relates to a flame-retardant wear-resisting modified polypropylene material which comprises the following raw materials by weight: 100 parts of polyethylene, 10-100 parts of acicular wollastonite, 10-30 parts of a flame retardant, 10-50 parts of glass fiber, 0.01-0.5 part of an acid removing agent, 0.2-0.5 part of an antioxidant, 0.1-1 part of a light stabilizer, 0.1-0.7 part of a compatible agent, and 0.1-0.3 part of a lubricant; and the present invention provides a preparation method of the modified polyethylene material. The flame-retardant wear-resisting modified polypropylene material uses the acicular wollastonite as an anti dripping agent of the flame retardant and the glass fiber as a filling reinforcing agent, and improves the fire retardant properties, mechanical properties and wear resistance of the material.

Owner:解波

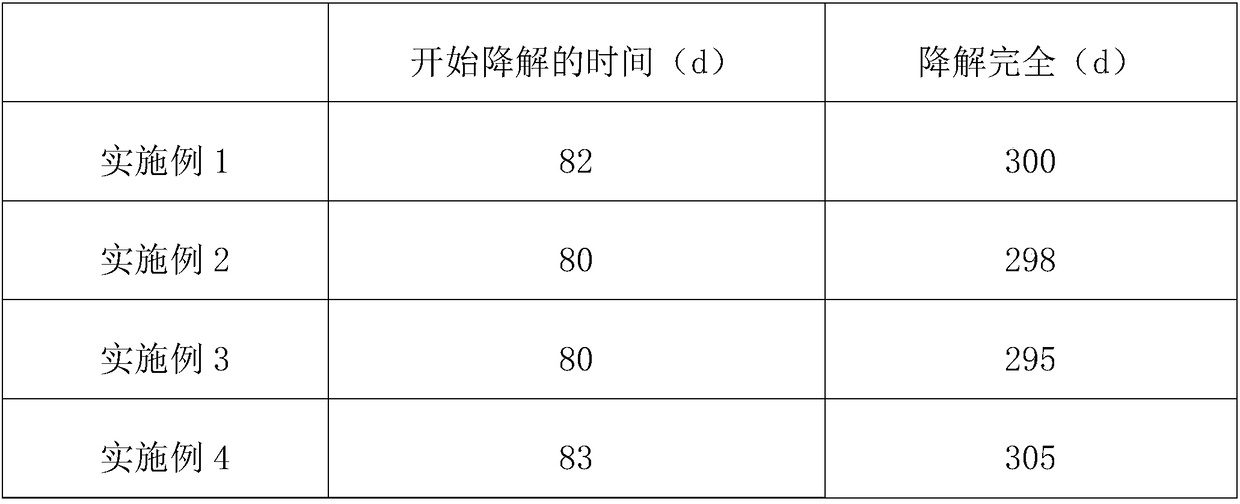

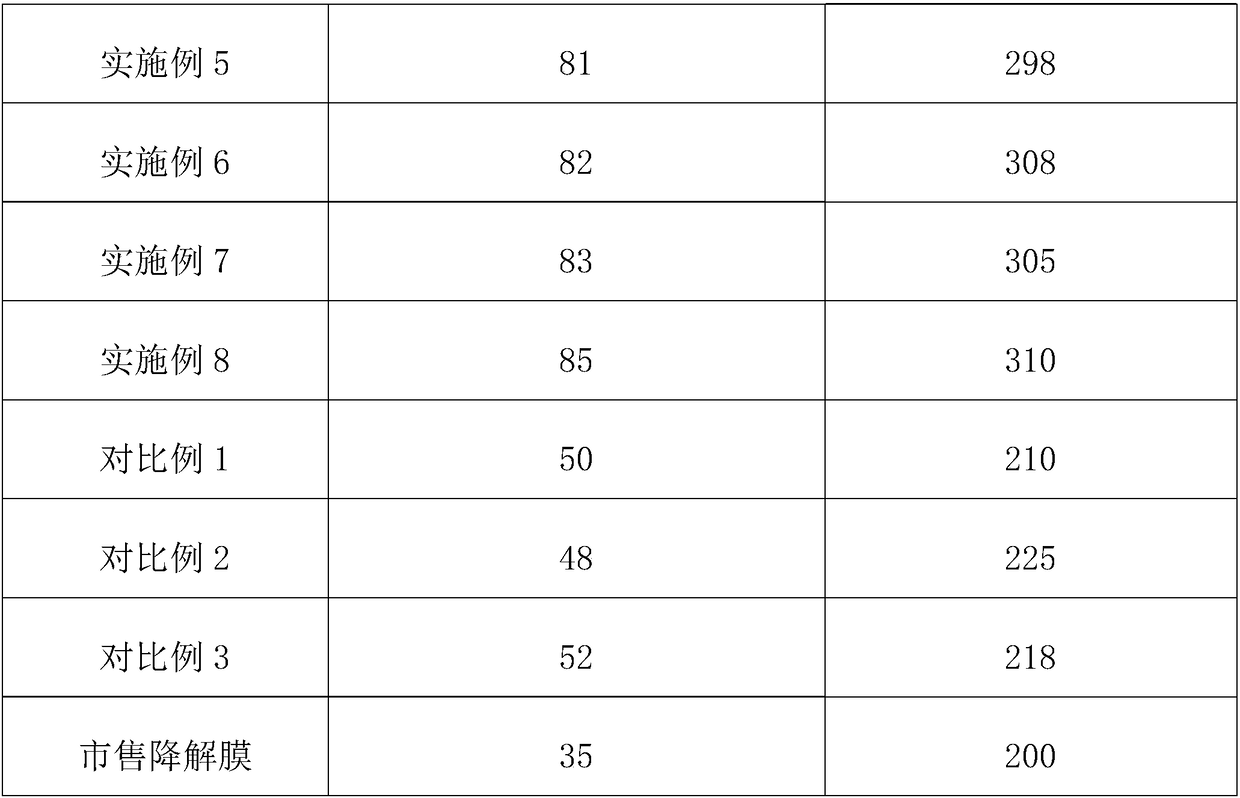

Degradable film coating material

InactiveCN108299876AGood optical performanceImprove weather resistanceAntifouling/underwater paintsPaints with biocidesNanometreTitanium dioxide

The invention provides a degradable film coating material, and belongs to the technical field of thin films. The degradable film coating material includes 20-40 parts by weight of nano silica, 50-70 parts by weight of nano titanium dioxide, 4-10 parts by weight of acrylic resin, and 4-10 parts by weight of polyimide resin, wherein the particle size of the acrylic resin is 10-15 nm. The coating material is applied to degradable films, can effectively prolong the degradation time of the degradable films and has low cost.

Owner:SICHUAN UNIV

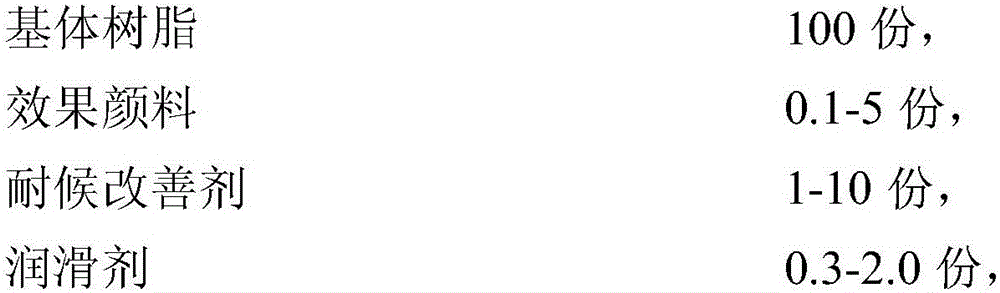

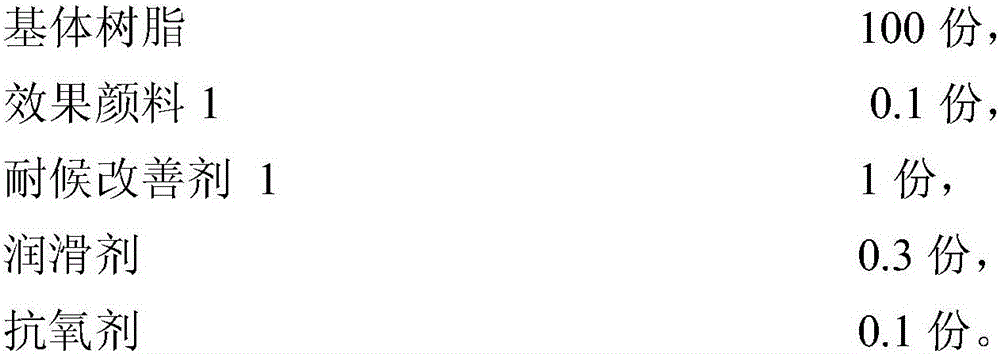

Highly weather-resistant aesthetic resin and preparation method thereof

The invention relates to a highly weather-resistant aesthetic resin. The highly weather-resistant aesthetic resin is prepared from the following components in parts by weight: 100 parts of a matrix resin, 0.1-5 parts of effect pigments, 1-10 parts of a weather-resistant modifier, 0.3-2.0 parts of a lubricating agent and 0.1-1.0 part of an antioxidant. The invention also provides a method for preparing the highly weather-resistant aesthetic resin. The invention has the advantages that the aesthetic resin prepared by the invention has excellent appearance, does not have any flow trace or weld line during injection molding, overcomes the defect in the prior art that the aesthetic resin is insufficient in weather resistance, greatly widens the application field and range of replacing spray with the aesthetic resin, really realizes a green, energy-saving and environmental-friendly spraying-free solution, and can be widely applied to the fields with particularly high weather resistance requirements, such as automobiles, household appliances, consumer electronics and the like.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

