A solvent-free liquid epoxy wear-resistant coating

A technology of liquid epoxy and wear-resistant coatings, applied in the field of wear-resistant coatings, can solve problems such as air pollution and human damage, achieve high mechanical strength, reduce labor intensity, and improve service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

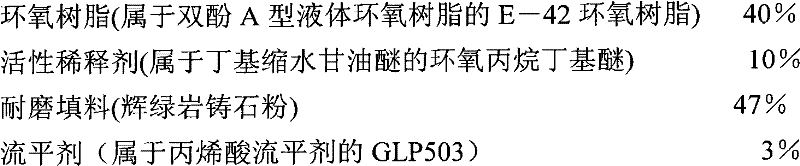

[0034] Top coat composition (according to important percentage):

[0035] A component:

[0036]

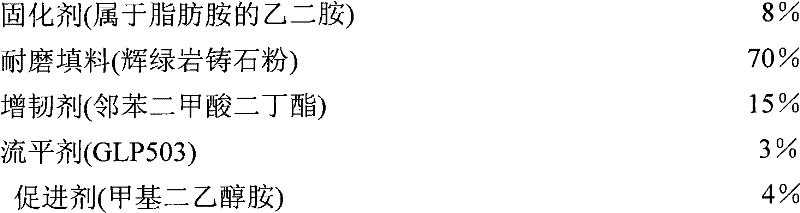

[0037] B component:

[0038]

[0039] The ratio of A and B groups is 1:1

[0040] Primer paint composition (according to important percentage):

[0041] C component:

[0042] Epoxy resin (E-42 epoxy resin) 80%

[0043] Reactive diluent (propylene oxide butyl ether) 15%

[0044] Leveling agent (GLP503) 5%

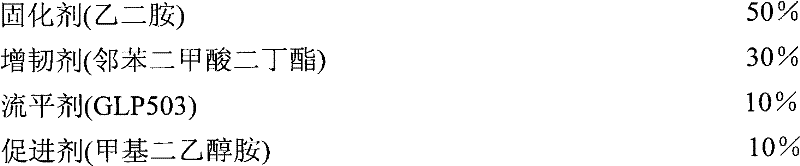

[0045] D component:

[0046]

[0047] The ratio of C and D groups is 5:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com