Large-scale PTA drying machine sealing surface abrasion on-site precise pulse surfacing welding repair process

A pulse surfacing and precision technology, applied in welding equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of complex and difficult operation of laser cladding welding equipment, low bonding strength of brush plating surfacing layer, high residual stress level, etc. , to achieve the effect of saving disassembly cost and time, overlaying welding efficiency, and small heat-affected zone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

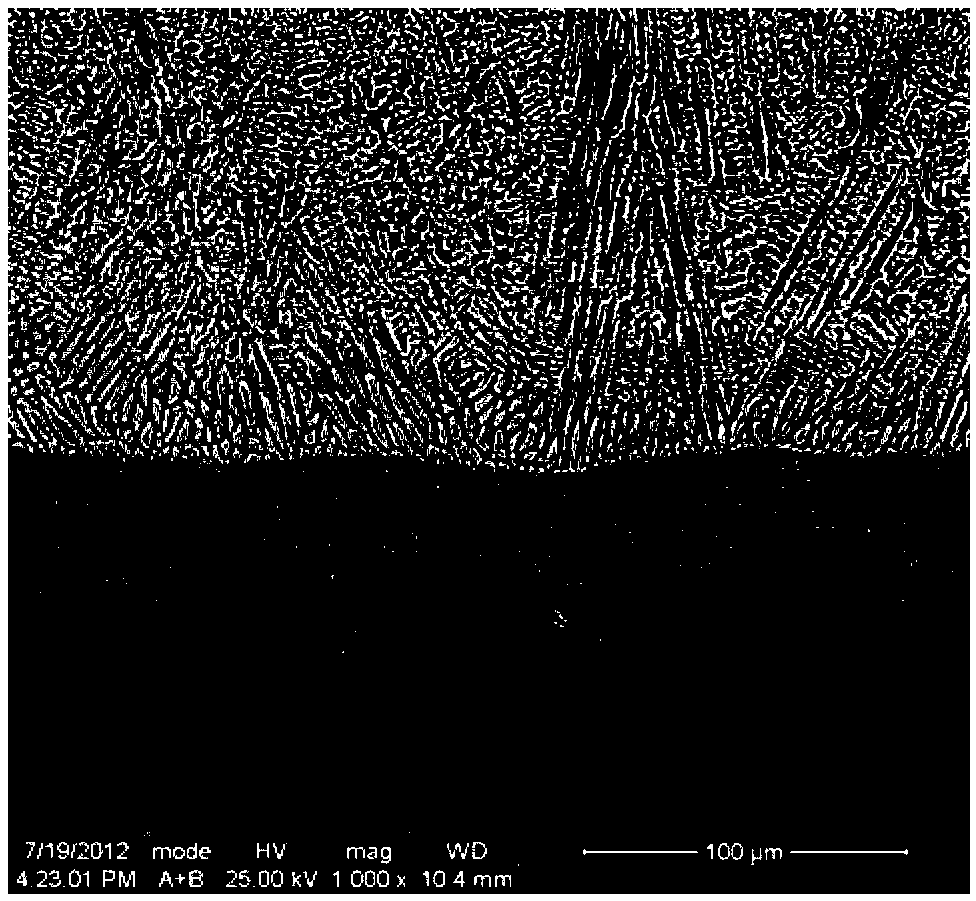

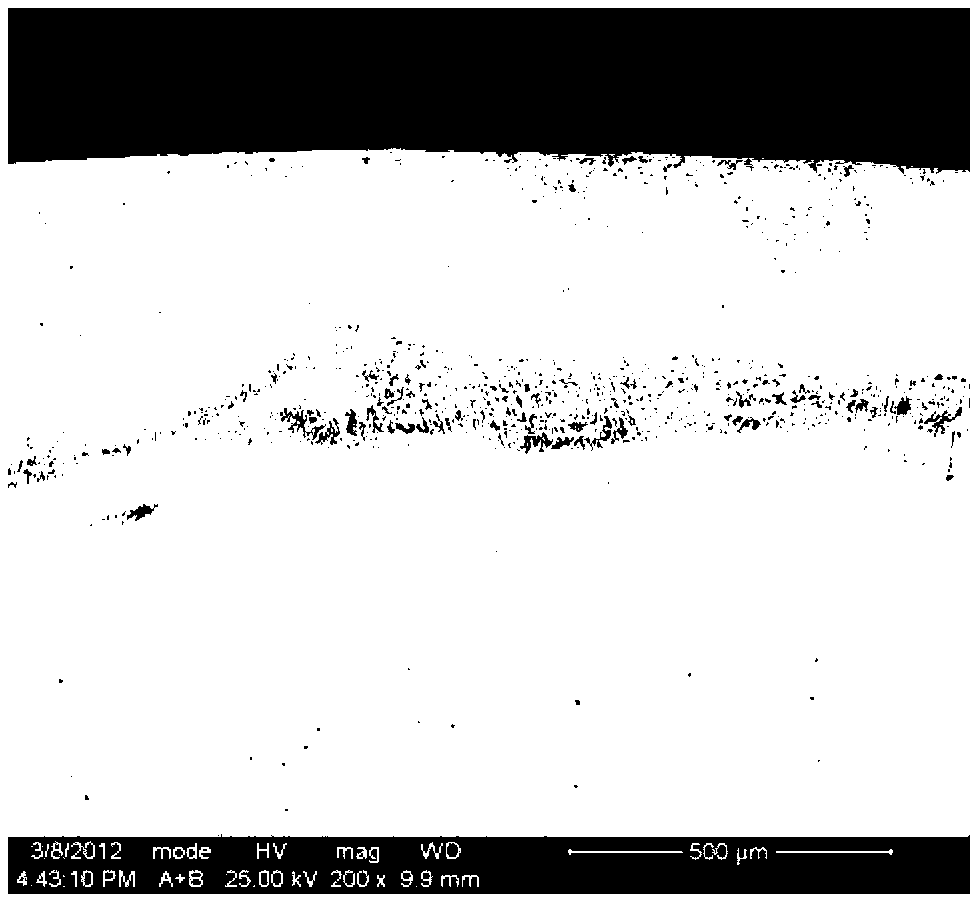

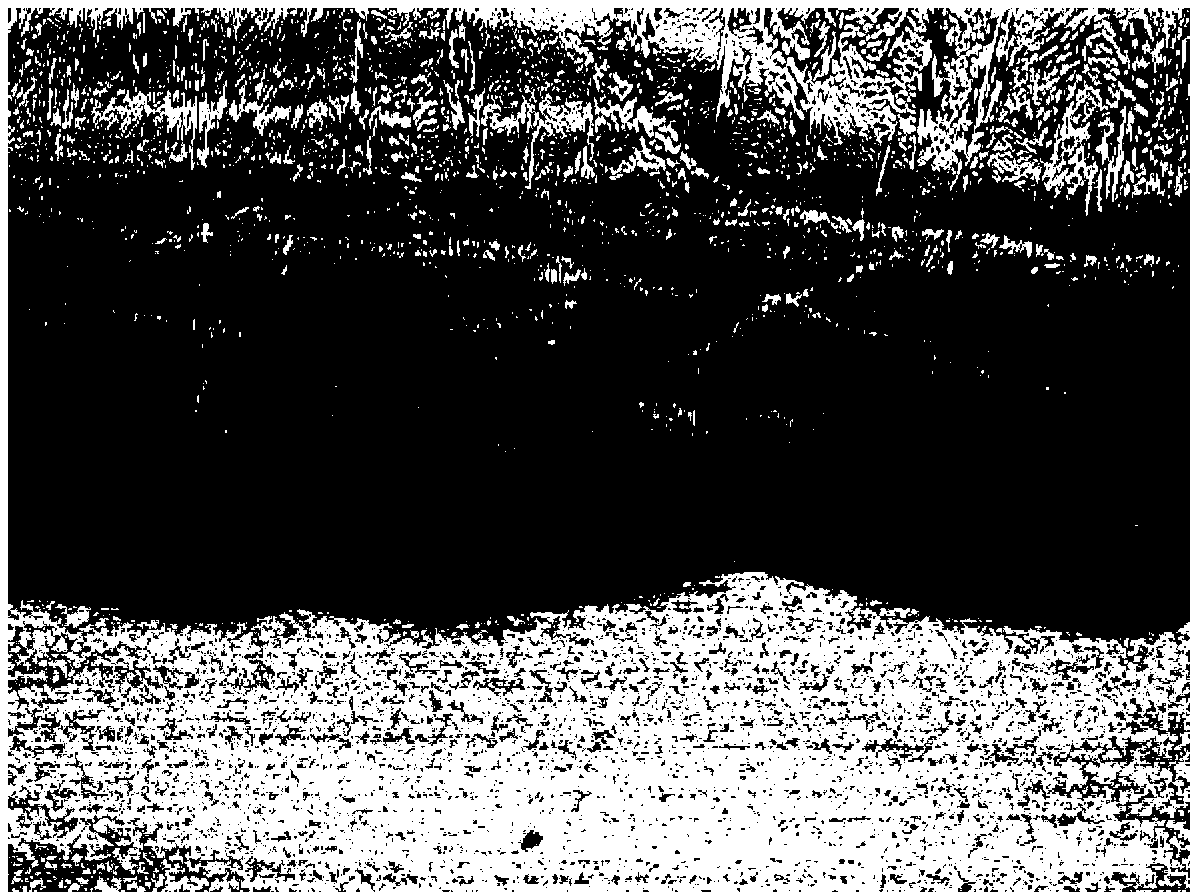

[0038] In this embodiment, the sealing surface of a large-scale PTA dryer with a weight of 300 tons is repaired. The repair process of precision pulse microscopic surfacing welding without deformation on the sealing surface of the dryer includes the following steps:

[0039] (1) Clean up the worn part before surfacing welding

[0040] First use a rag to wipe off most of the sealing grease, and use absorbent paper to wipe the remaining unremoved parts, then clean the worn part with kerosene and acetone; finally use precision electric grinding tools to remove the fatigue layer at the worn part;

