Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

64results about How to "Different hardness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

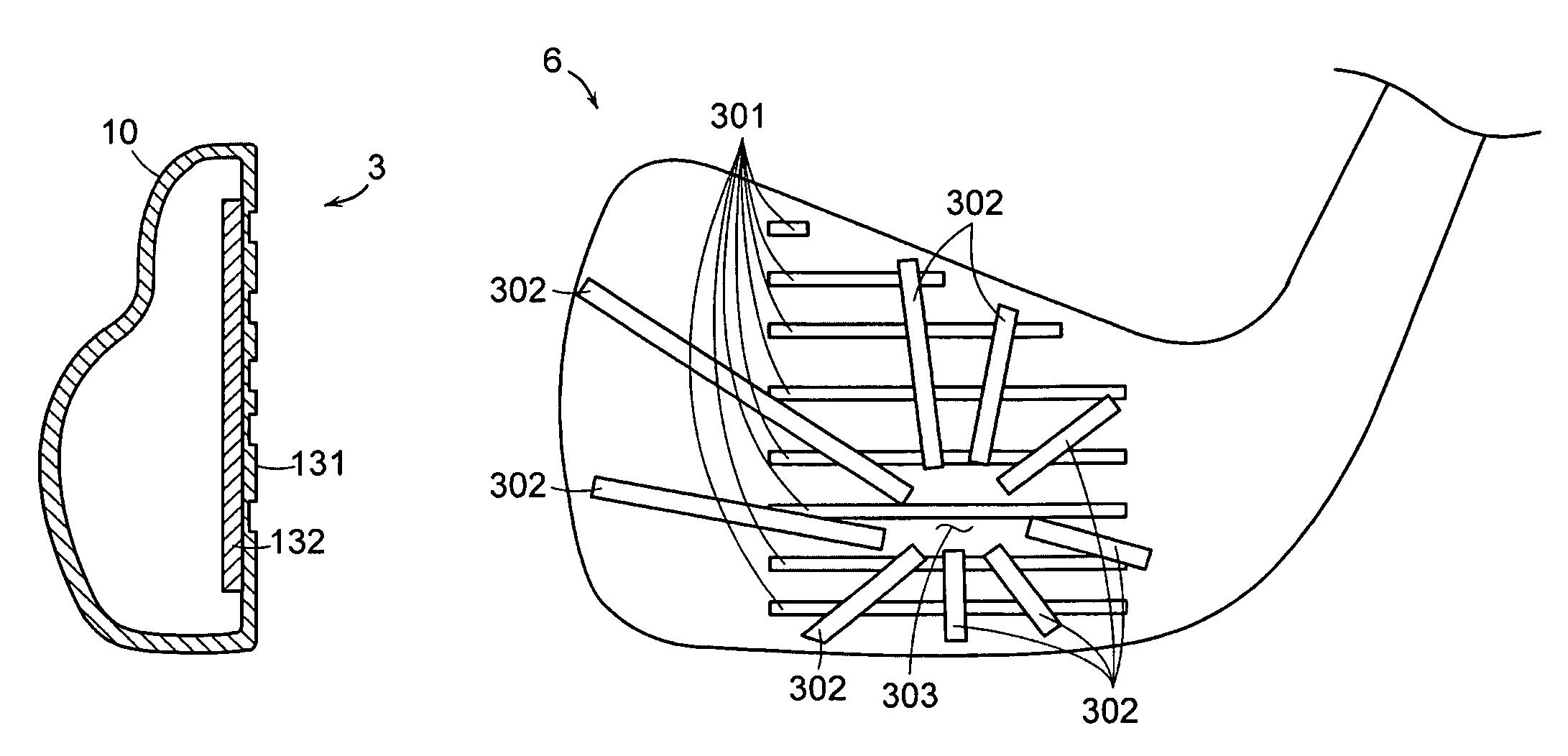

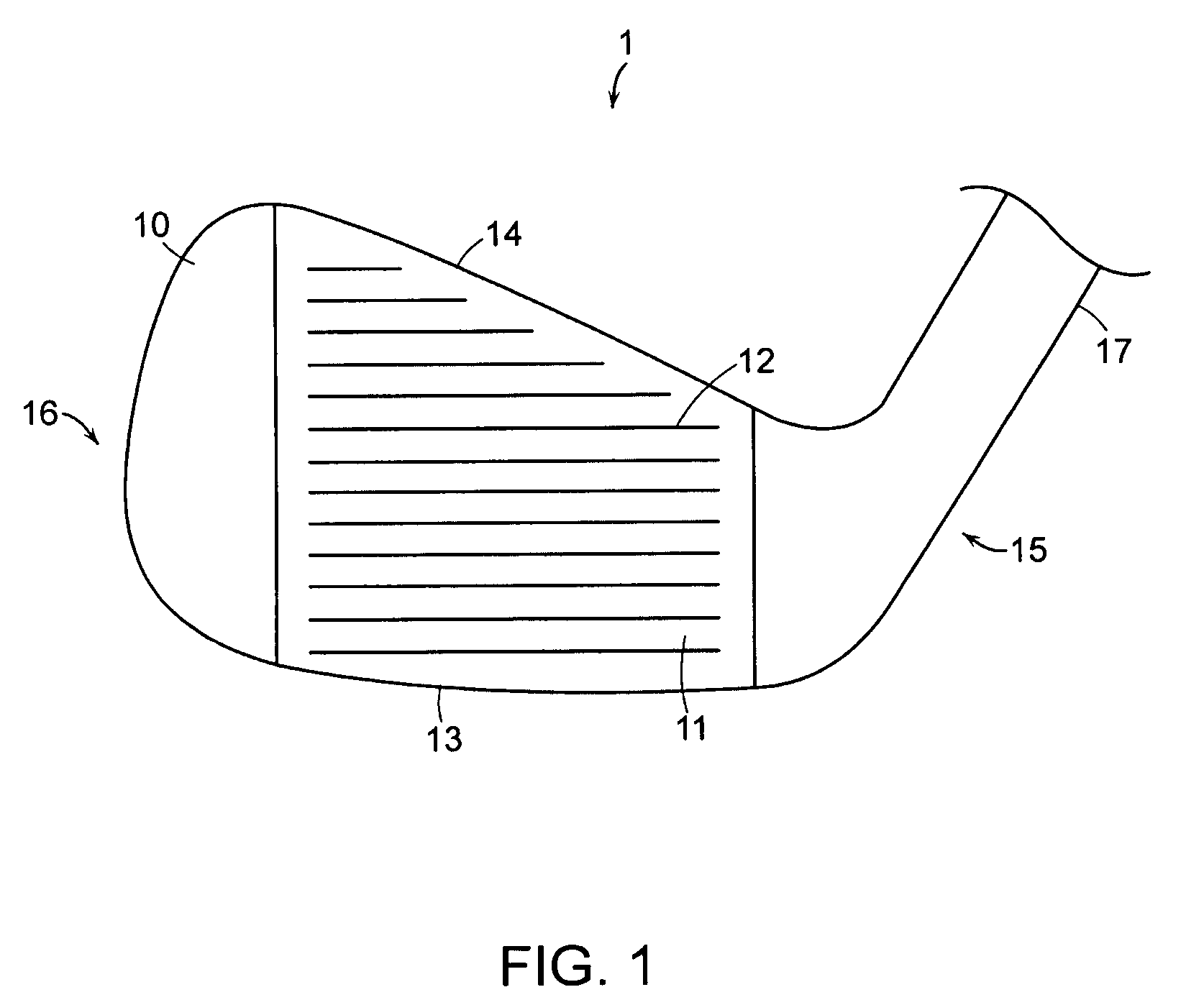

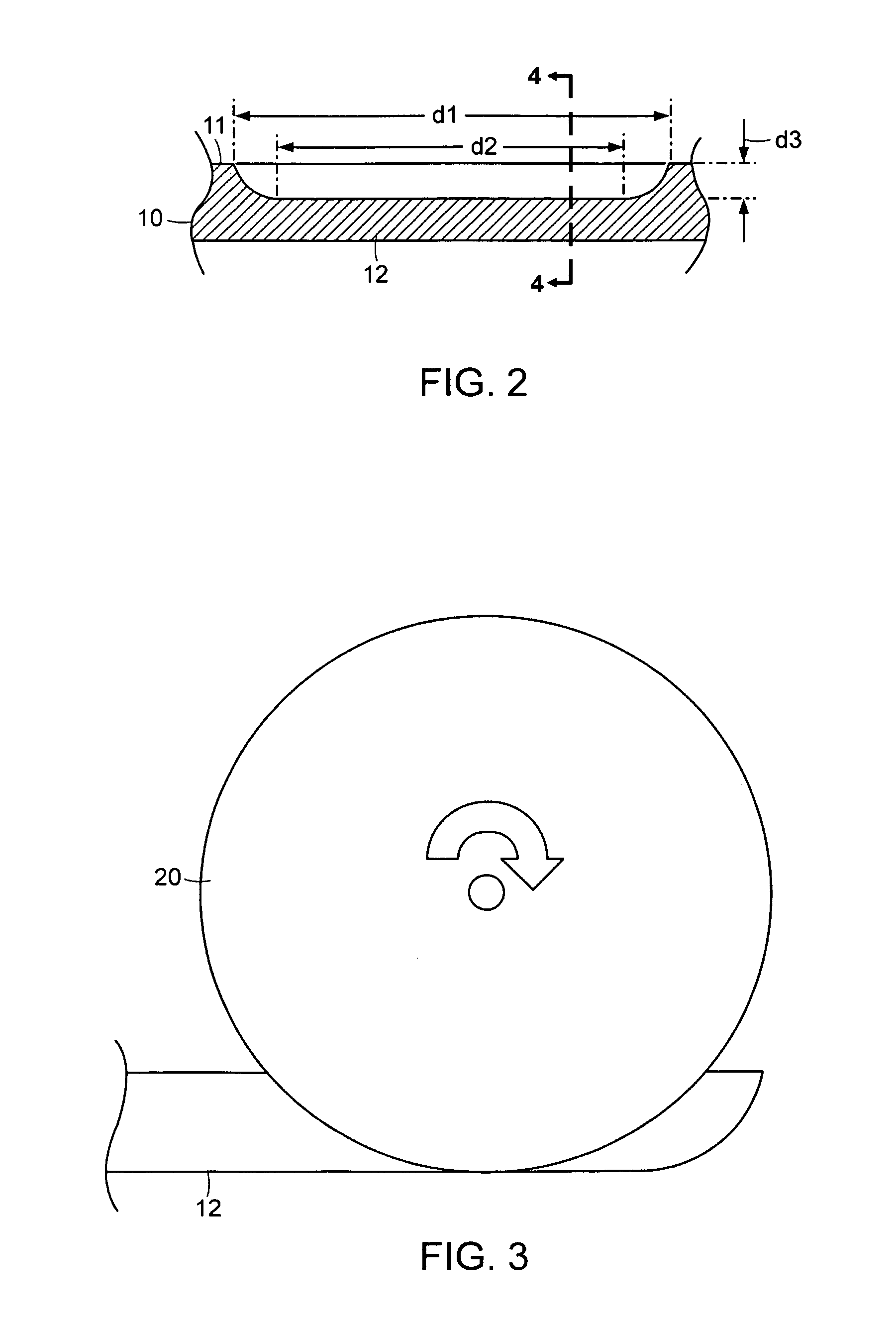

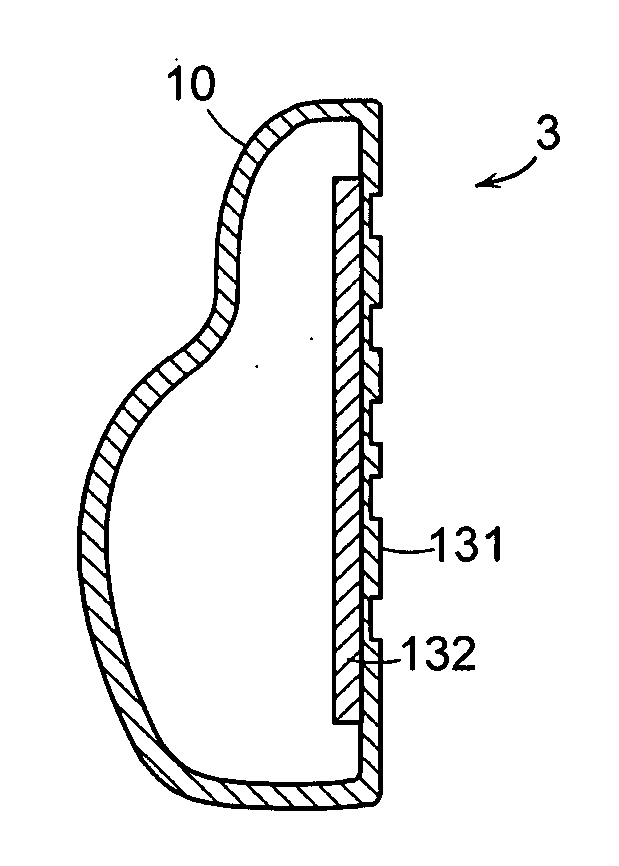

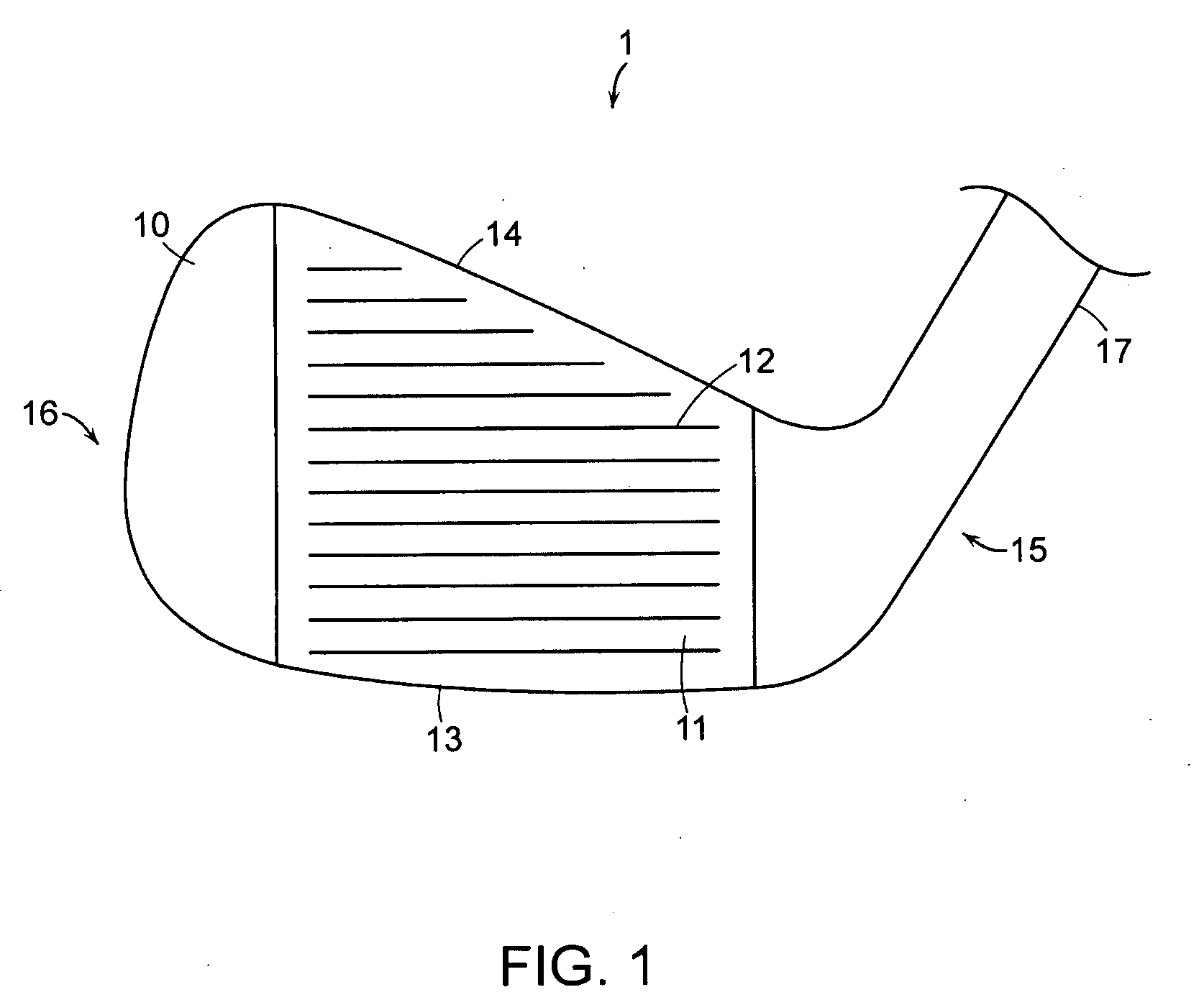

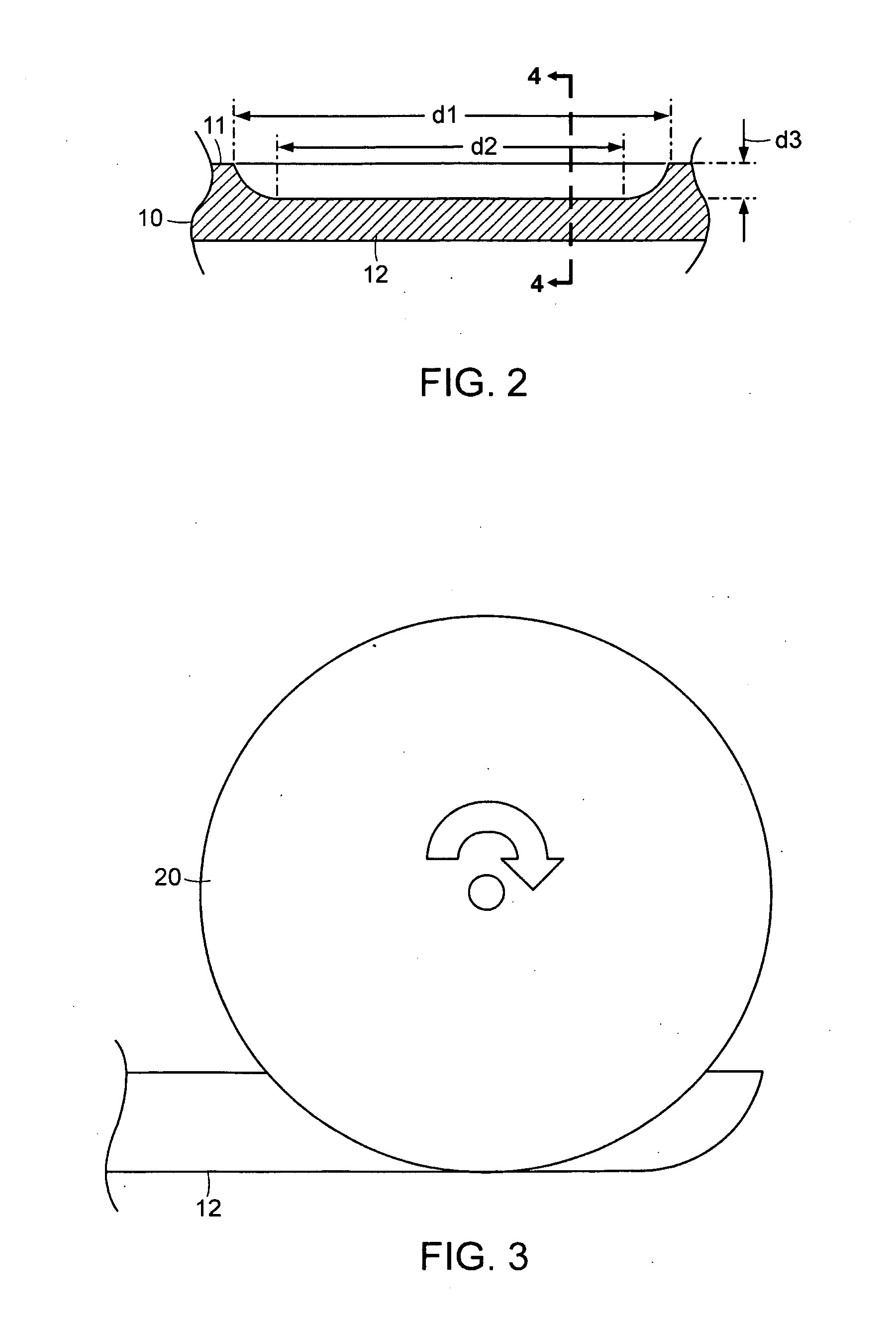

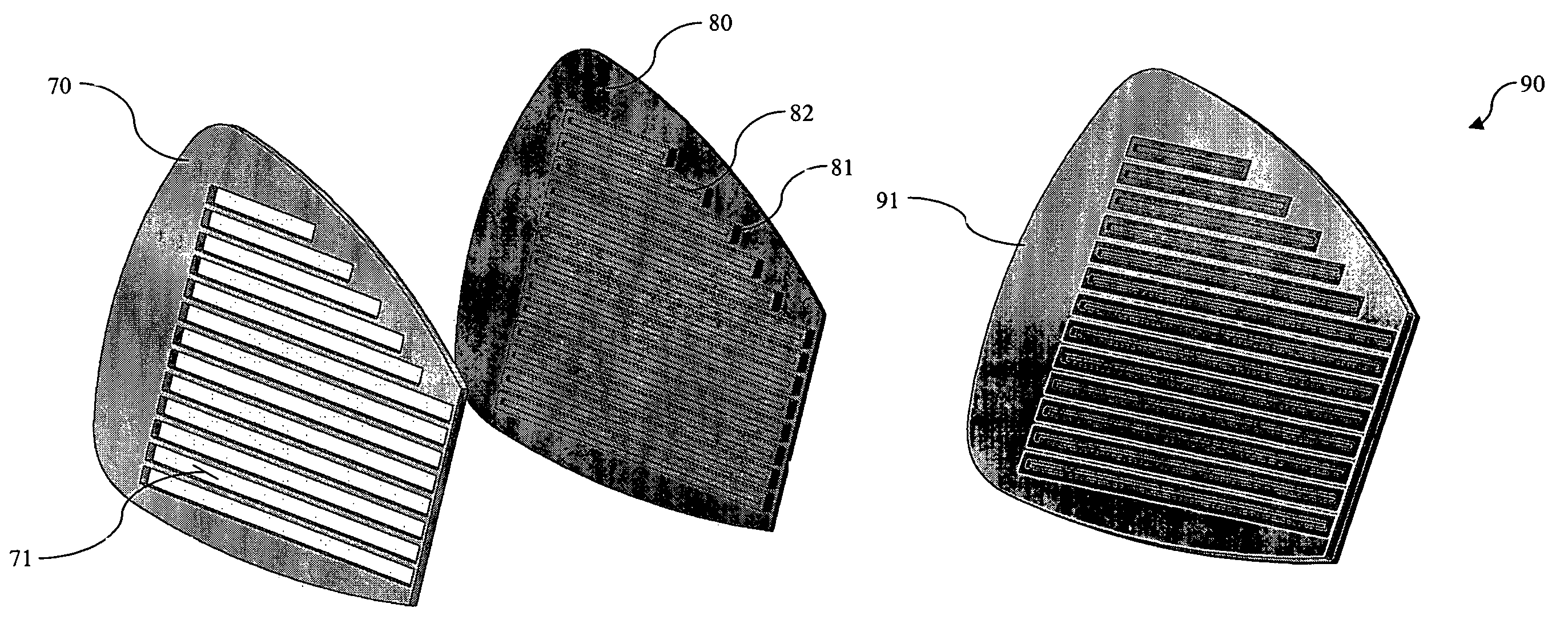

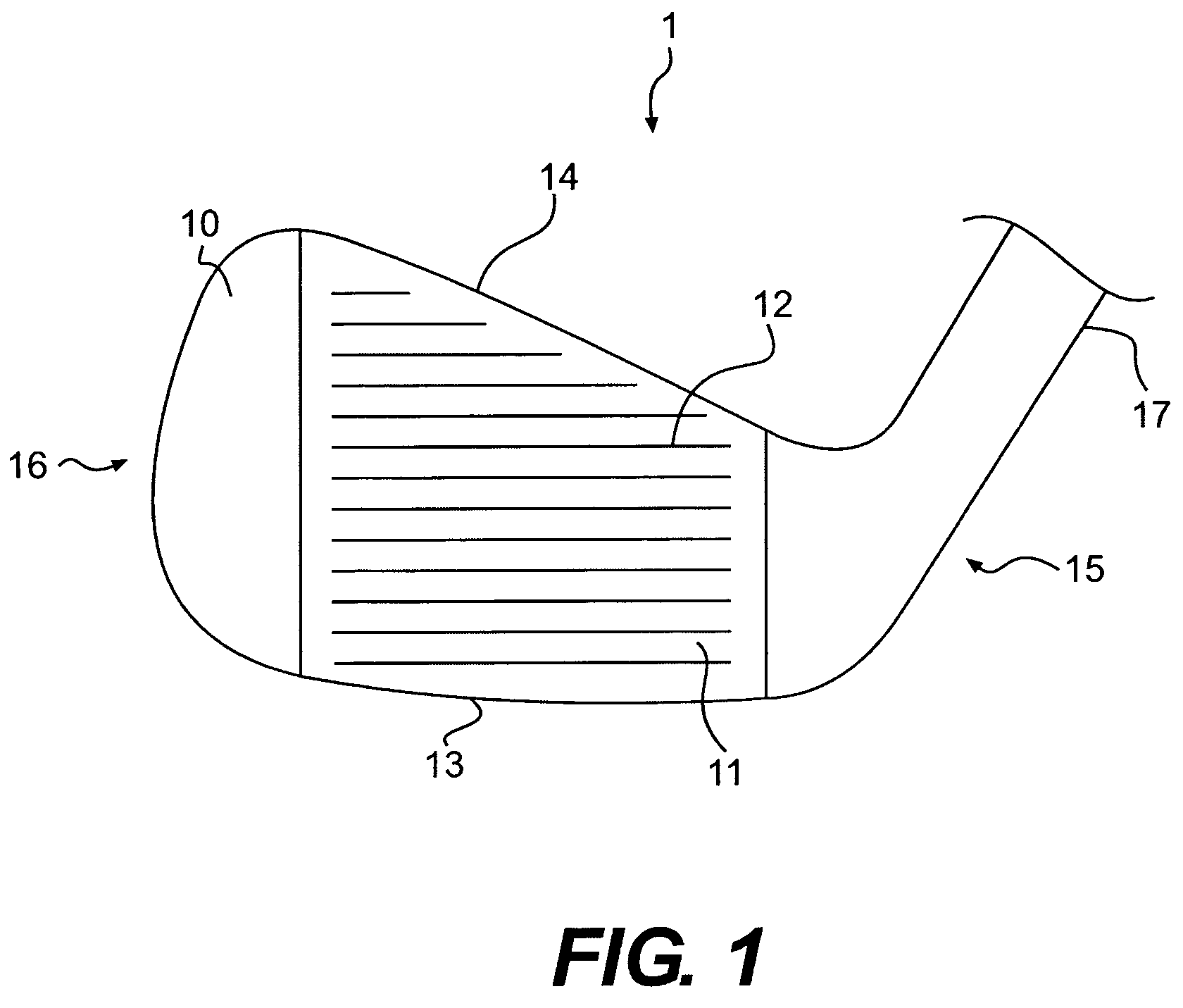

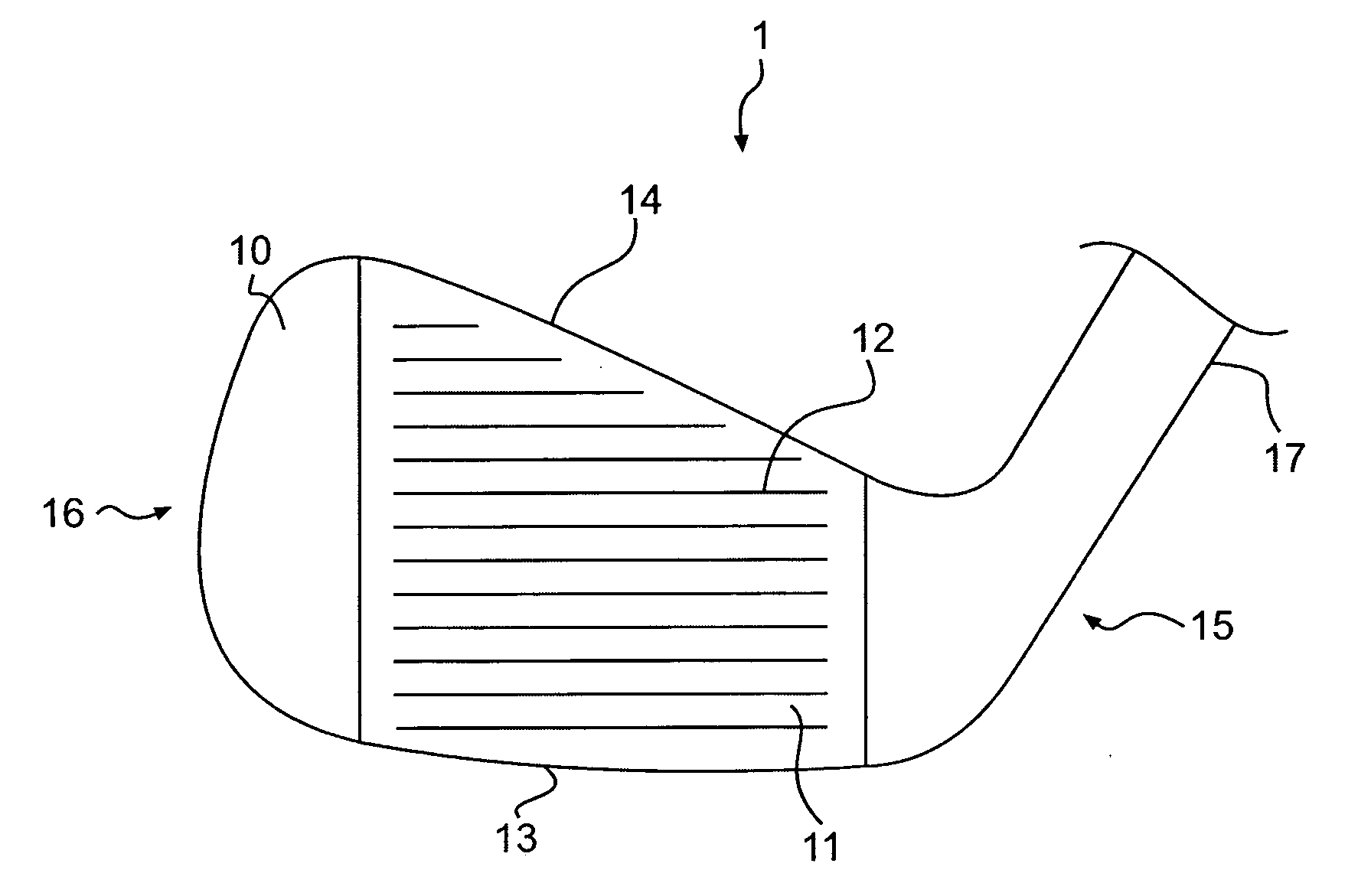

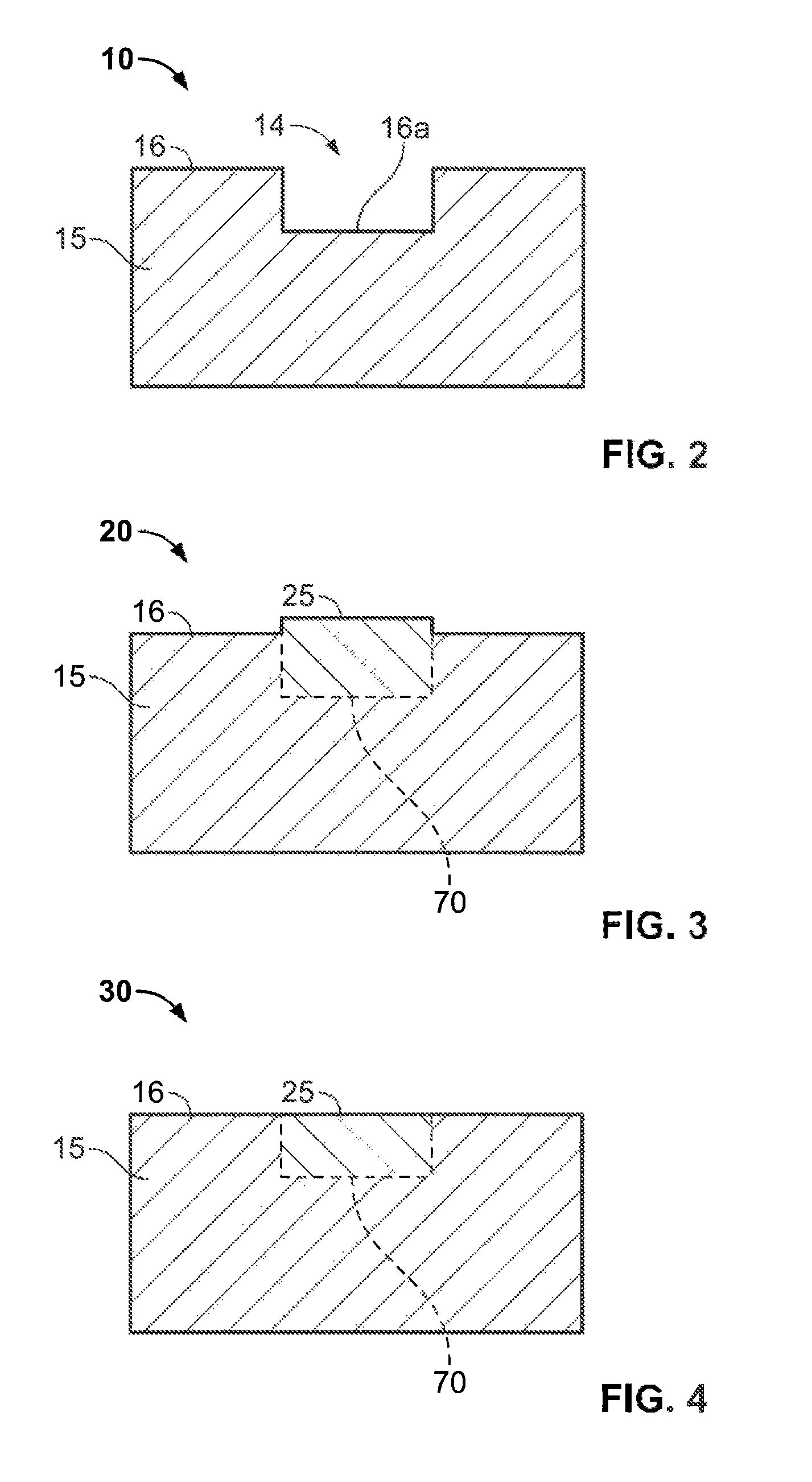

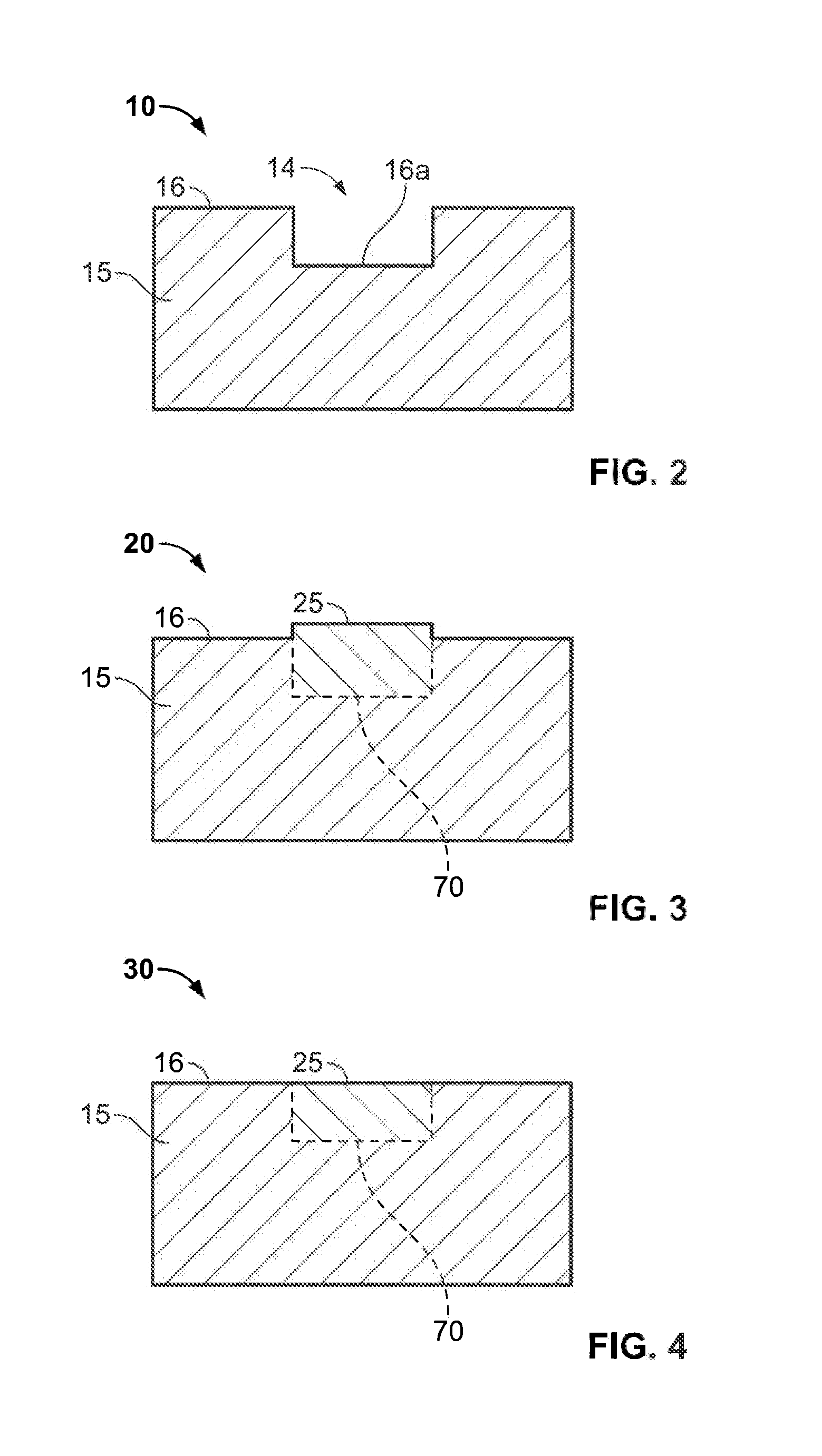

Golf club head

InactiveUS7594862B2Feel goodImprove wear resistanceGolf clubsRacket sportsMulti materialWear resistant

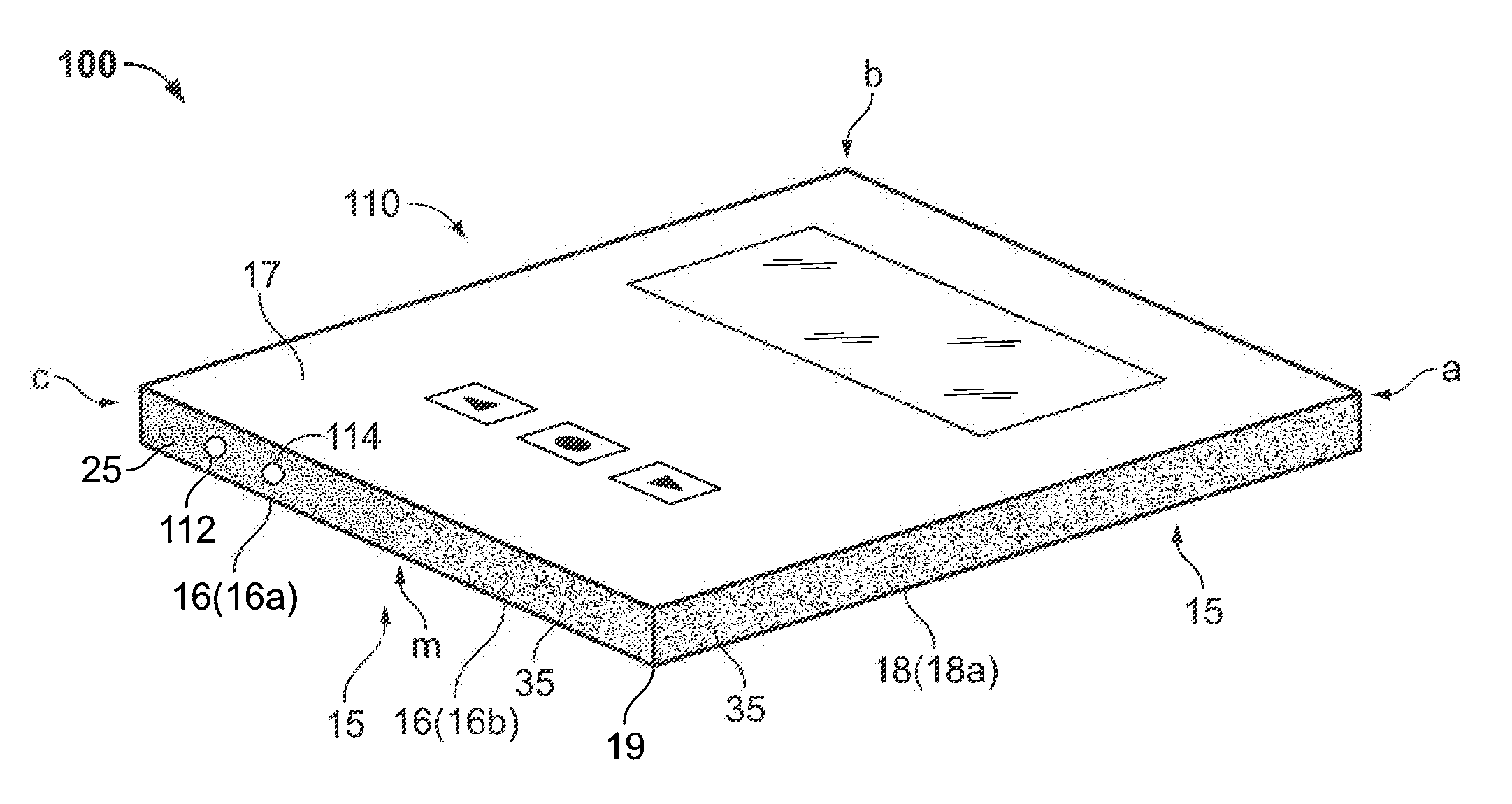

A golf club head having a multi-material face. The golf club head has a hard, wear resistant material as the ball-impacting face surface coupled to a softer material, allowing the multi-material face to be joined to a soft body material such that the body can be bent and customized. The multi-material face allows for improved playing characteristics by allowing the club designer to use a thinner face and lighter body material while still providing improved face wear resistance and durability.

Owner:ACUSHNET CO

Golf Club Head

InactiveUS20080293511A1Easy to adjustReadily customizable bodyGolf clubsRacket sportsMulti materialWear resistant

