High-heat-resistance copolymerized silicon resin and preparation method thereof

A technology of silicone resin and high heat resistance, applied in the field of organic polymer materials, can solve the problems of great hidden dangers in the use of products in high temperature environments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

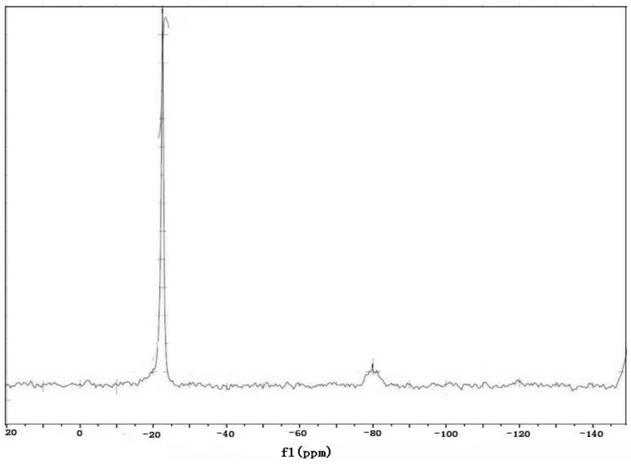

Image

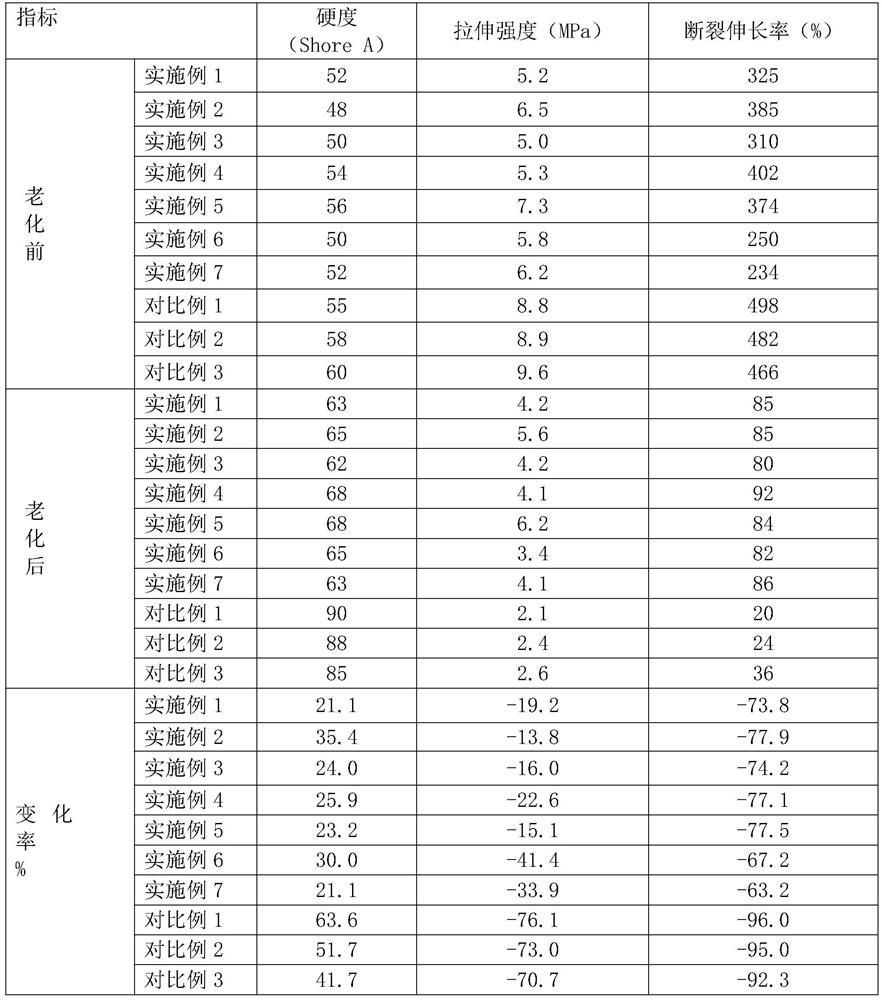

Examples

Embodiment 1

[0032] 200g hydroxyl-terminated polydimethylsiloxane (molecular weight 10×10 4 g / mol) and 6.5 g of triethylamine were dissolved in 600 g of toluene at room temperature, and were dropped into 125 g of phenyltrichlorosilane for 2 hours. After the feeding was completed, the reaction mixture was warmed up to reflux, reacted for 3h, then the mixture was cooled to room temperature, mixed with 18.5g tetramethyldivinyldisiloxane, added dropwise with 300g tetramethylammonium hydroxide (25% aqueous solution ) and 250g of water to make a strong alkali solution, and drop it in 3 hours. After the feeding was completed, the reaction was continued for 5 h at the reflux temperature of the solvent. After the reaction, the lower water layer was separated, the upper oil layer was washed with water until neutral, dried to remove water, and the solvent was evaporated under reduced pressure at 80°C, and the product was dried at 130°C for 3 hours to obtain 317g of copolymerized silicone resin with ...

Embodiment 2

[0034] 200g hydroxyl-terminated polydimethylsiloxane (molecular weight 5.8×10 5 g / mol) According to the reaction steps of Example 1, 310 g of copolymerized silicone resin was prepared, with a yield of 96%.

Embodiment 3

[0036] 200g hydroxyl-terminated polymethylphenylsiloxane (molecular weight 8.5×10 4 g / mol) and 6.5 g of triethylamine were dissolved in 800 g of xylene at room temperature, and were dropped into 125 g of phenyltrichlorosilane for 2 hours. After the feeding was completed, the temperature of the reaction mixture was raised to reflux for 3 hours of reaction, and then the mixture was cooled to room temperature and mixed with 20.6 g of dimethylvinylchlorosilane. Drop it into a strong alkali solution made of 85gKOH and 400g water, and finish dropping in 4h. After the feeding was completed, the reaction was continued for 5 h at the reflux temperature of the solvent. After the reaction, the lower water layer was separated, the upper oil layer was washed with water until neutral, dried to remove water, and the solvent was evaporated under reduced pressure at 80°C, and the product was dried at 130°C for 3 hours to obtain 314g of copolymerized silicone resin with a yield of 97% %.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com