Light-color modified epoxy static conductive anticorrosion coating and preparation method thereof

A technology for anti-corrosion coatings and epoxy coatings, applied in anti-corrosion coatings, conductive coatings, epoxy resin coatings, etc., can solve the problems of high price, low cost performance, and limited application range, and achieve good chemical resistance and wide application range The effect of broad and strong competitive advantage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

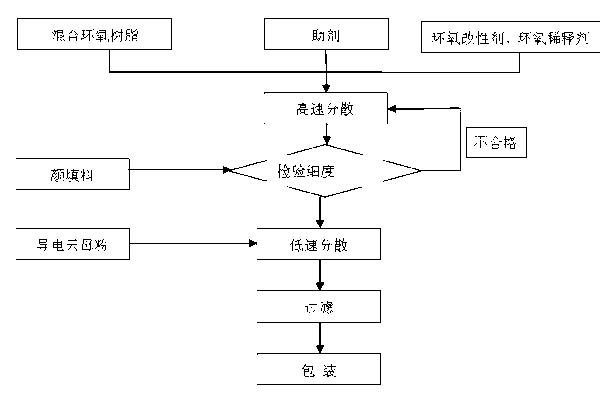

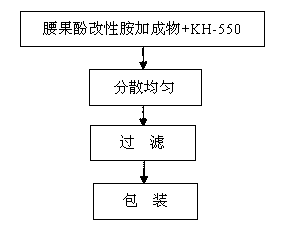

Method used

Image

Examples

Embodiment Construction

[0047] Below in conjunction with accompanying drawing, the present invention is further described, and the present invention is not limited to following embodiment:

[0048] The embodiment of light-color modified epoxy antistatic anticorrosion paint of the present invention is shown in Table 1:

[0049] Part A raw material name Example 1 Example 2 Example 3 E44 epoxy resin 5 7.5 10 F-51 Novolac Epoxy Resin 10 7.5 5 Modified Coumarone Petroleum Resin (BHS) 7 12 17 Epoxy Thinner 660A 5 10 15 Wetting and dispersing agent BYK-110 0.1 0.3 0.5 Defoamer BYK-A530 0.5 0.3 0.1 Silane coupling agent KH-560 1.0 1.2 1.5 Rheology Additives 1.5 1.3 1.0 Active silica 4 7 8 Conductive mica powder 20 15 8 Other pigments and fillers 35.8 22.6 13.4 Component B raw material name Example 1 Example 2 Example 3 Cardanol modified amine adduct 10 15 20 KH-550 0.1 0.3 0.5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com