A golf club head having a multi-material face. The golf club head has a hard, wear resistant material as the ball-impacting face surface coupled to a softer material, allowing the multi-material face to be joined to a soft body material such that the body can be bent and customized. The multi-material face allows for improved playing characteristics by allowing the club designer to use a thinner face and lighter body material while still providing improved face wear resistance and durability.

Owner:ACUSHNET CO

Golf club head

InactiveUS7846039B2Feel goodImprove wear resistanceGolf clubsRacket sportsMulti materialWear resistant

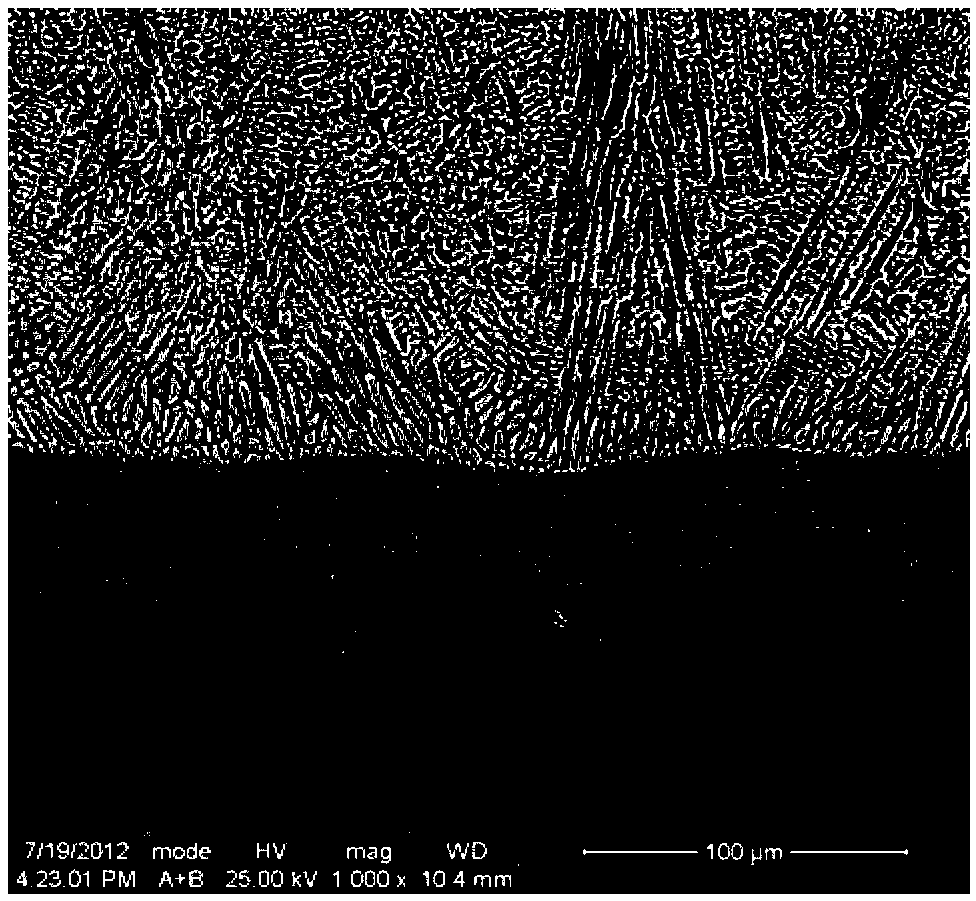

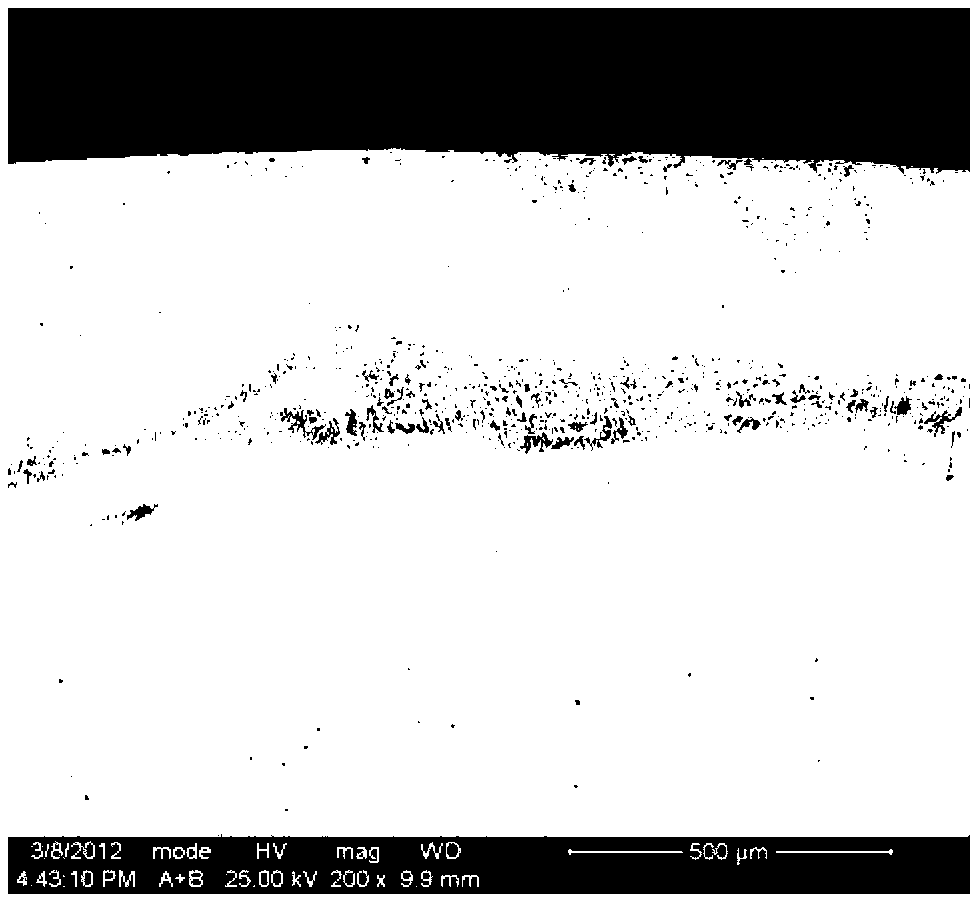

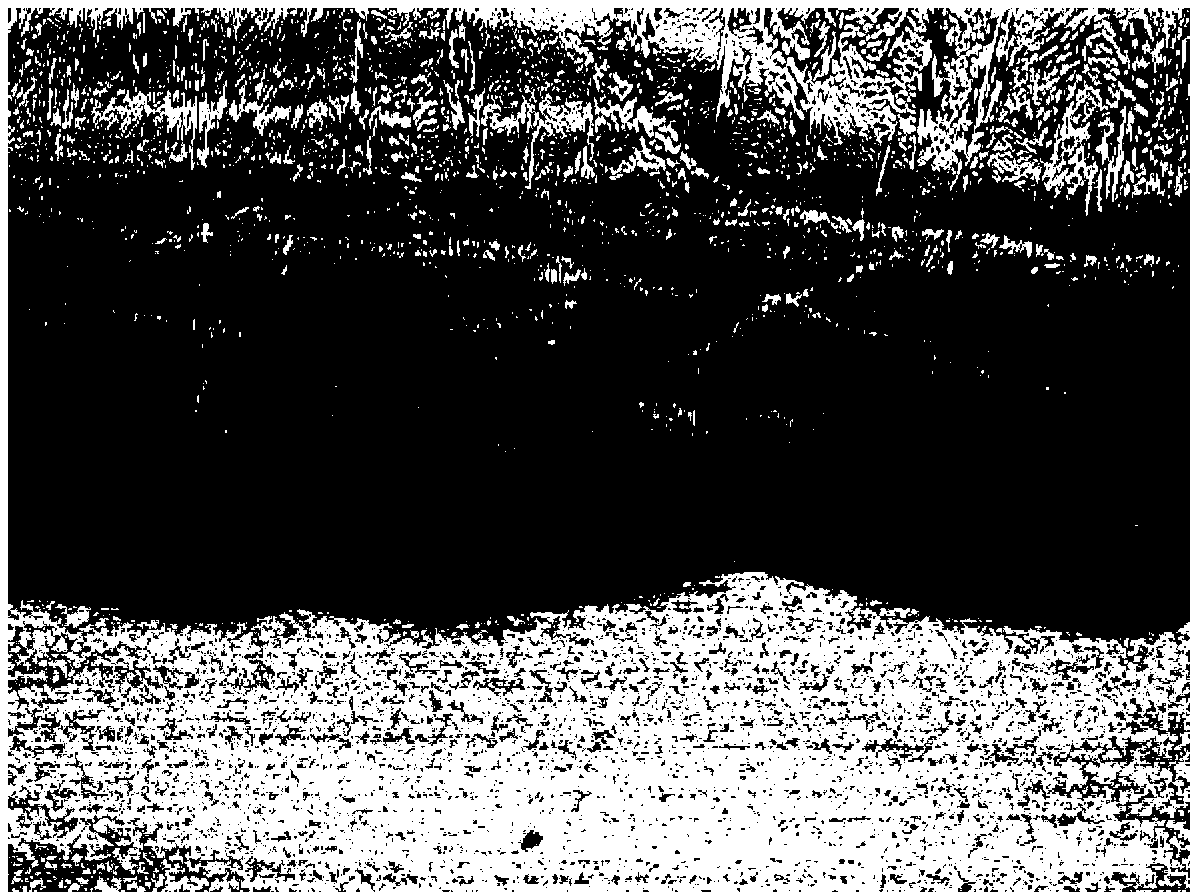

A golf club head having a multi-material face is disclosed and claimed. The face is formed by explosion welding, allowing materials having substantially different properties to be uniformly joined. Explosion welding allows the materials to be joined together via a cold-working process, allowing them to joined without losing their pre-bonded properties. Thus, the golf club head have a hard, wear resistant material as the ball-impacting face surface explosion welded to a softer material, allowing the multi-material face to be joined to a soft body material such that the body can be bent and customized. The multi-material face also allows for improved playing characteristics by allowing the club designer to use a thinner face and lighter body material while still providing improved face wear resistance and durability.

