Modified polyurethane acrylic resin and preparation method thereof

A polyurethane acrylic and acrylic technology, applied in the direction of adhesive additives, non-polymer adhesive additives, etc., can solve the problems of water resistance, poor impact resistance, poor weather resistance, yellowing resistance, poor durability, etc., to achieve weather resistance. The effect of improved performance, good impact resistance and high water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] A method for preparing modified polyurethane acrylic resin, comprising the following steps:

[0057] 1) Add 13.3 grams of isophorone diisocyanate, 0.08 grams of hydroquinone and 0.04 grams of stannous octoate into the reaction kettle, heat to 60°C and stir evenly;

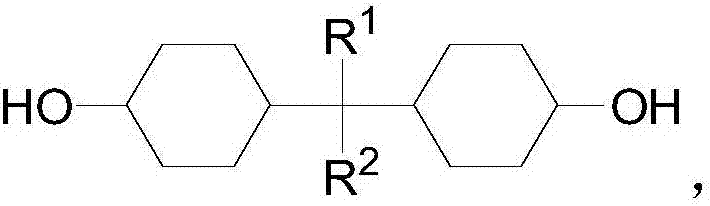

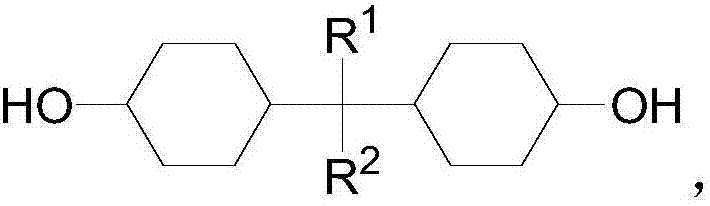

[0058] 2) Add 8 grams of 4,4'-(1-methylene)-bicyclohexanol, heat to 70°C and stir evenly until the mass percentage of isocyanate is 11.9±0.05%;

[0059] 3) Then add 0.05 g of antioxidant 1135, 0.02 g of Tinuvin517 and 6.7 g of acrylate-β-hydroxypropyl ester in sequence, heat to 80° C. and stir to complete the reaction;

[0060] 4) Add 33.3 grams of polyester diol with a hydroxyl value of 56 (the model is Daicel Placcel 220), and continue to react for 4 hours at a temperature of 80°C until the sample is taken out to track the NCO group content in the test system. When the mass percentage content is less than 0.05%, the reaction reaches the end point;

[0061] 5) Add 27.1 grams of tetrahydrofuryl acrylate an...

Embodiment 2

[0063] 1) Add 9 grams of hexamethylene diisocyanate, 0.1 grams of p-hydroxyanisole and 0.04 grams of 0.08 grams of dibutyltin dilaurate into the reaction kettle, heat to 60°C and stir evenly;

[0064] 2) Add 8 grams of 4,4'-(1-methylethylene)-bicyclohexanol, heat to 70°C and stir evenly until the mass percentage of isocyanate is 13.5±0.05%;

[0065] 3) Add 0.05 g of Irganox5057, 0.03 g of Tinuvin328 and 4 g of β-hydroxyethyl methacrylate in sequence, heat to 80°C and stir to complete the reaction;

[0066] 4) Add 26 grams of polyester diol with a hydroxyl value of 56 (the model is Daicel Placcel CD220PL), and continue to react for 4 hours at a temperature of 80° C. until the sample is taken out to track the NCO group content in the test system. When the mass percentage content is less than 0.05%, the reaction reaches the end point;

[0067] 5) Add 17.7 grams of isobornyl acrylate and 21.2 grams of isodecyl acrylate to reduce viscosity, stir evenly, cool and discharge, and obt...

Embodiment 3

[0069] 1) Add 15.3 grams of isophorone diisocyanate, 0.07 grams of p-tert-butylcatechol and 0.06 grams of dibutyltin dilaurate into the reaction kettle, heat to 68°C and stir evenly;

[0070] 2) Add 8 grams of 4,4'-(1-methylene)-bicyclohexanol, heat to 70°C and stir evenly until the mass percentage of isocyanate is 12.2±0.05% and the reaction is complete;

[0071] 3) Then add 0.05 g of 2,6-di-tert-butyl-p-cresol, 0.02 g of Tinuvin213 and 6 g of β-hydroxypropyl acrylate in sequence, heat to 70°C and stir to complete the reaction, and react for 3 hours;

[0072] 4) Add 20 grams of polyester diol with a hydroxyl value of 112 (the model is Daicel Placcel 210), and continue the reaction at a temperature of 80°C until the sample is taken out to track the NCO group content in the test system. When the mole content is less than 0.05%, the reaction reaches the end point;

[0073] 5) Add 20.4 grams of isodecyl acrylate and 16.3 grams of neopentyl glycol diacrylate to reduce viscosity, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com