Inorganic antibacterial formaldehyde-removing paint and preparation method thereof

An inorganic antibacterial and coating technology, applied in antifouling/underwater coatings, radiation-absorbing coatings, coatings, etc., can solve the problems of increased construction costs, failure, oxidation, etc., and achieve the effect of convenient construction and improved weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

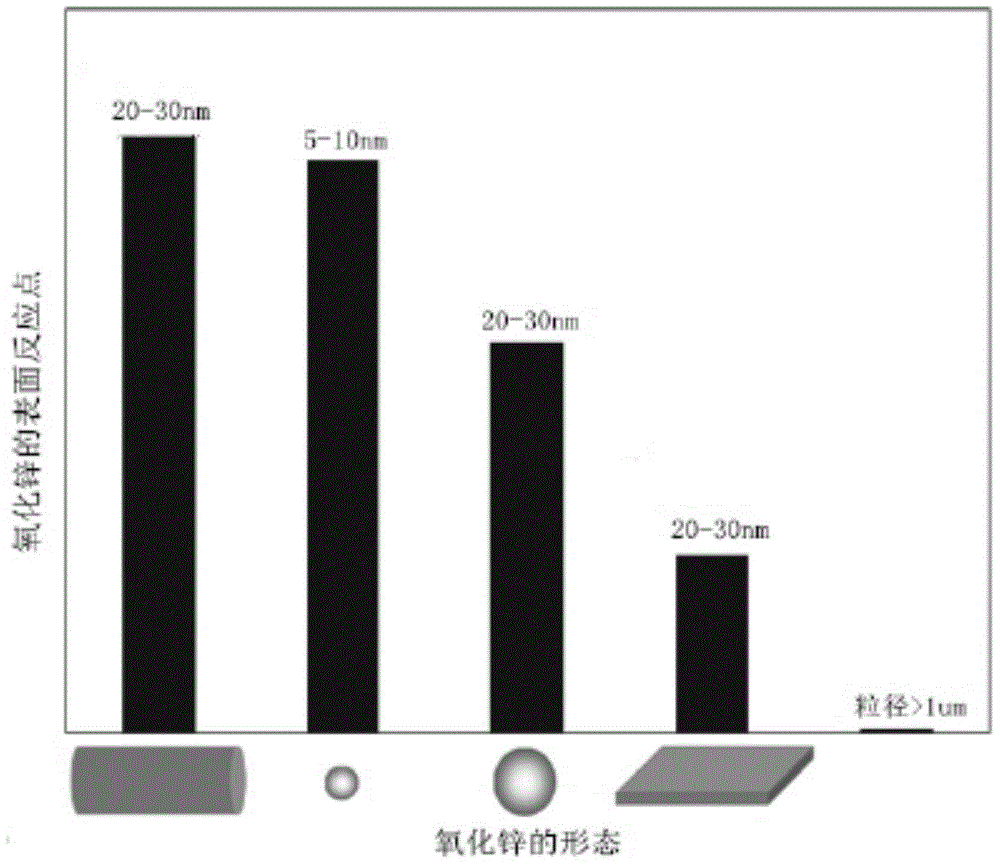

Method used

Image

Examples

Embodiment 1

[0024]

[0025] The preparation method of the inorganic antibacterial and aldehyde-removing coating is as follows:

[0026] (1) At a rotational speed less than 500r / min, add water, hydroxyethyl cellulose, and pH adjuster in turn to disperse for 1-3 minutes.