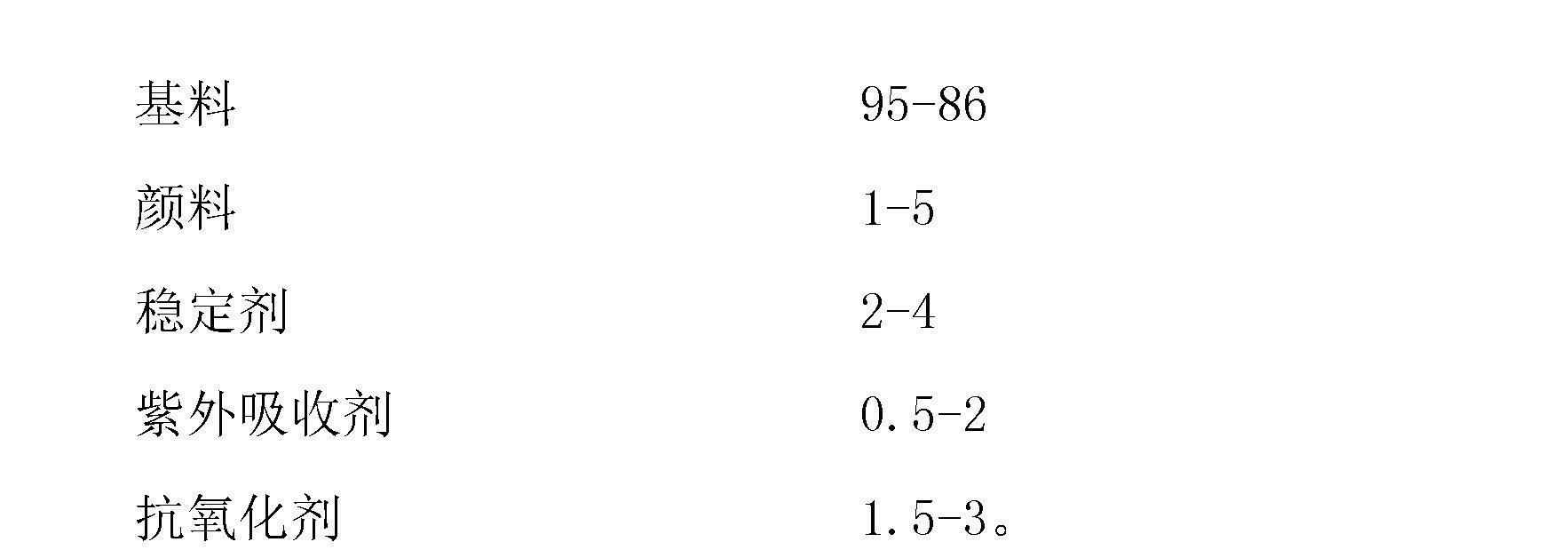

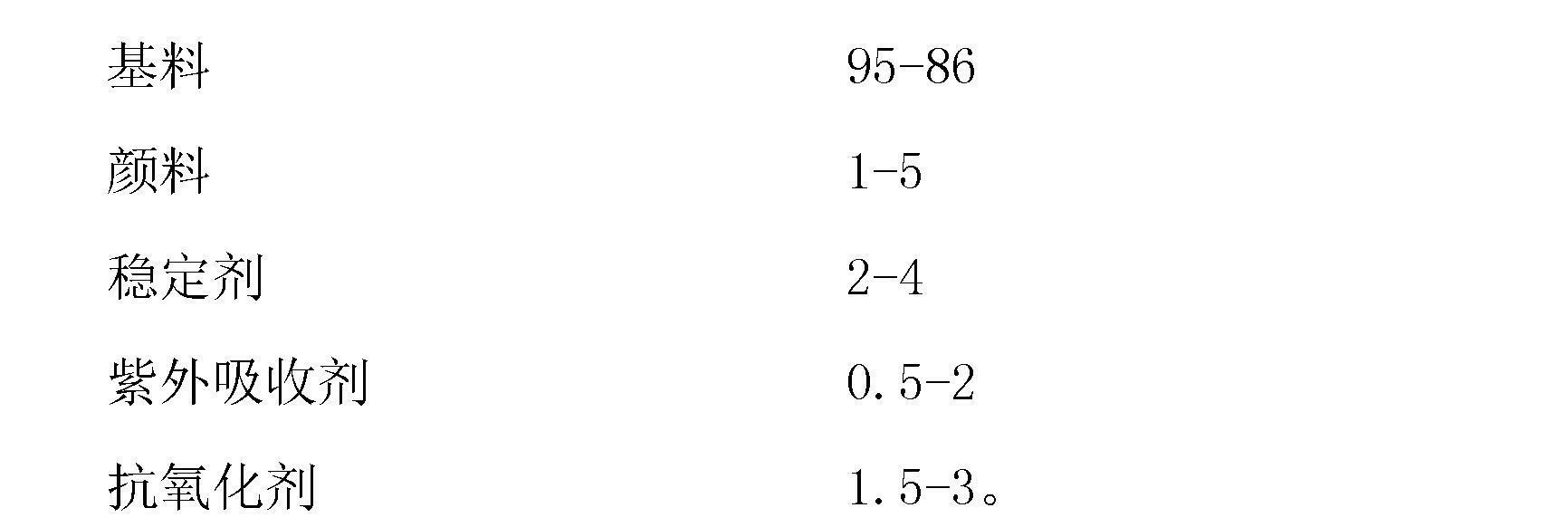

Weather resistant type color co-extruding dedicated material with pearly-luster decoration effect and manufacturing method thereof

The invention discloses a weather resistant type color co-extruding dedicated material with pearly-luster decoration effect and a manufacturing method thereof. The coating contains base stock, pigment, a flatting agent, a light stabilizer, an ultraviolet absorber and an antioxidant. Compared with the prior art, the material has the characteristics of being gorgeous in color and high in weather resistance.

Owner:WUHU CHUANGKE NEW MATERIAL TECH CO LTD

Organosilicon epoxy acrylic acid modified waterborne alkyd resin emulsion and coating thereof

InactiveCN105131263AImprove weather resistanceImprove hydrolysis resistancePolyester coatingsEmulsionOrganosilicon

The invention provides an organosilicon epoxy acrylic acid modified waterborne alkyd resin and a coating thereof; the formula of the coating comprises the components in parts by mass: 40-50 parts of an organosilicon epoxy acrylic acid modified waterborne alkyd resin emulsion comprising the components of 45-65 parts of tung oil, castor oil or linseed oil, 25-45 parts of phthalic anhydride, trimellitic anhydride or trimellitic anhydride, 3-10 parts of xylene, 5-10 parts of epoxy ester and 5-10 parts of organosilicon ester; 3-4 parts of a pigment; 6-26 parts of a packing; 10-20 parts of deionized water; 0.05-0.5 part of a dispersant; 0.1-0.3 part of a defoaming agent; and 0.9-2.5 parts of a drier. The preparation method of the emulsion comprises the steps: heating oil, glycerol, pentaerythritol and trimethylolpropane with nitrogen protection, adding an alcoholysis catalyst, heating up, keeping a reaction until the ethanol tolerance degree reaches 2.0-5.0 ml / 100 ml, and cooling; adding anhydride and xylene; adding organosilicon ester and epoxy ester, and modifying; and adding acrylate, and modifying; and cooling, and dispersing the mixture for two times. The coating has the advantages that easily-volatile organic compounds are reduced with water as a diluent.

