Recovery process and application of silicone rubber

A silicone rubber and process technology, applied in the field of silicone rubber recycling process, can solve the problems of complex process, environmental pollution, high cost, etc., and achieve the effect of fully utilizing resources and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

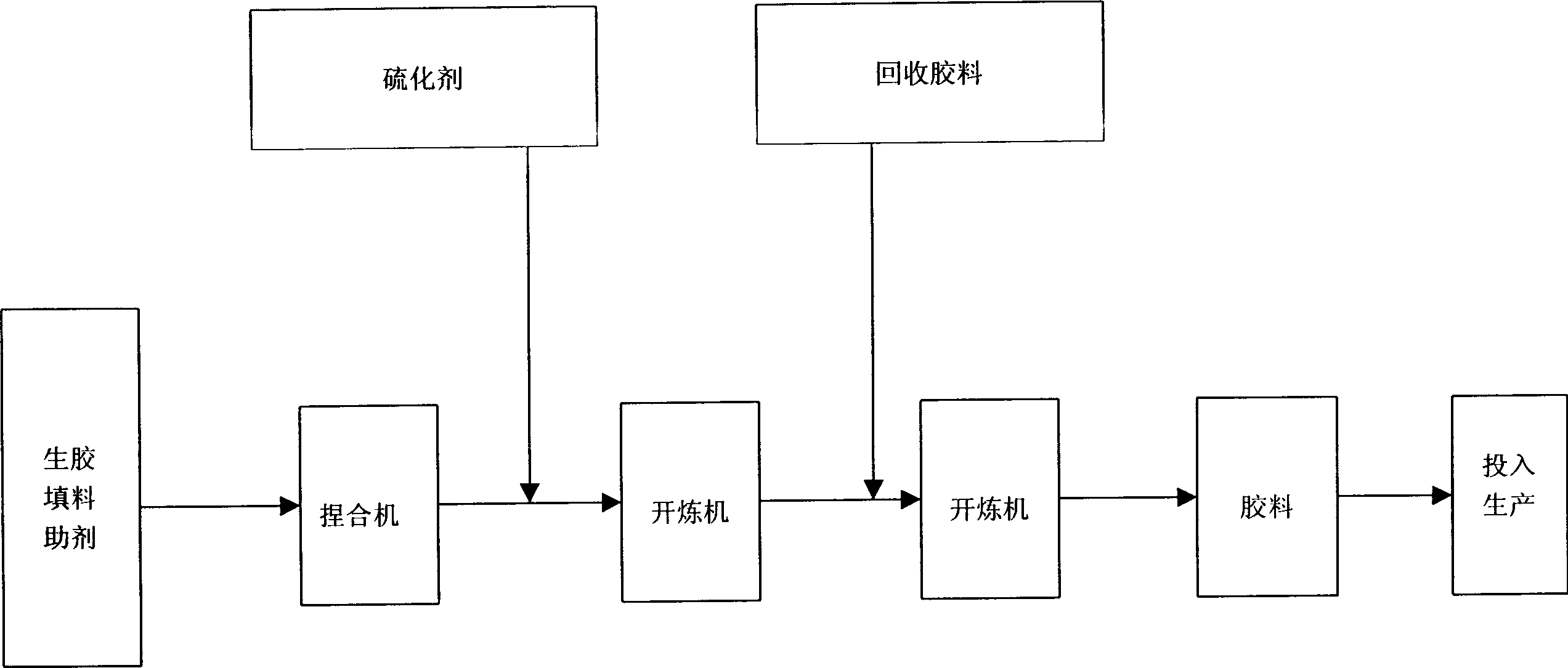

[0028] Such as image 3 Shown, it is the reclaiming of silicone rubber of the present invention and its application process flow chart, it is characterized in that: it is to process and reuse waste silicone rubber as filler, and this process flow comprises three operations:

