Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

115results about How to "Formed with ease" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Semiconductor device and manufacturing method therefor, circuit substrate, and electronic apparatus

InactiveUS20020151171A1Stress smoothWeaken energySemiconductor/solid-state device detailsSolid-state devicesDevice materialElectrical connection

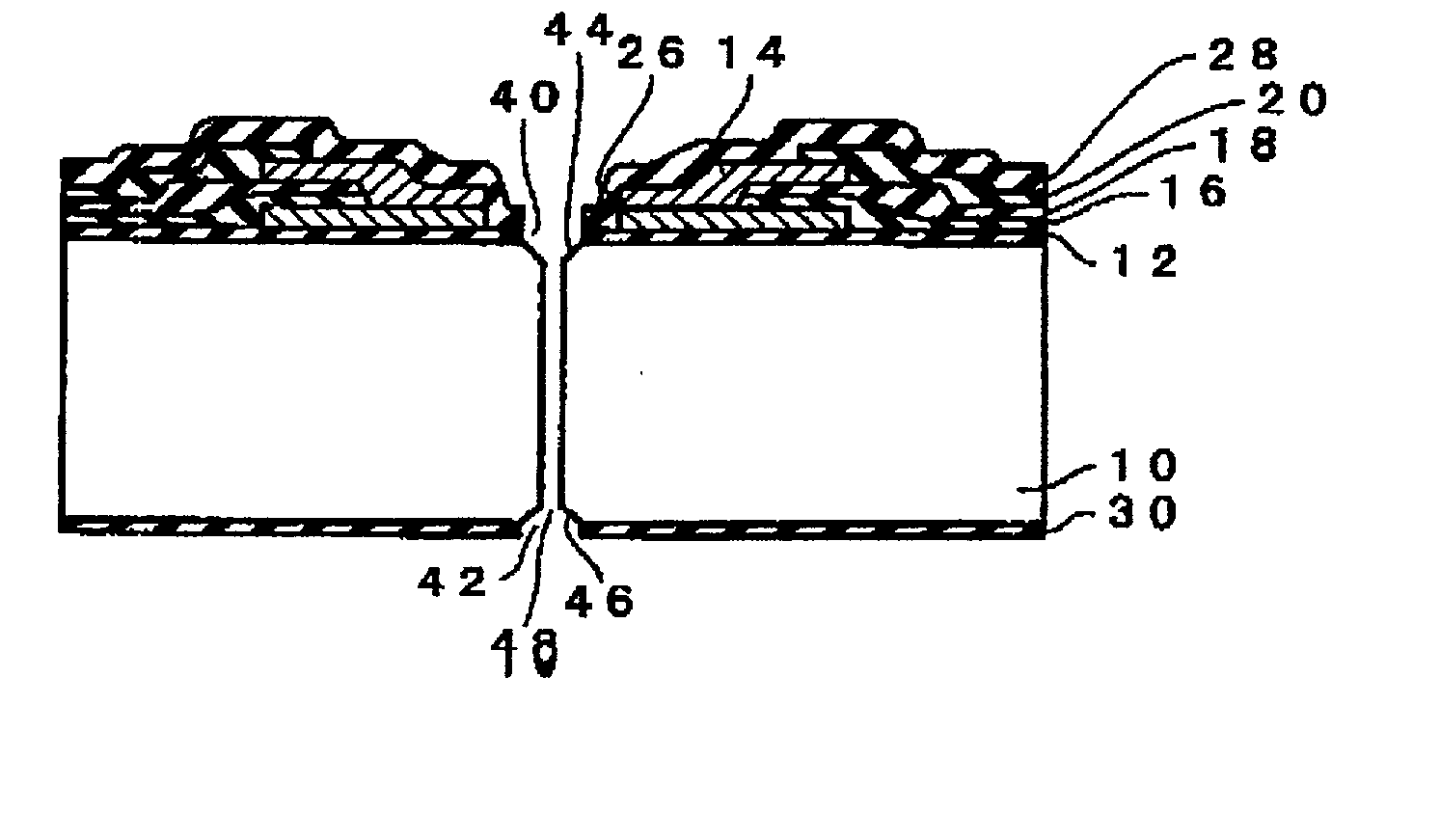

