Clinching method and tool therefor

A tool and riveting technology, which is applied in the field of tools to realize the method, can solve problems such as the influence of the rheological process, the skew of the guide rod, and uncontrollable problems, and achieve the effect of easy control, high density, and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

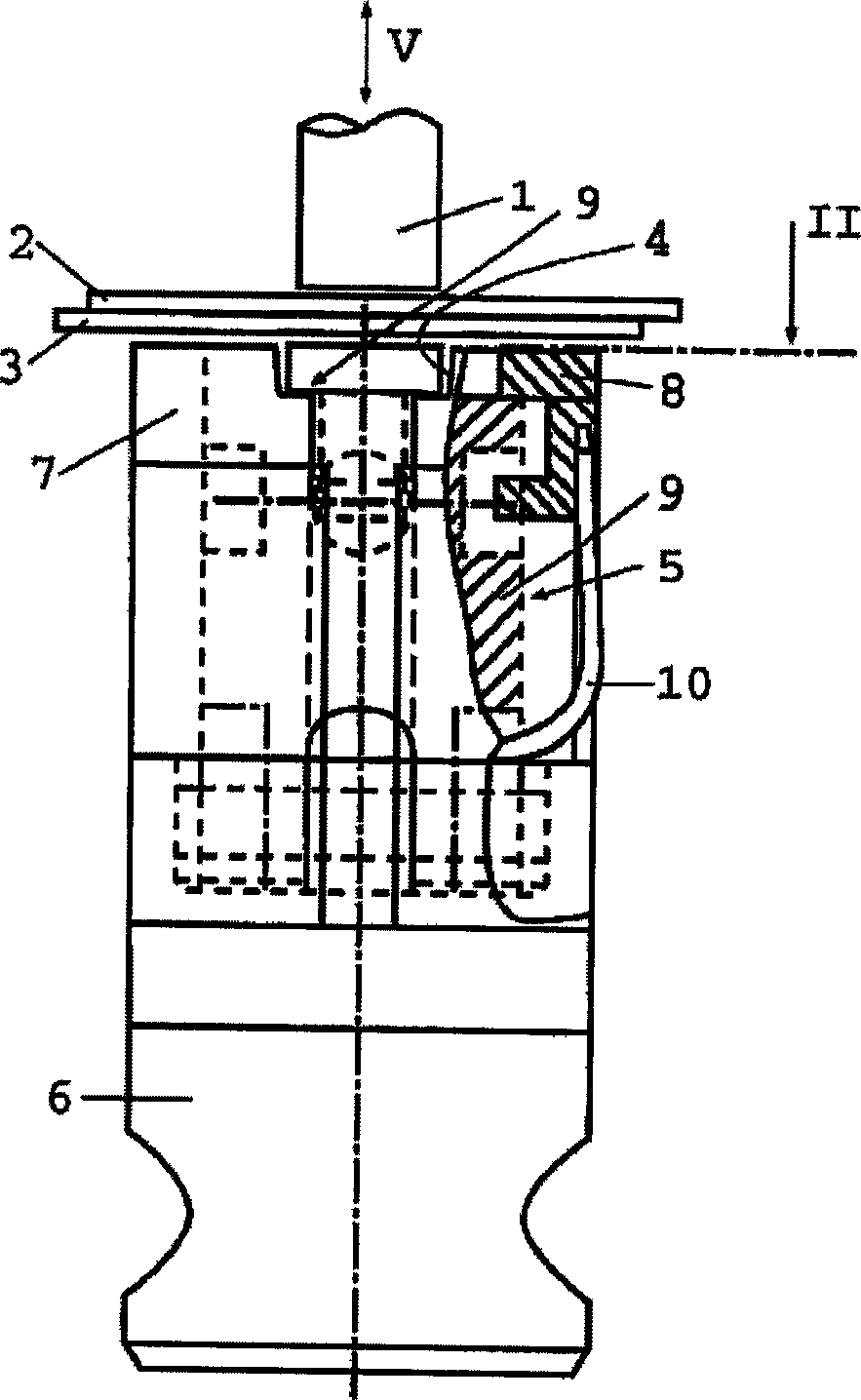

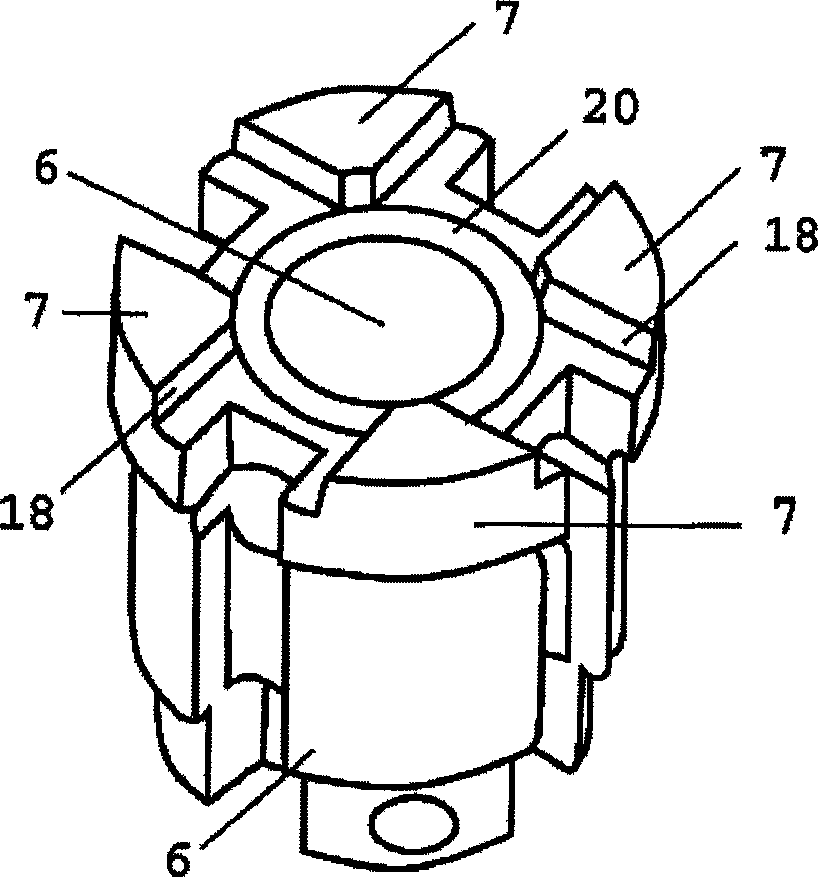

[0032] figure 1 and 2 A tool according to the invention is given in , in which the known machine tool is not used for riveting the sheet metal and for connecting the sheet metal with bolts, nuts etc., in particular the sheet metal is not perforated, but instead deep drawn, Causes significant distortion of deep-drawn material.

[0033] This tool is, on the one hand, a machine-driven plunger 1 which is placed on top of the two metal sheets 2 and 3 to be joined, opposite the working hole 4 of the multi-component mold 5 . The plunger 1 and the mold 5 are placed in the machine tool during use, wherein, for riveting, the plunger 1 is pressed down after the metal plates 2 and 3 have been placed. During the working stroke pointing downwards, the metal sheets 2 and 3 are first deep-drawn into the working hole 4 and then flow radially outwards on the bottom surface 9 of the working hole 4 as the driving force of the plunger 1 increases. , wherein the extruded material is first deep-d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com