Methanol-resistant, static-conducting and anti-corrosive paint

A technology for anti-corrosion coatings and electrostatic conduction, which is applied in the direction of anti-corrosion coatings, conductive coatings, epoxy resin coatings, etc. It can solve the problems of easy swelling of the coating film, foaming, and decline in electrostatic conductivity, and achieves simple preparation process and low-temperature curing properties. Good, excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

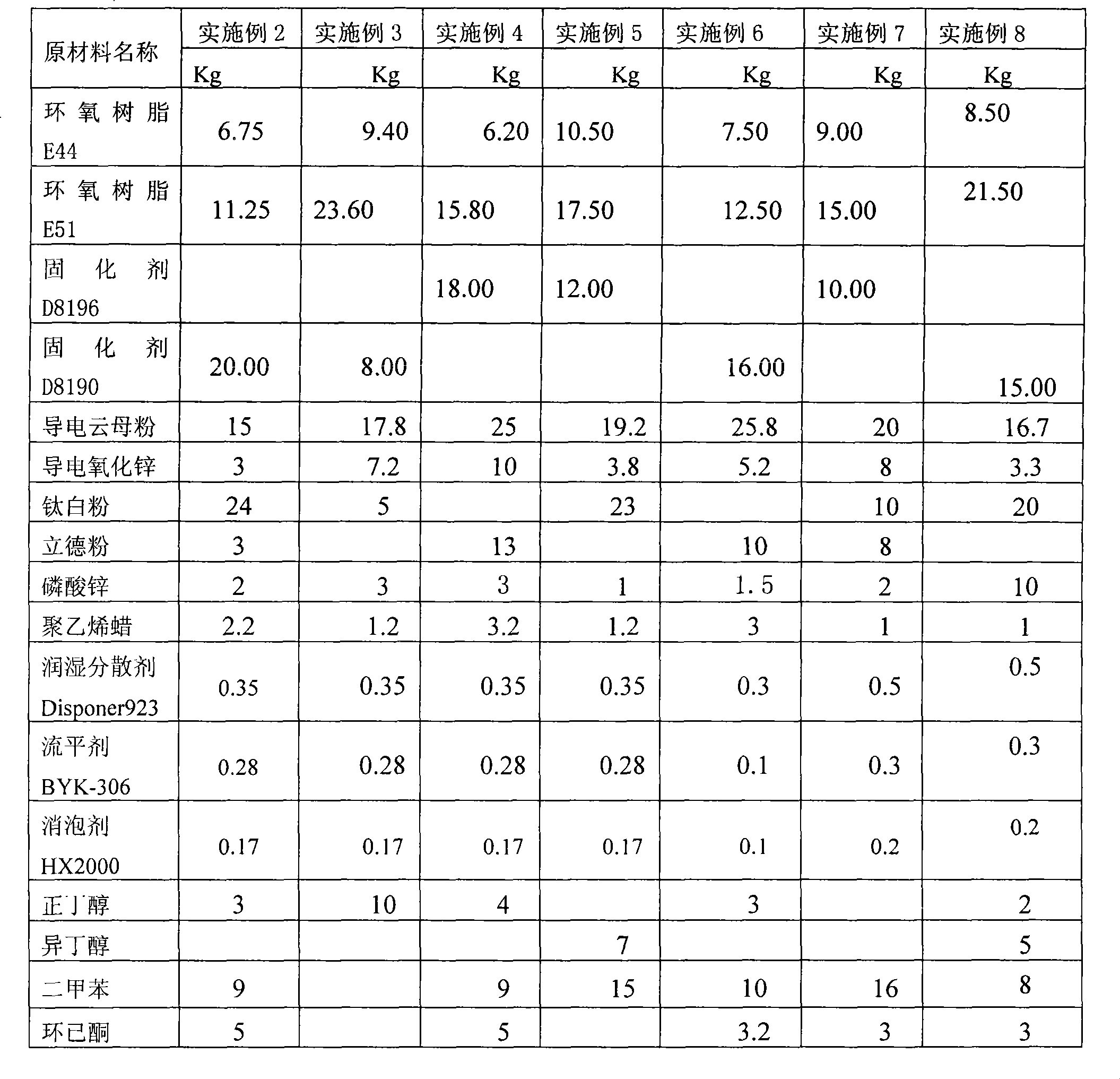

Examples

Embodiment 1

[0023] Preparation:

[0024] Weigh the following ingredients in proportion:

[0025] A component

[0026] Epoxy resin E44 9.75kg, Epoxy resin E51 16.25kg,

[0027] Conductive mica powder 20.80kg, conductive zinc oxide 4.2kg,

[0028] Titanium dioxide 16kg, lithopone 2.0kg,

[0029] Zinc phosphate 20kg, polyethylene wax 2kg,

[0030] Xylene 20kg;

[0031] B component

[0032] Curing agent D8190 16kg.

[0033] Mix epoxy resin E44 and epoxy resin E51 evenly. Put the pigment titanium dioxide, lithopone and filler zinc phosphate into the epoxy resin, add 8kg of diluent xylene and stir evenly, grind to a fineness of 25-40μm through a sand mill, and add conductive mica powder as a conductive filler after discharging Mix it with conductive zinc oxide, additive polyethylene wax and the remaining 12kg of xylene to obtain component A. When in use, add component B, namely the curing agent, into component A and mix evenly to obtain the final product.

[0034] The final product ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com