Owner:盘锦辽河油田金宇生态环境有限公司

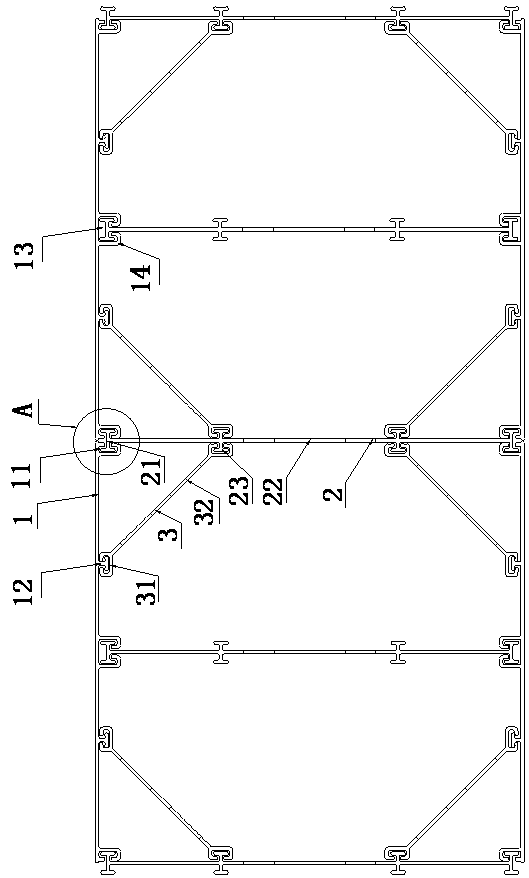

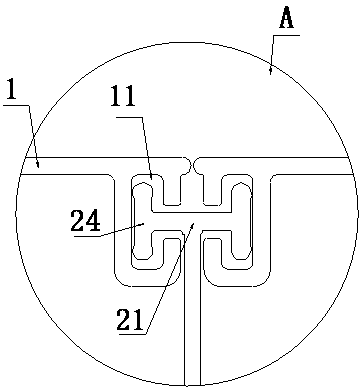

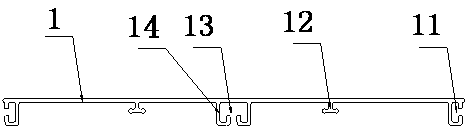

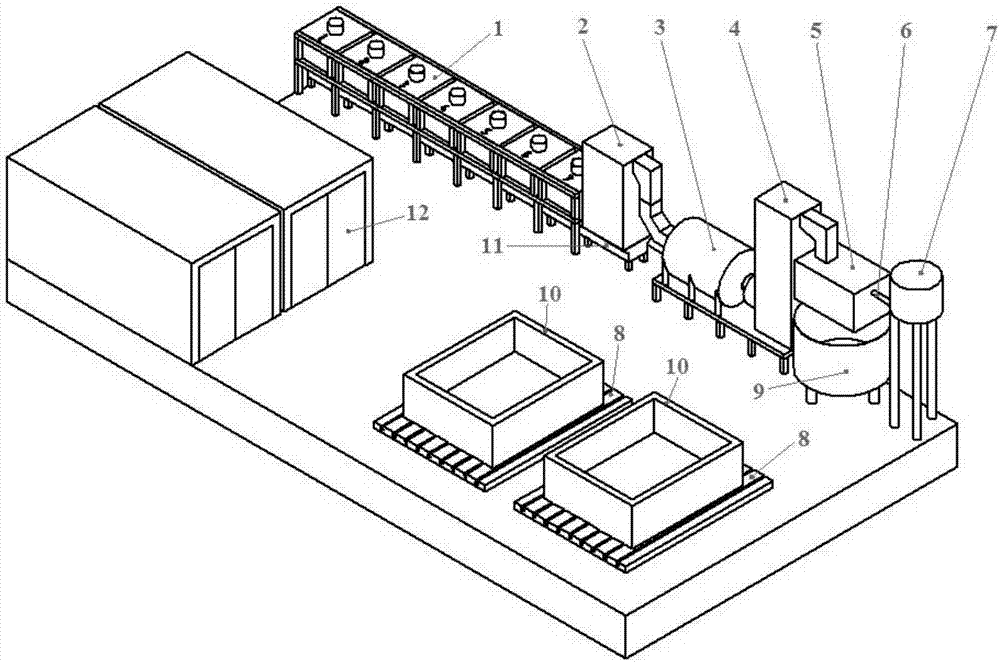

Combined PVC (Poly Vinyl Chloride) building template

InactiveCN102359266AImprove impact resistance and pressure resistanceImprove weather resistanceForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksEarthquake resistantSurface plate

Owner:HUAJUN PLASTIC BUILDING MATERIAL

High-performance modified chloroprene rubber adhesive

InactiveCN105238298AImprove weather resistanceGood cold resistanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesChemistryWeather resistance

The present invention discloses a high-performance modified chloroprene rubber adhesive, wherein the raw materials comprise chloroprene rubber, cis-polybutadiene rubber, styrene-butadiene rubber, an alkyl benzoic acid resin, a p-tert-butyl phenol formaldehyde resin, a terpene resin, nanometer silica, nanometer alumina, organic bentonite, white carbon black, active magnesium oxide, polystyrene, ethylene thiourea, zinc oxide, ethyl acetate, cyclohexane, dimethyl carbonate, propylene glycol, methyl cyclopentane, 120# solvent oil, a resorcinol-formaldehyde resin, an anti-aging agent, cerium oxide, a silane coupling agent KH-560 and a plasticizer. According to the present invention, the high-performance modified chloroprene rubber adhesive has characteristics of high bonding strength, good low temperature resistance, good weather resistance, good heat resistance, good aging resistance, and excellent storage stability.

Owner:安徽大松树脂有限公司

Color masterbatch with pearly luster color capable of changing along with angle

The invention relates to color masterbatch with pearly luster color capable of changing along with the angle. The color masterbatch with the pearly luster color capable of changing along with the angle is characterized by comprising, by weight percentage, 30-80% of carriers, 5-7% of additives, 6-9% of dispersants, 3-6% of pearl powder, 2-5% of paints, 1-2% of organic acid calcium and 1-2% of organic acid zinc. The color of the masterbatch can change continuously along with the angle, the masterbatch is indispensable additives for colorization of plastic products, and for PVC products formed in an extrusion mode, the color masterbatch with the pearly luster color capable of changing along with the angle is rich in type and color, good in lustrousness and high in controllability.

Owner:CHUZHOU HONGYUAN SPRAYING

A solvent-free liquid epoxy wear-resistant coating

ActiveCN102294860AStrong adhesionHigh mechanical strengthSynthetic resin layered productsEpoxy resin coatingsCoated surfaceEpoxy

The invention belongs to a solvent-free liquid epoxy wear resistant paint preparation technology. The solvent-free liquid epoxy wear resistant paint is composed of priming paint and primary layer coating; the primary layer coating is coated on the surface of the priming paint to form a wear resistant coating together. The priming paint and primary layer coating are composed of two components, the difference between the priming paint and primary layer coating is that a wear resistant filling material is added in the paint composition of the priming paint. The invention provides the solvent-free liquid epoxy wear resistant paint with high mechanical strength, strong adhesive force and low cost. The method of the present invention is capable of raising the chemical resistance and weather-resistance of the products, mitigating labor strength and saving the cost simultaneously, and prolonging the usage life of the product.

Owner:NINGBO KEXIN CORROSION CONTROL ENG

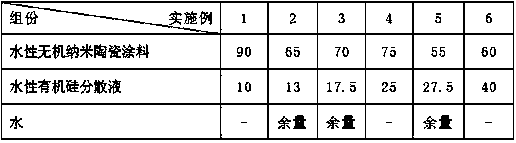

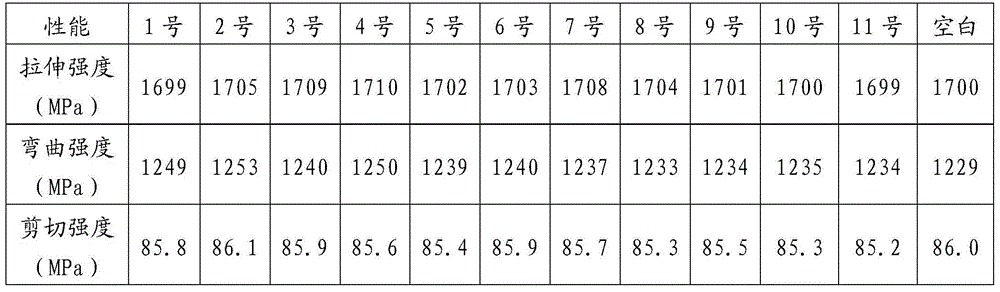

Normal temperature cured super weather-resistant and wear-resistant high-hardness water-based inorganic nanoceramic coating and preparation method thereof

ActiveCN109266057AImprove the inhibition effectImprove weather resistanceCoatingsWeather resistanceEmulsion

The invention relates to a normal temperature cured super weather-resistant and wear-resistant high-hardness water-based inorganic nanoceramic coating and a preparation method thereof. The inorganic nanoceramic coating comprises a water-based inorganic nanoceramic coating, water-based organosilicon dispersion liquid and water, wherein the water-based inorganic nanoceramic coating comprises the following raw materials: a water-based inorganic nanoceramic emulsion, a pigment, a filler, a wetting dispersing agent, a non-stick leveling agent, a thickening agent and water; the water-based inorganicnanoceramic emulsion comprises silica sol, silane, a surfactant and water; and the water-based organosilicon dispersion liquid comprise amino silane, a surfactant and water. The preparation method comprises a step of uniformly mixing the water-based inorganic nanoceramic coating and the water-based organosilicon dispersion liquid in weight ratio of (1-4):1, thereby obtaining the normal temperature cured super weather-resistant and wear-resistant high-hardness water-based inorganic nanoceramic coating. The coating product provided by the invention can be diluted with any water and stored stably for 1 year or longer, and has the characteristics of high hardness, high wear resistance, high weather resistance, normal temperature curing and the like.