Owner:ACUSHNET CO

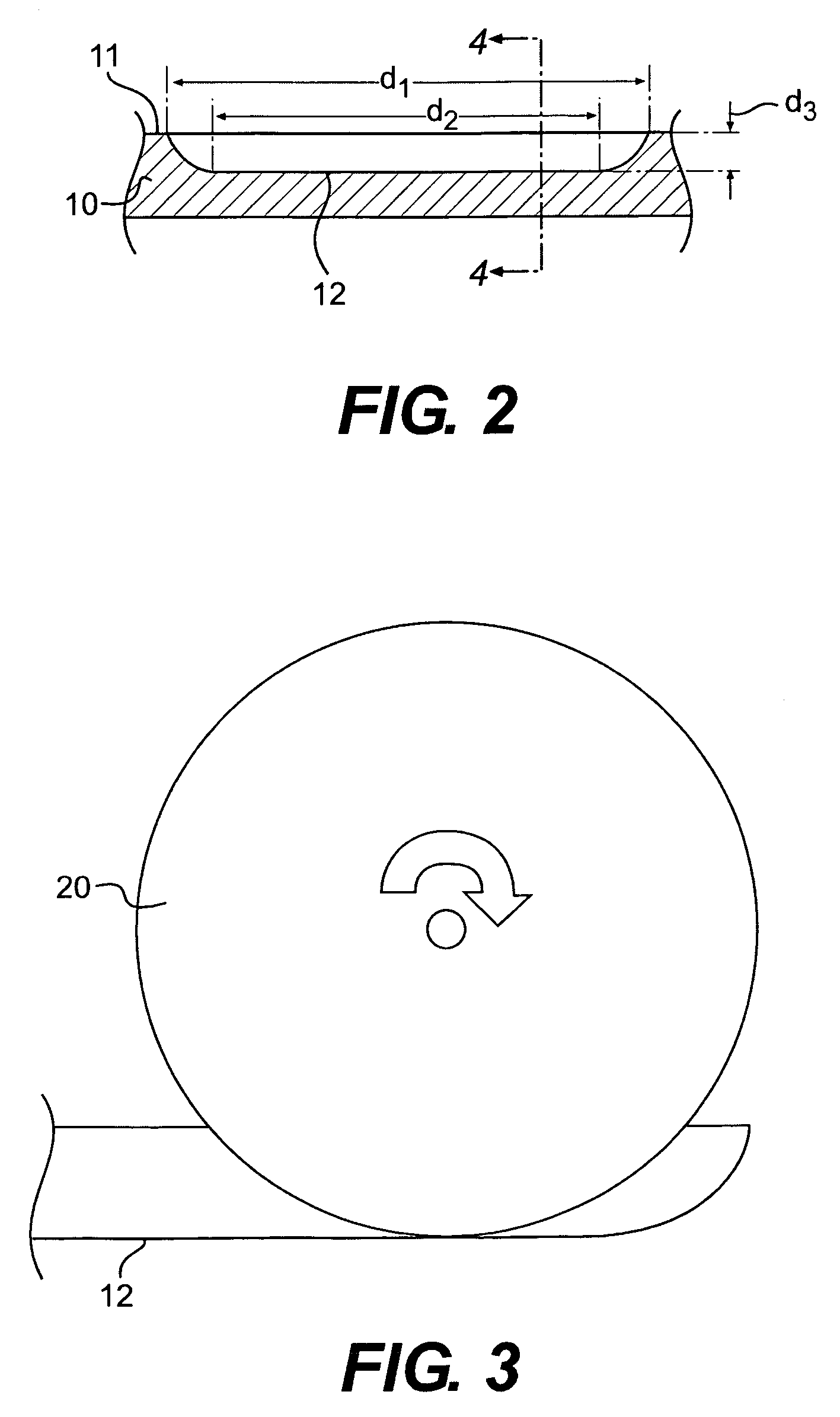

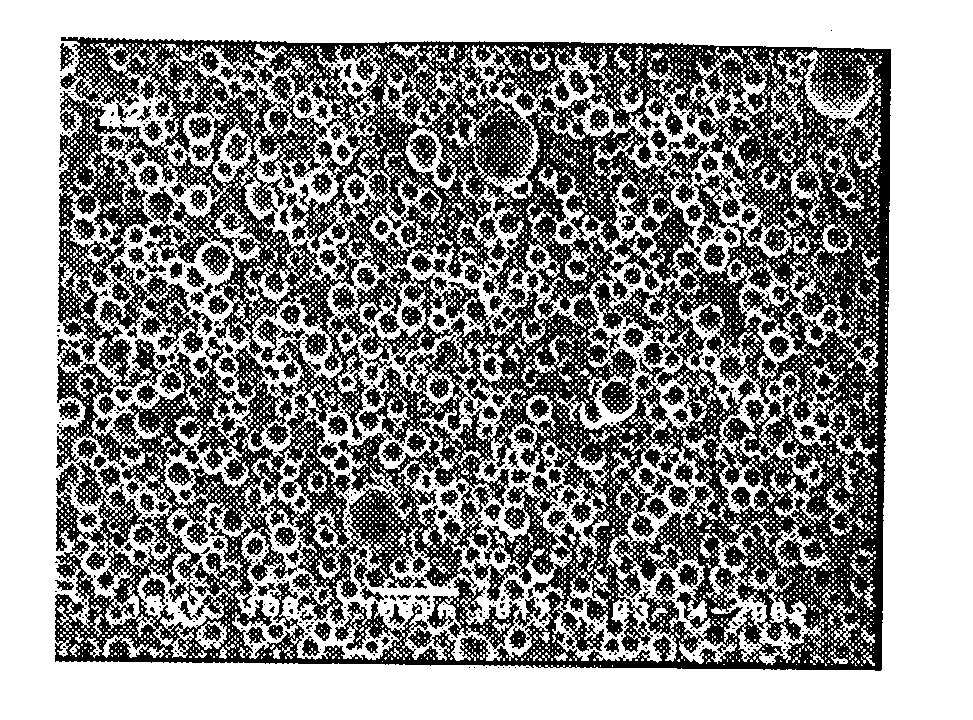

Method for manufacturing auxiliary gas-adding polyurethae/polyurethane-urea polishing pad

InactiveUS20040021243A1Improve accuracyImprove flatnessFlexible-parts wheelsLapping toolsHydrogenPolythiol resin

A method for manufacturing a PU (polyurethane) polishing pad is provided. Resins containing active hydrogen functional groups such as polyol resins, polyamine resins, and polythiol resins, and polyisocyanate resins containing -NCO functional groups are mixed to form a foamed PU polishing pad with excellent polishing properties by reaction injection-molding under high pressure, low temperature and auxiliary gas-adding. The PU polishing pad in accompany with an abrasive slurry can be widely used to polish high-level products such as wafers and optical glass.

Owner:IV TECH CO LTD

Golf club head

InactiveUS20070010346A1Feel goodImprove wear resistanceGolf clubsRacket sportsMulti materialWear resistant

A golf club head having a multi-material face is disclosed and claimed. The face is formed by explosion welding, allowing materials having substantially different properties to be uniformly joined. Explosion welding allows the materials to be joined together via a cold-working process, allowing them to joined without losing their pre-bonded properties. Thus, the golf club head have a hard, wear resistant material as the ball-impacting face surface explosion welded to a softer material, allowing the multi-material face to be joined to a soft body material such that the body can be bent and customized. The multi-material face also allows for improved playing characteristics by allowing the club designer to use a thinner face and lighter body material while still providing improved face wear resistance and durability.

Owner:ACUSHNET CO

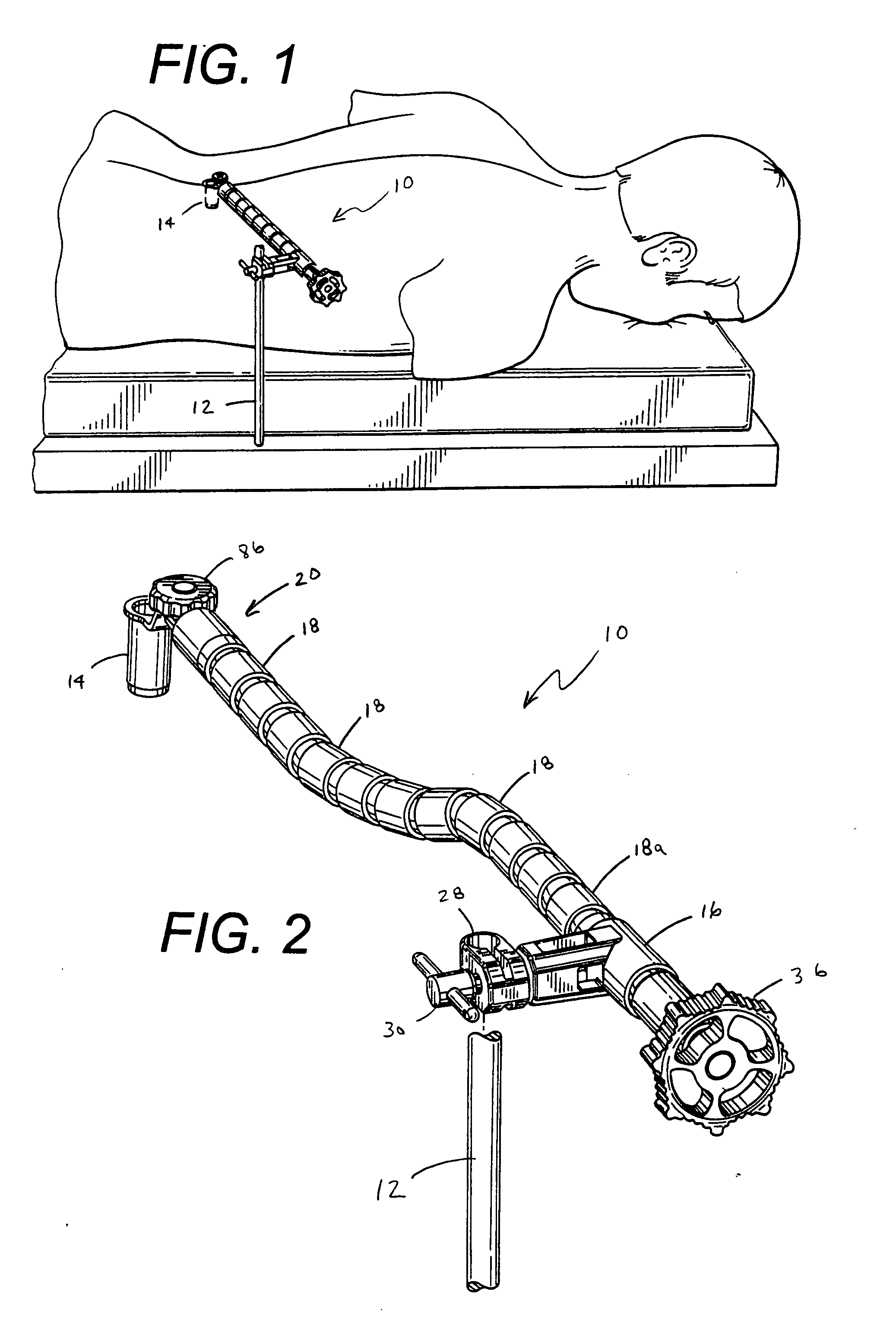

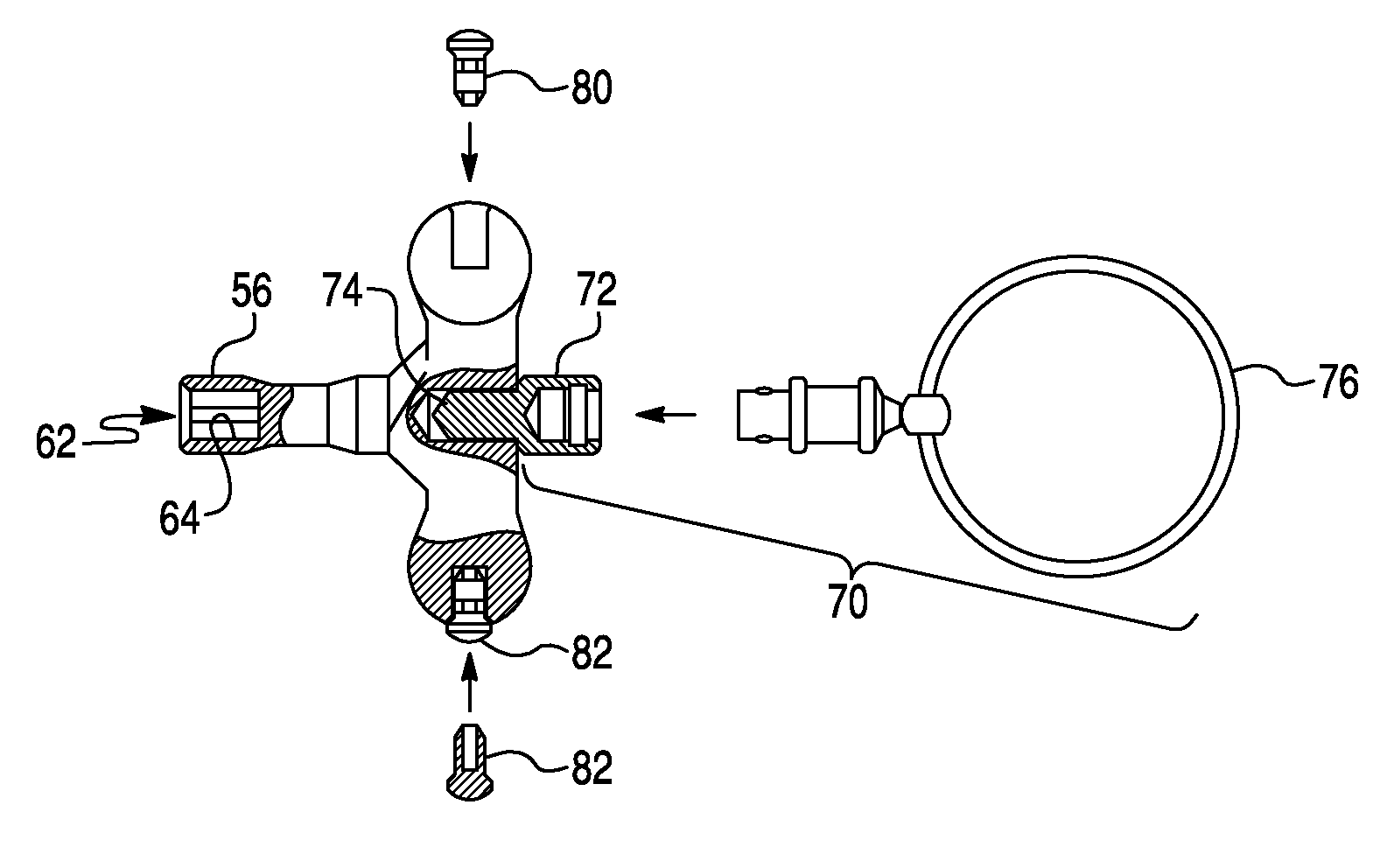

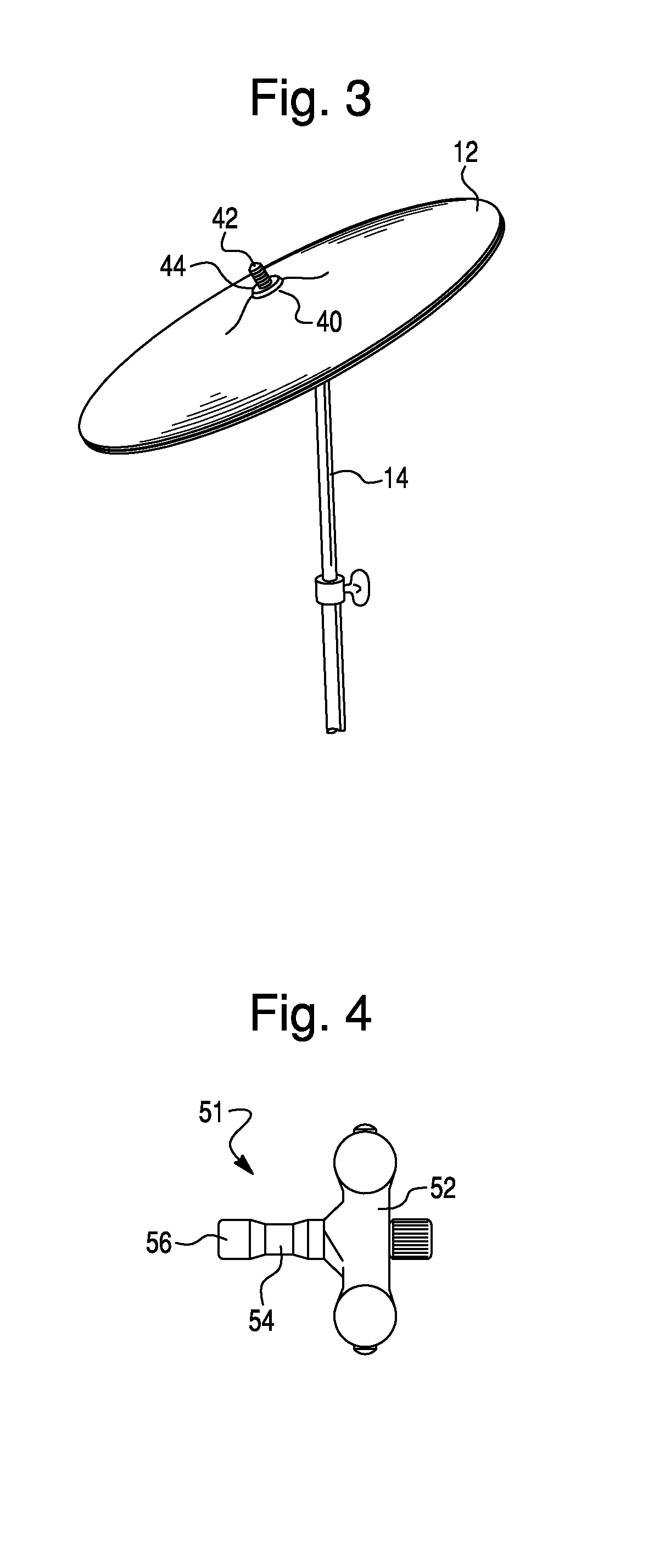

Surgical instrument support

InactiveUS20080121765A1Different hardnessDifferent surface surfaceDiagnosticsStands/trestlesEngineeringNon magnetic

The present invention generally provides a surgical instrument support for securing a surgical instrument in a fixed position in a surgical environment having a magnetic field. The surgical instrument support has a mounting clamp, a tightening mechanism, a plurality of mating arm segments, an end member with a connector to secure the surgical instrument thereto, and a wire extending from the tightening mechanism to the end member. The wire can be tightened to secure the mating arm segments in a desired position for the surgeon. In one embodiment all of the components of the surgical instrument support are made of a non-magnetic material, preferably titanium or a titanium alloy. In another embodiment the connector of the end member can be removed when the surgical instrument support is in both the rigid or actuated configuration and the untightened or non-actuated configuration.

Owner:FETZER PETER E

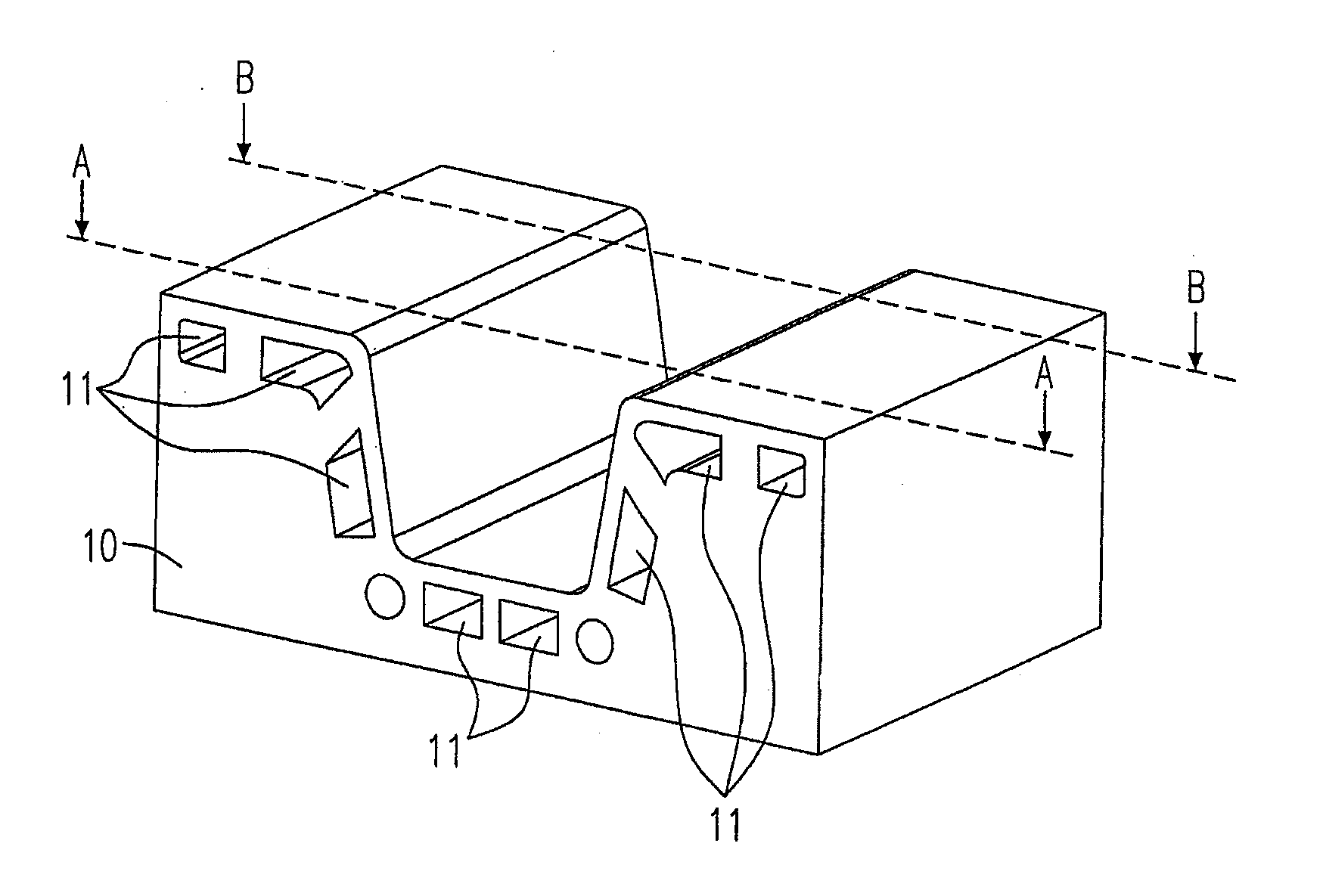

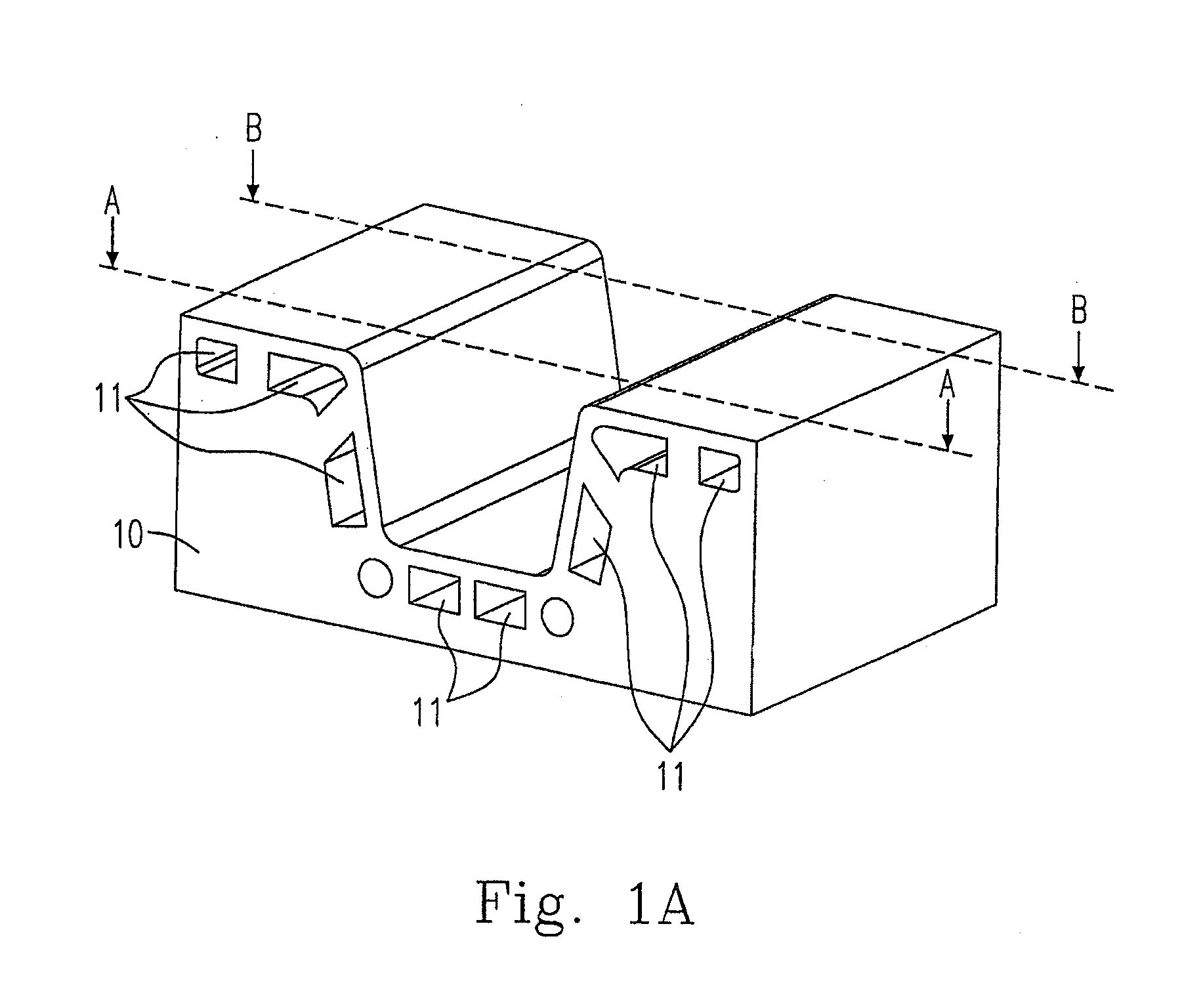

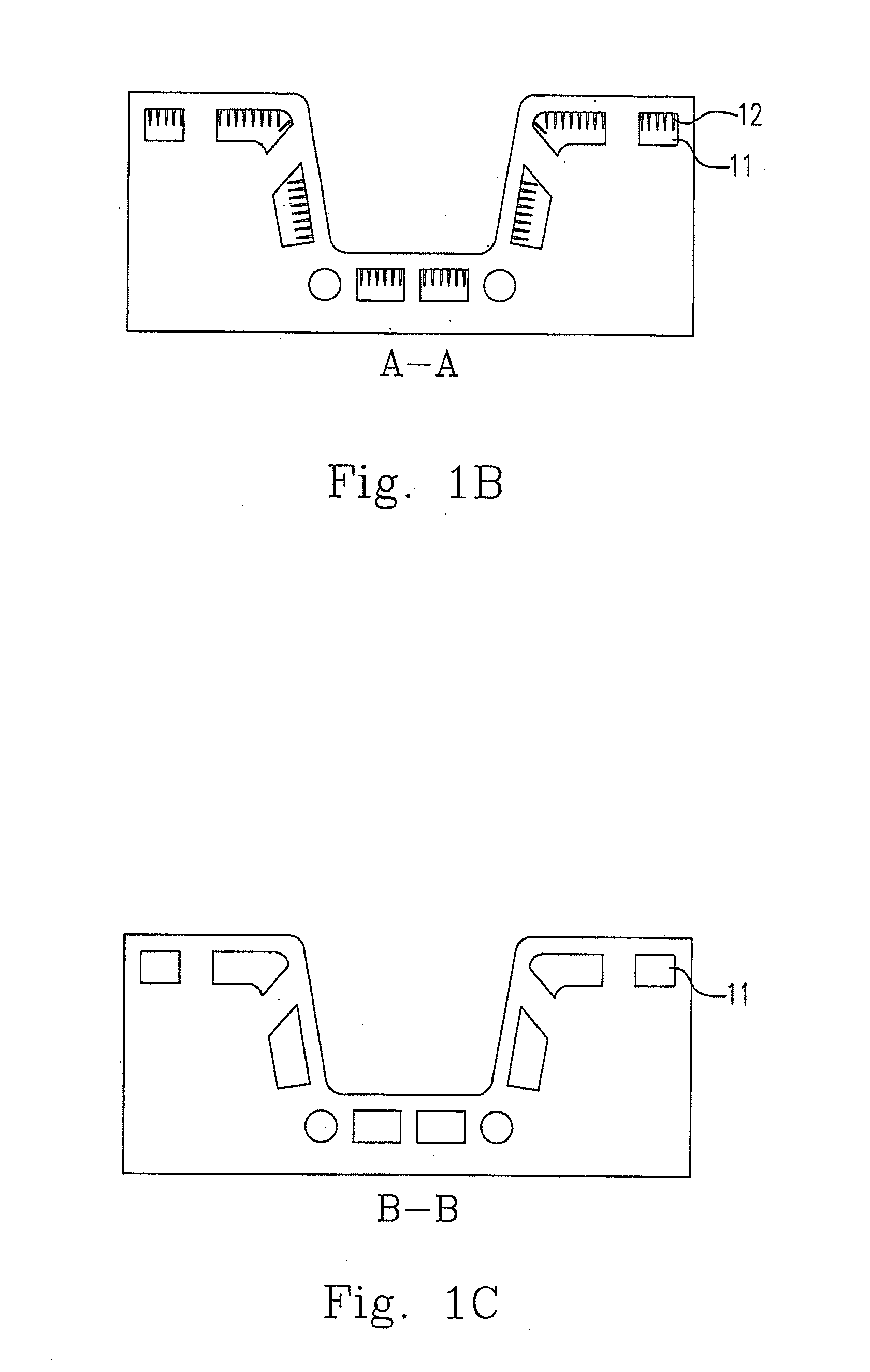

Mold and method for sectionally adjusting cooling efficiency of the mold

InactiveUS20130125603A1Adjusts the heat-dissipation rate or cooling efficiencyDifferent hardnessShaping toolsHeat exchange apparatusEngineeringCooling channel

The present invention provides a method for sectionally controlling a cooling efficiency of a mold. The method comprises steps of: (a) configuring at least a cooling passage including a first section having a first heat-dissipating inner surface area and a second section having a second heat-dissipating inner surface area in the mold; and (b) adjusting the first and the second heat-dissipating inner surface areas unequally by using a heat-dissipating element.

