Normal temperature cured super weather-resistant and wear-resistant high-hardness water-based inorganic nanoceramic coating and preparation method thereof

An inorganic nano, ceramic coating technology, applied in the direction of coating, can solve the problems of insufficient wear resistance, complex production process, long dry time, etc., and achieve ultra-long weather resistance, excellent wear resistance, and enhanced polymerization inhibition effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

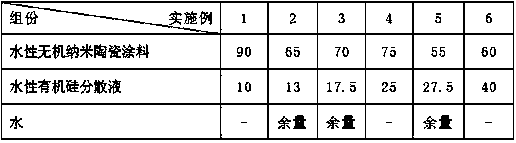

[0049]For the convenience of expression, the following five tables are used to express the ratio and product performance of the 6 embodiments, which are the raw material components and quality of the room temperature curing ultra-weather-resistant, high-hardness, wear-resistant, water-based inorganic nano-ceramic coatings of 1 to 6 examples Percentage Table; Component and Mass Percentage Table of Waterborne Inorganic Nano Ceramic Coating; Component and Weight Ratio Table of Waterborne Silicone Dispersion; Component and Weight Ratio Table of Waterborne Inorganic Nano Ceramic Emulsion; Product performance index table of wear-resistant water-based inorganic nano-ceramic coating.

[0050] Table 1: The raw material components and mass percentages of super-weather-resistant, high-hardness, wear-resistant water-based inorganic nano-ceramic coatings cured at room temperature are:

[0051]

[0052] Table 2: The components and mass percentages of water-based inorganic nano-ceramic co...

Embodiment 7

[0061] Embodiment 7: A kind of water-based inorganic nano-ceramic coating with super weather resistance, high hardness and wear resistance cured at room temperature, its preparation method is:

[0062] Step 1: Mix one or several silanes from Examples 1 to 6 in Table 4. After mixing evenly, add a surfactant and stir evenly, then add the above silane mixture dropwise to the pre-weighed silica sol In the process, the titration time is 30 minutes, then the temperature starts to rise, the reaction temperature is kept between 35-70°C, the constant temperature reaction is 0.5-5 hours, the measured water is added, the heating is stopped, the temperature is lowered and cooled, and the water-based inorganic nano-ceramic emulsion is obtained;

[0063] Step 2: Mix the water-based inorganic nano-ceramic emulsion obtained in the first step with the pigments and fillers in Table 2, disperse at high speed with a high-speed disperser, and the dispersion time is 10 to 30 minutes, and then grind ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com