Owner:CHANGSHA HUANGMEI PAINT

Fiber reinforced resin matrix composite weatherability improvement composition and application thereof

The present invention provides a fiber reinforced resin matrix composite weatherability improvement composition and application thereof, the composition comprises a complex antioxidant system and a light stabilizer system; and the weight ratio of the complex antioxidant system to the light stabilizer system is 1: 0.1-5. The composition can improve the fiber-reinforced resin matrix composite weatherability, can effectively inhibit the fiber reinforced resin matrix composite aging in processing and use processes, and can prolong the service life. Furthermore, the composition is a liquid composition, and when the composition is added into the fiber reinforced resin matrix composite, the product processing performance is not affected.

Owner:CHINA NAT BLUESTAR GRP CO LTD +1

High dispersion polyethylene coloring masterbatch

The invention discloses a high dispersion polyethylene coloring masterbatch, including the following raw materials by weight: 30-50 portions of low density polyethylene, 10-20 portions of linear low density polyethylene, 20-35 portions of rutile titanium dioxide, 102-8 portions of a wetting agent NP, 3-8 portions of a mixture of silica and alumina, 0.5-2 portions of white oil, 0.5-2 portions of a coupling agent, 1-3 portions of polyethylene wax, 0.1-1 portion of an antioxidant 1010 and 1-5 portions of calcium carbonate. The invention has the advantages of high dispersion and strong weatherability.

Owner:BLUESTAR CHENGDU NEW MATERIALS

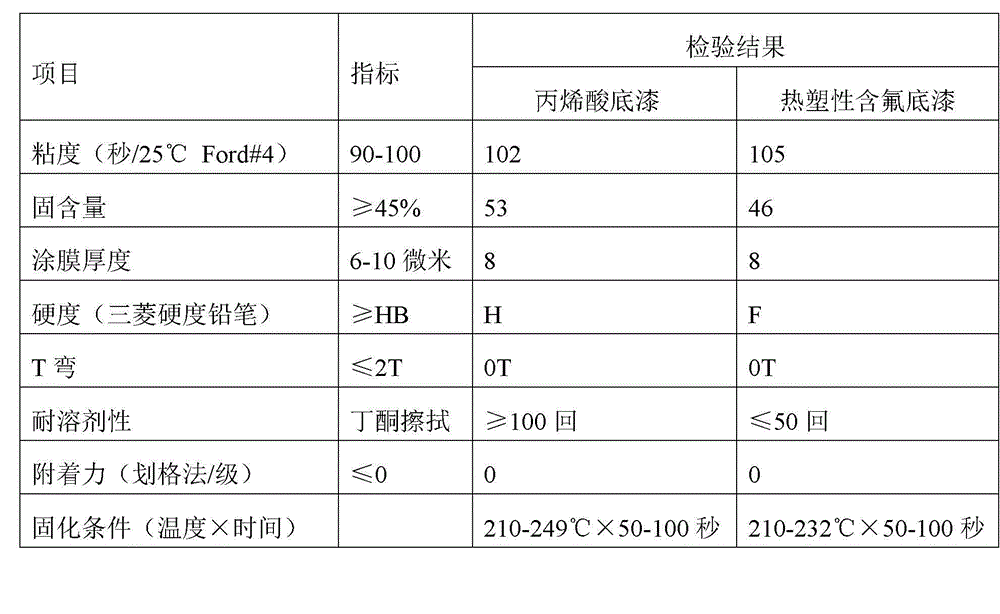

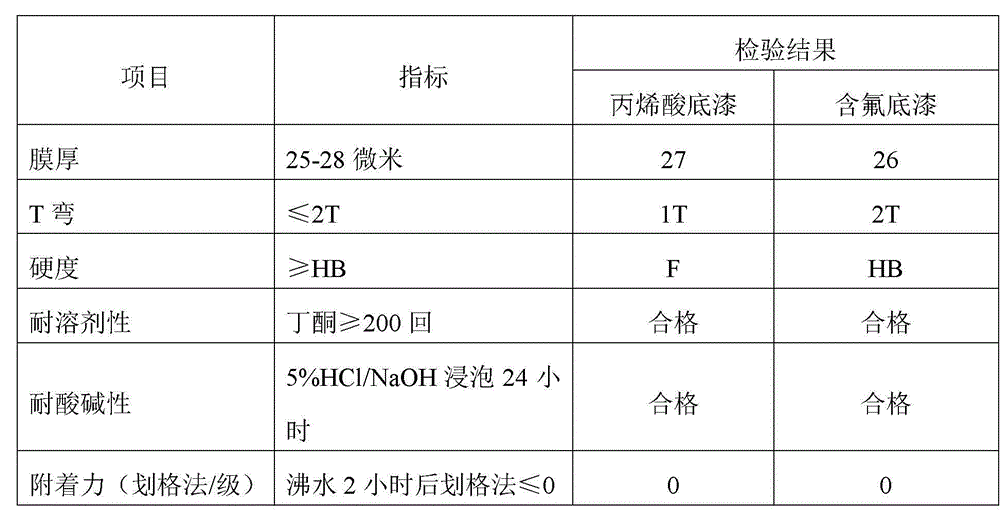

Acrylic primer suitable for polyvinylidene fluoride (PVDF) finish paint and preparation method thereof

ActiveCN102977709AImprove weather resistanceExtend the service lifeCoatingsIsocyanatePolyvinylidene fluoride

The invention discloses acrylic primer suitable for polyvinylidene fluoride (PVDF) finish paint. The acrylic primer comprises 20%-30% of thermosetting acrylic resin, 30%-40% of organic solvent, 15%-20% of titanium dioxide, 6%-10% of padding, 5%-10% of PVDF resin, 2%-5% of promoter, and 4%-8% of isocyanate resin. The invention further discloses a preparation method of the acrylic primer. The preparation method of the acrylic primer comprises choosing each component according to a formula, and placing the thermosetting acrylic resin, the organic solvent and the promoter into a stirring machine to stir for a first time; adding the titanium dioxide and the padding into the stirring machine to stir for a second time; placing the mixture into a basket-type sand mill to grind for a first time, adding the PVDF resin to grin for a second time and obtaining a semi-finished product; combining the semi-finished product and other components in the formula together to stir for a third time and disperse evenly and obtaining a finished product. The acrylic primer is good in weather fastness, machining property, shock resistance and flexibility.

