High-phosphorus steel plate of weather-proof structure and method for preparing steel plate

A structural steel plate and weather-resistant technology, which is applied in the production process of high-phosphorus weather-resistant structural steel plate, can solve the problems of high alloy composition and increased production cost, and achieve improved weather resistance, excellent welding performance and formability, and good comprehensive mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The steel plate of this embodiment is prepared by the following method:

[0028] Hot metal pretreatment→120t converter smelting→LF refining→RH refining→slab continuous casting→slab slow cooling→slab cleaning→heating→descaler→rough rolling→finish rolling→hot straightening→steel plate marking→slab slow cooling→ Cut→Identify→Storage.

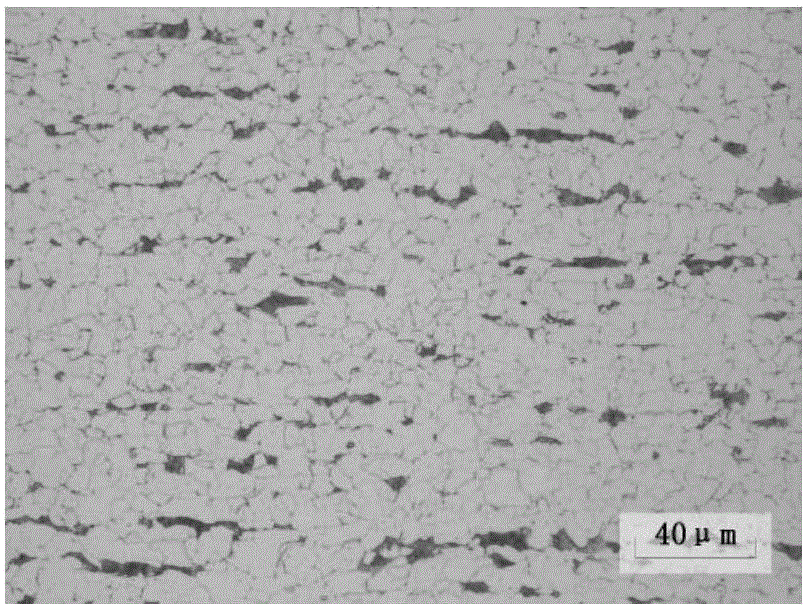

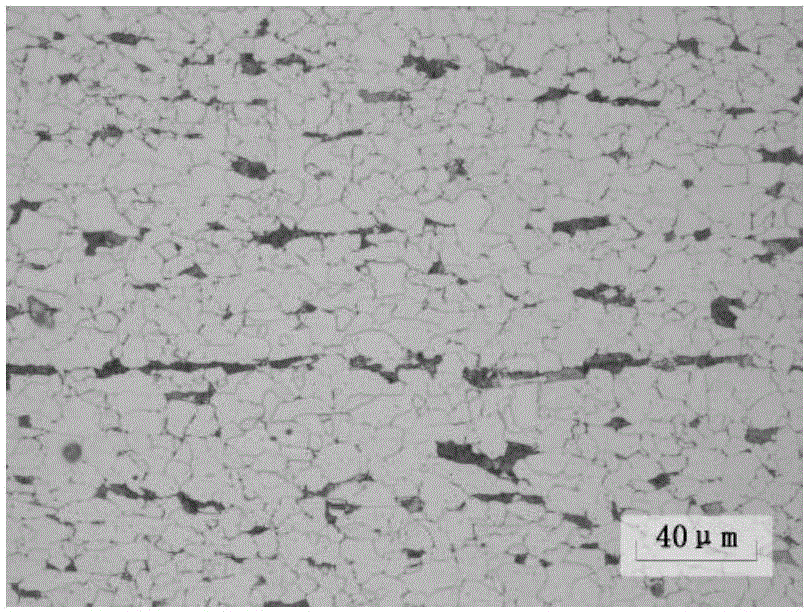

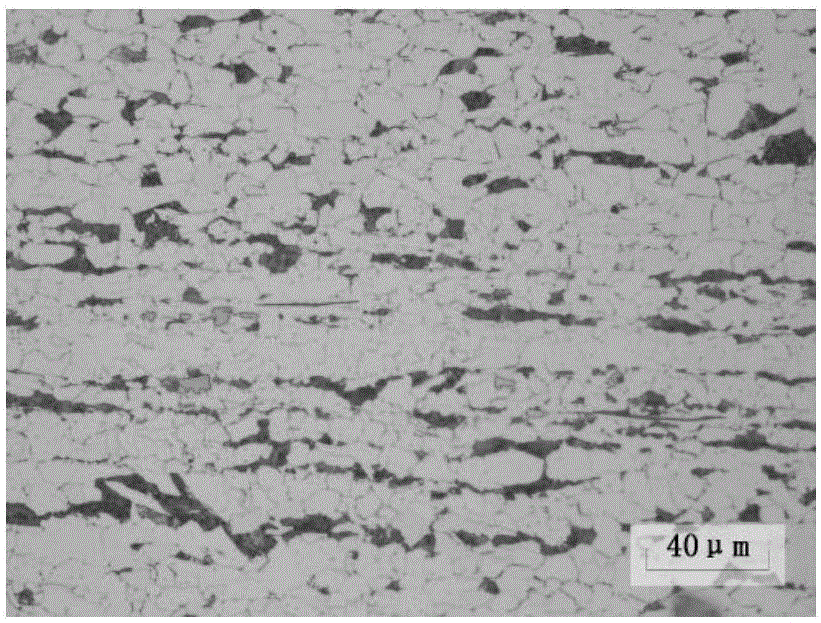

[0029] Referring to Table 1-3, the present embodiment 1-3 is all produced by the above process, the main chemical composition of the steel is shown in Table 1, the actual production process is shown in Table 2, the mechanical properties of the steel are shown in Table 3, and the near-surface, The microstructures at 1 / 4 and 1 / 2 thickness are shown in Figure 1-3 . It can be seen that the metallographic structure of the trial-produced steel plate is composed of ferrite and pearlite, the ferrite grains are uniform and fine, and the pearlite clusters are dispersedly distributed on the ferrite matrix, which provides gold for the good comprehens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com