Exterior wall dope and preparation method of exterior wall dope

A technology for exterior wall coatings and pigments, applied in the field of coatings for exterior walls and their preparation, can solve problems such as the growth of mold and algae, and achieve the effects of improving weather resistance, strong storage stability and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

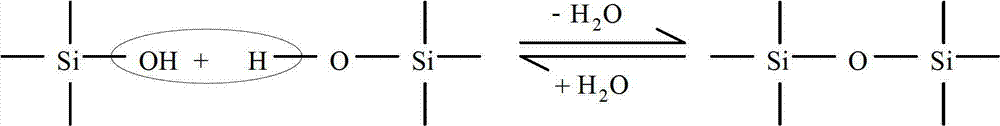

Method used

Image

Examples

Embodiment 1

[0032] Weigh the following components according to the weight ratio: emulsion base material: 10 parts of acrylate emulsion, filler: 30 parts of mica powder, dispersant: 0.1 part of polyphosphate, water glass: 30 parts of aqueous solution of potassium silicate, pigment: 10 parts of rutile titanium dioxide, defoamer: 0.1 part of saturated fatty acid, thickener: 0.2 part of hydroxyethyl cellulose, wetting agent: 0.1 part of polyethylene glycol aliphatic ether, anti-mold preservative: isothiazolin 0.5 parts of ketone derivatives, viscosity stabilizer: 5 parts of isotridecyloxypropyl amine oxide, film-forming aid: 2 parts of lauryl alcohol, 10 parts of water; then follow the steps below:

[0033] (1) Add water and thickener under stirring at 200rpm-500rpm, and stir for 3 minutes;

[0034] (2) Adjust the speed to 600rpm-900rpm, add 10% defoamer and dispersant, and stir for 2 minutes;

[0035] (3) Adjust the speed to 1100rpm-1400rpm, add pigments and fillers, and stir for 30 minutes...

Embodiment 2

[0041] Weigh the following components according to the weight ratio: emulsion base material: 30 parts of styrene-acrylic emulsion, filler: 15 parts of calcium carbonate, dispersant: 2 parts of polyacrylic acid sodium salt, water glass: 10 parts of aqueous solution of sodium silicate, pigment : 20 parts of rutile titanium dioxide, defoaming agent: 2 parts of fatty acid ester, thickener: 1 part of bentonite, wetting agent: 0.5 parts of modified aromatic polyether, anti-mold preservative: benzimidazole derivative 0.2 parts, viscosity stabilizer: 1 part of isotridecyloxypropyl amine oxide, film-forming aid: 1 part of lauryl alcohol, 20 parts of water; then follow the steps below:

[0042] (1) Add water and thickener under stirring at 200rpm-500rpm, and stir for 3 minutes;

[0043] (2) Adjust the speed to 600rpm-900rpm, add 25% defoamer and dispersant, and stir for 2 minutes;

[0044] (3) Adjust the speed to 1100rpm-1400rpm, add pigments and fillers, and stir for 30 minutes;

[0...

Embodiment 3

[0050] Weigh the following components according to the weight ratio: emulsion base material: 20 parts of silicon acrylic emulsion, filler: 15 parts of barium sulfate, dispersant: 1.2 parts of polyphosphate, water glass: 20 parts of aqueous solution of potassium silicate, pigment: 25 parts of rutile titanium dioxide, defoamer: 1 part of saturated fatty acid, thickener: 0.5 part of xanthan gum, wetting agent: 0.2 part of polyethylene glycol aliphatic ether, anti-mold preservative: pipetriazine derivative 0.5 parts, viscosity stabilizer: 4 parts of isotridecyloxypropyl amine oxide, film-forming aid: 3 parts of 200# solvent oil, 30 parts of water; then follow the steps below:

[0051] (1) Add water and thickener under stirring at 200rpm-500rpm, and stir for 3 minutes;

[0052] (2) Adjust the speed to 600rpm-900rpm, add 40% defoamer and dispersant, and stir for 2 minutes;

[0053] (3) Adjust the speed to 1100rpm-1400rpm, add pigments and fillers, and stir for 30 minutes;

[0054]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com