[0041] (2) Precision pulse microsurfacing welding

[0042] Choose a nickel-based or cobalt-based alloy with higher wear resistance and corrosion resistance than the substrate and excellent weldability as the surfacing material for the worn part. The diameter of the nickel-based welding wire is 1-1.6mm, and its nominal composition is: Ni-22Cr-10Mo -5Nb-4Fe-0.1C; the diameter of cobalt-b...

Embodiment 2

[0051] In this embodiment, the sealing surface of a large-scale PTA dryer with a weight of 400 tons is repaired. The repair process of precision pulse microscopic surfacing welding without deformation at the scene of the wear of the sealing surface of the dryer includes the following steps:

[0052] (1) Clean up the worn part before surfacing welding

[0053] First use a rag to wipe off most of the sealing grease, and use absorbent paper to wipe the remaining unremoved parts, then clean the worn part with kerosene and acetone; finally use precision electric grinding tools to remove the fatigue layer at the worn part;

[0054] (2) Precision pulse microsurfacing welding

[0055] Choose a nickel-based or cobalt-based alloy with higher wear resistance and corrosion resistance than the substrate and excellent weldability as the surfacing material for the worn part. The diameter of the nickel-based welding wire is 1-1.6mm, and its nominal composition is: Ni-22Cr-10Mo -5Nb-4Fe-0.1C;...

Embodiment 3

[0064] In this embodiment, the sealing surface of a large-scale PTA dryer with a weight of 200 tons is repaired. The repair process of precision pulse microscopic surfacing welding without deformation at the scene of the wear of the sealing surface of the dryer includes the following steps:

[0065] (1) Clean up the worn part before surfacing welding

[0066] First use a rag to wipe off most of the sealing grease, and use absorbent paper to wipe the remaining unremoved parts, then clean the worn part with kerosene and acetone; finally use precision electric grinding tools to remove the fatigue layer at the worn part;

[0067] (2) Precision pulse microsurfacing welding

[0068] Choose a nickel-based or cobalt-based alloy with higher wear resistance and corrosion resistance than the substrate and excellent weldability as the surfacing material for the worn part. The diameter of the nickel-based welding wire is 1-1.6mm, and its nominal composition is: Ni-22Cr-10Mo -5Nb-4Fe-0.1C;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com