Owner:METAL INDS RES & DEV CENT

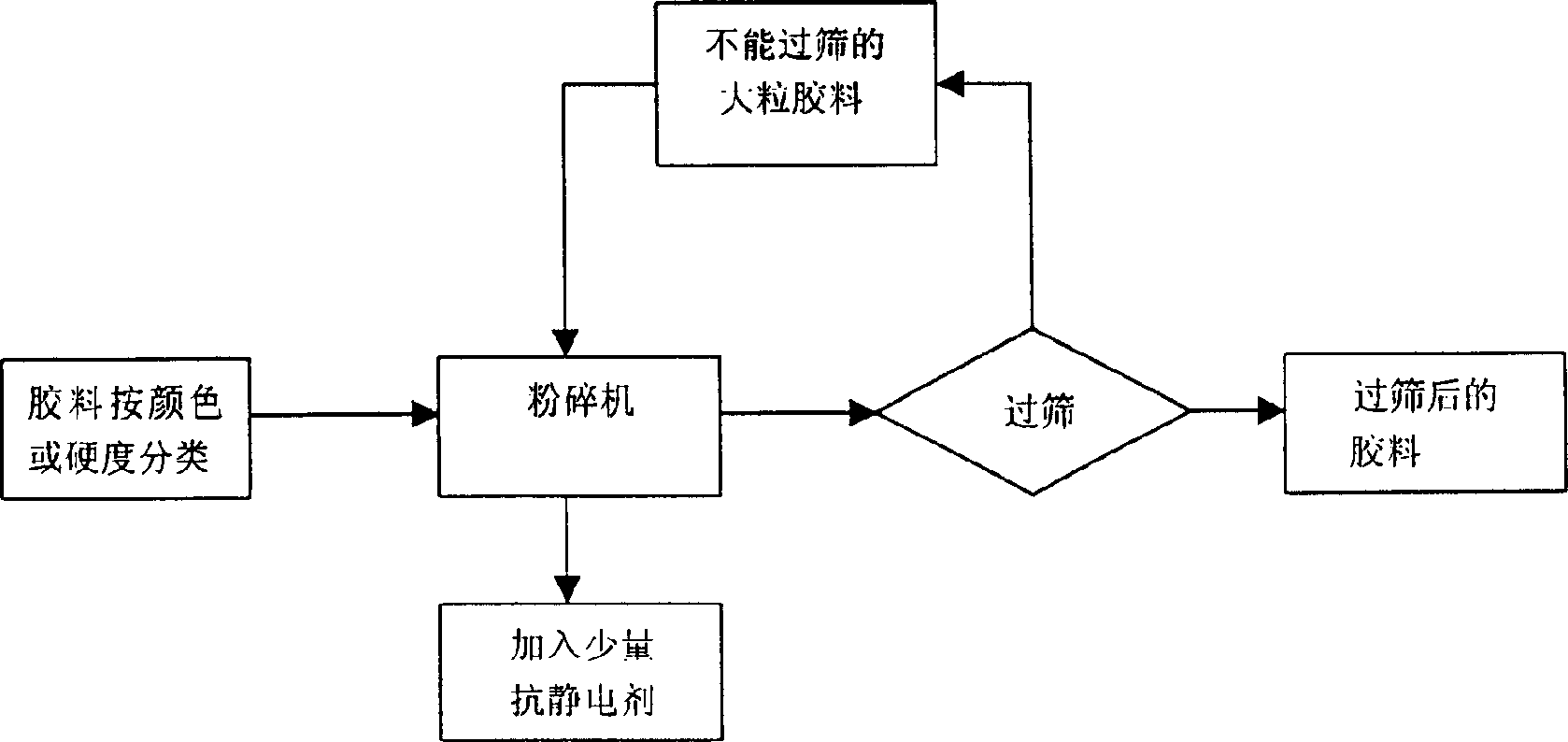

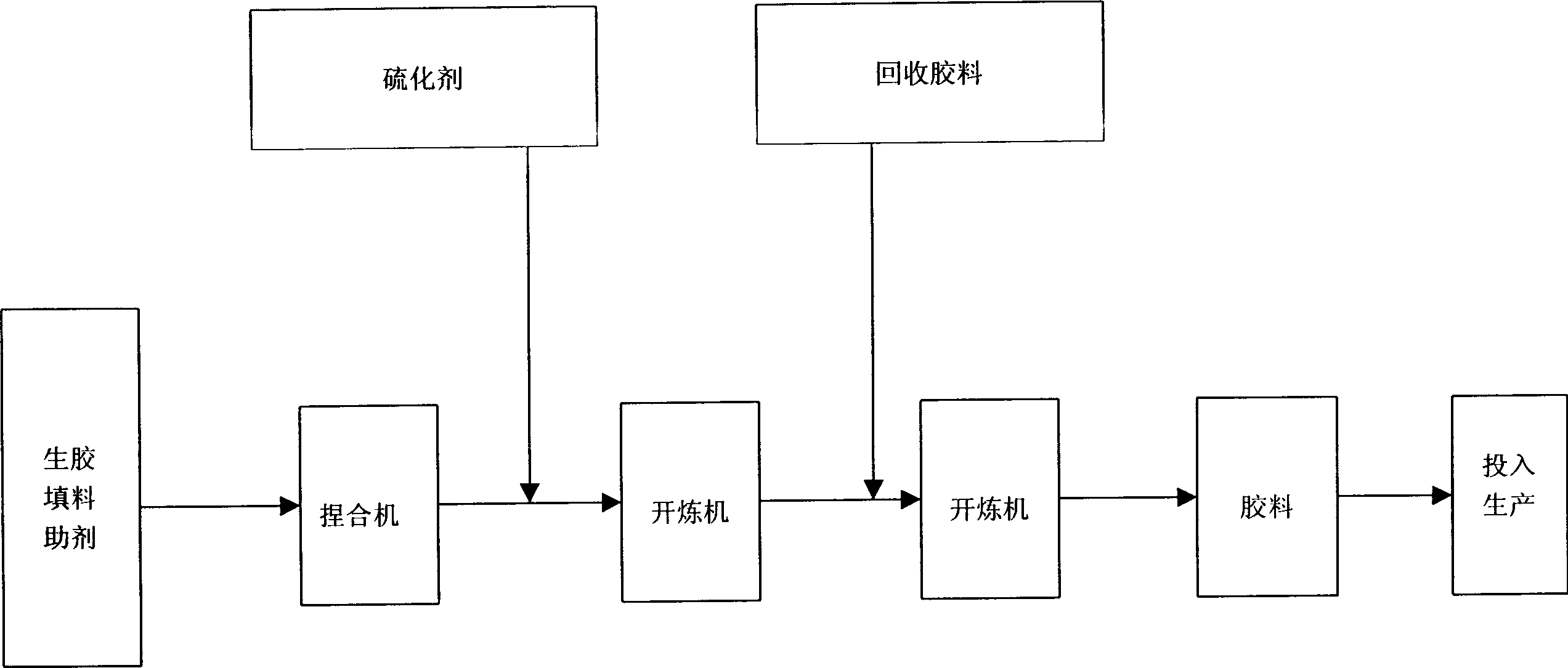

Recovery process and application of silicone rubber

The present invention is recovery process and application of silicone rubber and the recovered silicone rubber is reused as stuffing. The recovery process includes three steps: the crushing of waste silicone rubber, the pugging of waste silicone rubber, and throwing the recovered silicone rubber in the forming of silicone rubber product. The surface of the product with recovered silicone rubber particles has different elasticity, hardness and elongation, and thus special anti-sliding, anti-stick and other effects. The recovery process may be used in manufacturing bathing cap, carpet, foot padin automobile, swimming fins, etc.

Owner:FROXFIELD

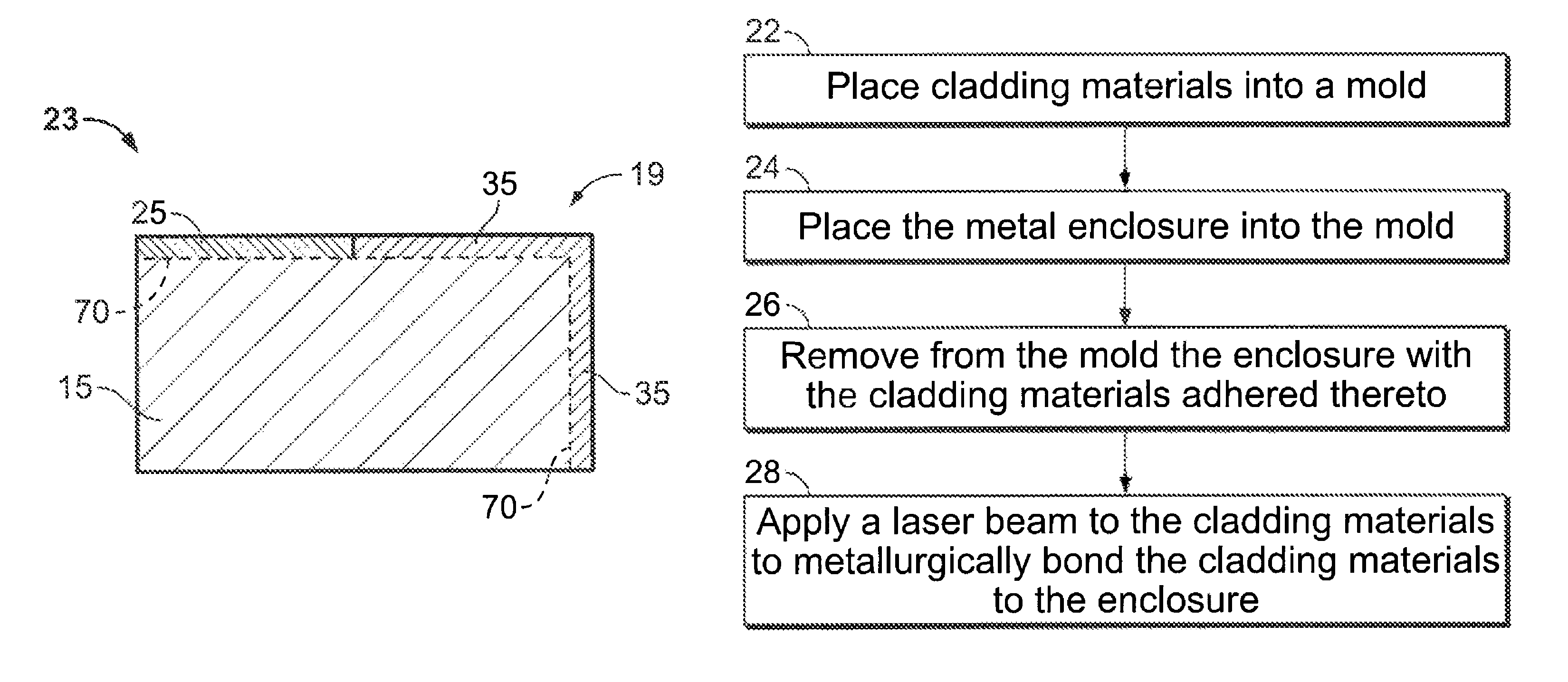

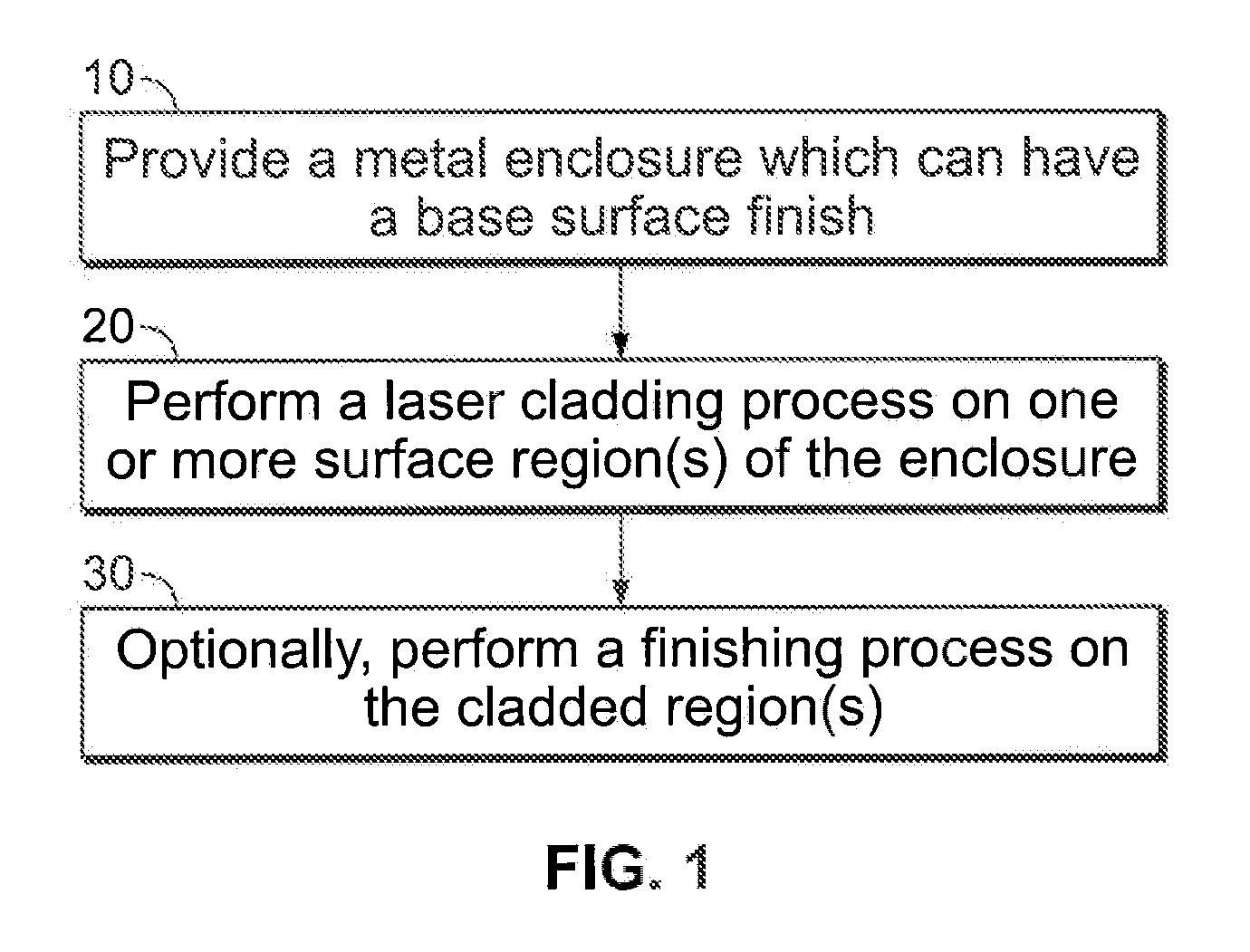

Laser cladding surface treatments

ActiveUS8733422B2Different propertyDifferent hardnessMetal rolling stand detailsMetal casingsOptoelectronicsCosmetic appearance

A metal enclosure has a surface region which is coated with cladding material using a laser cladding process. The metal enclosure can form at least a portion of an electronic device housing. All or part of one or more surfaces of the enclosure can be coated with cladding material. The coating of cladding material can be varied at selective regions of the enclosure to provide different structural properties at these regions. The coating of cladding material can be varied at selective regions to provide contrast in cosmetic appearance.

Owner:APPLE INC

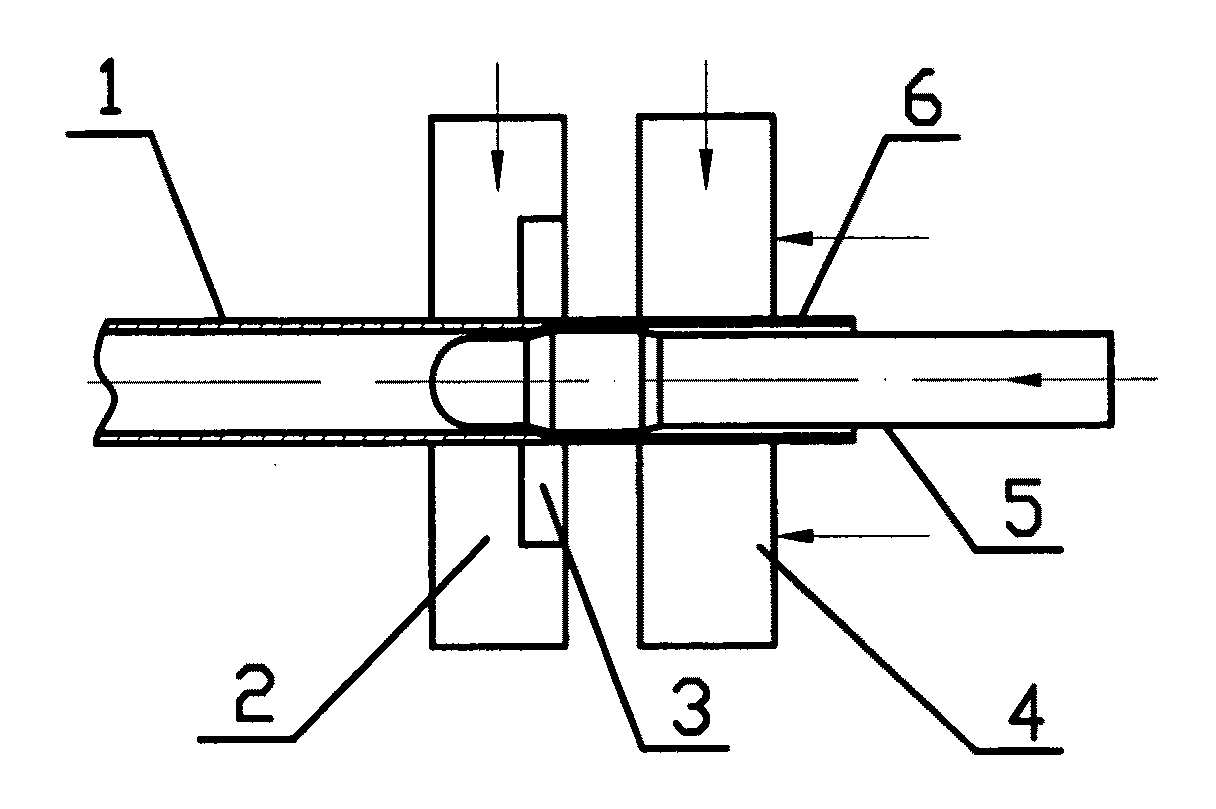

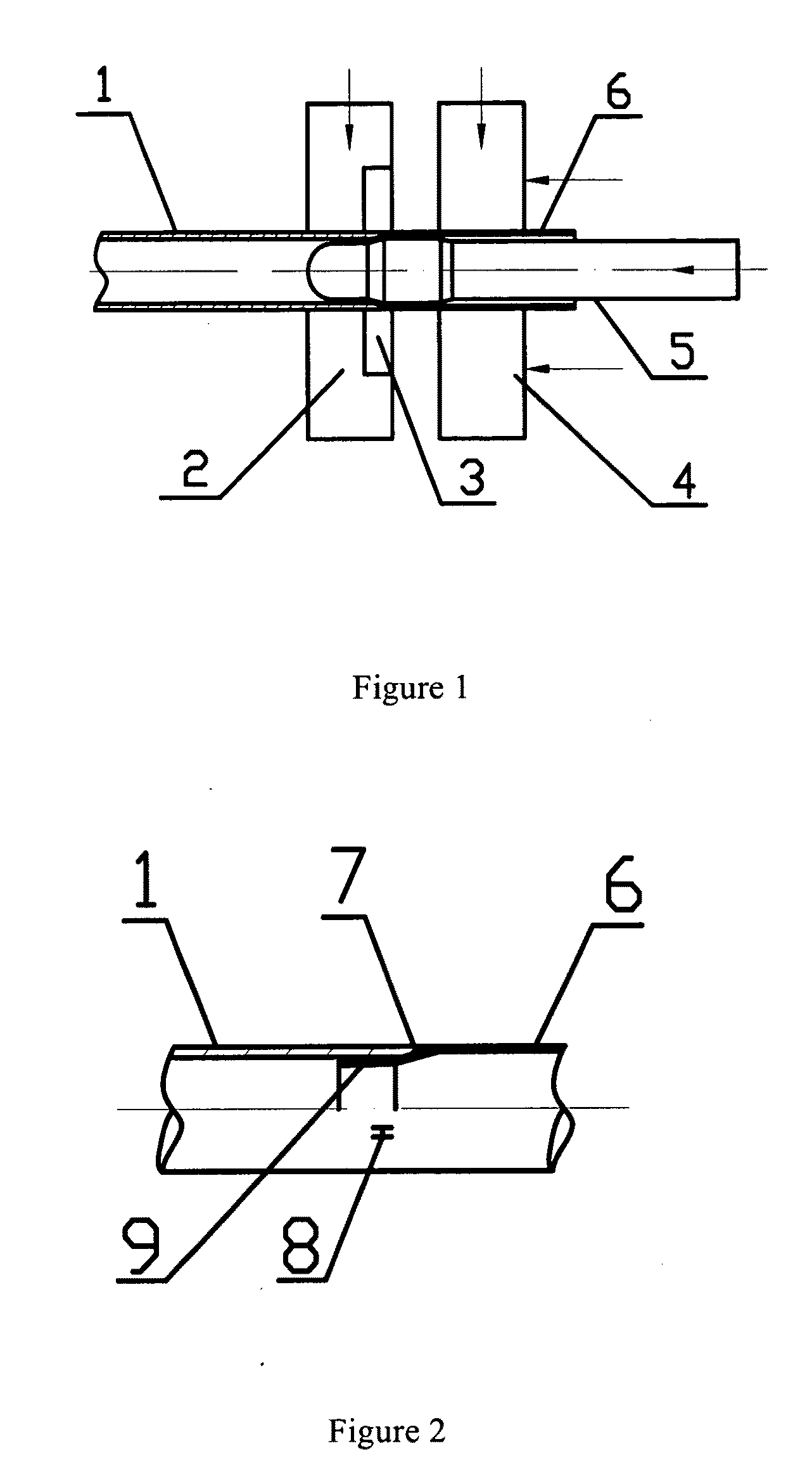

Non-eutectic structure weld joint of copper-aluminum thin wall pipe and its manufacturing method

InactiveUS20090212025A1Thick structureReduce contentPipe elementsRigid pipesElectrical resistance and conductanceUltimate tensile strength

This invention involves a non-eutectic structure welded joint of copper-aluminum thin wall pipe and its manufacturing method. This welded joint includes a chemical bond directly formed between the cone welding section of the copper pipe and the inner wall of the aluminum pipe, to form a columnar grain crystal with a toothed profile. The method includes providing a metal rod in a nosing end of copper pipe welded part, and installing a felder at the corresponding position of fixed electrode group. During welding, a pushing cylinder pushes the travelling electrode group with copper pipe to the aluminum pipe. At the same time a circuit is connected / powered, so the copper-aluminum combined zone is heated by electric resistance heating. The copper pipe moves to the interior of aluminum pipe continuously at the role of the pushing cylinder. The cooled metal rod is drawn out after power-down. The chemical bond directly forms in copper-aluminum joint. The weld does not have eutectic structure. The weld of copper-aluminum joint has characters of high strength and good sealability, thus this joint is appropriate for large-scale use in refrigerating industry.