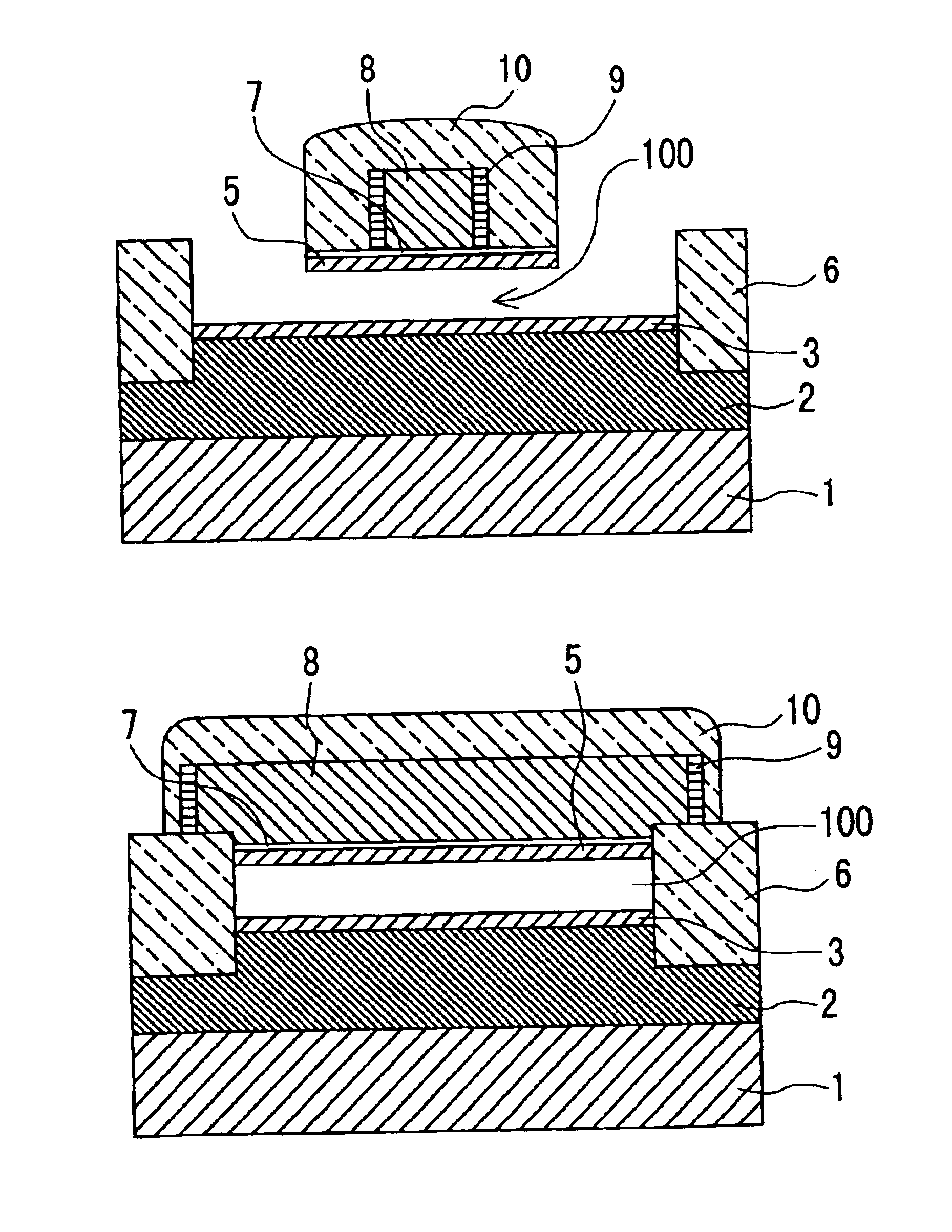

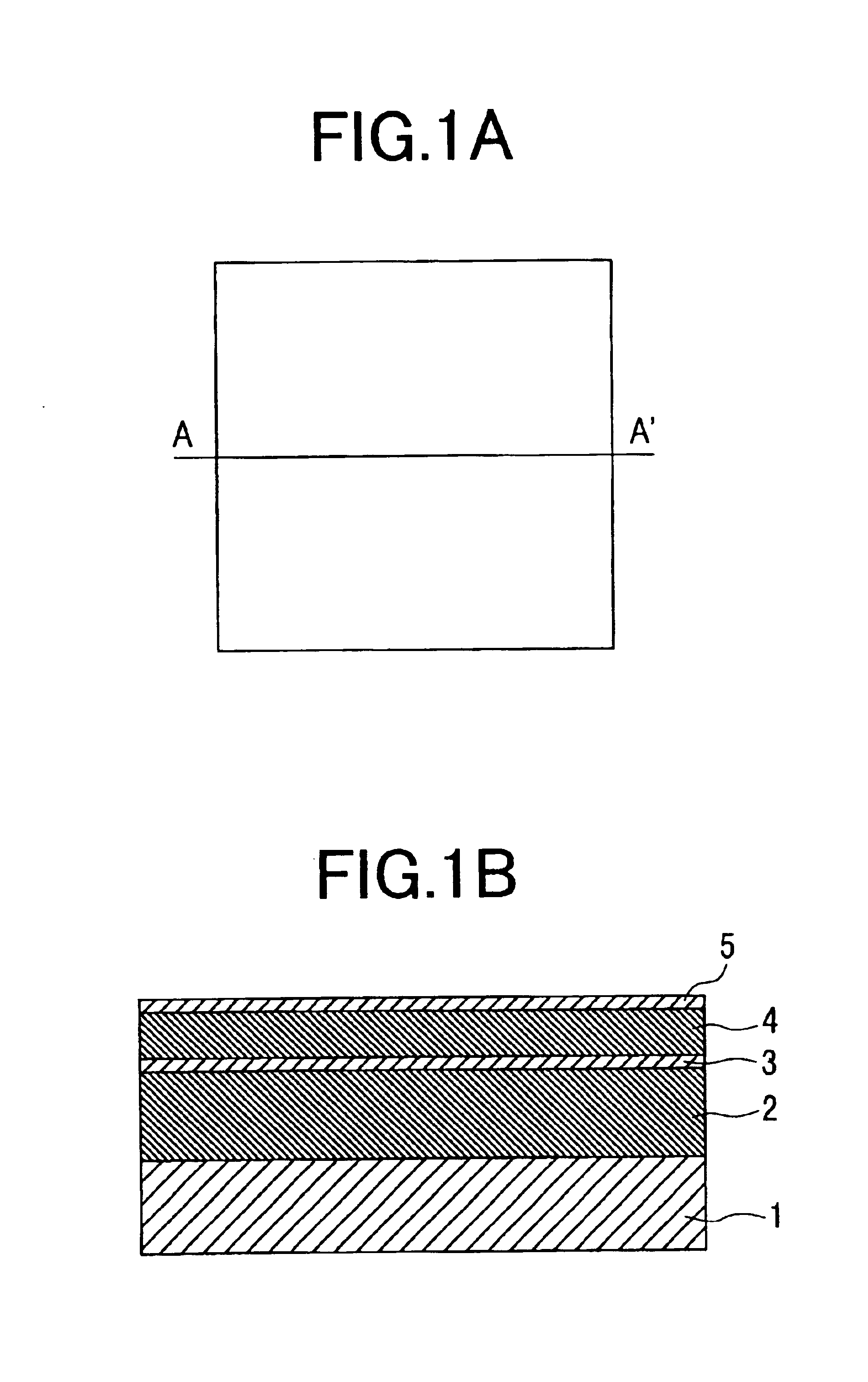

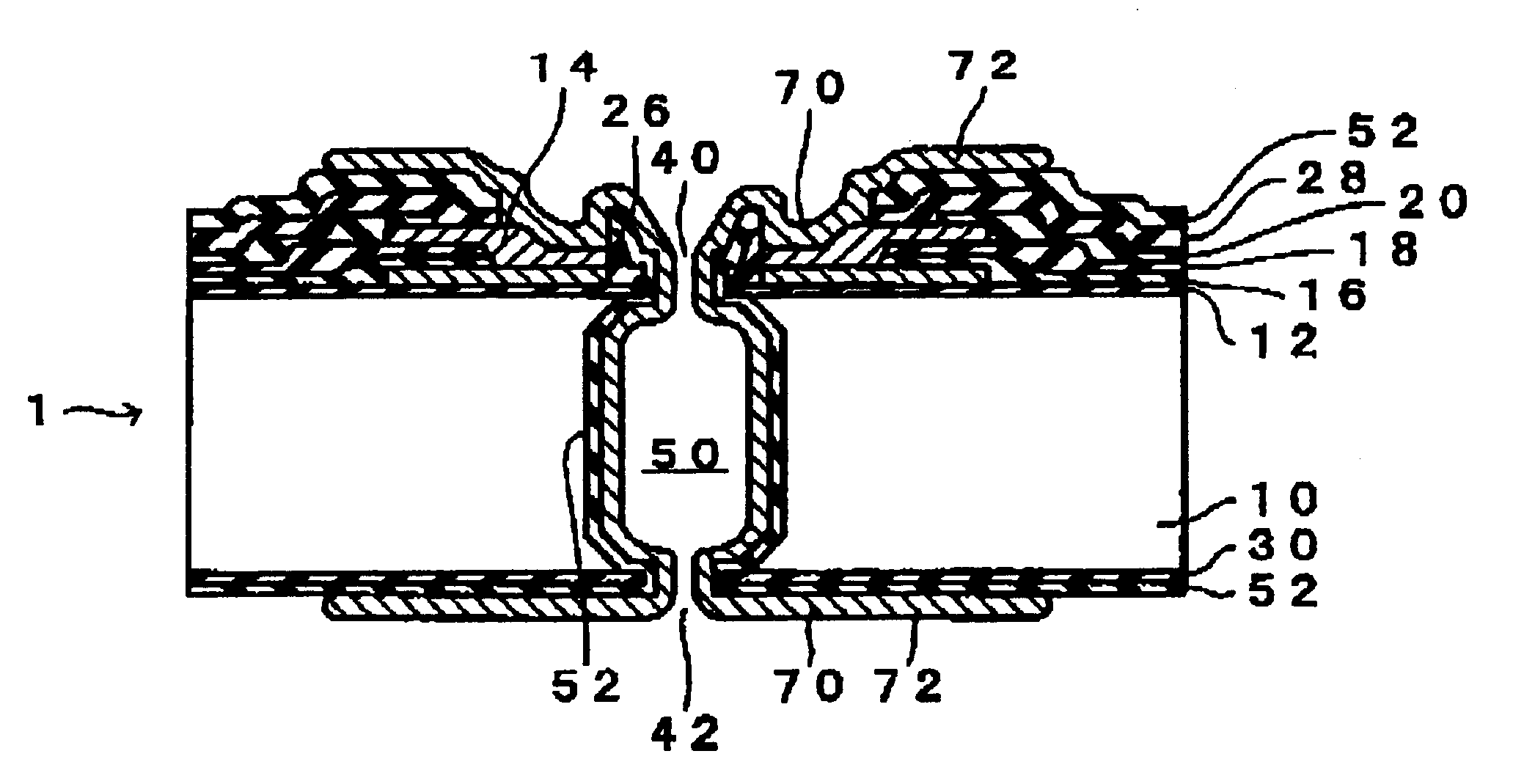

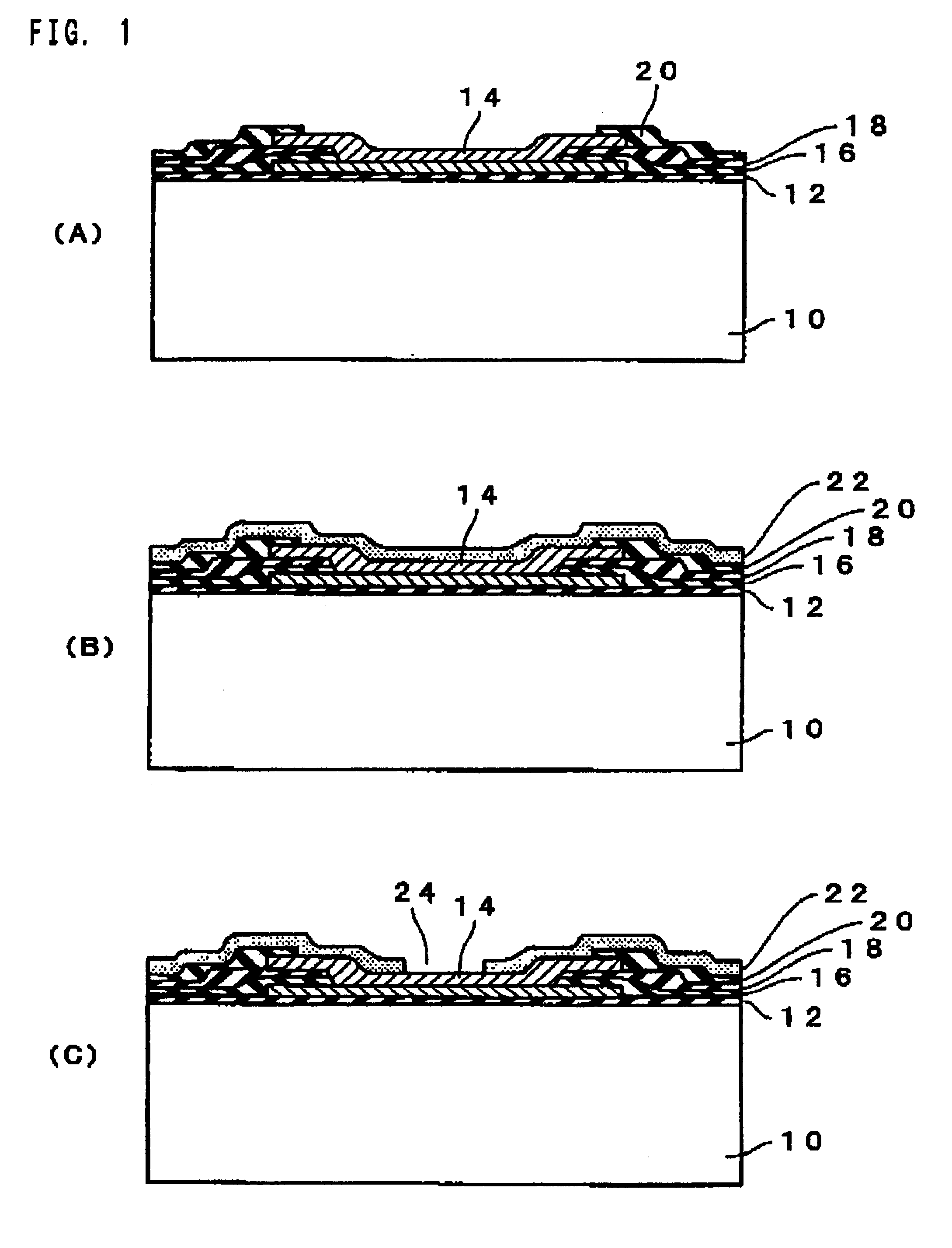

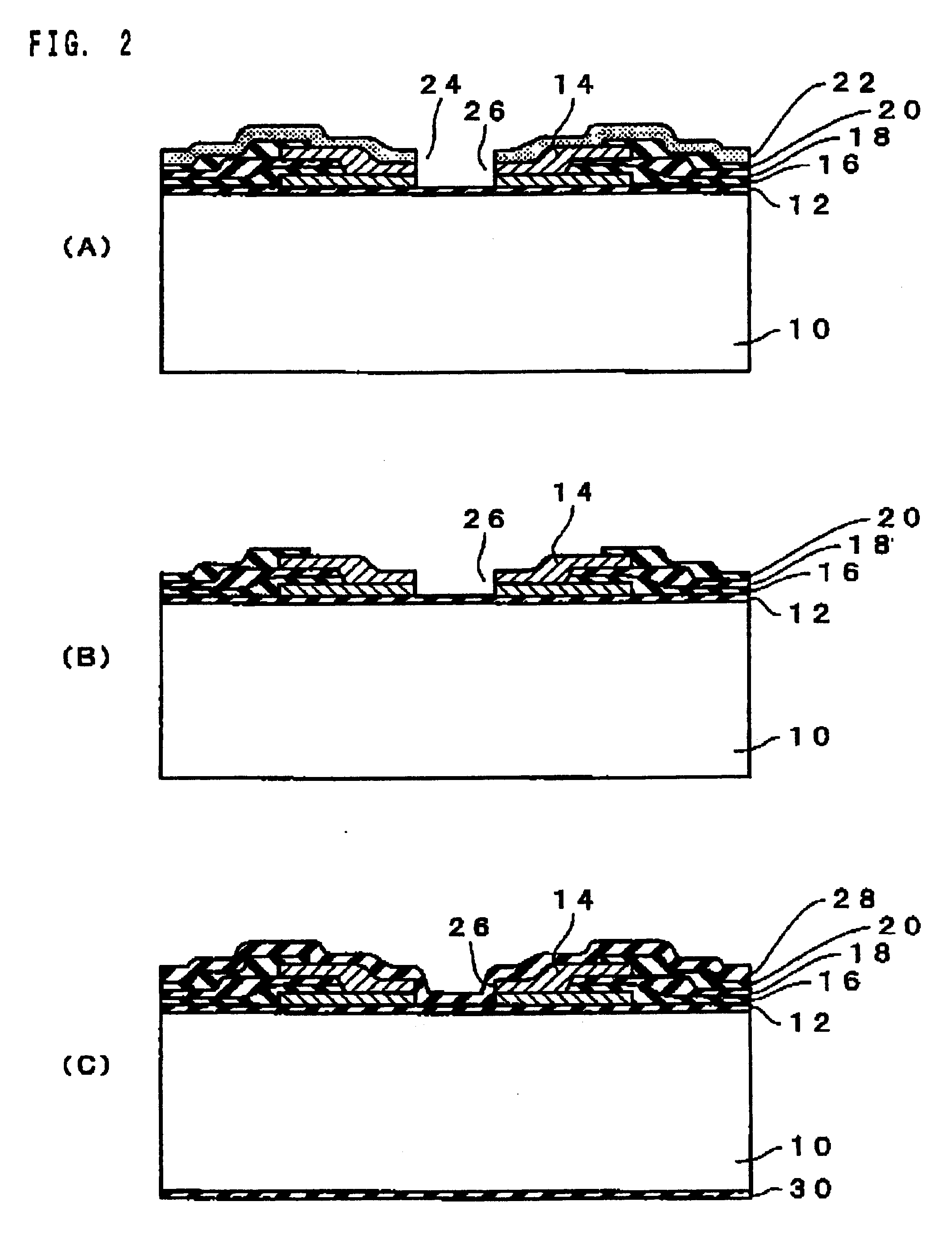

A semiconductor device and a manufacturing method therefor, a circuit substrate, and electronic apparatus are provided, in which electrical connection can be performed with high reliability and with ease. The manufacturing method for a semiconductor device includes the steps of forming a penetration hole 50 in a semiconductor chip 10 having an electrode 14, and forming a conductive layer 70 in the region including the inside of the penetration hole 50. Regarding the penetration hole 50, an intermediate portion is formed to be larger than an open end portion, and the conductive layer 70 is formed by applying a coating of a liquid containing metal fine particles by an ink-jet method.

