Preparation method of special titanium dioxide for oily system

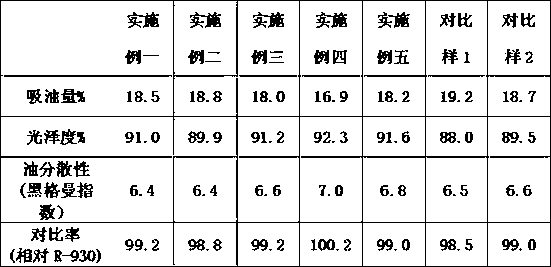

A titanium dioxide and system technology, applied in chemical instruments and methods, inorganic pigment treatment, dyed organosilicon compound treatment, etc., can solve the problems of low weather resistance, insufficient temperature resistance of titanium dioxide products, yellowing of ink layer, etc. Achieve the effect of good temperature resistance, high contrast ratio and low oil absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

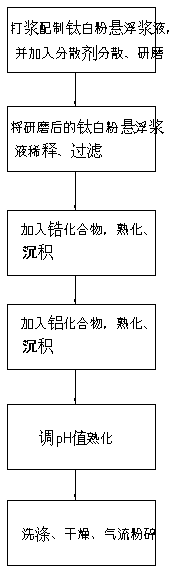

Method used

Image

Examples

Embodiment 1

[0027] (1) Add 400g of titanium dioxide to deionized water to make a suspension slurry with a concentration of 650g / l, add sodium hexametaphosphate as a beating dispersant to the suspension slurry, add 0.3% of the weight of titanium dioxide, and stir evenly Finally, adjust the pH value of the slurry to 10 with 100 g / l sodium hydroxide solution, and pump the titanium dioxide suspension slurry into the laboratory Netzsch sand mill for grinding.

[0028] (2) Dilute the sand-milled titanium dioxide suspension slurry to 300g / l with deionized water, and pass the slurry through a 325-mesh vibrating sieve to remove possible small coarse titanium dioxide particles and debris from sand-milled beads and other impurities.

[0029] (3) Heat the above-mentioned titanium dioxide suspension slurry to 50°C and adjust the pH value to 5-5.5, and add zirconium sulfate or zirconium oxychloride within this pH value range. Zirconium sulfate is preferred in this embodiment, and the weight of zirconiu...

Embodiment 2

[0034] The steps (1) to (6) of the second embodiment are basically the same as those of the first embodiment, except that in the step (1) of the second embodiment, 100 g / l sodium silicate solution is used as the dispersant for sanding and beating.

Embodiment 3

[0036] Steps (1) to (6) of Example 3 are exactly the same as those of Example 1. Finally, in the jet milling stage, 0.5% trimethylolpropane is added for organic treatment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com