Owner:ZUO TIEJUN +1

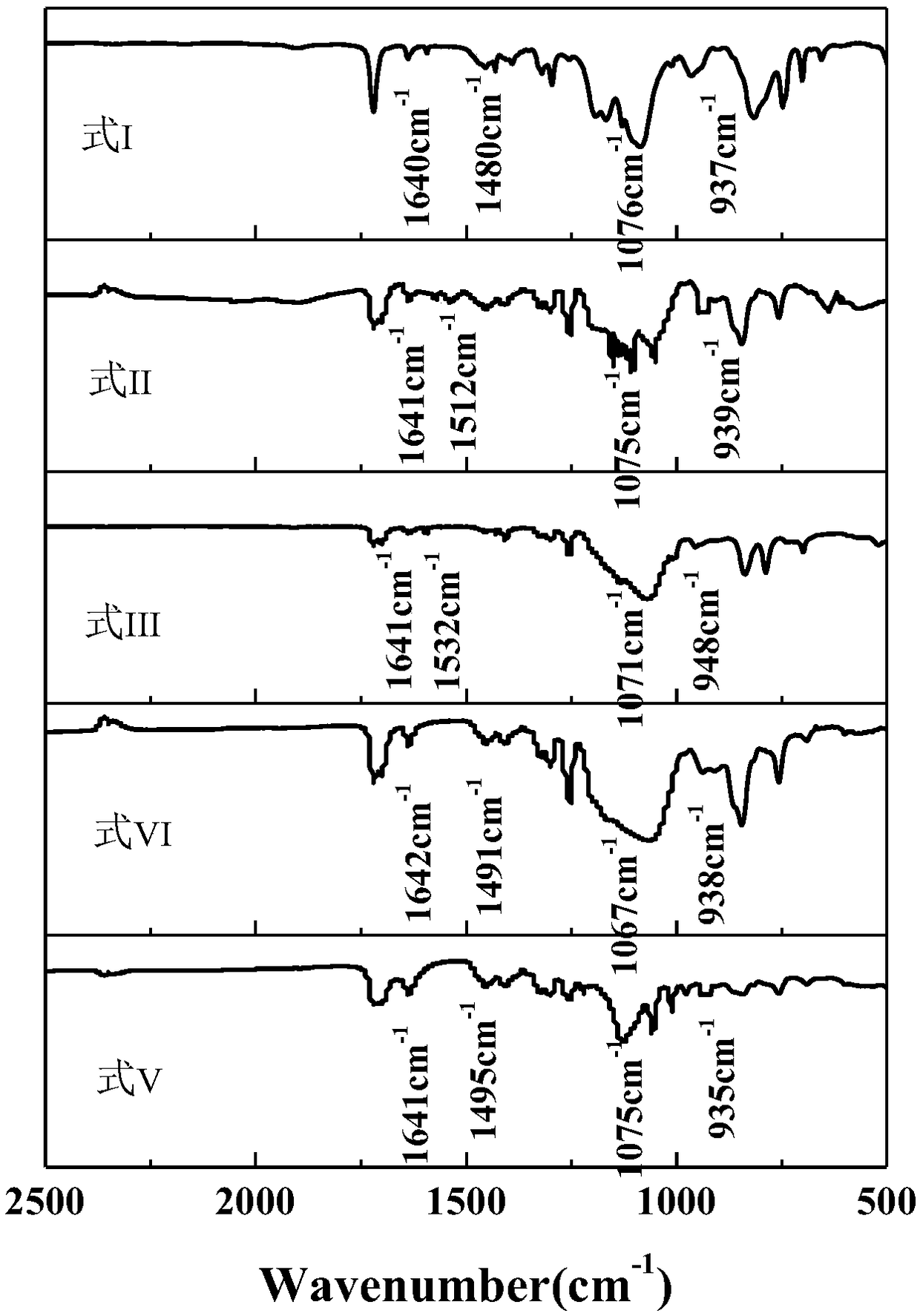

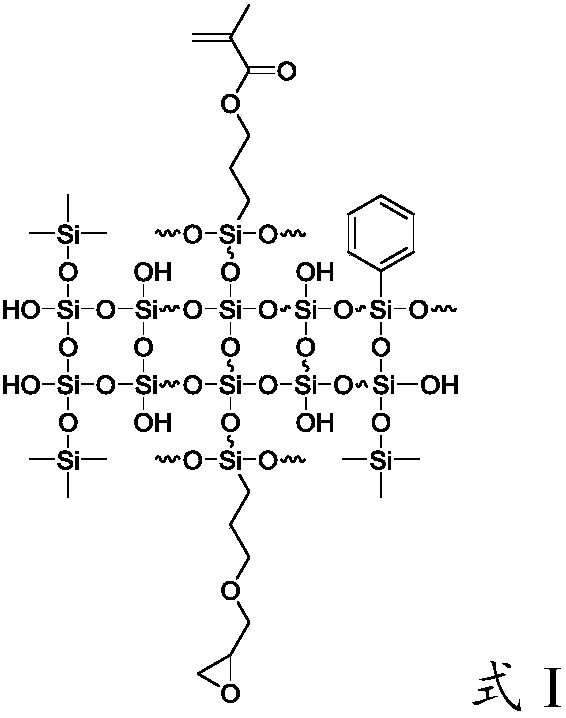

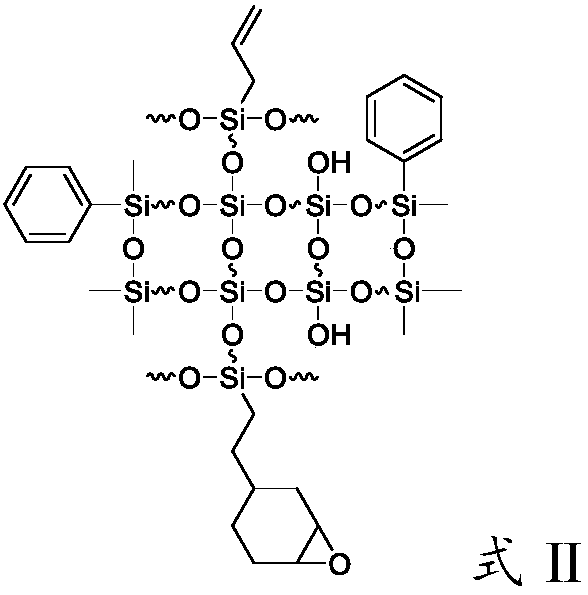

Light-cured organic silicon resin and preparation method thereof, photosensitive resin and application

The invention provides light-cured organic silicon resin. The light-cured organic silicon resin is prepared by performing cohydrolysis-polycondensation reaction on at least one of siloxane containingalkyl and siloxane containing aryl as well as siloxane containing epoxy group and siloxane containing unsaturated double bond under the action of a catalyst. Epoxy functional group and unsaturated double bond group in the light-cured organic silicon resin, serving as special functional groups, improve the curing property of organic silicon resin, improve the curing rate, reduce molding volume shrinking percentage and warping degree, and have important application in the fields of aviation, electronic engineering, light industry, mechanical engineering, chemical engineering and medicine.

Owner:GUANGDONG UNIV OF TECH

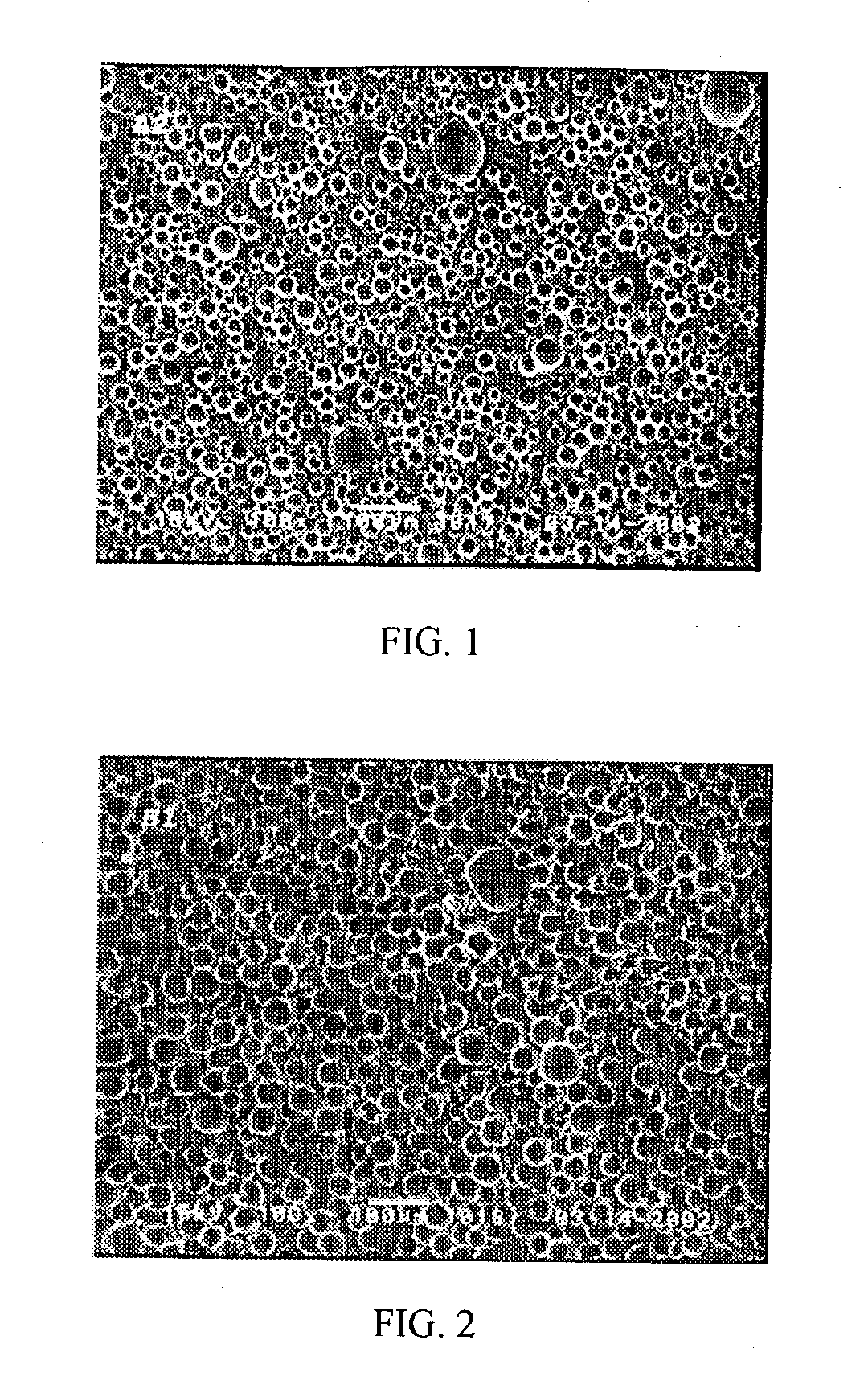

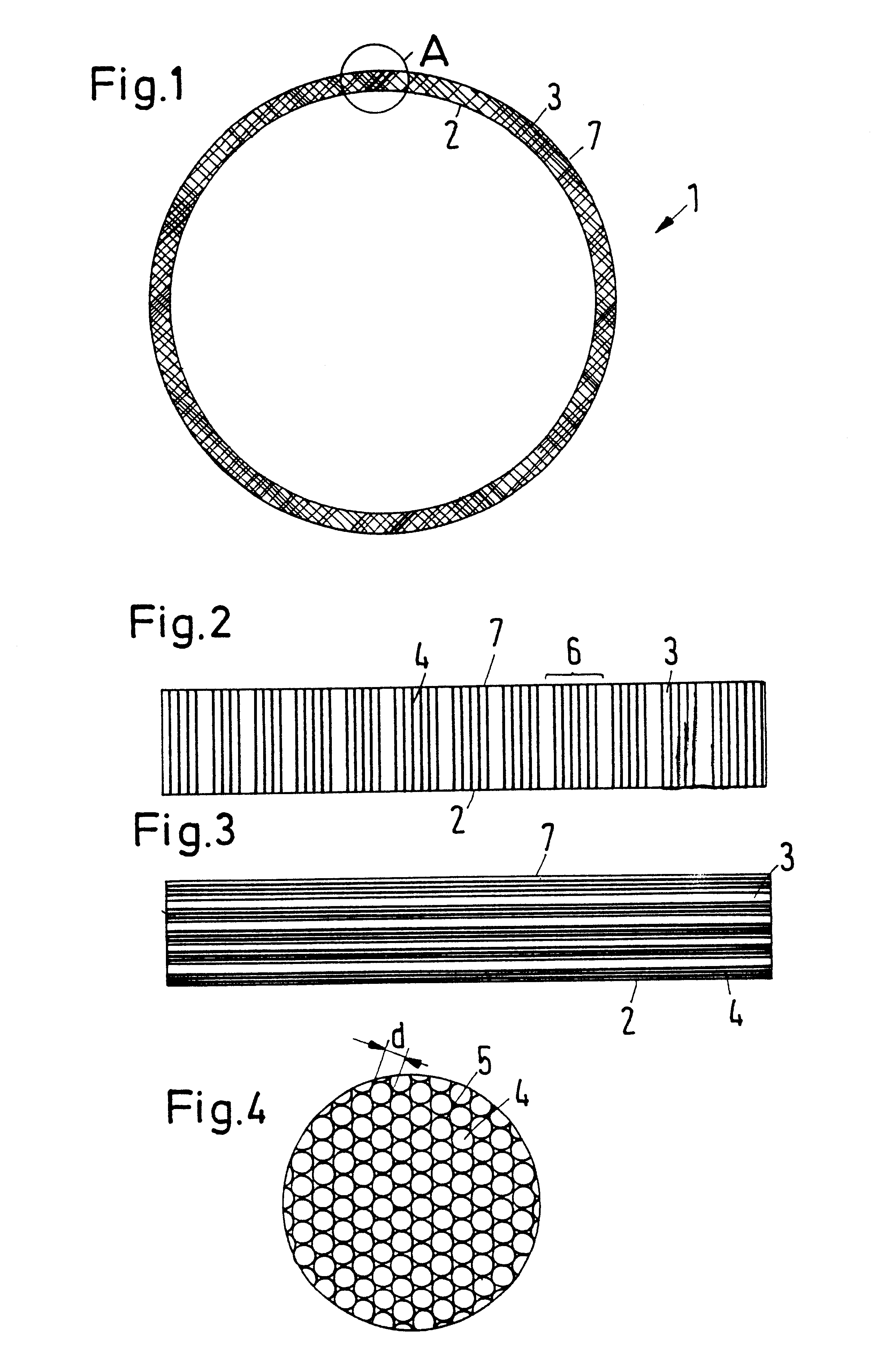

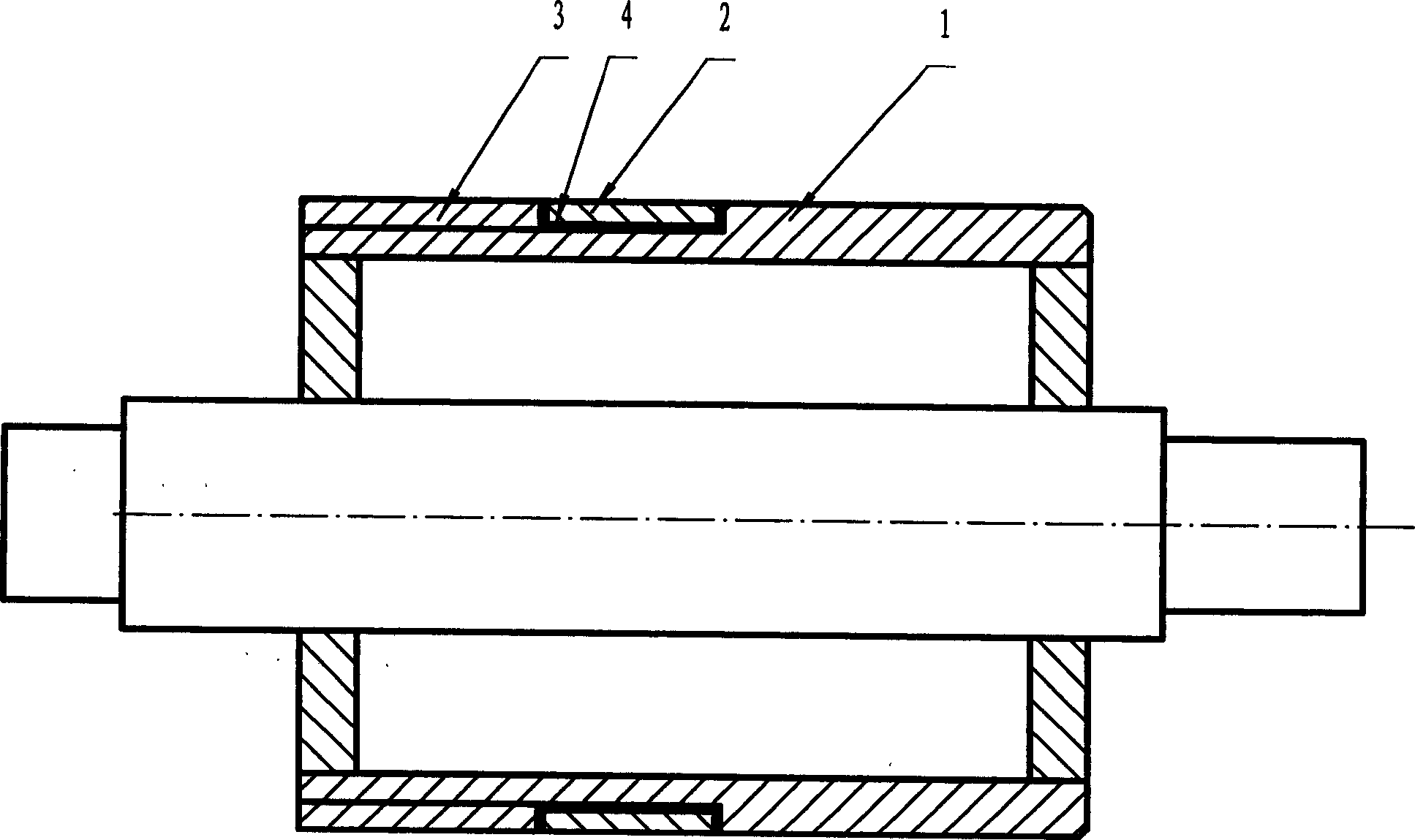

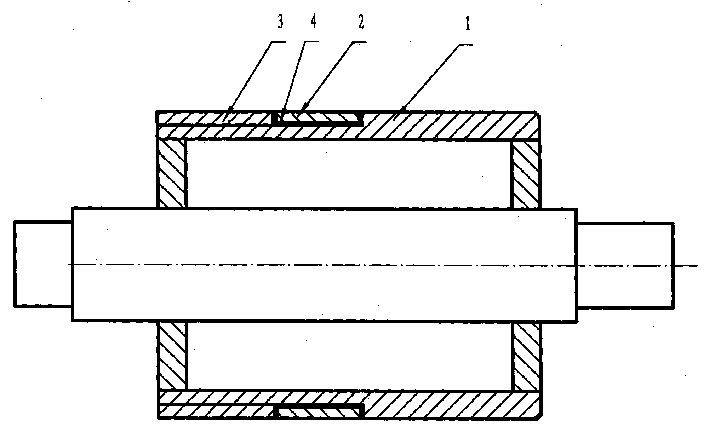

Process for glazing a material web and roller for a glazing calender

InactiveUS6253671B1Reduce transferHigh transparencyLiquid surface applicatorsMechanical working/deformationFiberHardness

Process and apparatus for glazing a material web so as to influence or control the transparency of a material web. The material web is guided through at least one nip which is formed by a roller having an elastic covering made, in particular of a plastic reinforced with fibers or appropriate fillers, and an opposing roller. In one embodiment, a primary orientation of the fibers in the covering is selected as a function of the desired glazing result. In another embodiment, the roller surface has uniform nonhomogeneous hardness distribution over a substantial portion of its rolling surface.