Owner:SAMSUNG ELECTRONICS CO LTD

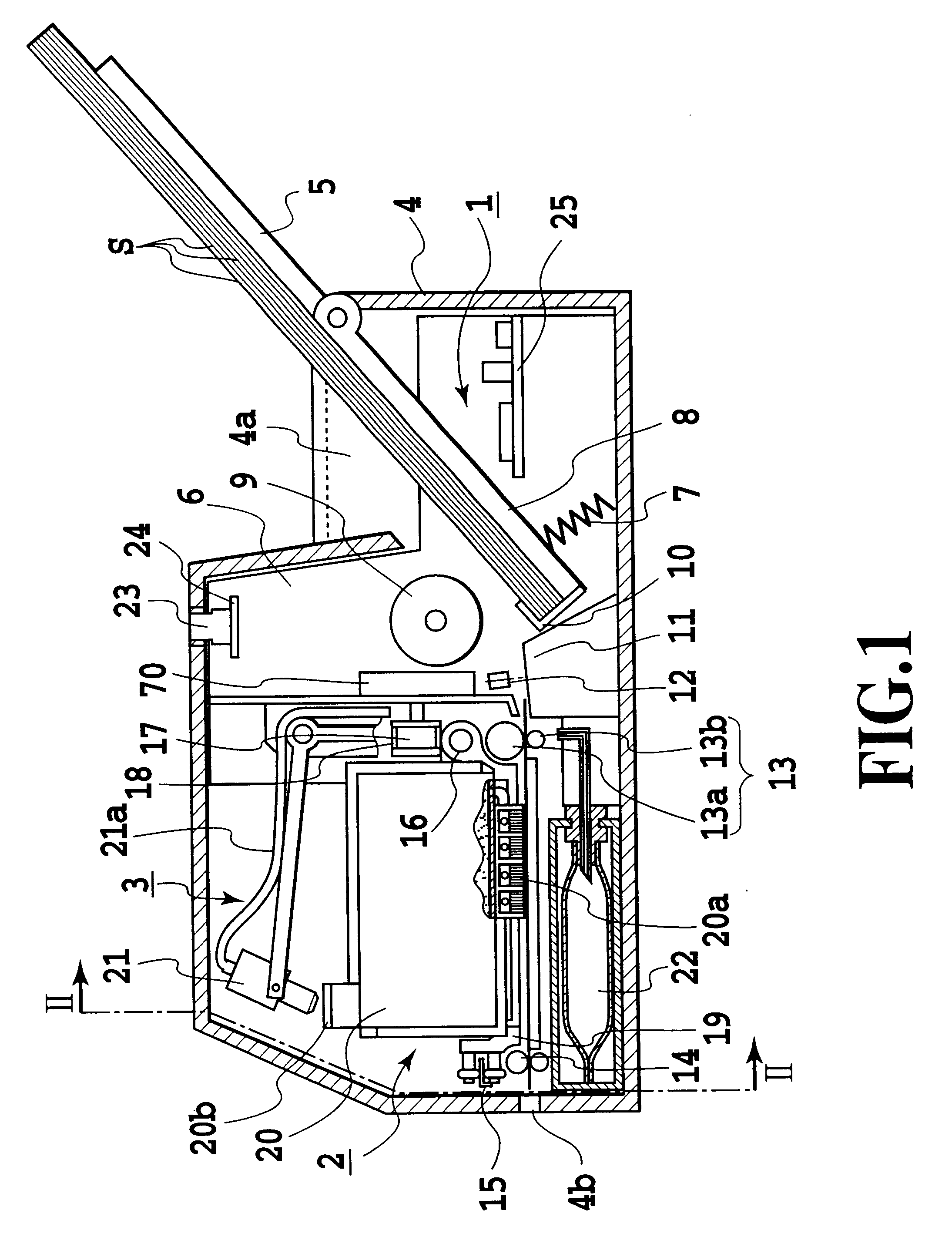

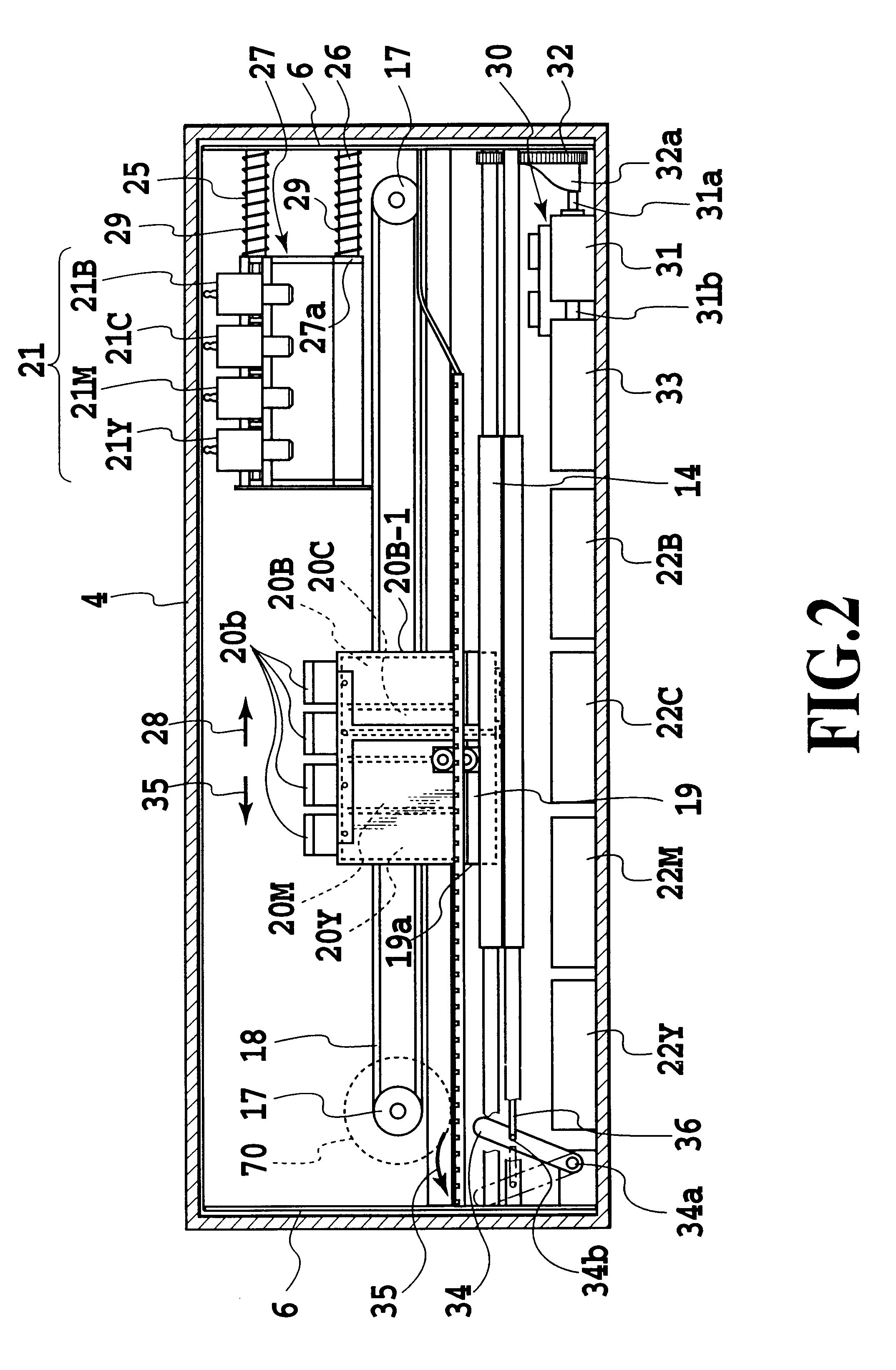

Ink tank, ink-jet cartridge, ink-supplying apparatus, ink-jet printing apparatus and method for supplying ink

Owner:CANON KK

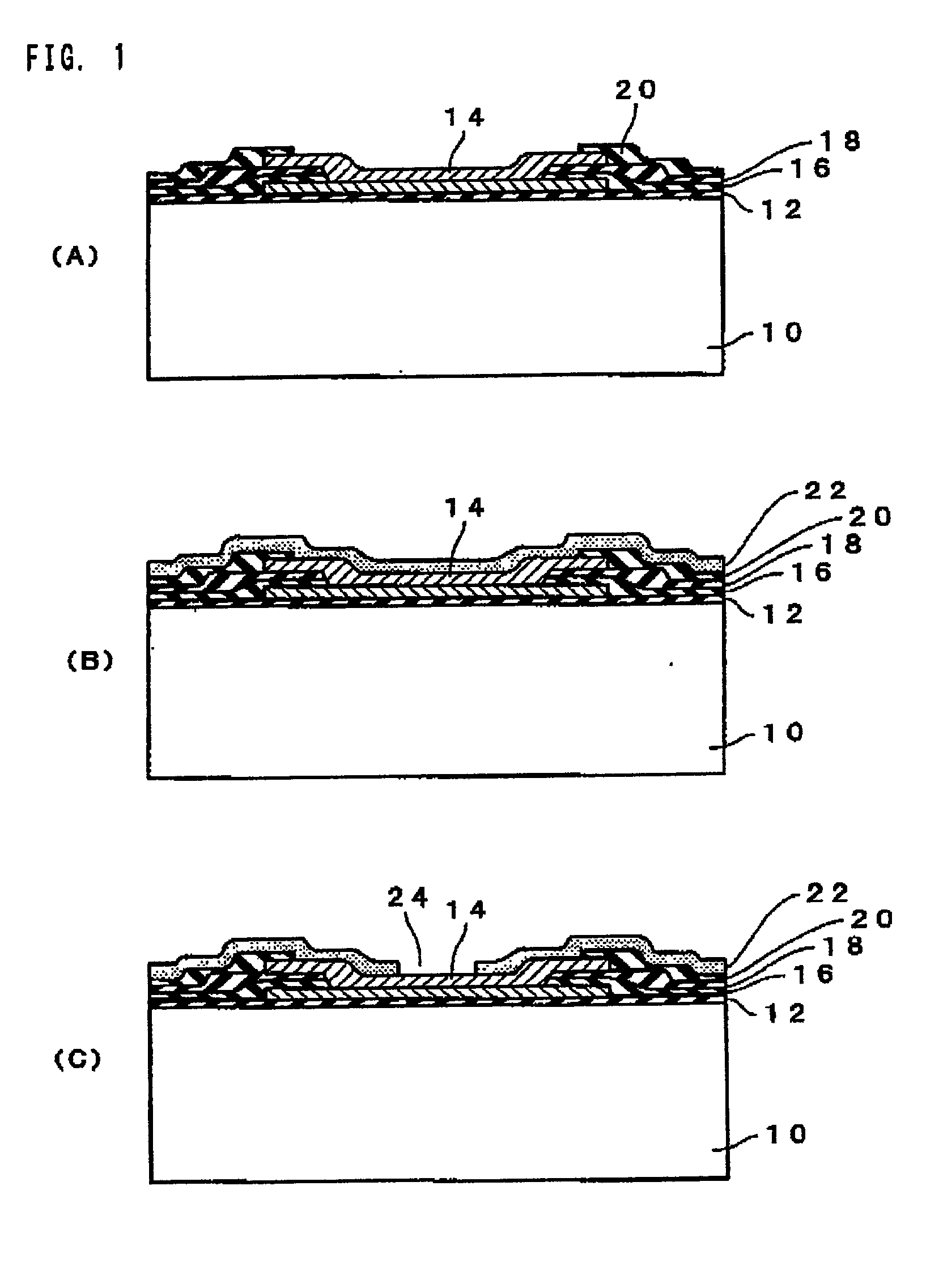

Insulated-gate field-effect transistor, method of fabricating same, and semiconductor device employing same

InactiveUS6936875B2Improve mobilityShorten the lengthTransistorSolid-state devicesDevice materialField-effect transistor

With the invention, it is possible to avoid deterioration in short-channel characteristics, caused by a silicon germanium layer coming into contact with the channel of a strained SOI transistor. Further, it is possible to fabricate a double-gate type of strained SOI transistor or to implement mixedly mounting the strained SOI transistor and a conventional silicon or SOI transistor on the same wafer. According to the invention, for example, a strained silicon layer is grown on a strain-relaxed silicon germanium layer, and subsequently, portions of the silicon germanium layer are removed, thereby constituting a channel layer in the strained silicon layer.