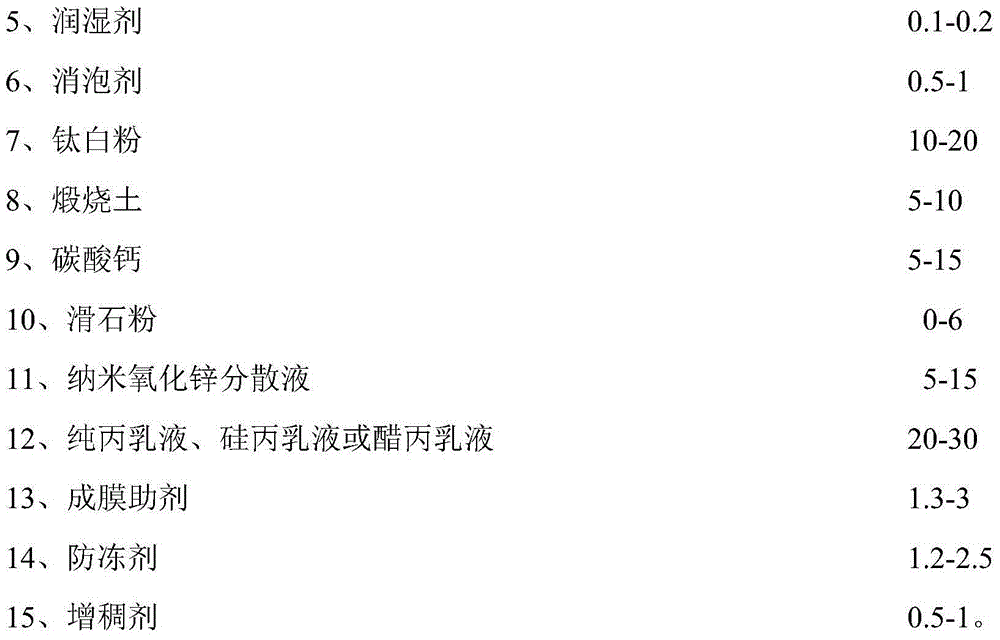

[0027] (2) Increase the speed to 800-1000r / min, add wetting agent, dispersant, defoamer, titanium dioxide, calcined soil, calcium carbonate, talcum powder, nano-zinc oxide dispersion in sequence, and increase the speed to 1800-2000r / min min, disperse for 15-20min.

[0028] (3) Reduce the rotating speed to 1000-1200r / min, add emulsion, film-forming aid, antifreeze and thickener in sequence, disperse for 10-15min, and sieve through 200 mesh to obtain the product of the present invention. The antibacterial rate of this formula coating against Staphylococcus aureus, Escherichia coli and Candida albicans is 99.87%, the mildew resistance level against mold is 0, the purification rate of formaldehyde is as high as 91%, and t...

Embodiment 2

[0030]

[0031] The preparation method of the inorganic antibacterial and aldehyde-removing coating is as follows:

[0032] (1) At a rotational speed less than 500r / min, add water, hydroxyethyl cellulose, and pH adjuster in turn to disperse for 1-3 minutes.

[0033] (2) Increase the speed to 800-1000r / min, add wetting agent, dispersant, defoamer, titanium dioxide, calcined soil, calcium carbonate, talcum powder, nano-zinc oxide dispersion in sequence, and increase the speed to 1800-2000r / min min, disperse for 15-20min.

[0034] (3) Reduce the rotating speed to 1000-1200r / min, add emulsion, film-forming aid, antifreeze and thickener in sequence, disperse for 10-15min, and sieve through 200 mesh to obtain the product of the present invention. The antibacterial rate of this formula coating against Staphylococcus aureus, Escherichia coli and Candida albicans is 99.99%, the mildew resistance level against mold is 0, the purification rate of formaldehyde is as high as 95%, and t...

Embodiment 3

[0036]

[0037]

[0038] The preparation method of this inorganic antibacterial and aldehyde-removing coating is as follows:

[0039] (1) At a rotational speed less than 500r / min, add water, hydroxyethyl cellulose, and pH adjuster in turn to disperse for 1-3 minutes.

[0040] (2) Increase the speed to 800-1000r / min, add wetting agent, dispersant, defoamer, titanium dioxide, calcined soil, calcium carbonate, talcum powder, nano-zinc oxide dispersion in sequence, and increase the speed to 1800-2000r / min min, disperse for 15-20min.

[0041] (3) Reduce the rotating speed to 1000-1200r / min, add emulsion, film-forming aid, antifreeze and thickener in sequence, disperse for 10-15min, and sieve through 200 mesh to obtain the product of the present invention. The antibacterial rate of this formula coating against Staphylococcus aureus, Escherichia coli and Candida albicans is 99.99%, the mildew resistance level against mold is 0, the purification rate of formaldehyde is as high ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com