Antibacterial and weatherproof polyurethane coating and preparation method thereof

A technology of polyurethane coatings and raw materials, applied in the direction of polyurea/polyurethane coatings, antifouling/underwater coatings, coatings, etc., can solve the problems of poor overall performance, achieve improved construction, low temperature flexibility and lubricity, and application wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

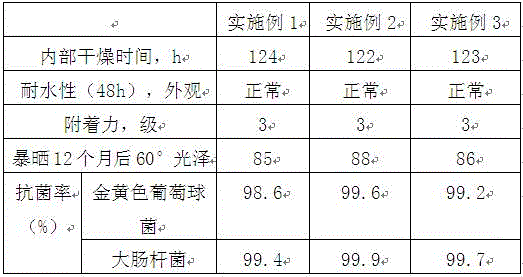

Examples

Embodiment 1

[0015] An antibacterial and weather-resistant polyurethane coating prepared from the following raw materials in parts by weight (kg): polyethylene adipate glycol 100, polytetrahydrofuran ether glycol 50, cyclopentyl isocyanate 20, chlorosulfonyl isocyanate 30, methyl Acrylic acid 10, N,N-diethylethylamine 20, calcium benzoate 10, diethyl tartrate 5, propylene glycol 15, acrylate 4, cobalt naphthenate 3, benzyldimethylamine 2, polyvinylpyrrolidone 3, Dimethyloctadecyl[3-(trimethoxysilyl)propyl]ammonium chloride 6, nanomolybdenum disulfide 8, polyoxyethylene polyoxypropanolamine ether 12, acetone 20, abietic acid polyoxyethylene Ester 1, Hydroxypropyl Distarch Phosphate 3, Quinoline Copper 8, Fluorocarbon Surfactant FC-4430 0.6, Magnesium Stearate 8, Carbon Black 6, Titanium Silicon Powder 6, Fumed Titanium Dioxide 5.

[0016] A preparation method for an antibacterial weather-resistant polyurethane coating, comprising the following steps:

[0017] (1) Add polyethylene adipate g...

Embodiment 2

[0022] An antibacterial and weather-resistant polyurethane coating prepared from the following raw materials in parts by weight (kg): polyethylene adipate glycol 110, polytetrahydrofuran ether glycol 55, cyclopentyl isocyanate 22.5, chlorosulfonyl isocyanate 35, methyl Acrylic acid 12, N, N-diethylethylamine 22.5, calcium benzoate 11, diethyl tartrate 6, propylene glycol 17.5, acrylate 5, cobalt naphthenate 4, benzyl dimethylamine 3, polyvinylpyrrolidone 3.5, Dimethyloctadecyl[3-(trimethoxysilyl)propyl]ammonium chloride 6.5, nanomolybdenum disulfide 8.5, polyoxyethylene polyoxypropanolamine ether 13, acetone 22.5, abietic acid polyoxyethylene Ester 1.5, hydroxypropyl distarch phosphate 4.5, quinoline copper 9, fluorocarbon surfactant FC-4430 0.7, magnesium stearate 10, carbon black 8, titanium silicon powder 6.5, fumed titanium dioxide 6.5.

[0023] The preparation method is the same as in Example 1.

Embodiment 3

[0025] An antibacterial and weather-resistant polyurethane coating prepared from the following raw materials in parts by weight (kg): polyethylene adipate glycol 120, polytetrahydrofuran ether glycol 60, cyclopentyl isocyanate 25, chlorosulfonyl isocyanate 40, methyl Acrylic acid 14, N,N-diethylethylamine 25, calcium benzoate 12, diethyl tartrate 7, propylene glycol 20, acrylate 6, cobalt naphthenate 5, benzyldimethylamine 4, polyvinylpyrrolidone 4, Dimethyloctadecyl[3-(trimethoxysilyl)propyl]ammonium chloride 7, nanomolybdenum disulfide 9, polyoxyethylene polyoxypropanolamine ether 14, acetone 25, abietic acid polyoxyethylene Ester 2, Hydroxypropyl Distarch Phosphate 6, Quinoline Copper 10, Fluorocarbon Surfactant FC-4430 0.8, Magnesium Stearate 12, Carbon Black 10, Titanium Silicon Powder 7, Fumed Titanium Dioxide 8.

[0026] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com