Owner:SUZHOU COLOR WAY ENTERPRISE DEV

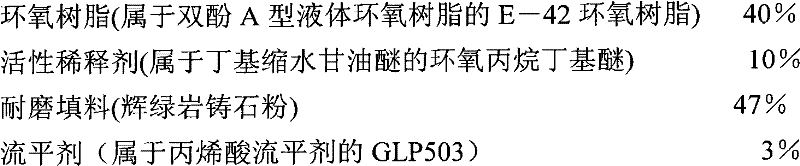

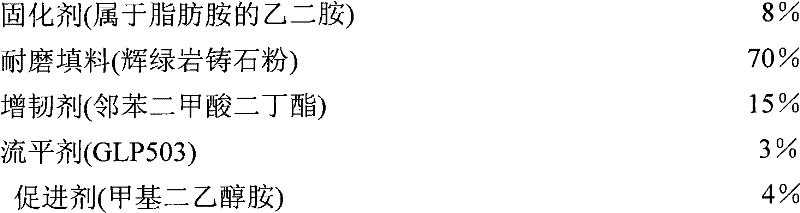

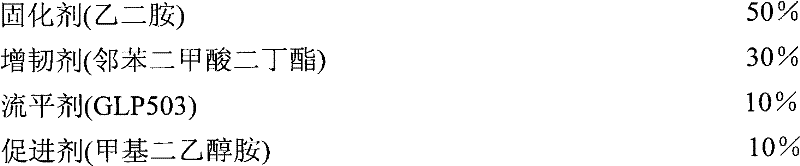

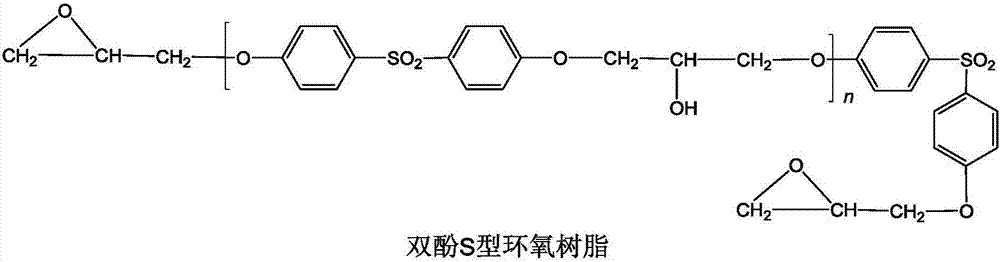

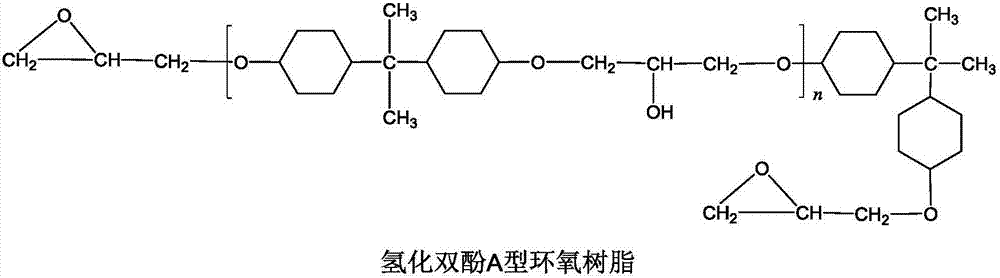

Resin concrete-based mechanical part and preparation method thereof

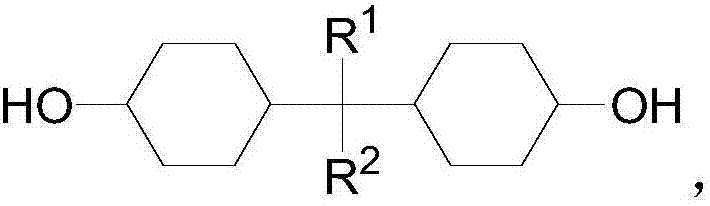

ActiveCN107399927AImproved impact toughness and split resistanceImprove weather resistanceBisphenol SCycloaliphatic epoxy

The invention provides a resin concrete-based mechanical part and a preparation method thereof. The mechanical part is prepared from the following raw materials: aggregate, filler, an epoxy resin component and a curing agent component, wherein the aggregate is prepared from the following granite or marble particles in parts by weight: 10-15 parts of 19-20mm particles, 25-30 parts of 16-17mm particles, 15-20 parts of 13-14mm particles, 10-15 parts of 10-11mm particles, 5-10 parts of 7-8mm particles, 5-10 parts of 4-5mm particles and 10-15 parts of 1-2mm particles; the filler is prepared from powder such as 15-25 parts by weight of pulverized fuel ash; the epoxy resin component is prepared from 3-4 parts by weight of bisphenol S type epoxy resin, 4-6 parts by weight of hydrogenated bisphenol A type epoxy resin and 1-2 parts by weight of cycloaliphatic epoxy resin; the curing agent component is prepared from 1.0-1.5 parts by weight of an aliphatic polyamine curing agent, 0.3-0.5 part by weight of a tertiary amine curing agent and 0.7-1.0 part by weight of an imidazole curing agent.

Owner:常州高鼎新材料科技有限公司

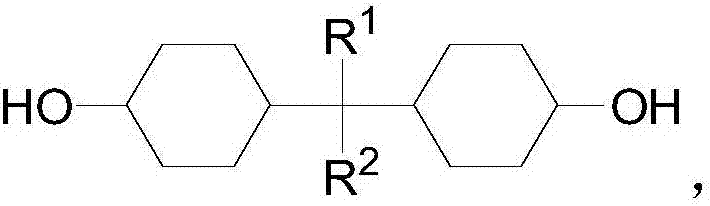

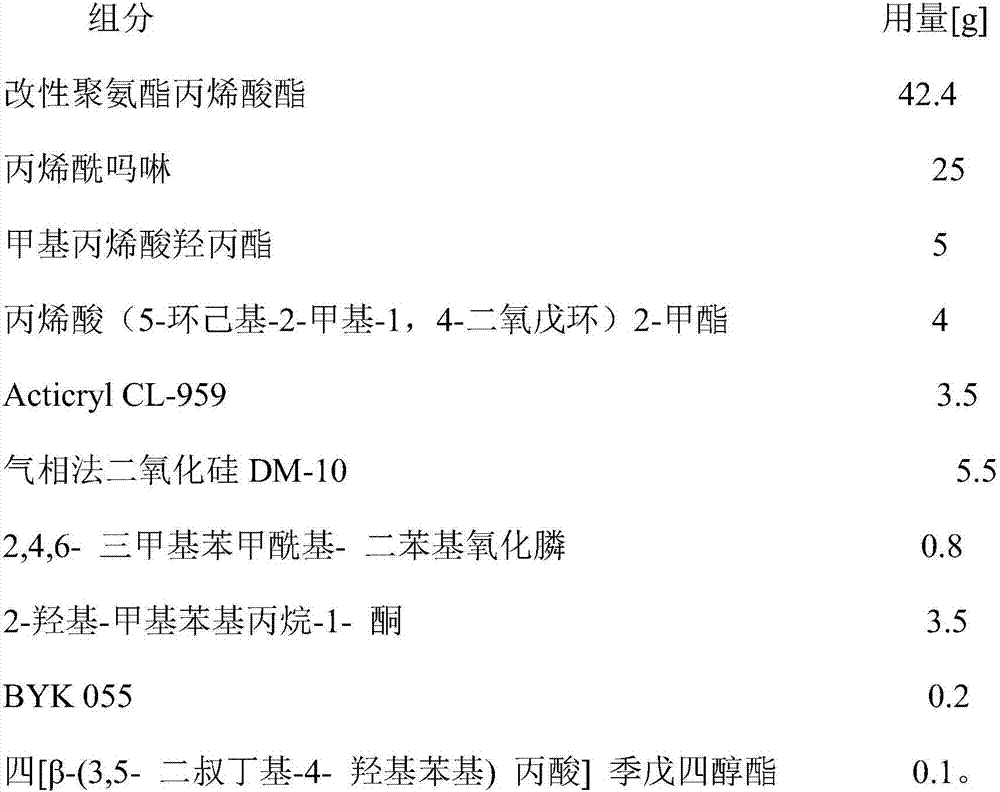

Modified polyurethane acrylic resin and preparation method thereof

InactiveCN107353865AGood impact resistanceImprove weather resistanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesIsocyanatePolyester

The invention discloses a modified polyurethane acrylic resin, which is prepared by polymerization among hydroxyl acrylate, diisocyanate, alkylated 4,4'-dicyclohexanol, and polyester / polyether glycol. The invention provides a method of preparing the modified polyurethane acrylic resin at the same time. The provided modified polyurethane acrylic resin does not contain active functional group such as phenyl ring, amino group, or the like, so the modified polyurethane acrylic resin will not become yellow even if the modified polyurethane acrylic resin is irradiated by light, and the weatherability is good. The resin can be applied to an adhesive, and has a good waterproof performance, good anti-falling performance, good drug resistant property, and excellent thermal stability.