Owner:VOITH PATENT GMBH

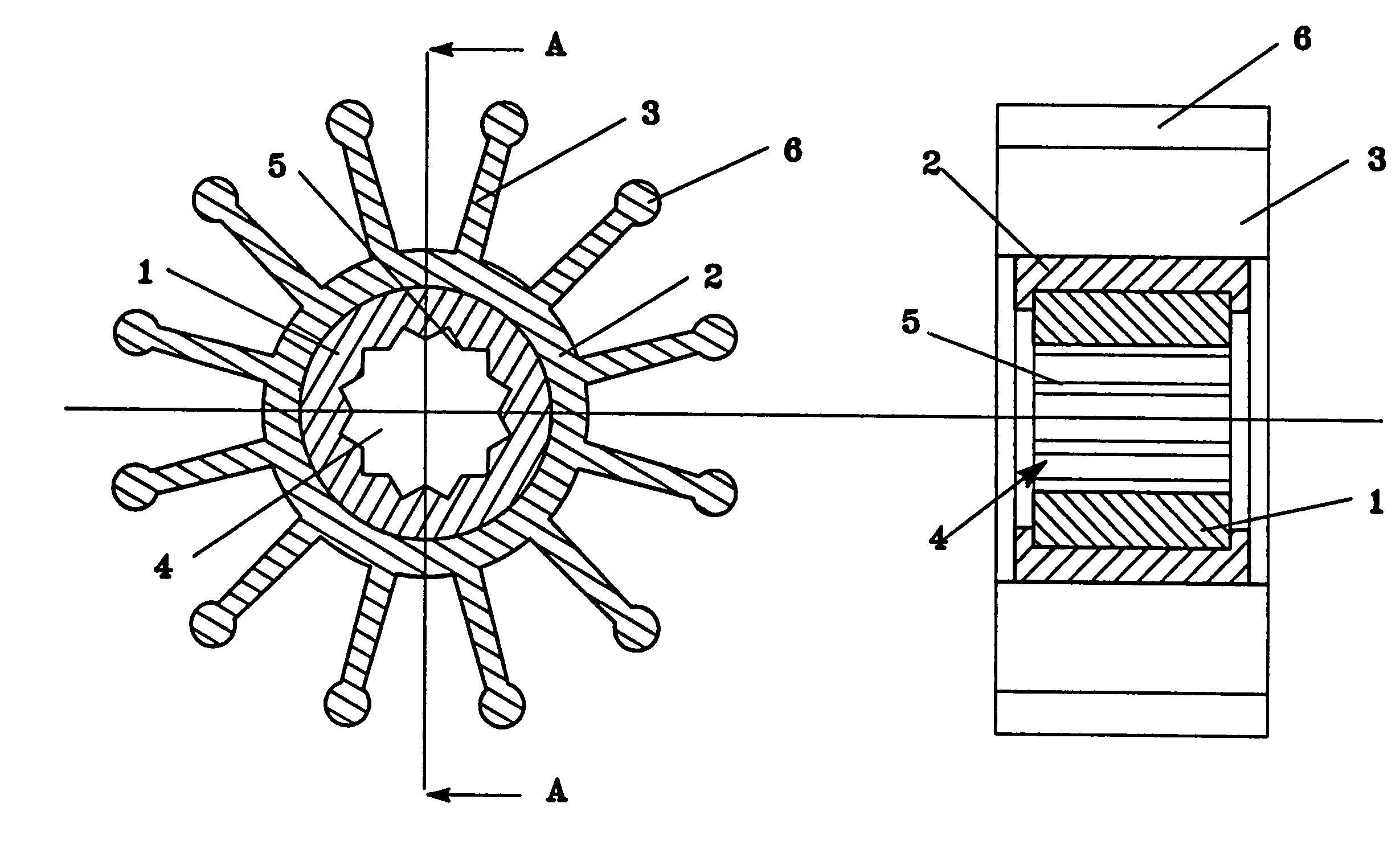

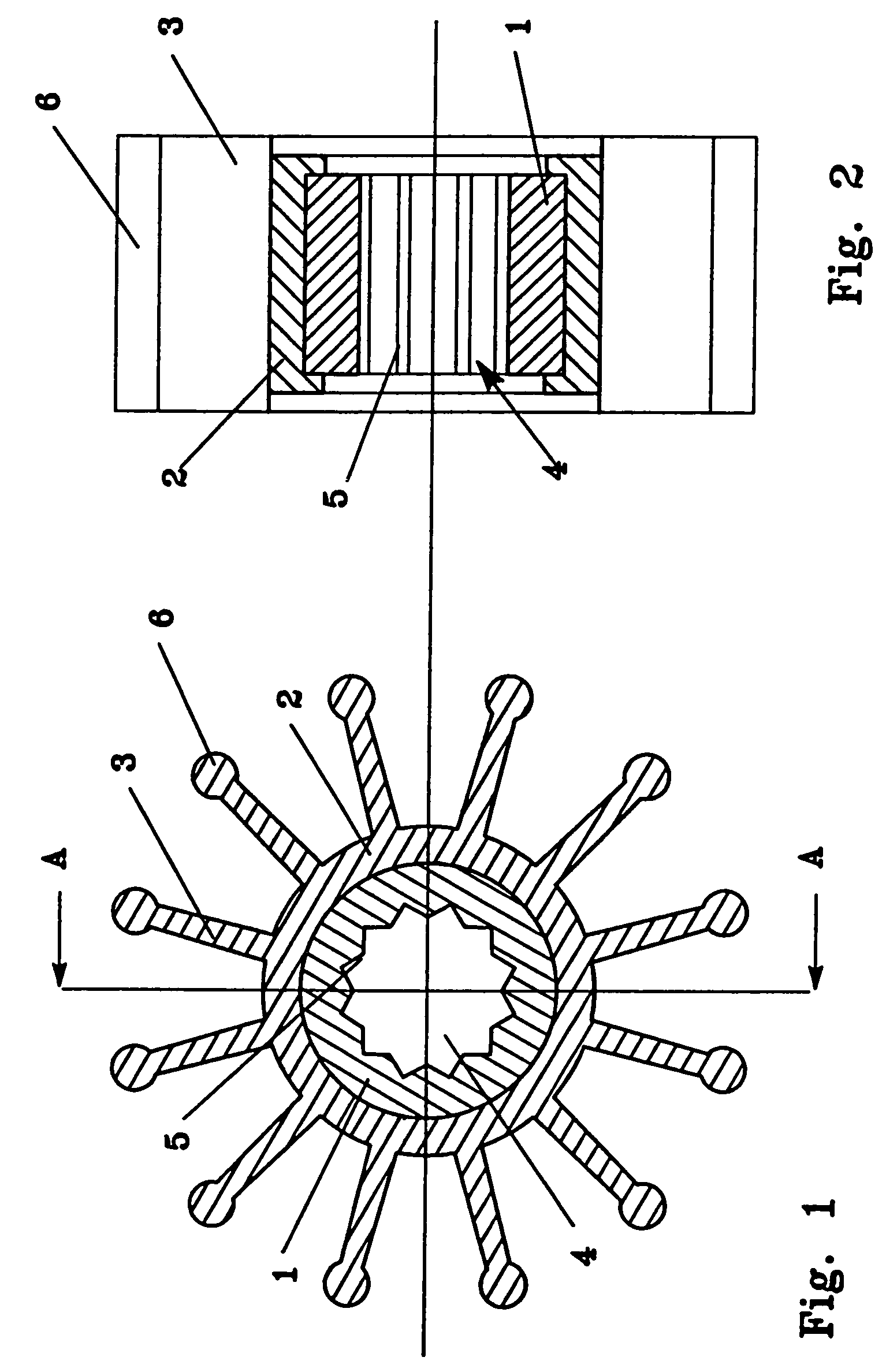

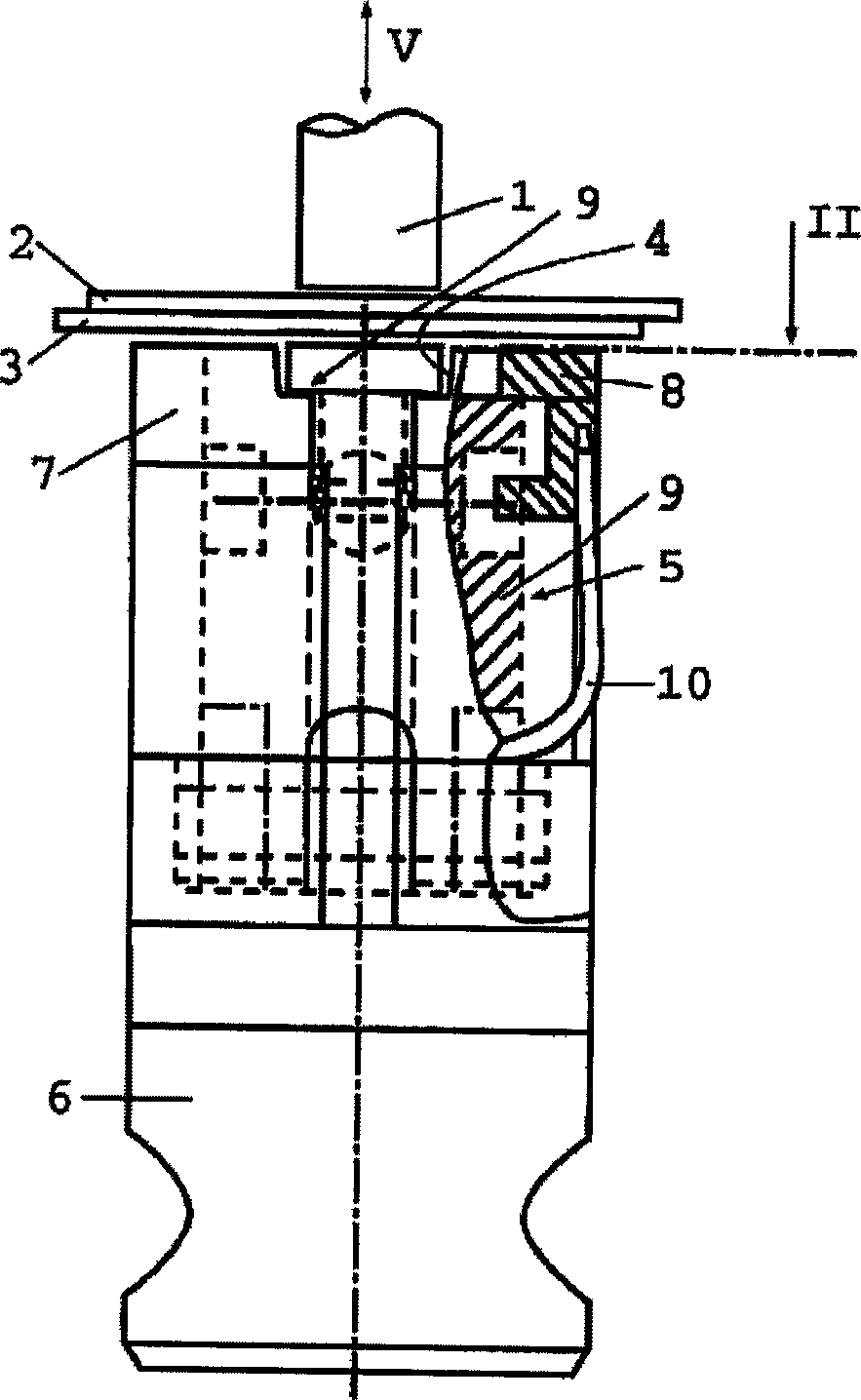

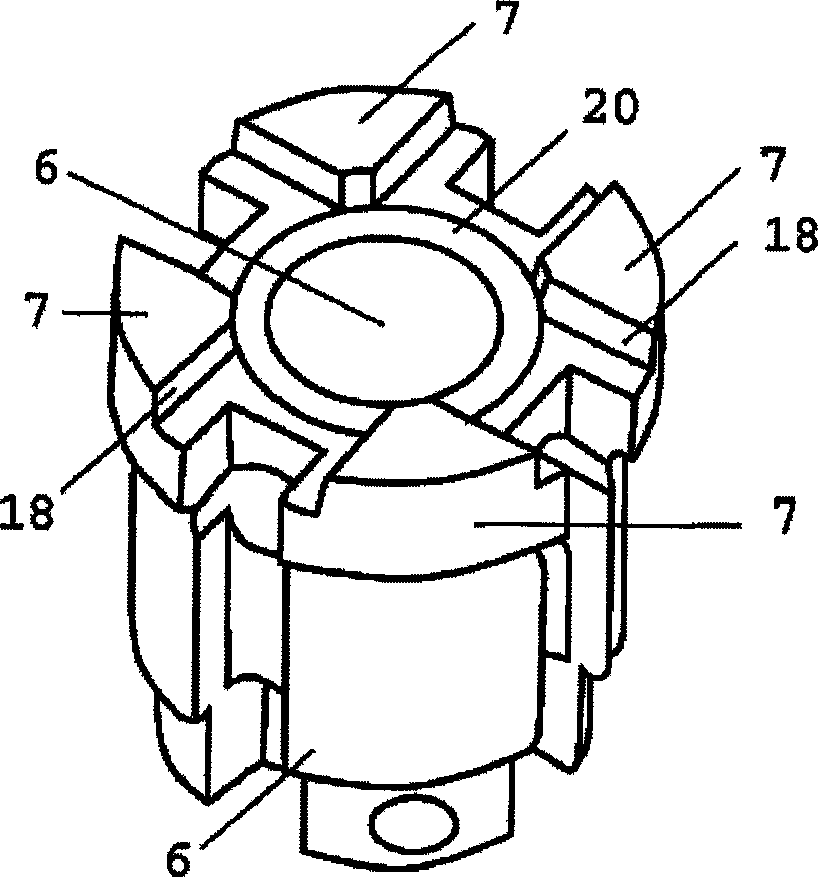

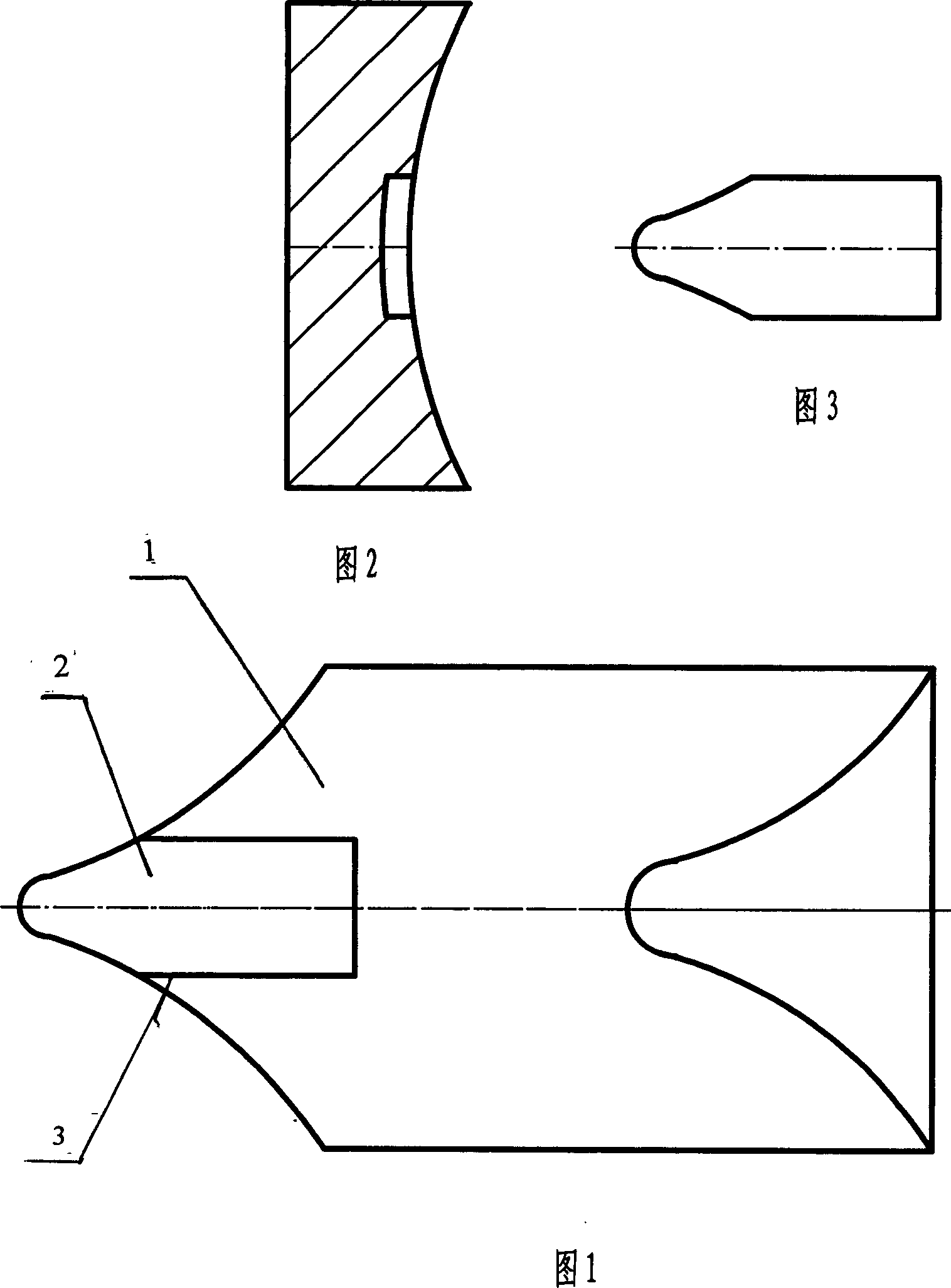

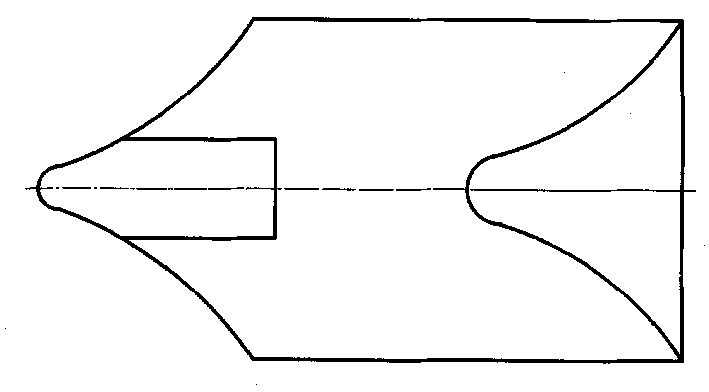

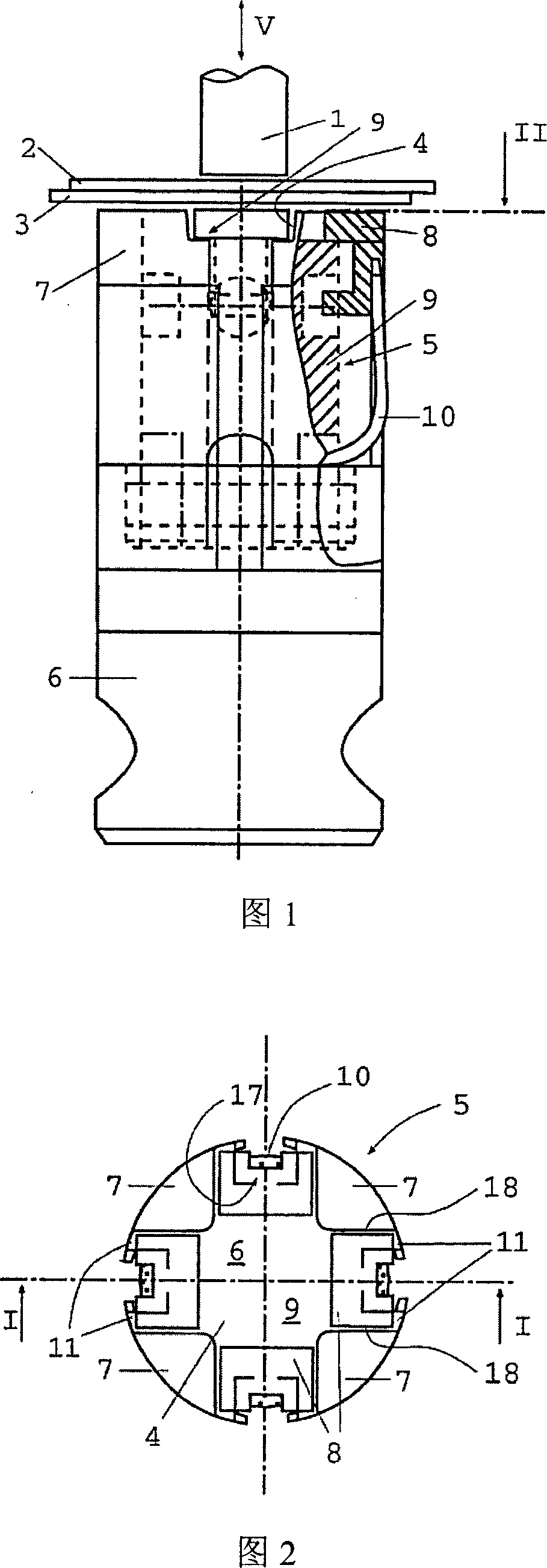

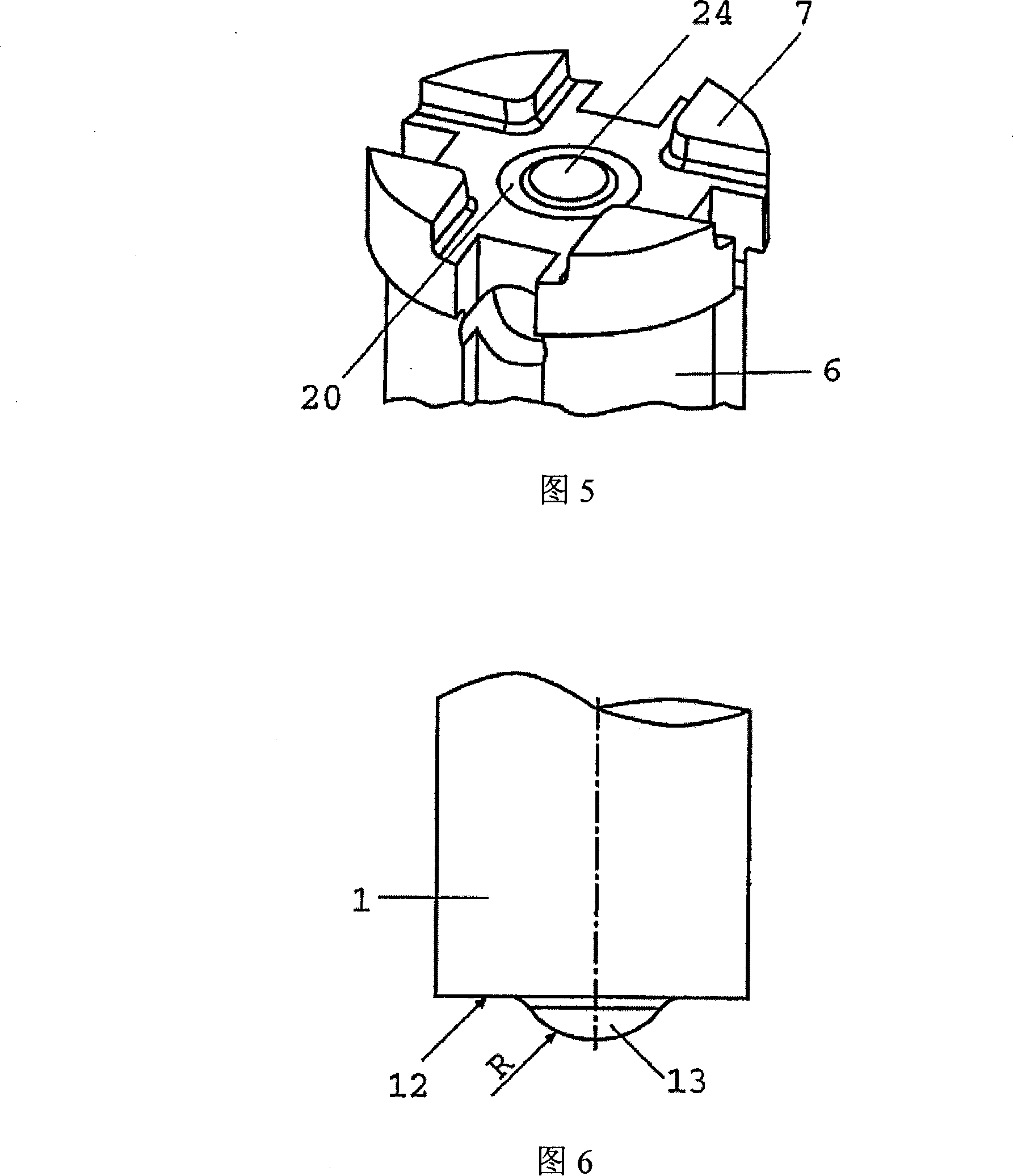

Rotor for cooling pumps, in particular for marine engines and relevant manufacturing process

A rotor for cooling pumps is provided. The rotor is of the type which includes a core to be assembled on a shaft connected with an engine and a body, fitted in the core, provided with a plurality of radial tabs in flexible material. The core and the body with the tabs are both of a material like rubber, but with different hardness. In particular the core is made of a mixture of neoprene, nitrile, PVC and aramidic fiber. The rotor combines the features of lightness and wearproof of the rotors with a nylon core, but it is as strong and resistant as rotors with a metallic core.

Owner:MFR GOMMA FINNORD

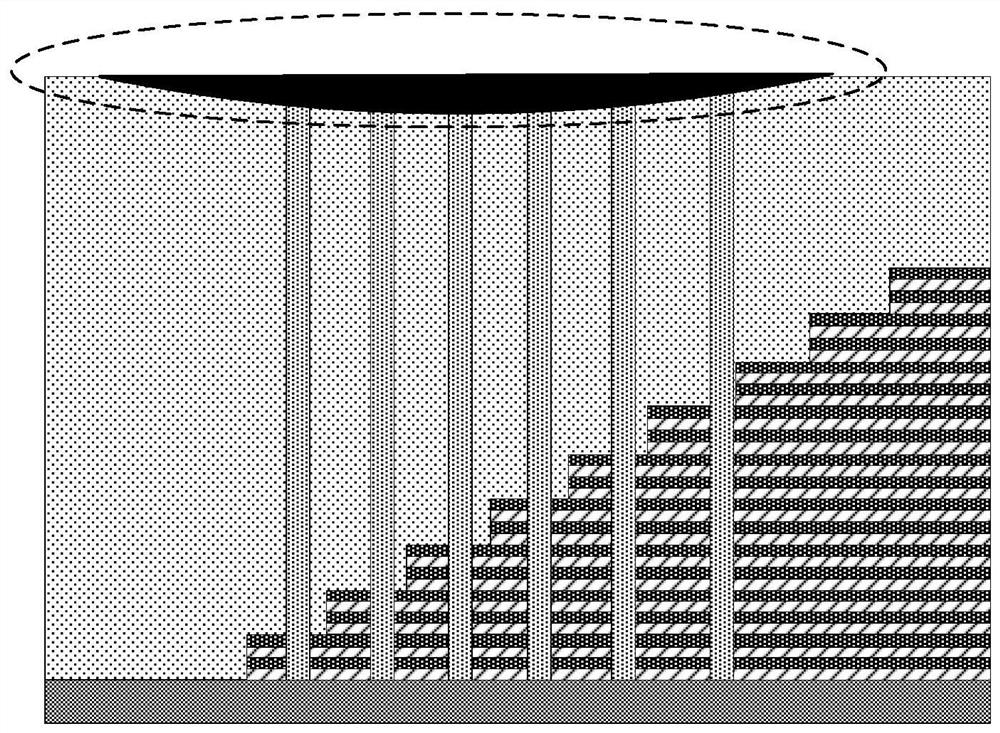

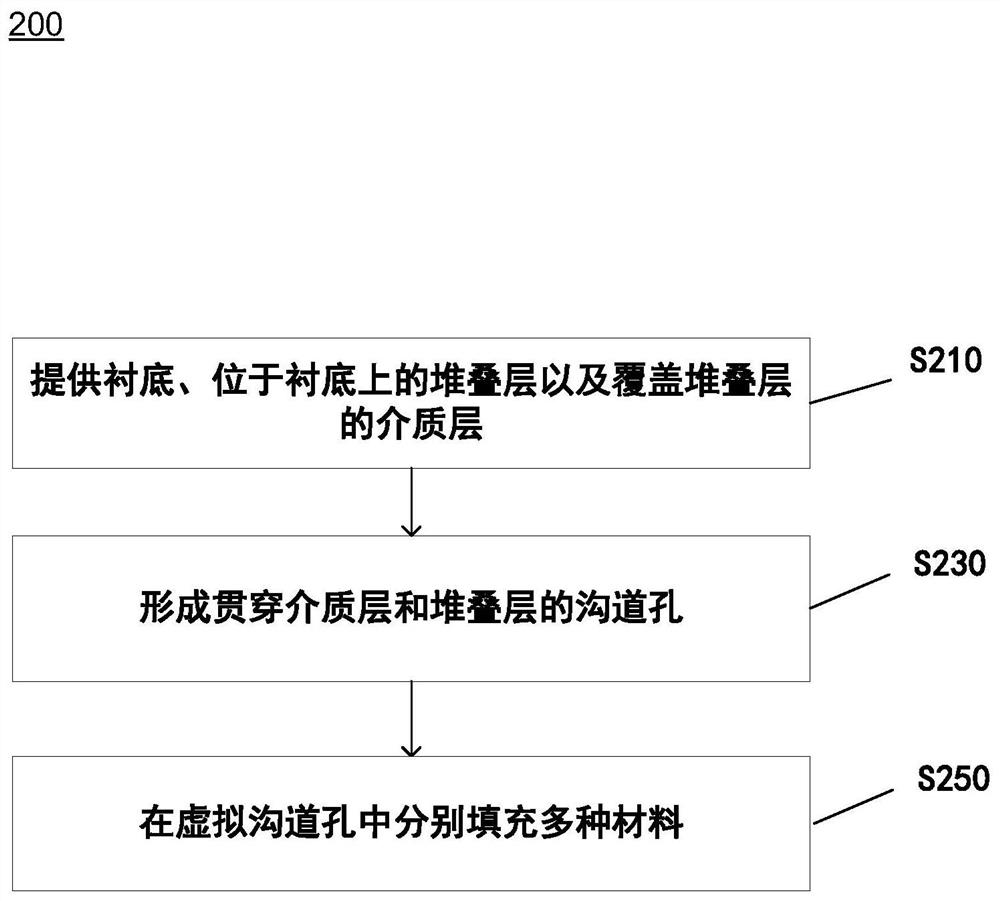

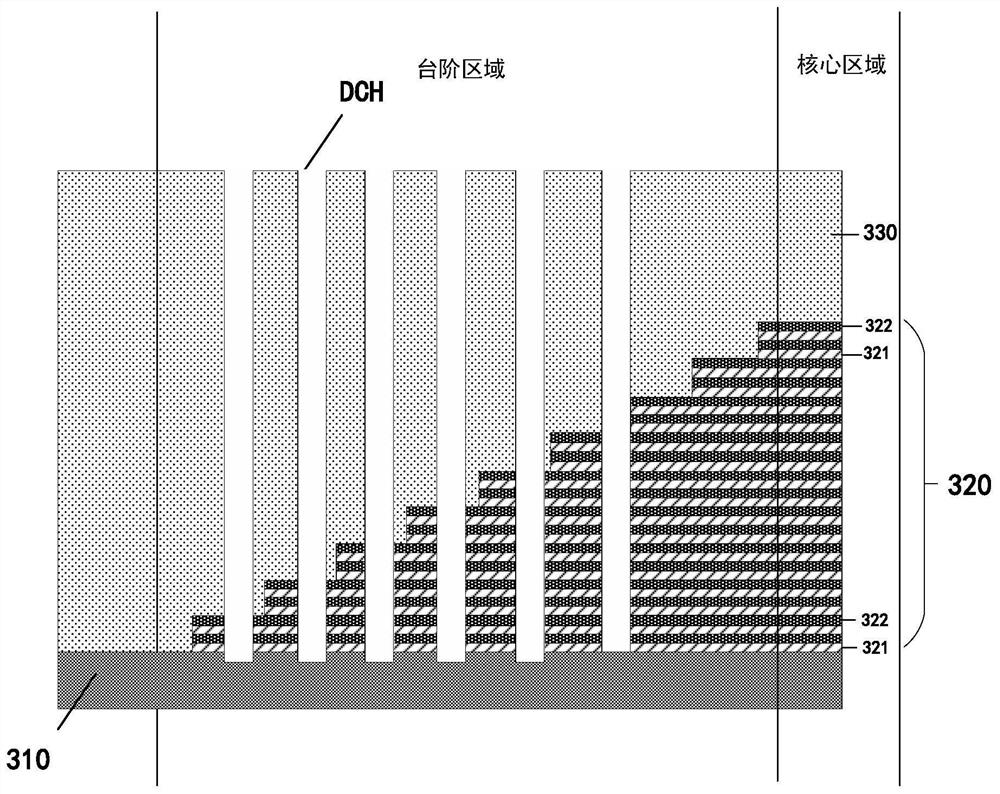

Method for forming channel hole of three-dimensional memory device, and three-dimensional memory device

PendingCN112018122AStable supportPrevent collapseSolid-state devicesSemiconductor devicesDielectric layerCondensed matter physics

The present invention relates to a method for forming a channel hole of a three-dimensional memory device. The method comprises the steps: providing a substrate, a stacking layer located on the substrate and a dielectric layer covering the stacking layer, wherein the stacking layer comprises a plurality of insulating layers and a plurality of dummy gate layers which are stacked alternately; forming virtual channel holes penetrating through the dielectric layer and the stacking layer, wherein the virtual channel hole reaches the substrate; and respectively filling the virtual channel holes witha plurality of materials, wherein the plurality of materials have different hardness.

Owner:YANGTZE MEMORY TECH CO LTD

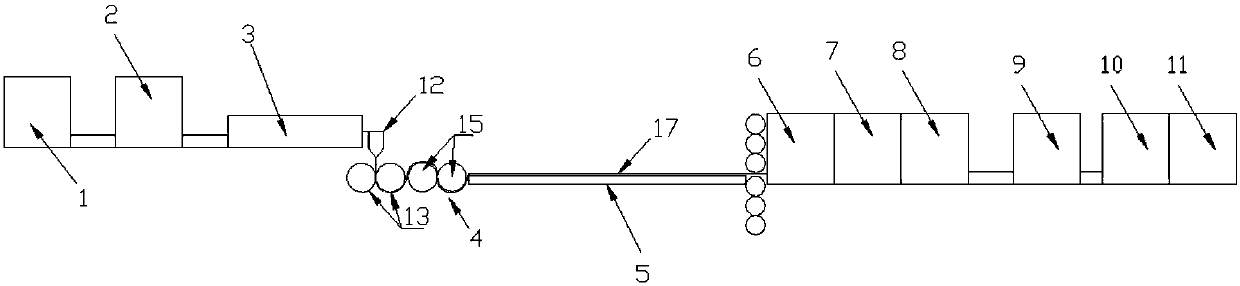

Preparing system and method of PMMA light-guide-stage transparent membranes

PendingCN107813512ALess interferenceReduce the impactOptical articlesCleaning using toolsLight guideMembrane surface

The invention discloses a preparing system of PMMA light-guide-stage transparent membranes. The preparing system comprises a washing device, a drying device, an extruding device, a polishing device, aconveying device, a relay type membrane surface dust removal device, a film pasting device, a first cutting device, a traction device, an edge cutting device, a second cutting device and a piece loading device which are sequentially arranged and further comprises negative-pressure chip sucking devices arranged on the discharging sides of the first cutting device, the edge cutting device and the second cutting device correspondingly. Squeezing rollers below a mouth die of the extruding device are a pair of flexible rollers. The relay type membrane surface dust removal device comprises an upperdust removal roller set and a lower dust removal roller set which are arranged on the two faces of the membranes. The negative-pressure chip sucking devices each comprise a plurality of negative-pressure chip sucking parts arranged on one face or two faces of a to-be-cut product. Ultra-thin and ultra-wide PMMA membranes can be produced, inner stress of prepared products is evenly distributed, andthus the products are not prone to being cracked. Meanwhile, the very small thickness tolerance (smaller than 1.5%) and extremely perfect optical quality can be obtained, and the defect that powderedscraps press the appearances of the products to be damaged is effectively overcome.

