Method and apparatus for repairing superalloy components

a superalloy and component technology, applied in non-electric welding apparatus, electron beam welding apparatus, machines/engines, etc., can solve the problems of incomplete bonding, difficult and expensive manufacturing of components, and no other alloy class can match the high temperature strength of high-temperature alloys

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

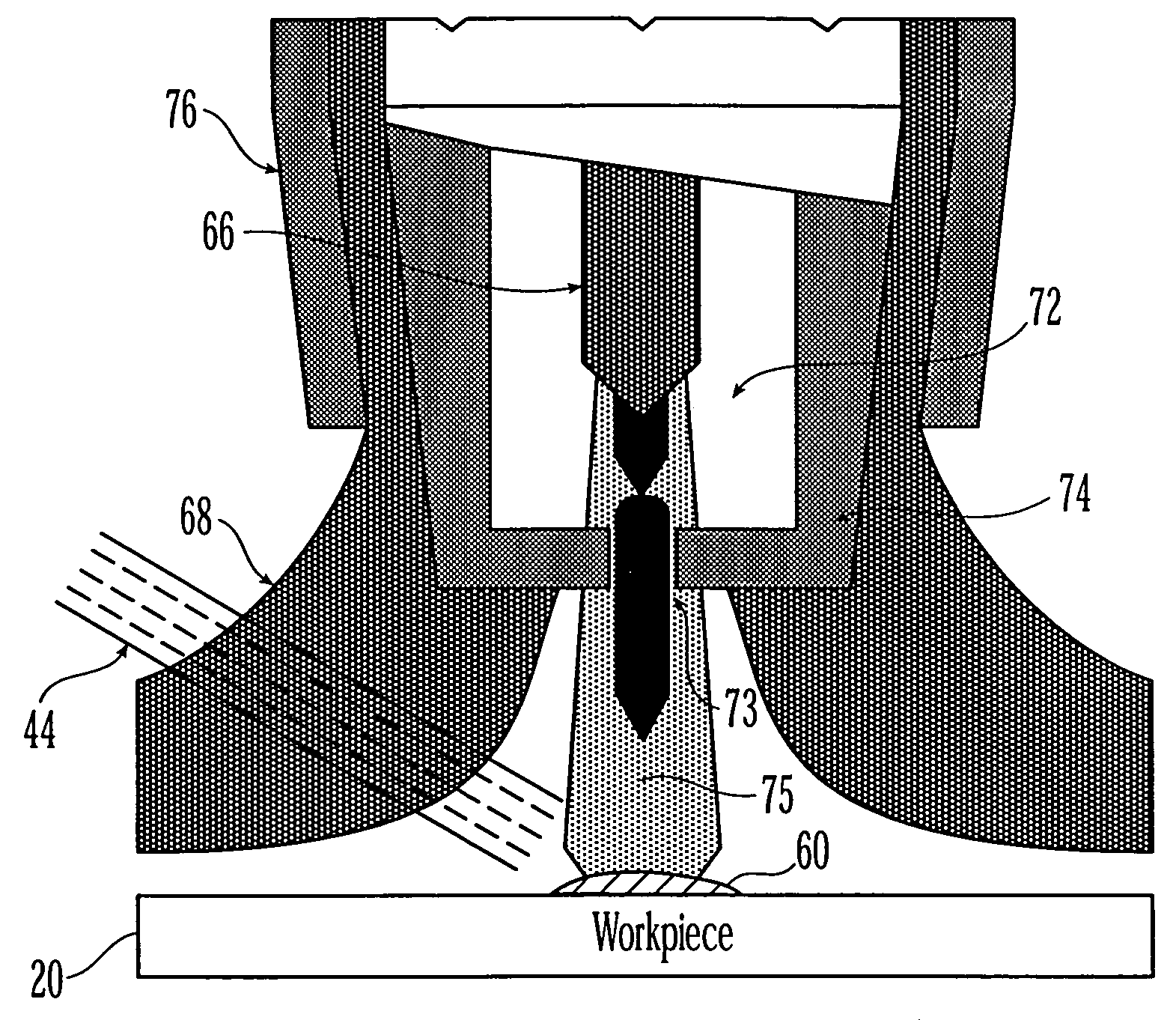

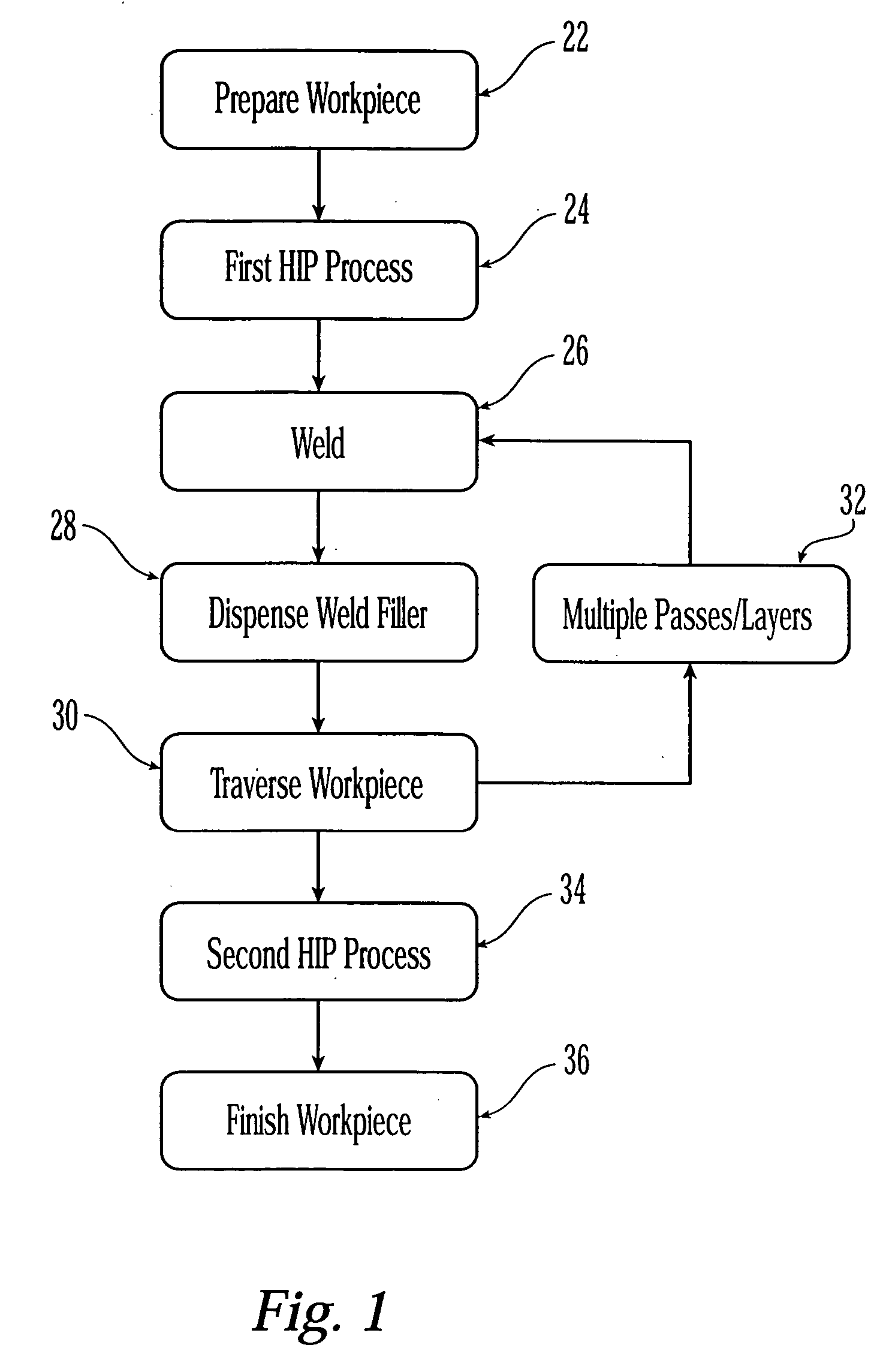

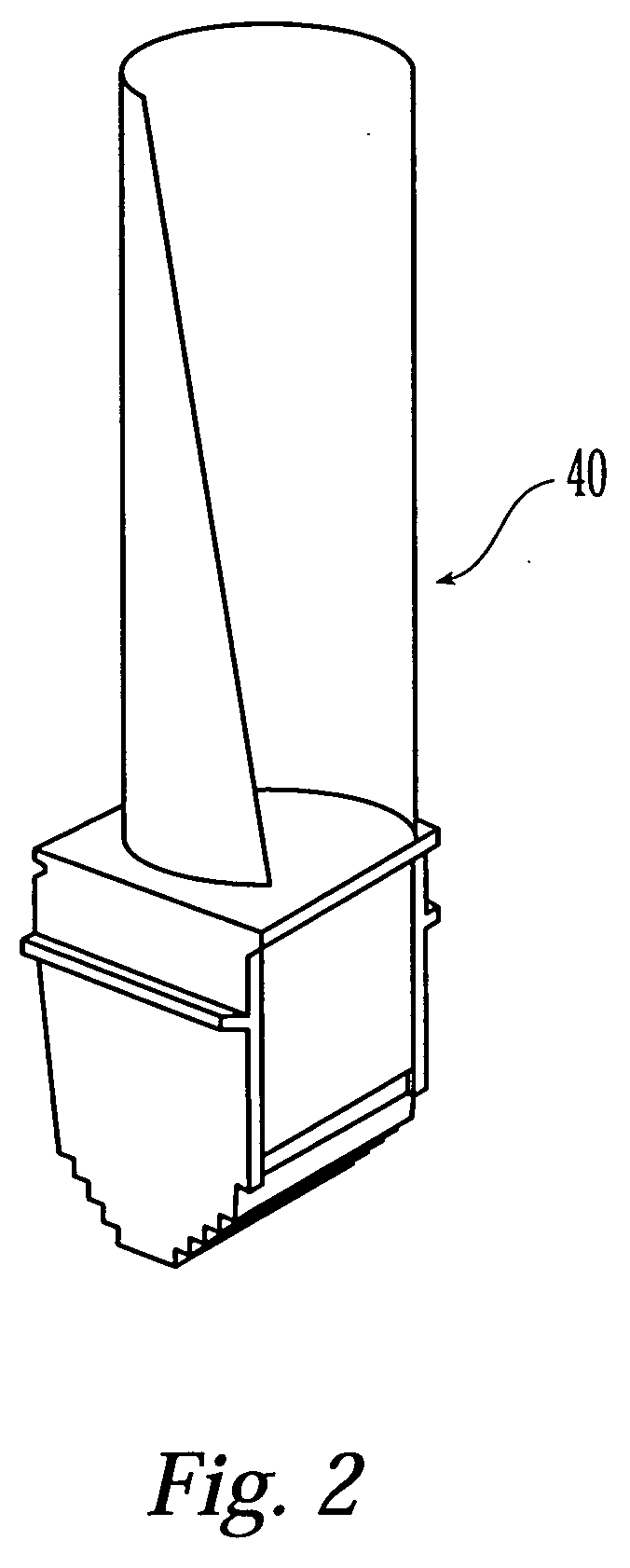

[0023]FIG. 1 is a flow chart of an embodiment of the method of the invention. In the step 22, a workpiece, such as a turbine blade, a turbine nozzle, or other metallic component that has been removed from service, is initially prepared for its repair. This prepare workpiece step 22 may include the stripping of any protective coatings from the workpiece, which is commonly accomplished with chemical stripping solutions. The prepare workpiece step 22 further includes preparing the specific areas of the workpiece that are to be repaired by conventional methods such as machining and grinding.

[0024] In the step 24, the workpiece is pre-conditioned for welding by subjecting it to a first hot isostatic process (HIP). Hot isostatic processing can be described as an idealized hot pressing or forging operation, or as high-pressure heat treatment. The basic HIP process subjects a workpiece to a combination of elevated temperatures and isostatic gas pressures (usually inert). Processing is usua...

PUM

| Property | Measurement | Unit |

|---|---|---|

| metallic | aaaaa | aaaaa |

| mechanical strength | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com