Owner:深圳市百丽春粘胶实业有限公司

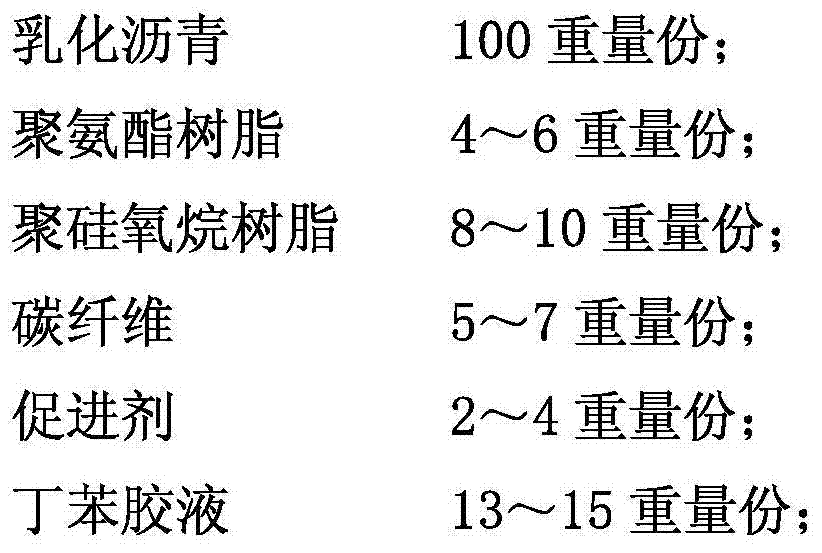

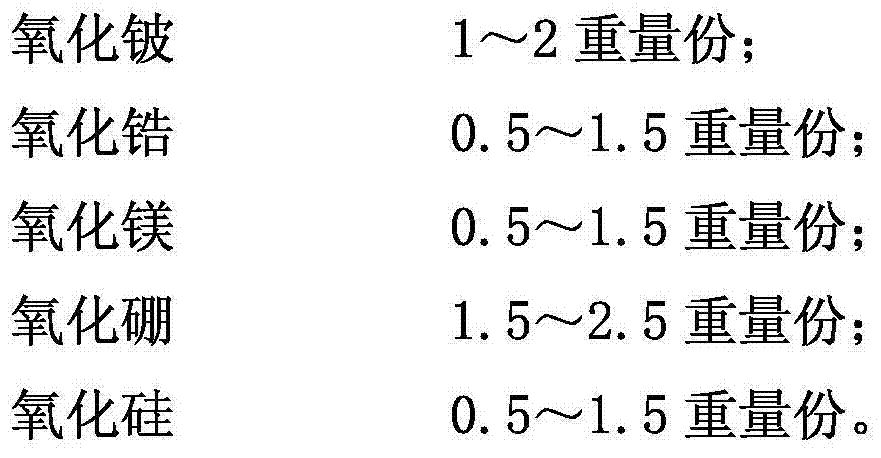

Special asphalt mixture for sand-containing fog seal

ActiveCN104773974AOptimize internal structureImprove weather resistanceCorrosionButadiene-styrene rubber

The invention discloses a special asphalt mixture for a sand-containing fog seal. The special asphalt mixture comprises the following materials by weight: emulsified asphalt, polyurethane resin, polysiloxane resin, carbon fiber, an accelerant, butadiene-styrene rubber liquid and extending oil, wherein the accelerant is thioacetamide or sulfolane. According to the invention, through optimization of the formula for the special asphalt mixture, the internal structure of the special asphalt mixture is microscopically improved; the added polyurethane resin and polysiloxane resin can effectively improve weatherability, bonding strength and toughness of the asphalt mixture; the added carbon fiber can enhance the structural strength and resistance to low temperature and high temperature of the asphalt mixture; the added accelerant has higher thermal stability compared with traditional sulfur powder, amine and imidazole accelerants; and the added metal oxide or sinter can improve ageing resistance, corrosion resistance and cracking resistance of the asphalt mixture and greatly prolongs the service life of an asphalt pavement.

Owner:NANJING ROAD KEEPER TECH

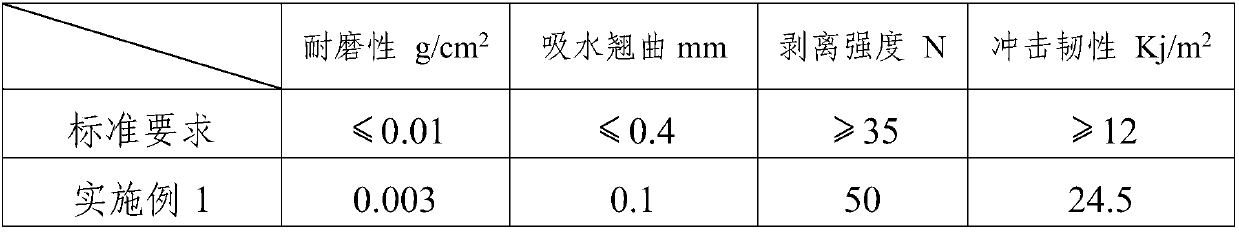

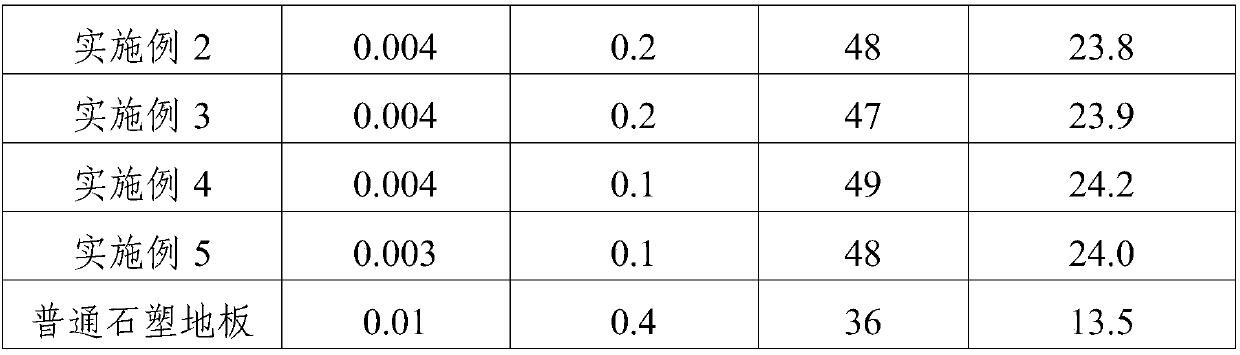

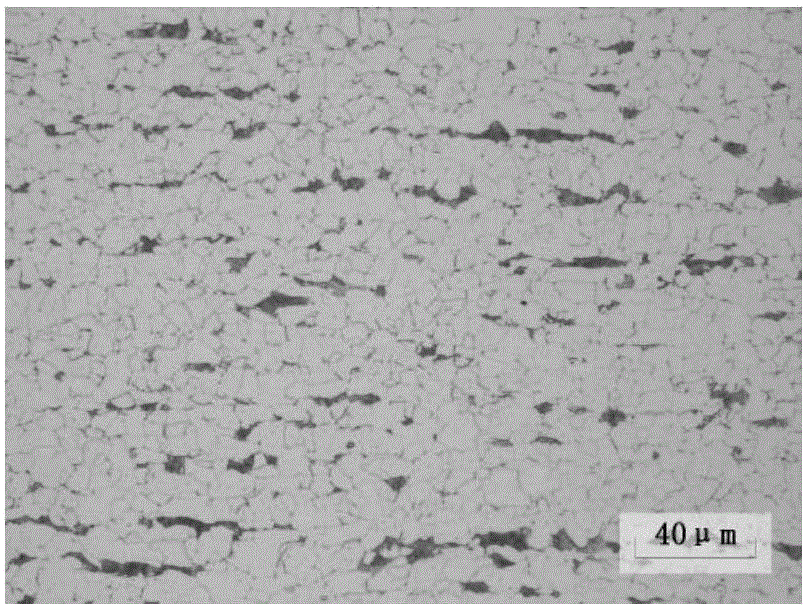

PVC stone plastic floor and preparation method thereof

InactiveCN109535599AImprove mechanical propertiesImprove weather resistanceFlooring insulationsWeather resistanceDefoaming Agents

The invention discloses a PVC stone plastic floor and a preparation method thereof, which belong to the field of stone plastic floor manufacture. The stone plastic floor comprises the following raw materials in parts by weight: 200-300 parts of PVC resin powder, 400-800 parts of calcium filler, 20-40 parts of glass fiber, 1-2 parts of an activator, 3-7 parts of a thickener, 5-10 parts of a dispersant, 10-15 parts of a stabilizer, 5-15 parts of a plasticizing regulator, and 5-10 parts of a defoaming agent. The method not only significantly improves the mechanical properties of the PVC stone-plastic floor, but also improves the weather resistance of the PVC stone-plastic floor, enhances the chemical corrosion resistance of the PVC stone-plastic floor surface, and avoids the deformation of the PVC stone-plastic floor during the processing by the specific ratio of the raw material components, the prepared PVC stone plastic floor has excellent waterproof performance and sound insulation effect, and has higher toughness, high strength and lower weight than that of the traditional stone plastic floor, and has short production cycle and low cost, and is suitable for production of the PVC stone plastic floor.

Owner:安徽可尔海思新材料科技有限公司

High-phosphorus steel plate of weather-proof structure and method for preparing steel plate

ActiveCN105154784AImprove weather resistanceGood comprehensive mechanical propertiesAlloy elementSteel plates

The invention discloses a high-phosphorus steel plate of a weather-proof structure. The high-phosphorus steel plate of the weather-proof structure comprises, by weight, 0.05-0.11% of C, 0.20-0.45% of Si, 0.55-0.95% of Mn, 0.07-0.10% of P, 0-0.005% of S, 0.25-0.40% of Cu, 0.30-0.65% of Cr, 0-0.10% of Ni, 0.015-0.040% of Nb, 0-0.025% of Ti, 0.020% or more of Al, 0.001-0.005% of Ca, and the balance Fe and the unavoidable impurities. According to the steel plate, the reasonable alloy element ratio and the optimal rolling process are combined, the effects of anti-corrosion elements of Cu, Cr, Ni and P on improving the weather-proof performance are given to play to the largest extent, and good comprehensive mechanical performance and outstanding welding performance and moldability are guaranteed; the steel plate is particularly suitable for non-coating steel structures in heavy atmosphere corrosion conditions and particularly meets the requirement for steel of a new generation of high-strength railway vehicle.