Owner:JIANGSU HANYANG NEW MATERIAL TECH

Large-scale PTA drying machine sealing surface abrasion on-site precise pulse surfacing welding repair process

ActiveCN103286459ASmall heat affected zoneHigh bonding strengthWelding apparatusGranularityEngineering

The invention belongs to the large-scale chemical equipment sealing surface on-site in-situ repair technology, and particularly relates to a large-scale PTA drying machine sealing surface abrasion on-site precise pulse surfacing welding repair process which comprises the steps that (1) an abrasion portion is cleared before surfacing welding; (2) precise pulse microscope surfacing welding is carried out: nickel / cobalt-base alloys with higher abrasion resistance to a base body and excellent weldability are chosen to serve as surfacing welding materials on the abrasion portion, and a precise pulse microscope surfacing welding machine is adopted to carry out surfacing welding on the abrasion portion; (3) a surfacing welding layer is preprocessed: a power-driven or pneumatic polishing tool is adopted to carry out preprocessing on the surfacing welding layer; (4) finish machining is carried out: oilstone and multi-granularity abrasive paper is adopted to carry out final finish machining on a repair surface to meet requirements for sealing surface dimension and precision. According to the large-scale PTA drying machine sealing surface abrasion on-site precise pulse surfacing welding repair process, the on-site in-situ surfacing welding repairing is carried out on the sealing surface of a large-scale device, and the base body is kept to be in a low temperature basically in a surfacing welding process and does not deform; the surfacing welding layer and the base body are in metallurgical bonding, strength is high, the surfacing welding materials are higher in abrasion resistance than the base body, surfacing welding efficiency is high, and cost is low.

Owner:浙江翰德圣智能再制造技术有限公司

Laser Cladding Surface Treatments

ActiveUS20130248219A1Different propertyDifferent corrosion resistanceMetal rolling stand detailsMetal casingsOptoelectronicsCosmetic appearance

A metal enclosure has a surface region which is coated with cladding material using a laser cladding process. The metal enclosure can form at least a portion of an electronic device housing. All or part of one or more surfaces of the enclosure can be coated with cladding material. The coating of cladding material can be varied at selective regions of the enclosure to provide different structural properties at these regions. The coating of cladding material can be varied at selective regions to provide contrast in cosmetic appearance.

Owner:APPLE INC

Steel billet feeding cylinder and the method of making and repairing it

InactiveCN1481945ADifferent hardnessImprove red hardnessMetal rolling arrangementsHardnessSteel casting

The present invention is the manufacture and repair of roller for conveying steel billet. The roller consists of basal body of cast steel or cast iron and roller ring, which is made of WC is braze welded onto the basal body and has hole. The manufacture and repair process includes machining the basal body, cleaning, and braze welding the WC roller ring to the basal body. Owing to the high hardness, especially the high red hardness of the roller ring, the roller has long service life, 10-15 times that of cast steel and cast iron ones. The roller is suitable for use in conveying steel billet in rolling mill and steel plant.

Owner:王树敏

Laser cladding repairing method for end tooth wear or cracks of general high speed pump gear shafts

ActiveCN107419262AThorough repairSimple processMetallic material coating processesGear pumpWear resistant

The invention belongs to the field of repairing of high speed pump shafts for petrochemical industry and relates to a laser cladding repairing method for end tooth wear or cracks of general high speed pump gear shafts. The method aims at repairing of parts with wear and cracks on end teeth in long-time running process and comprises the steps of firstly removing damaged end teeth and remanufacturing new end teeth, carrying out hot charging by utilizing the part size change caused by temperature difference, selecting stainless steel powder and wear-resistant Co-based alloy powder which have mechanical properties similar to those of a base material, carrying out cladding by adopting laser cladding process parameters, removing residual stress in cladded parts through a hammering method, finally recovering the parts to a design size through a precise mechanical processing method, thereby recovering the operational performance of the high speed pump gear shafts. The method disclosed by the invention has the advantages that in the laser cladding repairing process of the high speed gear pump shafts, the base material is maintained at a low temperature all the time during cladding and the part deformation rate is almost zero; and the obtained cladding layer is metallurgically combined with a matrix, the automatic efficiency is high and the cost is low.

Owner:浙江翰德圣智能再制造技术有限公司

Clinching method and tool therefor

Owner:TOX PRESSOTECHNIK GMBH & CO KG

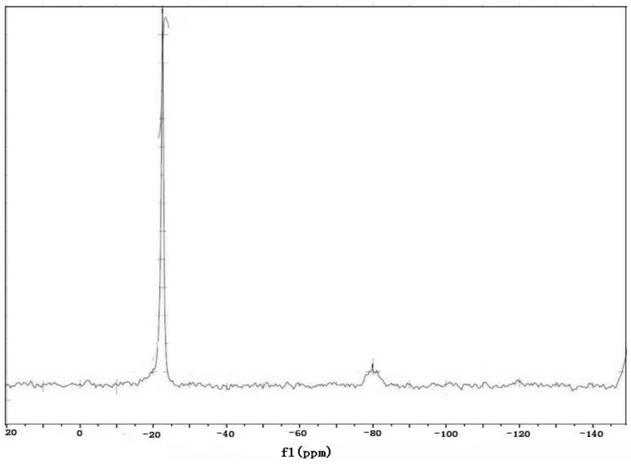

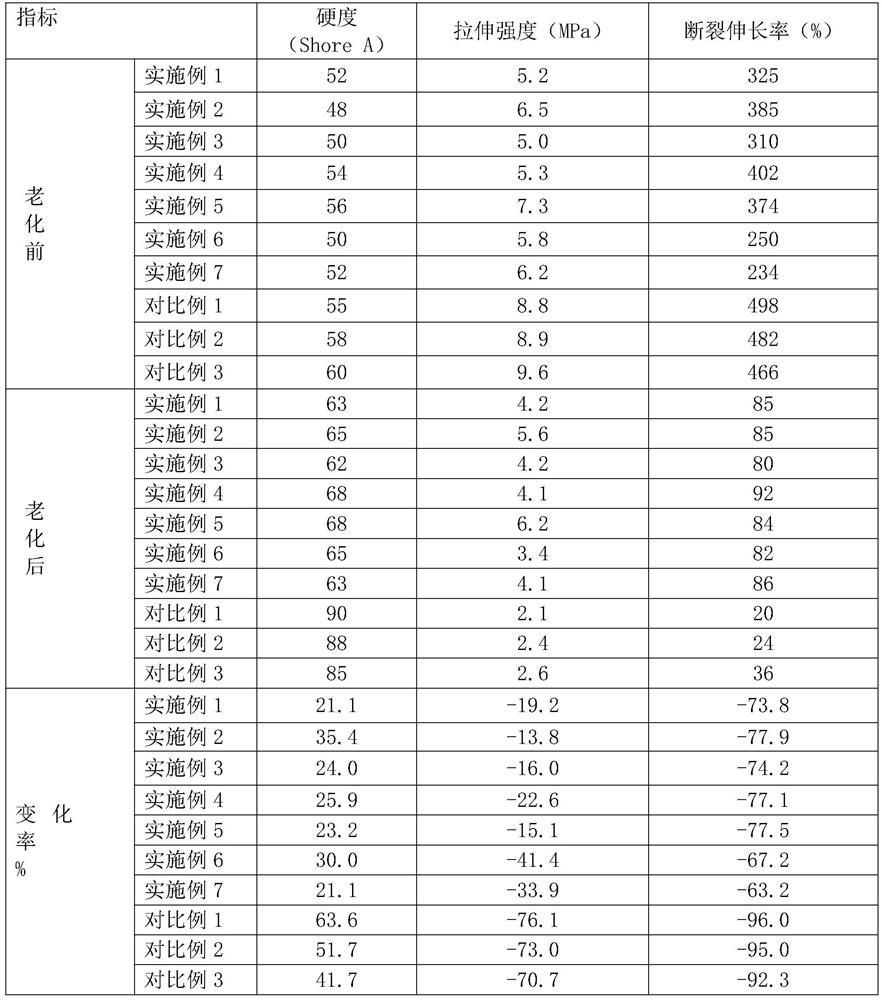

High-heat-resistance copolymerized silicon resin and preparation method thereof

The invention relates to a high-heat-resistance copolymerized silicon resin and a preparation method thereof. The preparation method comprises the following steps: catalyzing hydroxyl-terminated linear polysiloxane and organic trichlorosilane to be precondensed by using a weak base compound in an organic solvent medium, then carrying out cohydrolytic condensation under the action of a strong base to obtain a copolymer, and carrying out high-temperature curing on the copolymer to obtain a product with the structural formula of (R1R2ViSiO0.5)a(R1R2SiO)b(R3SiO1.5)c, wherein a+b+c=1, a:c=(3-20):1, b:c=(1-6):1, R1, R2 and R3 are the same or different and are selected from one or more of Me, Ph and Vi, and the number-average molecular weight is 5*10<4>-10<6>. The copolymerized silicon resin not only can keep good physical and mechanical properties, but also has high heat resistance, can be used for a long time at 300 DEG C, and still keeps high strength and high elasticity after being subjected to thermo-oxidative aging for 72 hours in an environment at 350 DEG C.

Owner:NEW MATERIAL INST OF SHANDONG ACADEMY OF SCI

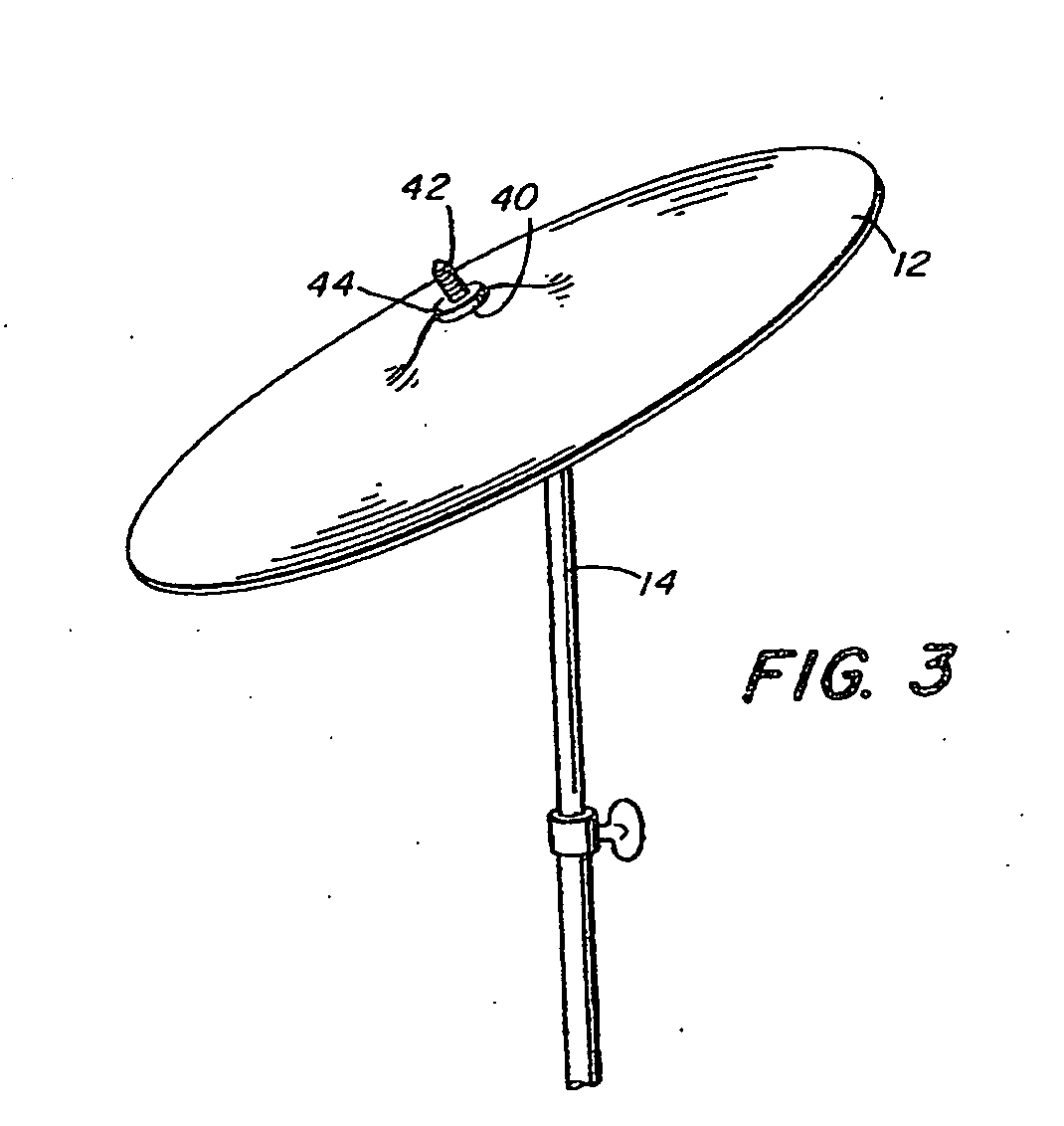

Drum tuning key

InactiveUS7371955B2Different hardnessEasy to assemblePercussion musical instrumentsMusic aidsEngineeringMechanical engineering

A drum tuning key comprises a handle portion, a barrel portion defining an axis connected to the handle portion, the barrel portion having internal walls defining a cavity extending inwardly along the axis from an end of the barrel portion, the cavity being square in cross section and adapted to turn a drum tension rod. The tuning key further comprises an indicator member removably disposed on at least one of the handle portion and the barrel portion. The indicator member may comprises a single plug member removably disposed on said handle portion, or a pair of plug members disposed on opposite lateral ends of said handle portion. The plug members may be different colors, different materials, and / or different hardness to enhance the assembly and tuning operation as well as pitch adjustment.

Owner:PEARL MUSICAL INSTRUMENT CO

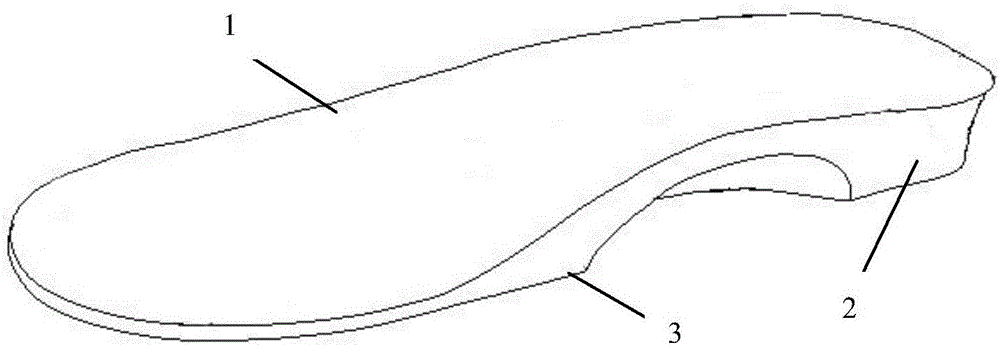

Shoe pad

ActiveCN106551463AIncrease elasticityGood flexibilityInsolesMedical scienceEngineeringMechanical engineering

Owner:广州康沃森康复科技有限公司

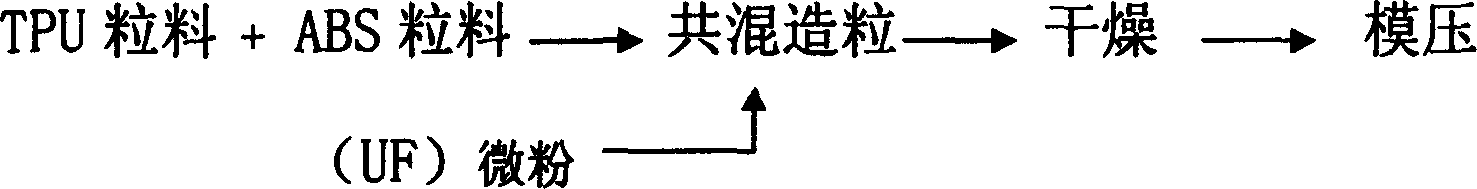

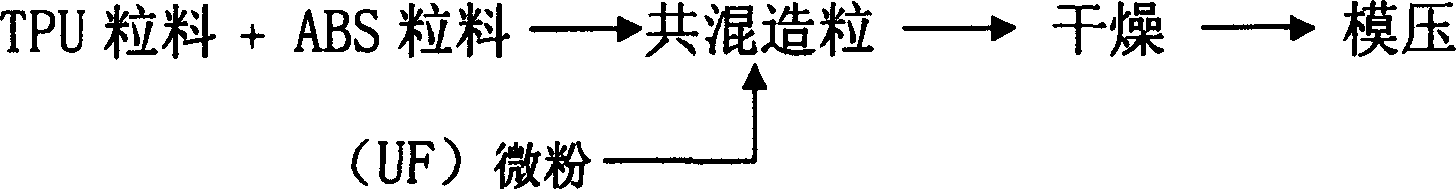

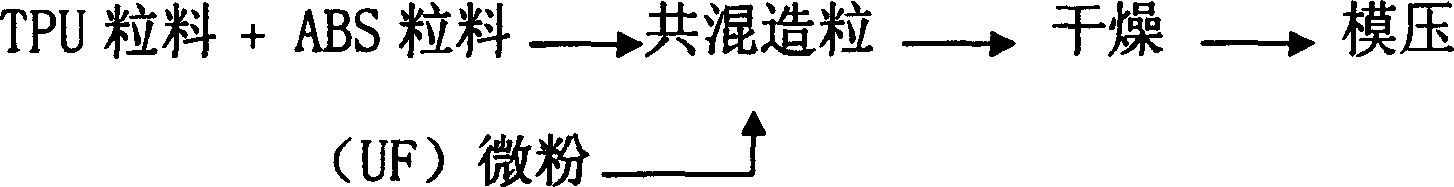

Modified TPU abrasive sealing materials, production and use thereof

InactiveCN1818001AHigh hardnessIncrease elasticityOther chemical processesUltra fineGranular material

A modified TPU abrasive sealing material, its production and use are disclosed. The process is carried out by adding TPU granular into ABS granular material, co-mixing, granulating, drying, molding and choosing. It consists of TPU granular material 100 proportion, ABS granular material 20-35 proportion and ultra-fine powder 0-15 proportion.

Owner:ZHUZHOU HONGDA POLYMER MATERIALS

Guide plate for rolling mill and its manufacture and repair method

InactiveCN1453079ADifferent hardnessImprove wear resistanceGuiding/positioning/aligning arrangementsCrack resistanceAdhesive

The guide plate may have tungsten carbide blocks with hardness over HRA80 adhered with inorganic adhesive to its wearable parts. During its manufacture and repair, the wearable parts are machined, cleaned and adhered with tungsten carbide blocks. The guide plate has high wear resistance, crack resistance and long service life. The guide plate is suitable for use of rod rolling mill, wire rolling mill and shape steel rolling mill.

Owner:王树敏

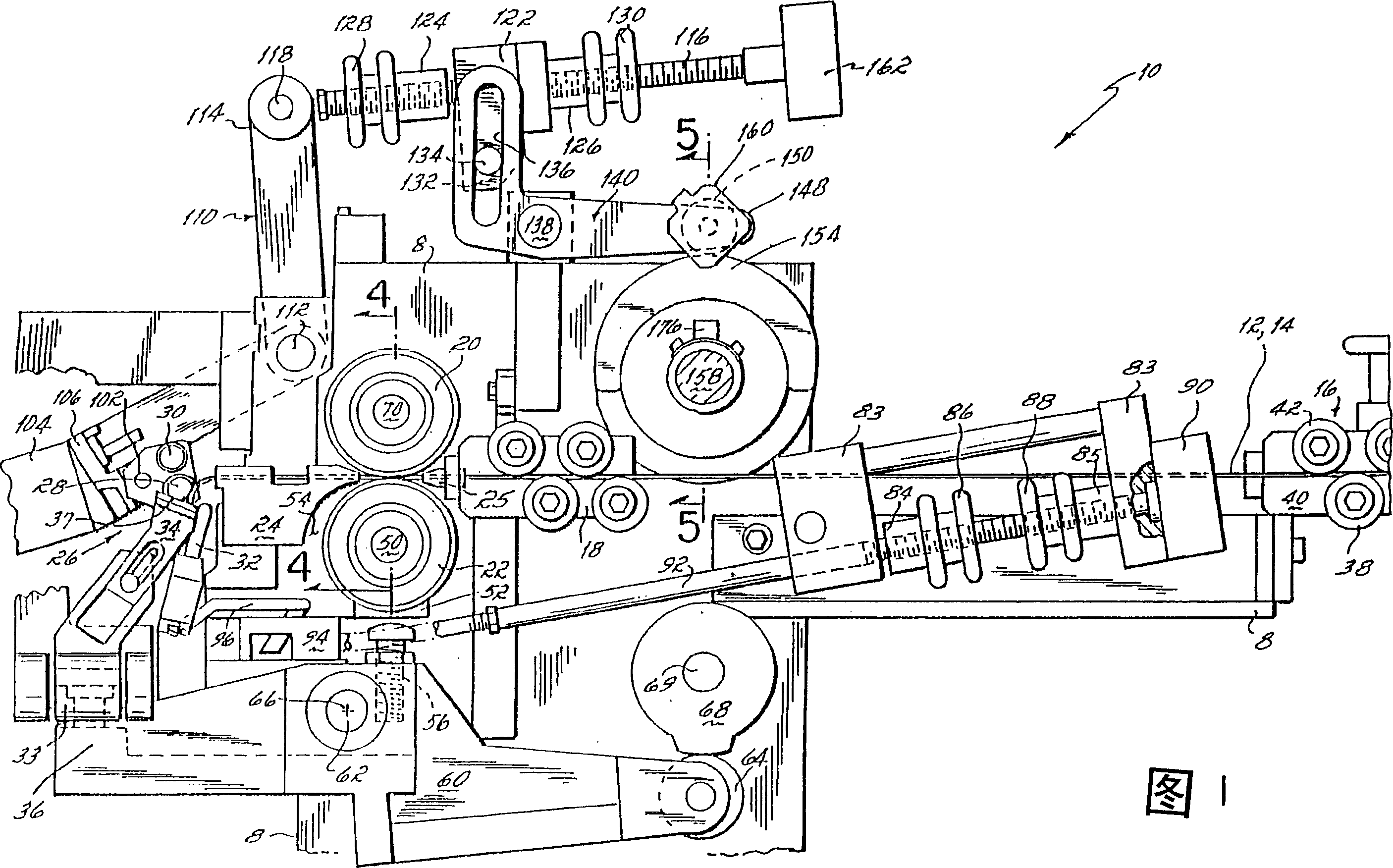

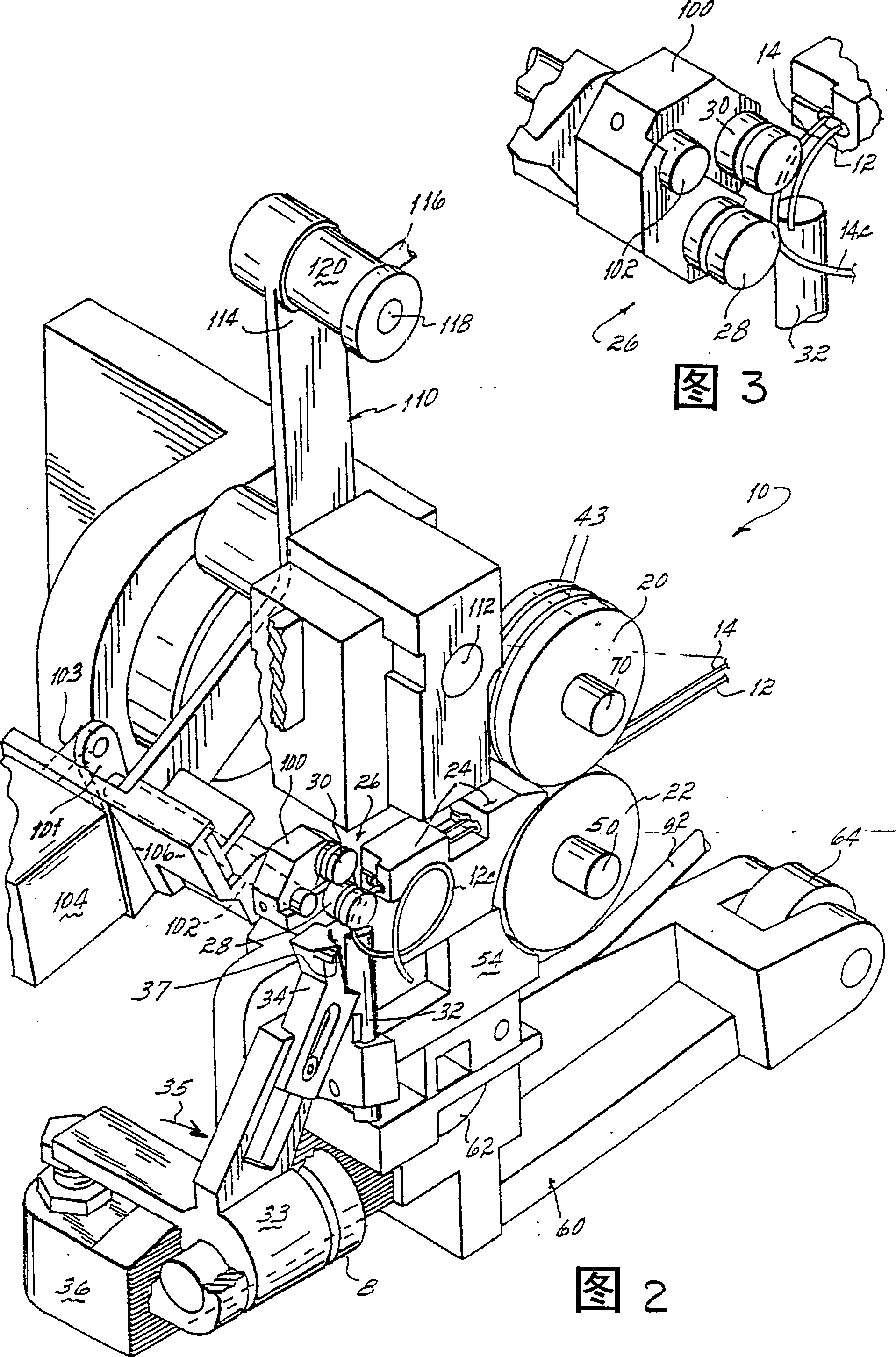

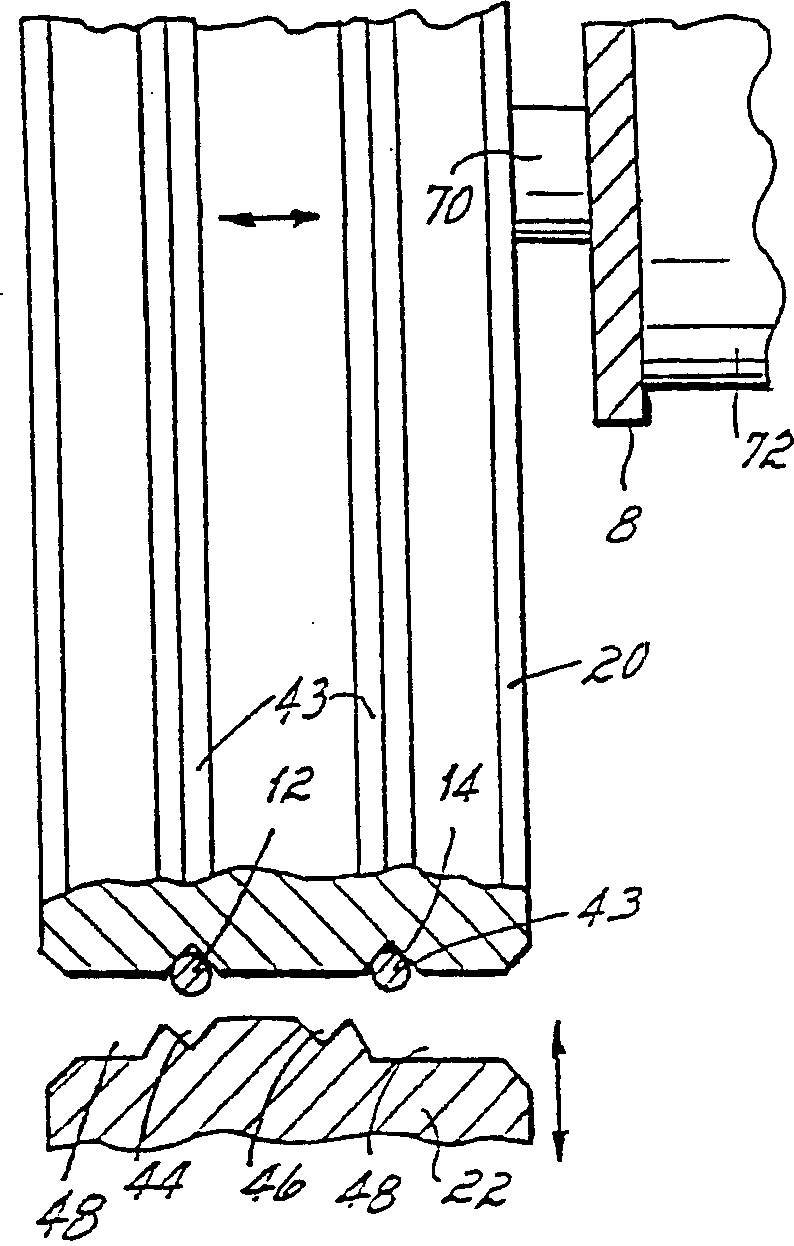

Two wire spring making machine and method

A method and machine for selectively manufacturing wire springs from two different wires by feeding the wires through a pair of continuously rotatable opposed feed rollers, which rollers are operative to feed only one of the wires at a time into engagement with a coil forming mechanism having a pair of coil forming tools. The tools are selectively positionable for engagement with one or the other of the two wires depending upon which of the two wires is being fed into the coil forming mechanism.

