Degradable film coating material

A coating material and degradable film technology, applied in the field of degradable film coating materials, can solve the problems of crop yield reduction, animal ingestion, environmental pollution, etc., achieve good light resistance and anti-aging properties, increase weather resistance, and prolong degradation time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

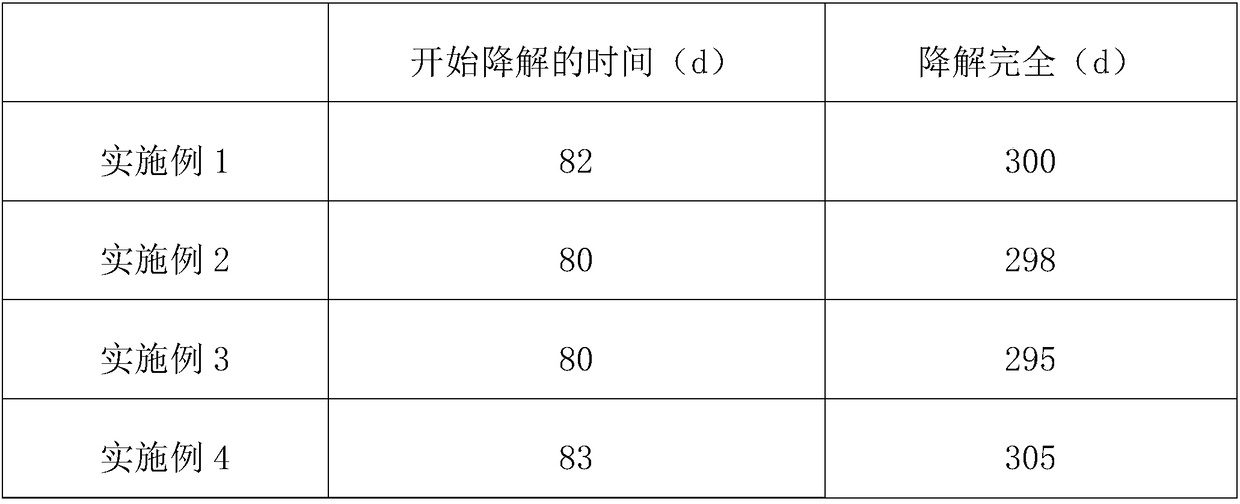

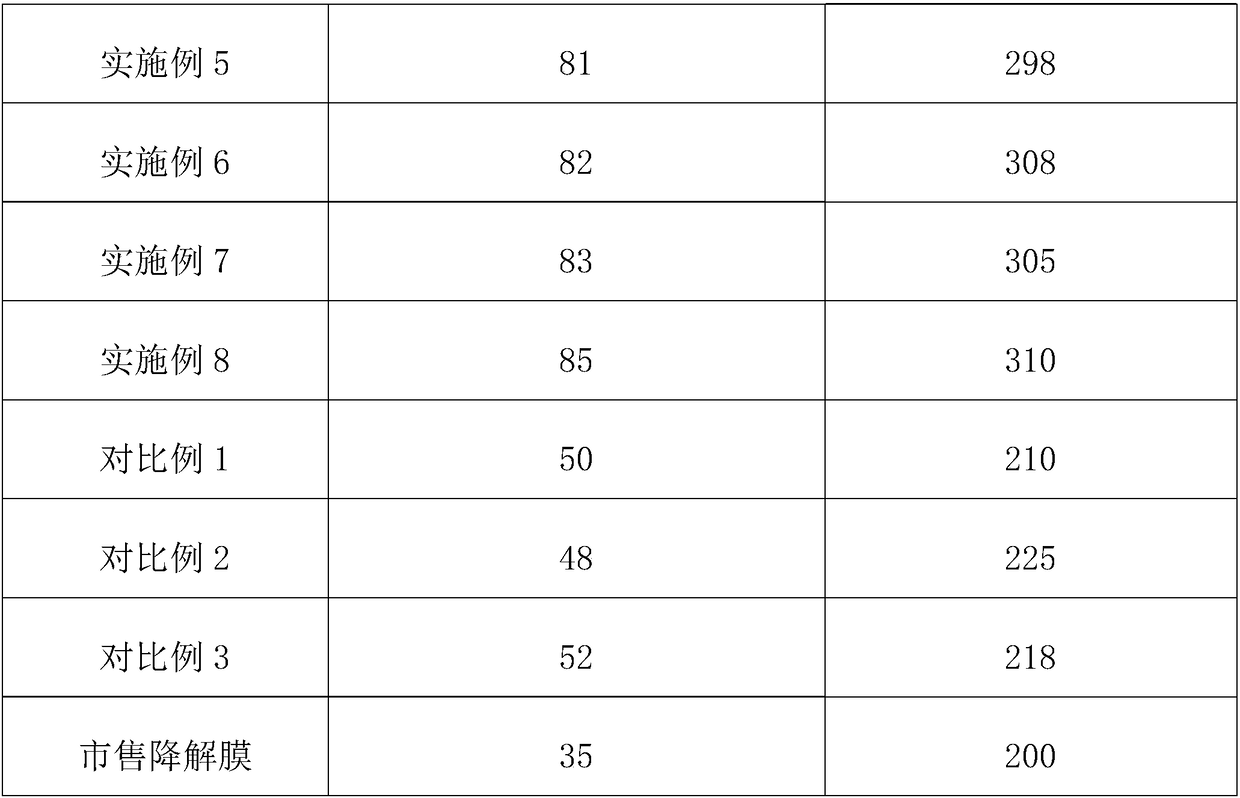

Examples

Embodiment 1

[0024] A kind of degradable film coating material, comprises the nano-silica of 20 weight parts, the nano-titanium dioxide of 50 weight parts, the acrylic resin of 4 weight parts, the polyimide resin of 4 weight parts, wherein, the particle diameter of nano-silica The particle size of nano-titanium dioxide is 3nm.

Embodiment 2

[0026] A kind of degradable film coating material, comprises the nano-silica of 40 weight parts, the nano-titanium dioxide of 70 weight parts, the acrylic resin of 10 weight parts, the polyimide resin of 10 weight parts, wherein, the particle diameter of nano-silica The particle size of nano-titanium dioxide is 5nm.

Embodiment 3

[0028] A kind of degradable film coating material, comprises the nano-silica of 25 weight parts, the nano-titanium dioxide of 55 weight parts, the acrylic resin of 5 weight parts, the polyimide resin of 5 weight parts, wherein, the particle diameter of nano-silica The particle size of nano-titanium dioxide is 4nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com