Owner:SHANDONG IRON & STEEL CO LTD

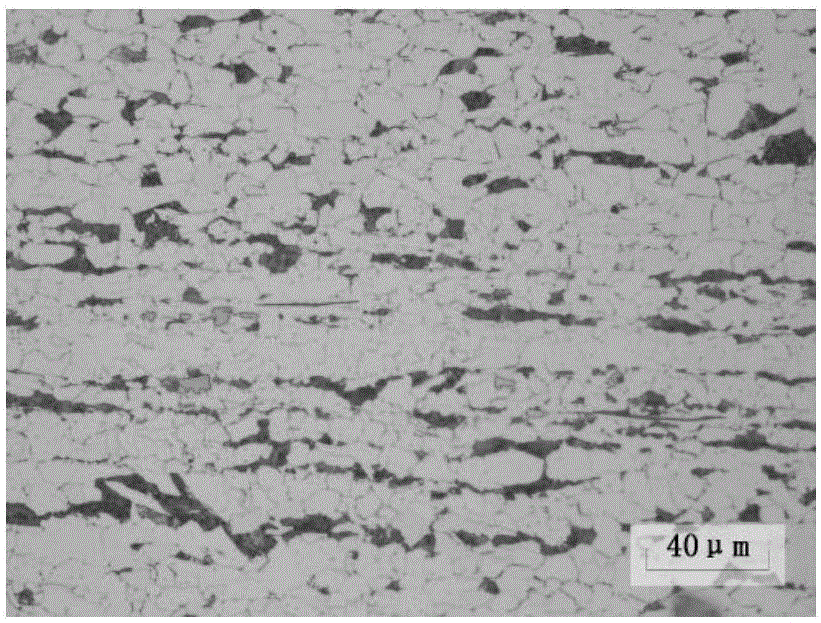

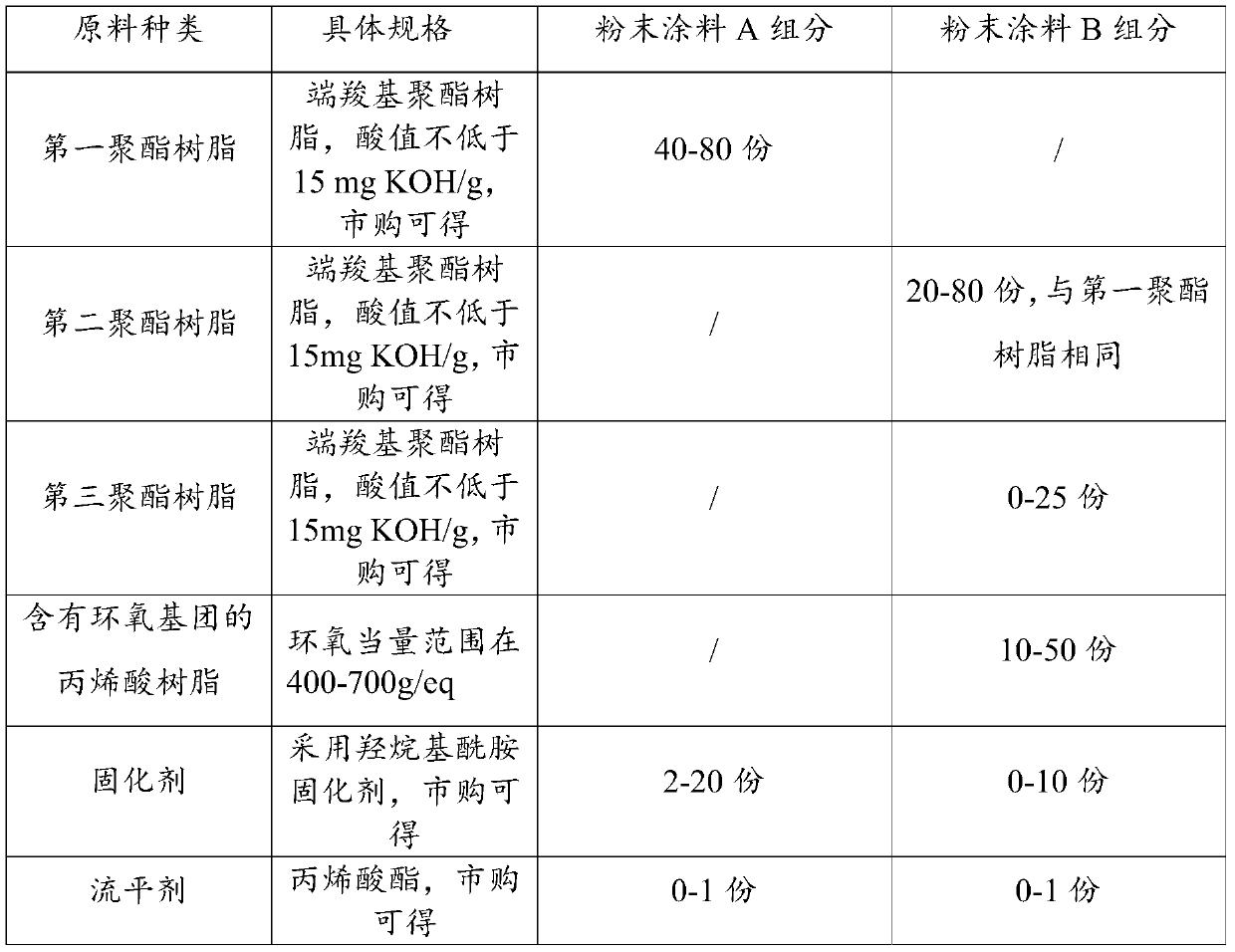

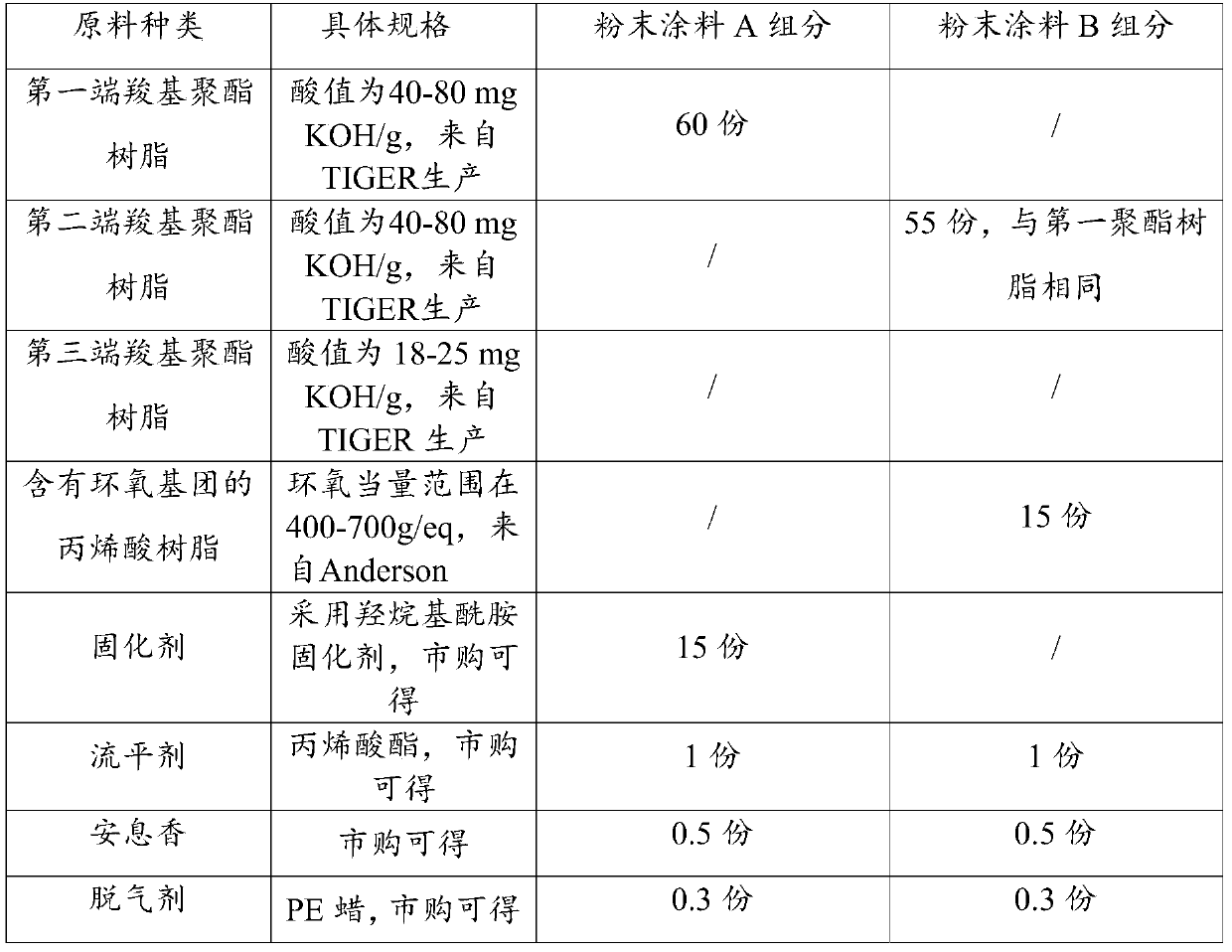

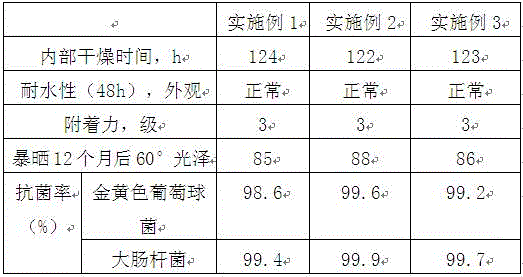

Powder coating with ultrahigh weather-proof extinction effect

ActiveCN110922856AAchieve weather resistanceImprove weather resistancePowdery paintsEpoxy resin coatingsChemistryComposite material