Owner:L & P PROPERTY MANAGEMENT CO

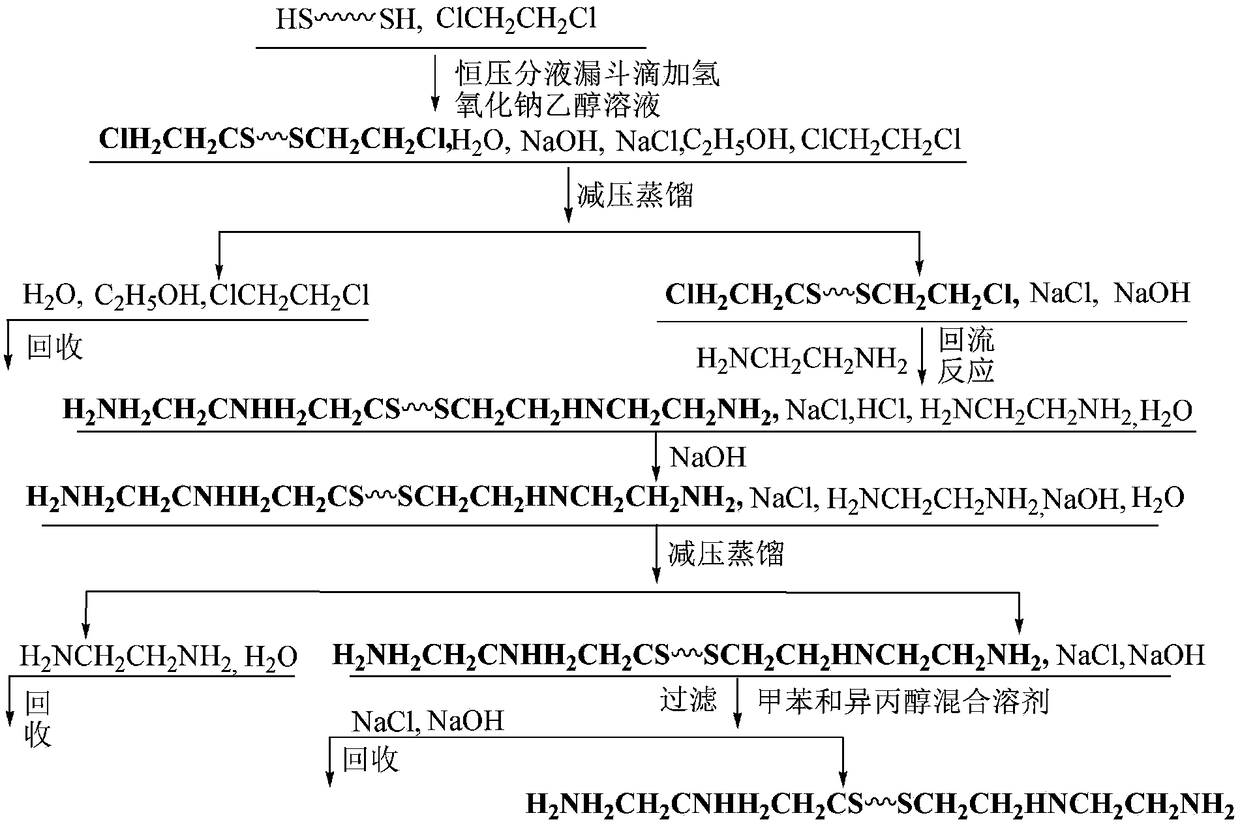

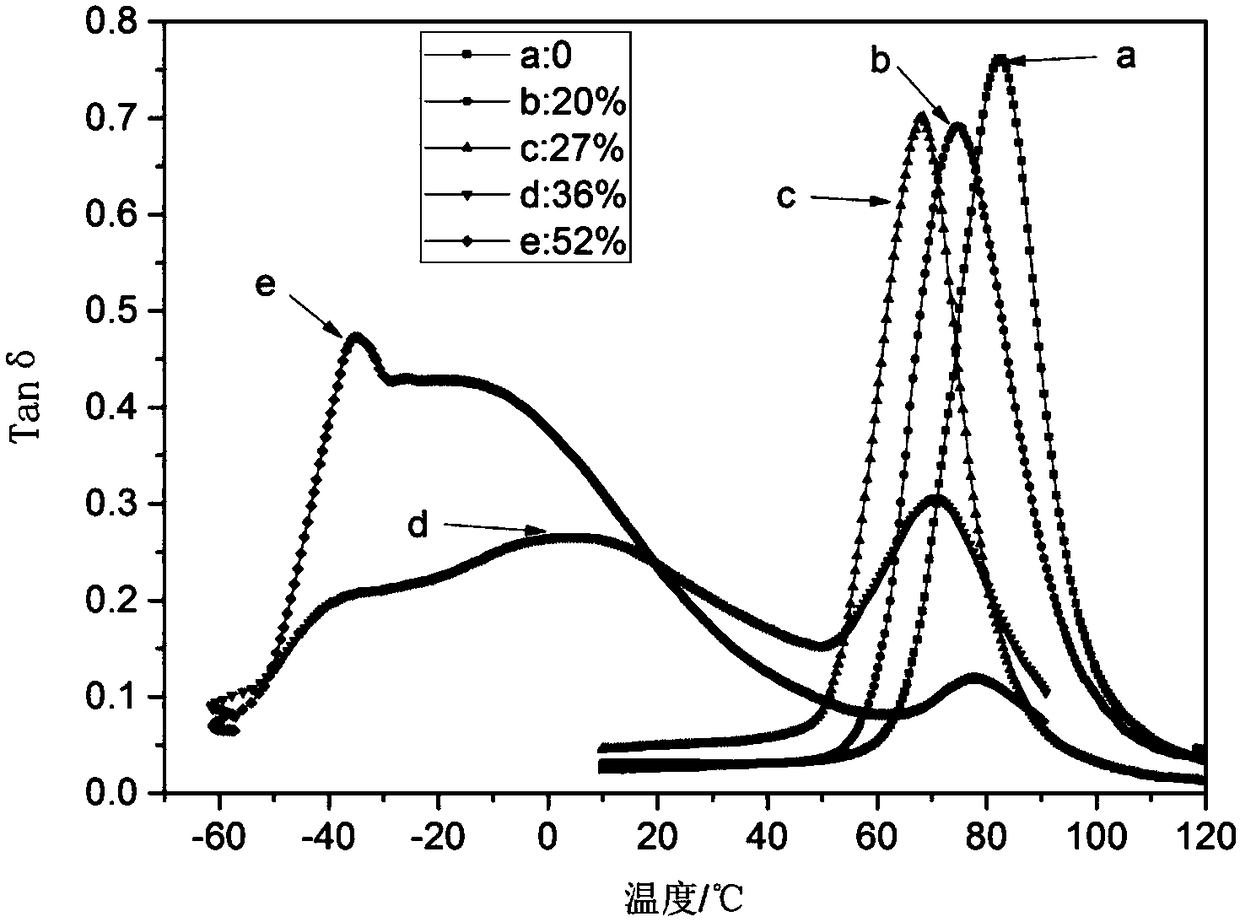

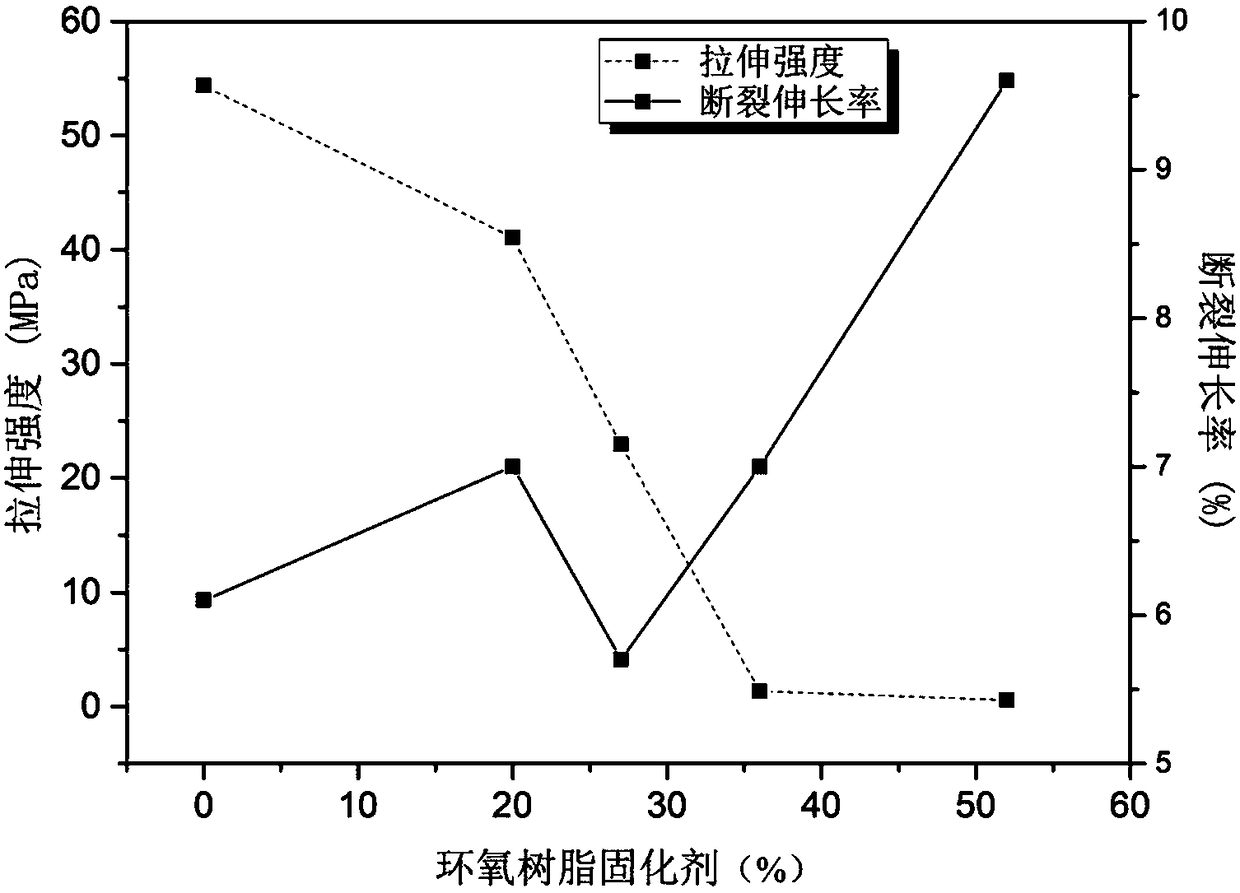

Epoxy resin curing agent, and preparation method and application of epoxy resin curing agent

InactiveCN108084436AIncreased active hydrogen contentIncrease crosslink densityPolysulfide rubberSulfur

The invention discloses an epoxy resin curing agent, and a preparation method and an application of the epoxy resin curing agent. Sulfydryl is introduced into ethidene diamine, so that an active hydrogen content of liquid polysulfide rubber is greatly increased; a condensate with higher crosslinking density can be obtained by a reaction between the epoxy resin curing agent and epoxy resin; the epoxy resin curing agent is both a flexibilizer and a curing agent of the epoxy resin, similar to a commonly-used fatty amine curing agent; curing rates are matched, so that the epoxy resin curing agentcan be mixed with a general organic amine curing agent freely to achieve different rigidity and strength; and the epoxy resin curing agent is flexible in molecular design. A preparation condition of the epoxy resin curing agent is easy to implement; a preparation technology is environment-friendly; and the preparation cost is low.

Owner:NAVAL UNIV OF ENG PLA

Drum tuning key

InactiveUS20070193433A1Easy to assembleEnhance tuning operationPercussion musical instrumentsEngineeringMechanical engineering

A drum tuning key comprises a handle portion, a barrel portion defining an axis connected to the handle portion, the barrel portion having internal walls defining a cavity extending inwardly along the axis from an end of the barrel portion, the cavity being square in cross section and adapted to turn a drum tension rod. The tuning key further comprises an indicator member removably disposed on at least one of the handle portion and the barrel portion. The indicator member may comprises a single plug member removably disposed on said handle portion, or a pair of plug members disposed on opposite lateral ends of said handle portion. The plug members may be different colors, different materials, and / or different hardness to enhance the assembly and tuning operation as well as pitch adjustment.

Owner:PEARL DRUMS

Clinching method and tool therefor

Owner:TOX PRESSOTECHNIK GMBH & CO KG

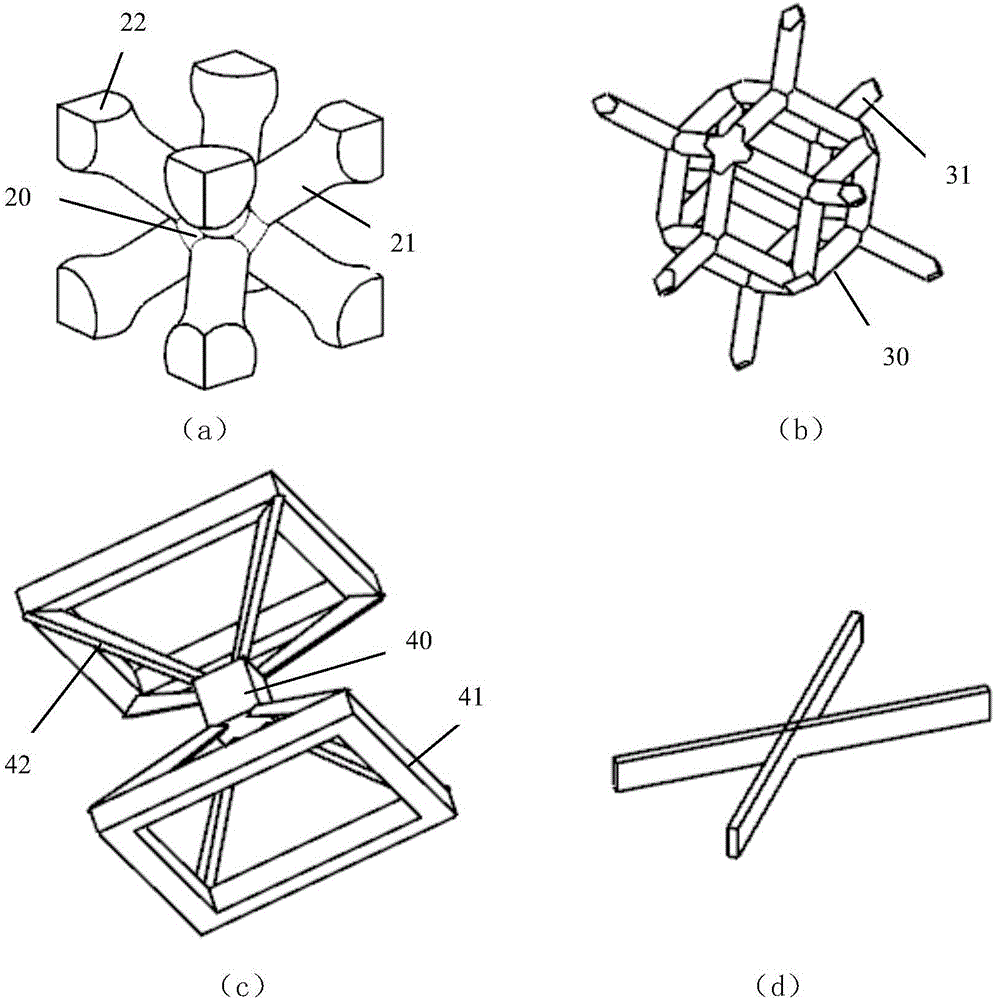

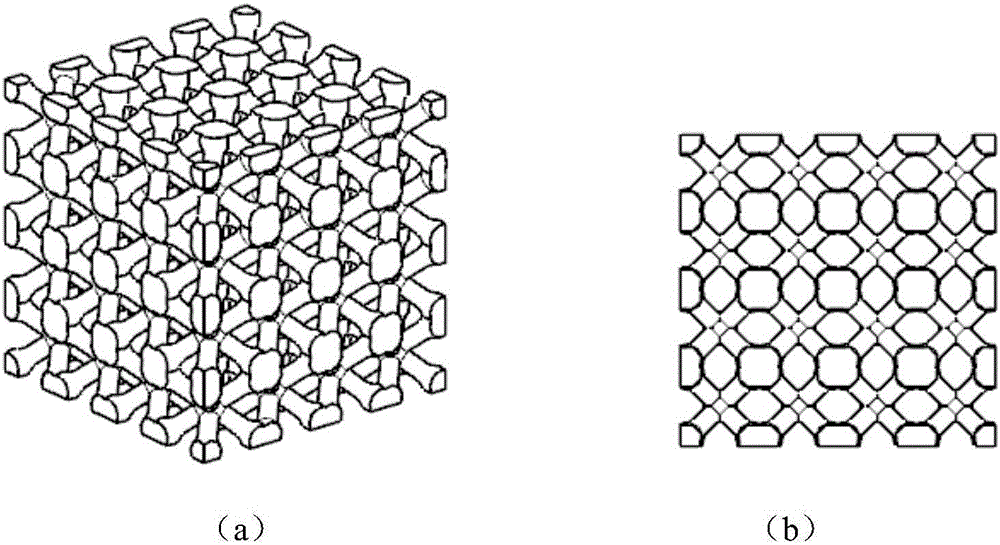

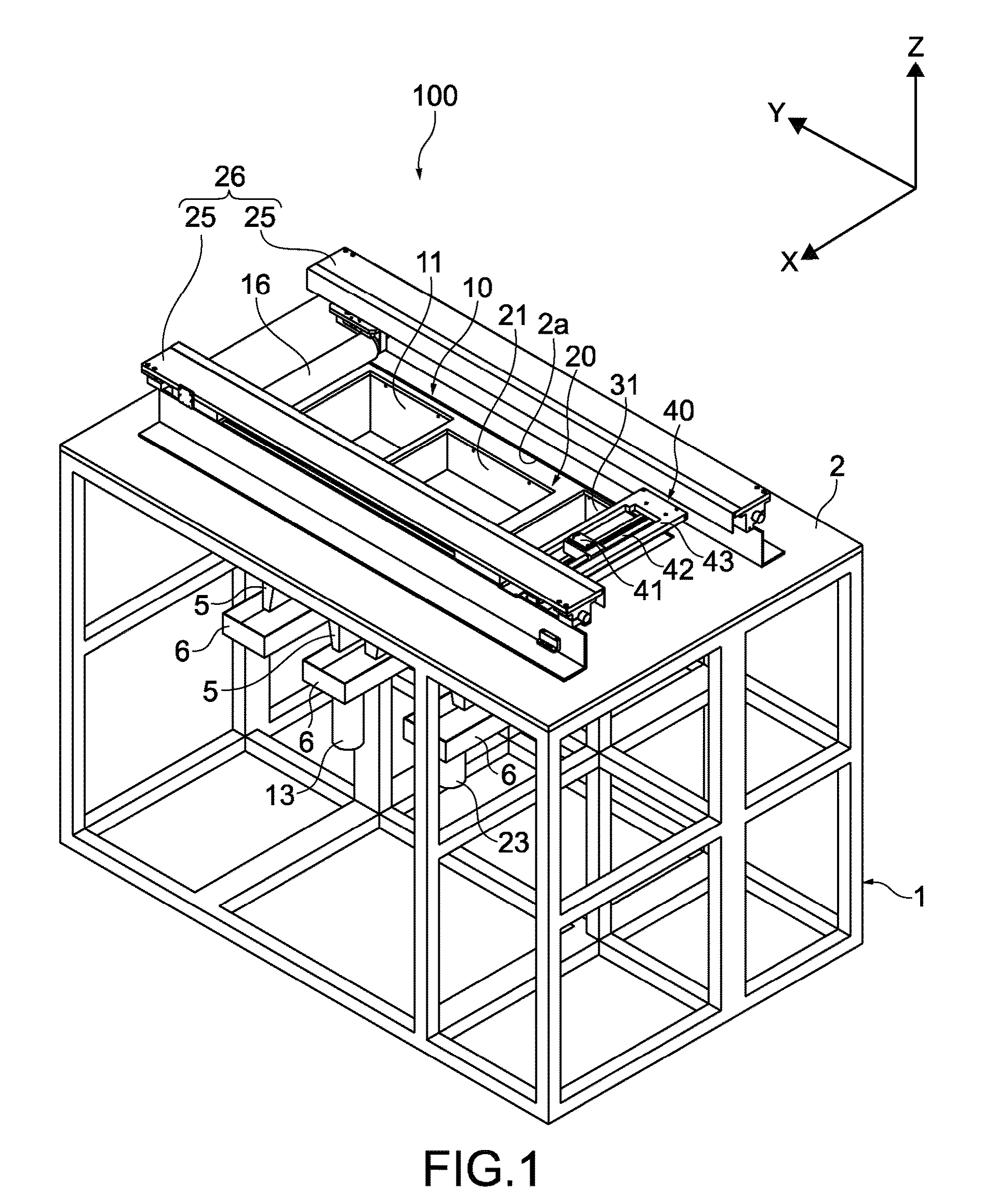

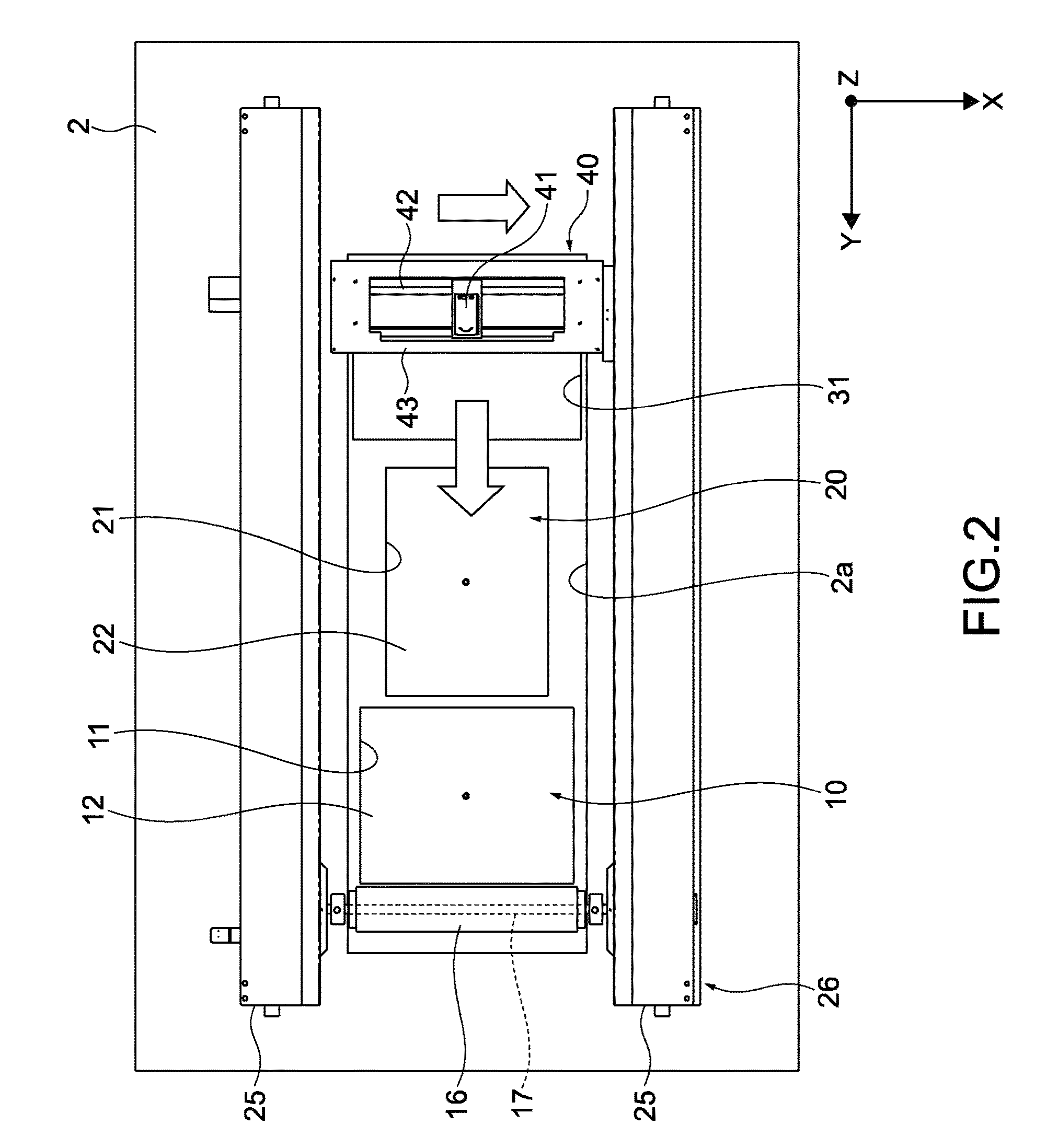

Three-dimensional modeling apparatus, control apparatus, control method, and three-dimensional object

InactiveUS8845050B2Desire hardnessDifferent hardnessPower drive mechanismsOther printing apparatusSlice thicknessEngineering

A three-dimensional modeling apparatus includes a stage, a head, an adjustment mechanism, an ejection command means, and a control means. On the stage, a powder material is accumulated. The head ejects ink to the powder material on the stage. The adjustment mechanism adjusts a relative height of the stage and the head for each predetermined layer thickness so that a three-dimensional object is formed on the stage by the predetermined layer thickness. The ejection command means causes the ink to be ejected from the head so that the powder material is colored a plurality of colors corresponding to multilevel luminance information items in a multivalued image obtained by performing a multivalued processing of luminance with respect to a two-dimensional cross-sectional image data of a modeling target object. The control means controls the adjustment mechanism and the ejection command means so that the multivalued image is drawn for each layer thickness.

Owner:SONY CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com