Steel billet feeding cylinder and the method of making and repairing it

A technology of rollers and steel billets, which is applied in the field of conveying devices, can solve the problems of low service life of conveying rollers, and achieve the effects of good red hardness, not easy to wear, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

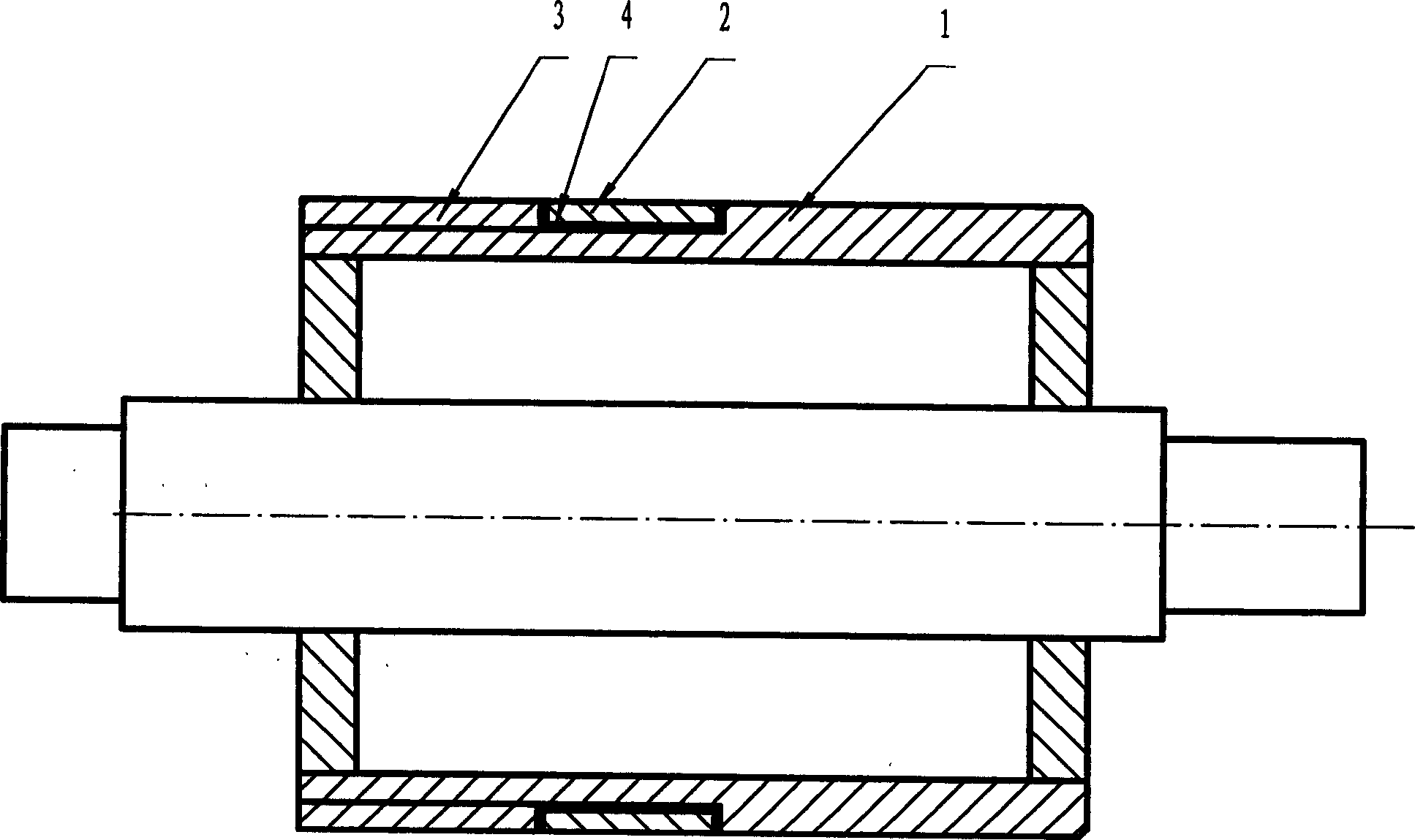

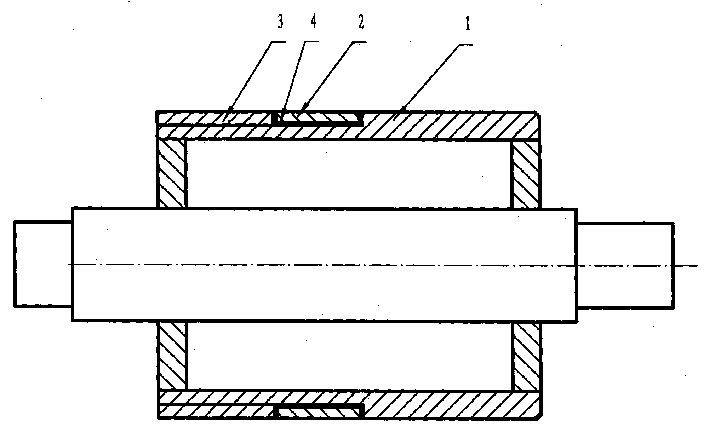

[0014] Such as Figure 1 to Figure 2 As shown, a roller for conveying steel billets is composed of a tungsten carbide roll ring 2 with holes and a base body 1. There is a solder 4 between the tungsten carbide roll ring 2 and the base body 1, and the tungsten carbide roll ring 2 is brazed to the base body 1. Above, the substrate 1 is made of cast steel, the unilateral thickness of the tungsten carbide roller ring 2 is 5 mm, the single-sided gap between the substrate 1 and the tungsten carbide roller ring 2 is 0.2 mm, and the roughness of the joint between the substrate 1 and the tungsten carbide roller ring 2 is ▽5. The main components of the tungsten carbide roll ring 2 are WC80% and Co20%. The hardness of the tungsten carbide roll ring 2 is HRA84.

[0015] A method for manufacturing and repairing a roller for conveying billets, brazing a tungsten carbide roller ring 2 on a substrate 1, the method is as follows:

[0016] 1) Cut 10mm in the diameter of the base body 1;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com