The invention discloses a powder coating with ultrahigh weather-proof extinction effect, wherein the powder coating comprises the raw materials: a powder coating component A and a powder coating component B, wherein the powder coating component A and the powder coating component B are dry-mixed into a whole and have different curing speeds; the powder coating component A is composed of the raw materials: a first polyester resin and a curing agent capable of carrying out curing reaction with the first polyester resin; the powder coating component B is composed of the raw materials: second polyester resin and acrylic resin containing epoxy groups, wherein the acrylic resin and the second polyester resin can be subjected to curing reaction. The powder coating is prepared from the powder coating component A and the powder coating component B through a dry mixing process; the acid value range of the first polyester resin is not less than 15, and the acid value range of the second polyesterresin is not less than 15. By adopting a polyester curing system dry-mixed polyester and acrylic resin curing system, a coating extinction product with the gloss not higher than 10 degrees can be realized at the same time, and meanwhile, a quite excellent super weather-proof effect is achieved.

Owner:TIGER NEW SURFACE MATERIALS QINGYUAN CO LTD

Antibacterial and weatherproof polyurethane coating and preparation method thereof

InactiveCN106752869AImprove weather resistanceWide range of applicationsAntifouling/underwater paintsPaints with biocidesPolyethyleneSolid content

The invention discloses antibacterial and weatherproof polyurethane coating and a preparation method thereof. The antibacterial and weatherproof polyurethane coating is prepared from the following raw materials in parts by weight: 100 to 120 parts of polyethylene diglycol adipate glycol, 50 to 60 parts of polytetrahydrofuran glycol, 20 to 25 parts of cyclopentyl isocyanate, 30 to 40 parts of chlorosulfonyl isocyanate, 10 to 14 parts of methacrylic acid, 20 to 25 parts of N,N-diethyl ethylamine, 10 to 12 parts of calcium benzoate and the like. By means of choosing propylene glycol as a chain extender, a waterproof effect of the coating is improved under cooperation of flatting agent fluorocarbon surfactant FC-4430; as the calcium benzoate, copper quinolate and dimethyloctadecyl[3-(trimethoxysilyl)propyl]ammonium chloride are added, the coating has an antibacterial and mildewproof effect; by means of adding carbon black, titanium-silicon powder, gas-phase titanium dioxide and the like, weatherproof performance of the coating is improved, and an application range of the coating can be wider; by means of adding the defined amount of acrylate and nanometer molybdenum disulfide, low temperature flexibility and lubrication performance of the coating are improved, the solid content of the coating is also improved, and constructability of the coating is improved.

Owner:潘赵翔

Epoxy resin curing agent capable of improving anti-ultraviolet performance of epoxy resin and preparation method for epoxy resin curing agent

ActiveCN106008926AImproves UV resistanceImprove weather resistanceOrganic chemistryChemistryWeather resistance

The invention provides an epoxy resin curing agent capable of improving the anti-ultraviolet performance of epoxy resin and a preparation method for the epoxy resin curing agent. The epoxy resin curing agent is obtained by reacting ultraviolet adsorbent molecules 2-hydroxy-4-(2,3-ethylene oxide glycidyl ether)-diphenyl ketone with diethylenetriamine, and the molecular structure of the epoxy resin curing agent is formed by connecting at least one ultraviolet adsorbent molecule 2-hydroxy-4-(2,3-ethylene oxide glycidyl ether)-diphenyl ketone to each diethylenetriamine molecule. After the epoxy resin is cured by the prepared epoxy resin curing agent, the anti-ultraviolet performance of the cured epoxy resin can be improved, and the weather resistance of the epoxy resin is improved.

Owner:CHINA ENERGY CONSTR GRP SHAANXI ELECTRIC POWER DESIGN INST CO LTD +2

Friction-resistant plastic and preparation method thereof

InactiveCN104788853AImprove high temperature resistanceImprove thermal shock resistancePolyvinyl chlorideBisphenol

The invention discloses a friction-resistant plastic and a preparation method thereof. The friction-resistant plastic comprises the following components in parts by mass: 90-92 parts of polyvinyl chloride resin, 6-8 parts of silicon carbide, 1-3 parts of talcum powder, 5-7 parts of graphite powder, 50-55 parts of bisphenol A epoxy resin, 5-10 parts of sodium tripolyphosphate, 3-5 parts of mineral oil, 7-9 parts of polyvinylidene chloride, 7-9 parts of sodium tripolyphosphate, 6-8 parts of hydroxypropyl methacrylate, 1-3 parts of titanium dioxide, 5-7 parts of iron powder, 30-40 parts of deionized water, 3-5 parts of a silane coupling agent KH560 and 2-4 parts of auxiliaries.

Owner:SUZHOU JIN YUAN OIL MACHINERY

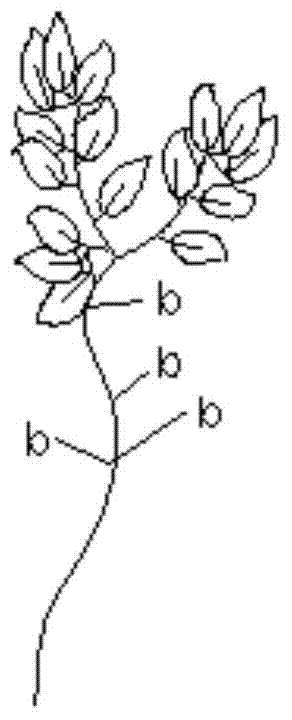

Simulation banyan and manufacturing method thereof

InactiveCN103754054AImprove weather resistanceGood weather resistanceSpecial ornamental structuresSteel tubeBanyan

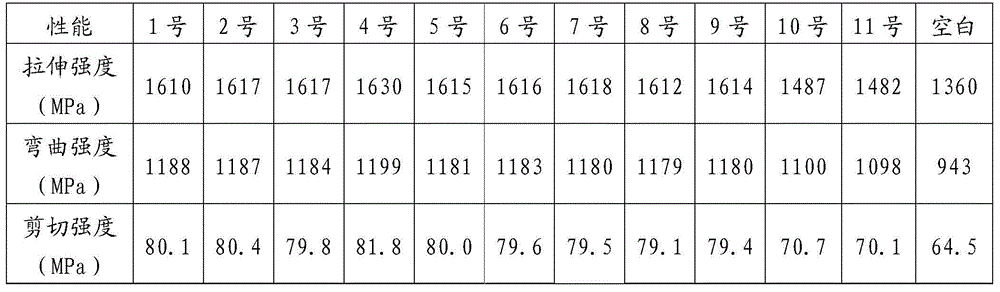

The invention discloses a simulation banyan and a manufacturing method thereof, and is used for solving the technical problem of poor weatherability of a conventional simulation tree. According to the technical scheme, each of single forked branches is composed of a plurality of leaves (5) and a branch in the simulation banyan, each of second-level branches (4) is composed of two single forked branches, each of first-level branches (3) is composed of a plurality of second-level branches (4), and the simulation banyan is composed of a plurality of first-level branches (3) and a trunk (2); a steel pipe (1) is fixedly connected to the lower end part of the trunk (2), so as to be connected with a ground fixing object. Because the single forked branches, the second-level branches, the first-level branches and the trunk adopt an injection-molding mixed material composed of LDPE, HDPE, EVA and a compound stabilizer Ciba2020, and thus the simulation tree weatherability is improved. Through testing, the tensile strength and the elongation at break of the trunk and the branches obtained by injection molding of the injection molding material are significantly higher than those of a trunk and branches obtained by injection molding of injection molding materials in the background art.

Owner:ARCHITECTURAL ENG INST GENERAL LOGISTICS DEPT P L A

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com