Owner:RENESAS ELECTRONICS CORP

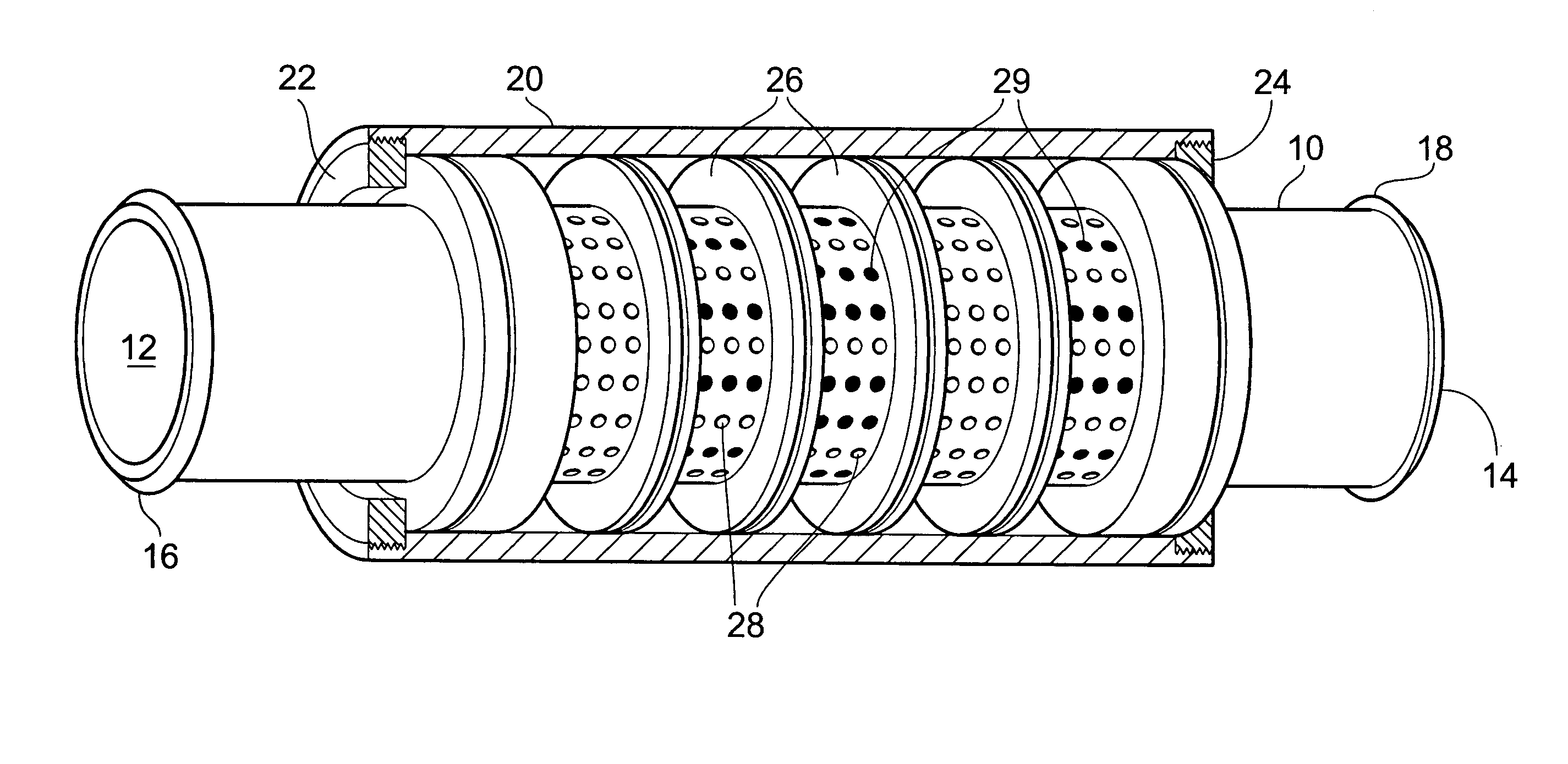

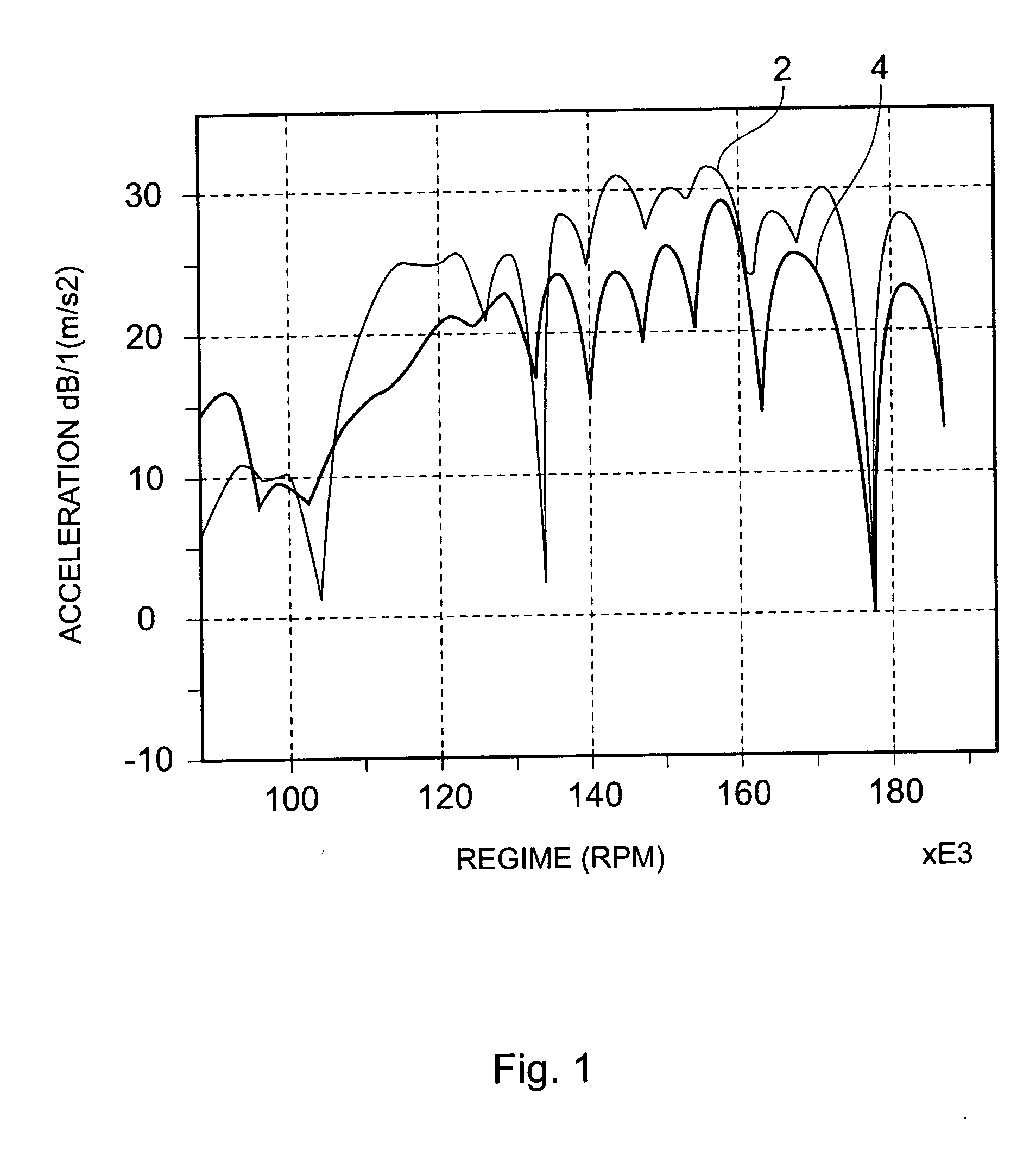

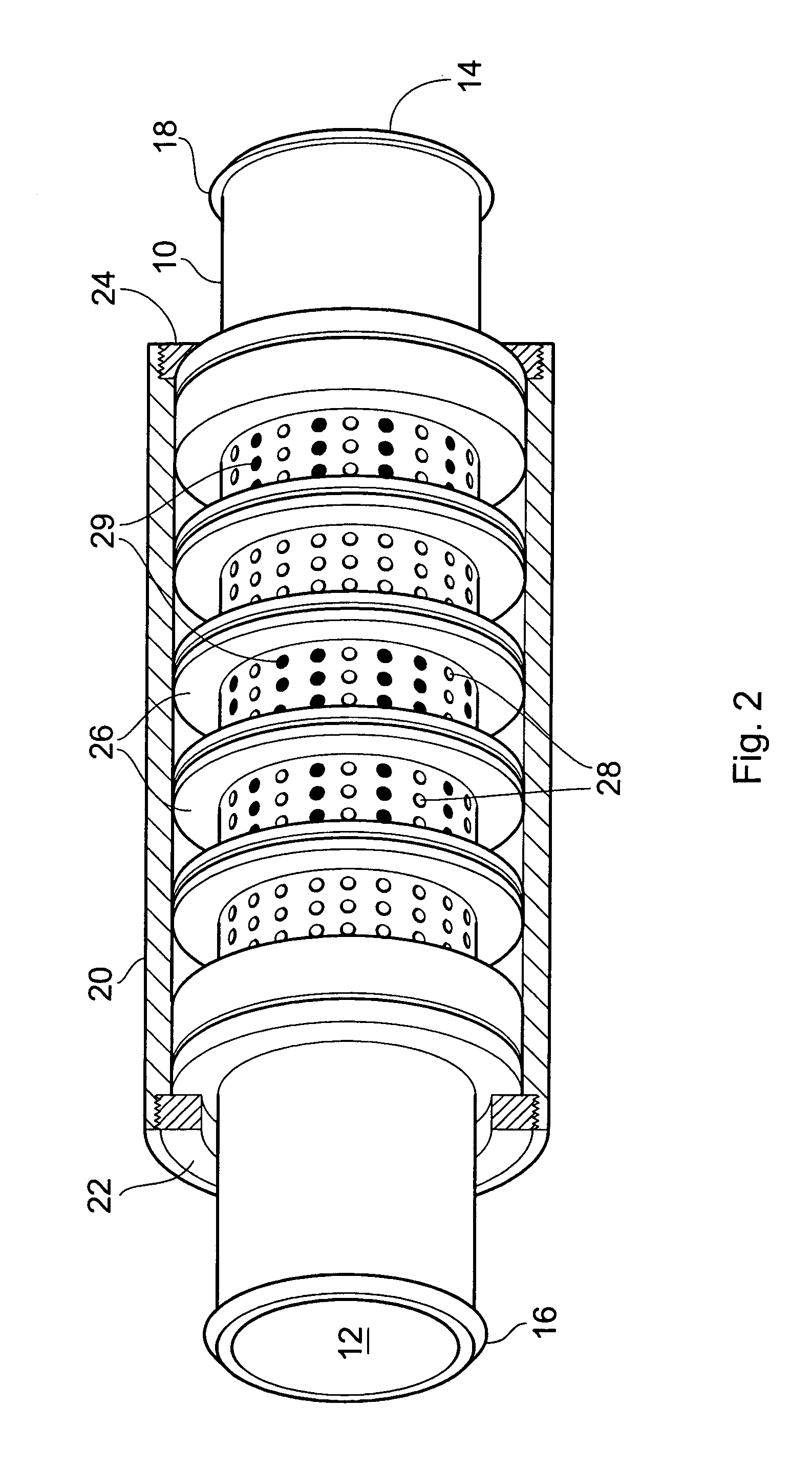

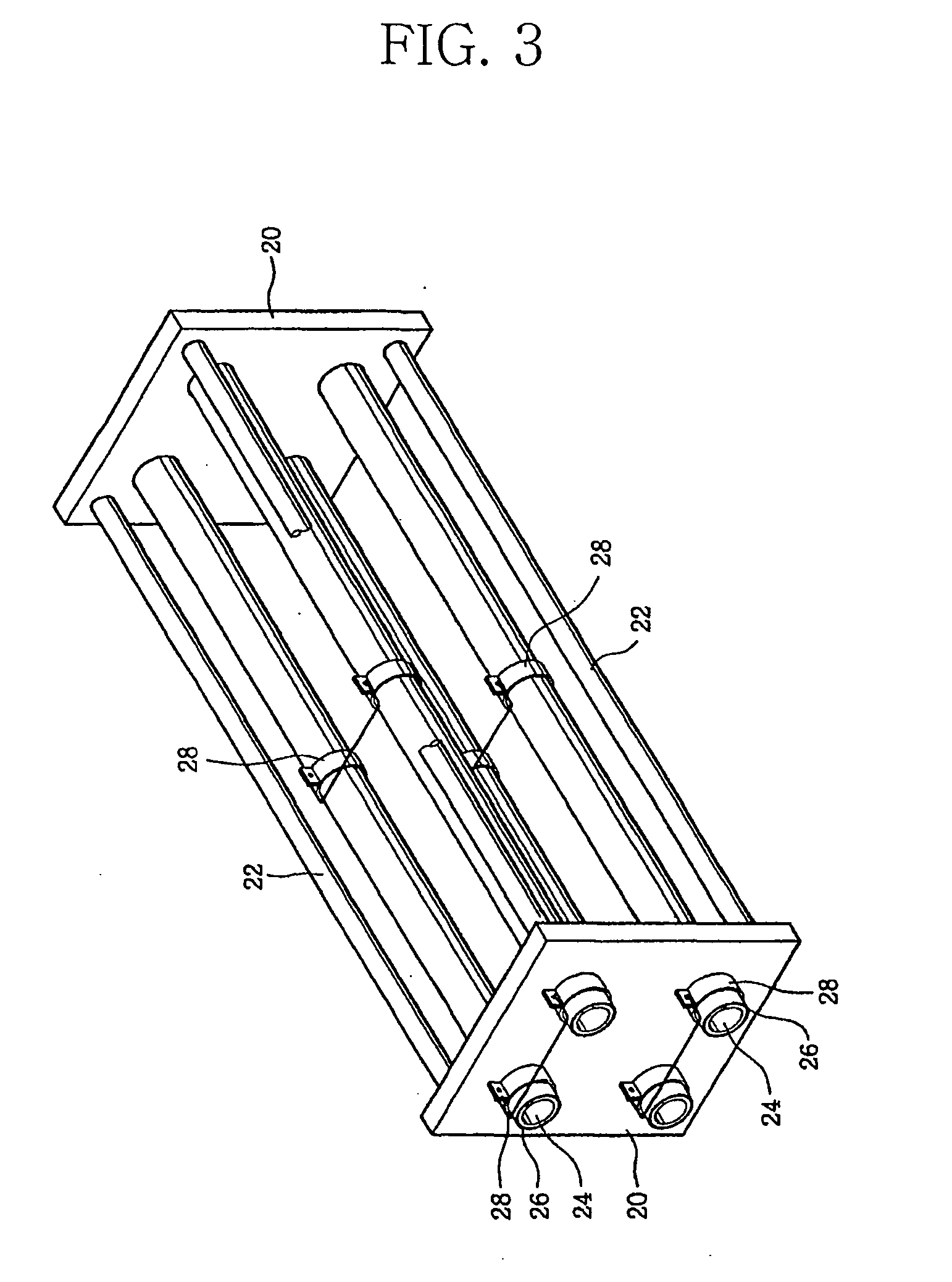

Noise and vibration suppressors

InactiveUS6983820B2Increase dampingSuppress noisePositive displacement pump componentsSilencing apparatusSuppressorModularity

In order to form a noise suppressor in a hose of e.g. a motor vehicle, modular portions are connected in series to define suppression chambers with particular noise suppression characteristics. Those characteristics are due to the volume of each chamber, to the size of the apertures from the chambers to the central duct of the suppressor, and optionally due to spacers which are inserted into at least one aperture of the chambers to alter the effective open area of that aperture. Such spacers may also be used in which the noise suppressor is not modular. Where modular portions are used, it is preferable that each chamber is bounded by parts of two modular portions. A wall of one modular portion may then close the chamber in another modular portion, making the manufacture of the modular portions easier. Also disclosed is the use of a mass acting as a damper, which may be a noise suppressor as previously discussed, within a hose. The mass is connected to the hose by resilient means, e.g. electrometric material.

