Light emitting diode (LED) high-power encapsulation silica gel

A high-power, silicone technology, used in adhesives, electrical components, circuits, etc., can solve the problems of high temperature resistant silicone material research and development lag, low thermal conductivity and other problems, and achieve the effect of simple and easy production process, long storage period and convenient storage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

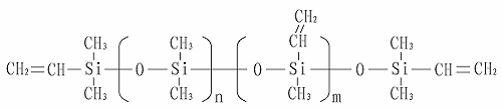

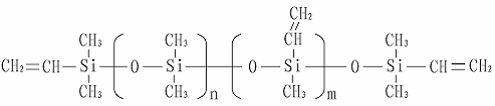

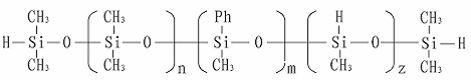

[0030] A glue (resin part), 100 parts of vinyl phenyl polysiloxane, 50 parts of vinyl polysiloxane, 0.02 parts of catalyst; B glue (crosslinking agent part), 100 parts of hydrogen phenyl polysiloxane, 50 parts of hydropolysilane, 0.01 part of polymerization inhibitor.

Embodiment 2

[0032] A glue (resin part), 100 parts of vinyl phenyl polysiloxane, 65 parts of vinyl polysiloxane, 0.5 part of catalyst; B glue (crosslinking agent part), 100 parts of hydrogen phenyl polysiloxane, 65 parts of hydropolysilane, 0.5 part of polymerization inhibitor.

Embodiment 3

[0034] A glue (resin part), 100 parts of vinyl phenyl polysiloxane, 85 vinyl polysiloxane, 1.2 parts of catalyst; B glue (crosslinking agent part), 100 parts of hydrogen phenyl polysiloxane, 85 parts of hydropolysilane, 1.0 part of polymerization inhibitor.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com