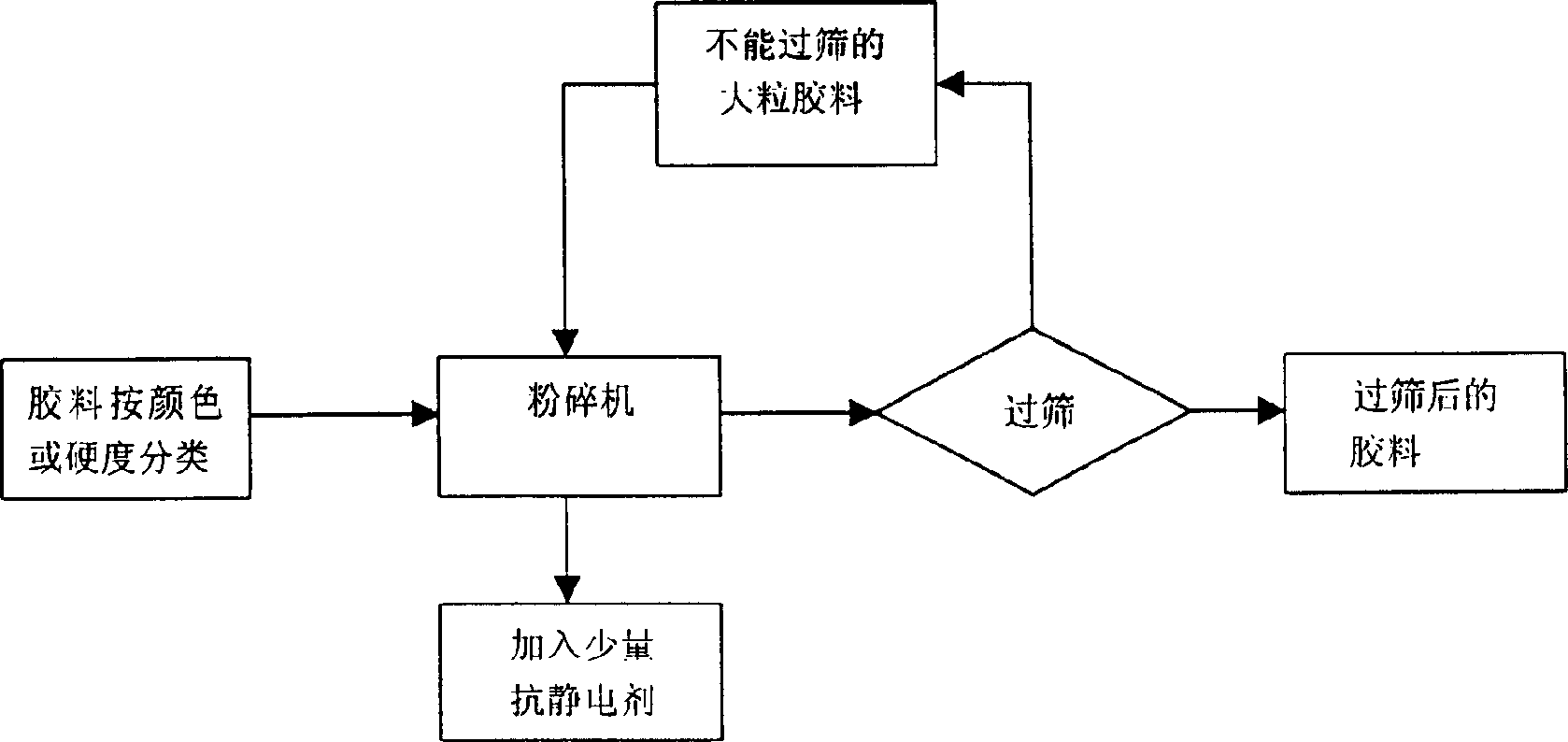

[0029] 1) Crushing of rubber

[0030] Such as figure 1 As shown, it is a flow chart of the crushing process of the sizing material of the present invention. After the silicone rubber is formed, it has different physical shapes, such as color, hardness, etc. Therefore, before recycling, the rubber materials to be recycled must be classified according to color or hardness, and then added with antistatic agent and crushed with a pulverizer. The glass transition temperature Tg is -189°C. When crushed mechanically, it will stick together, so an antistatic agent should be added when crushing. Wherein the antistatic agent component is 0.1%-0.15% quaternary ammonium salt aqueous solution, and in the crushing p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com