Owner:CADILLAC RUBBER & PLASTICS

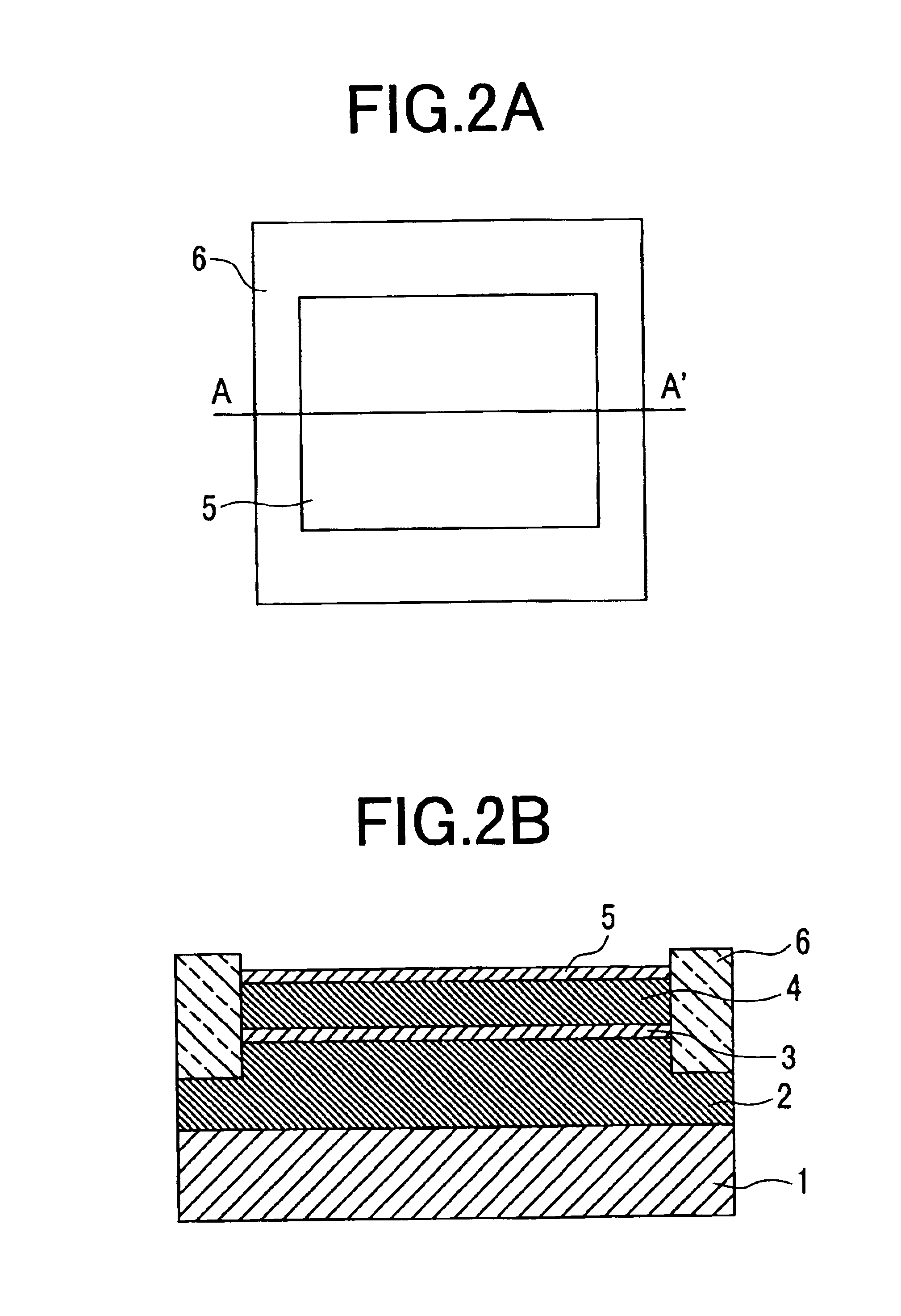

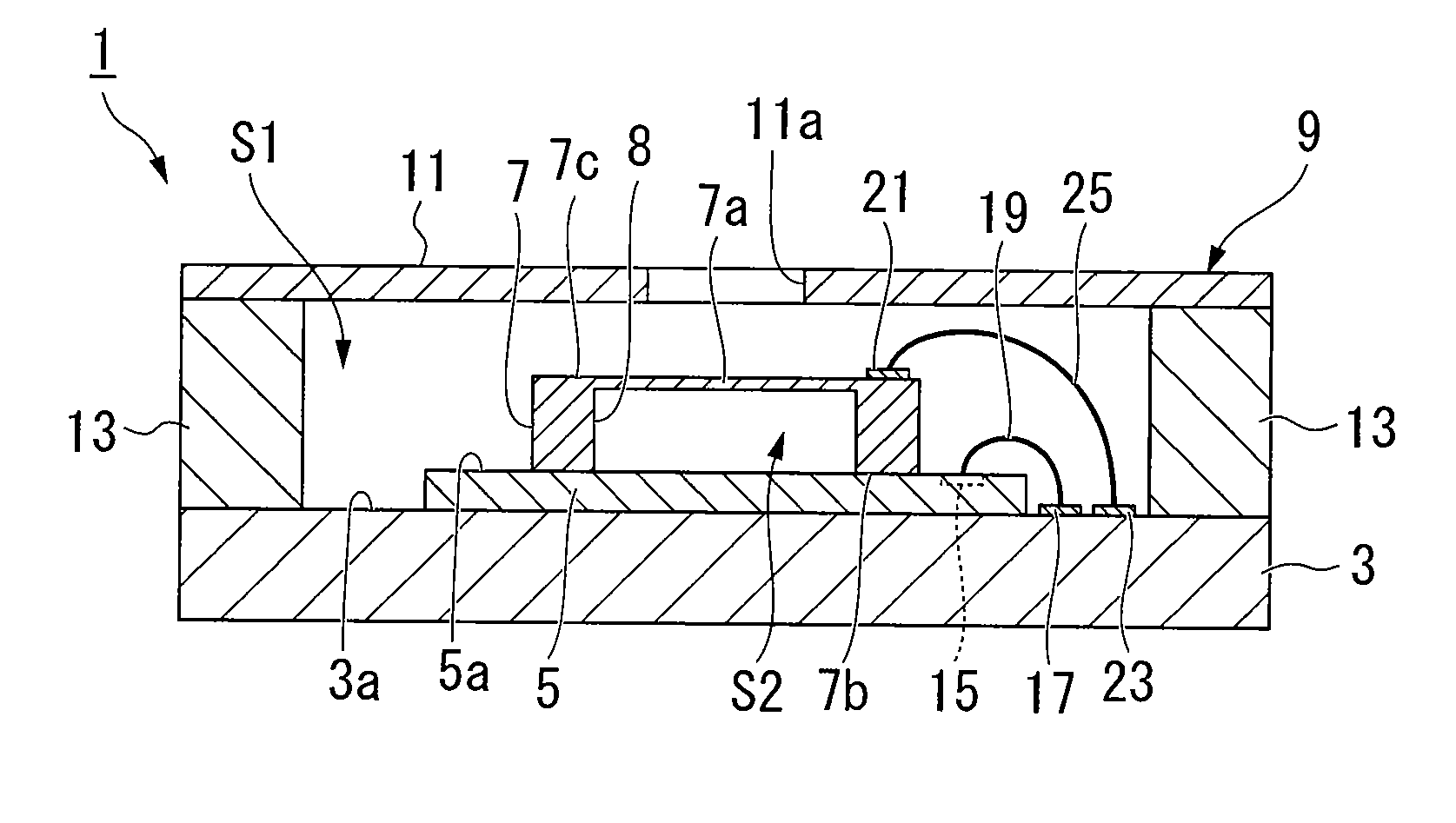

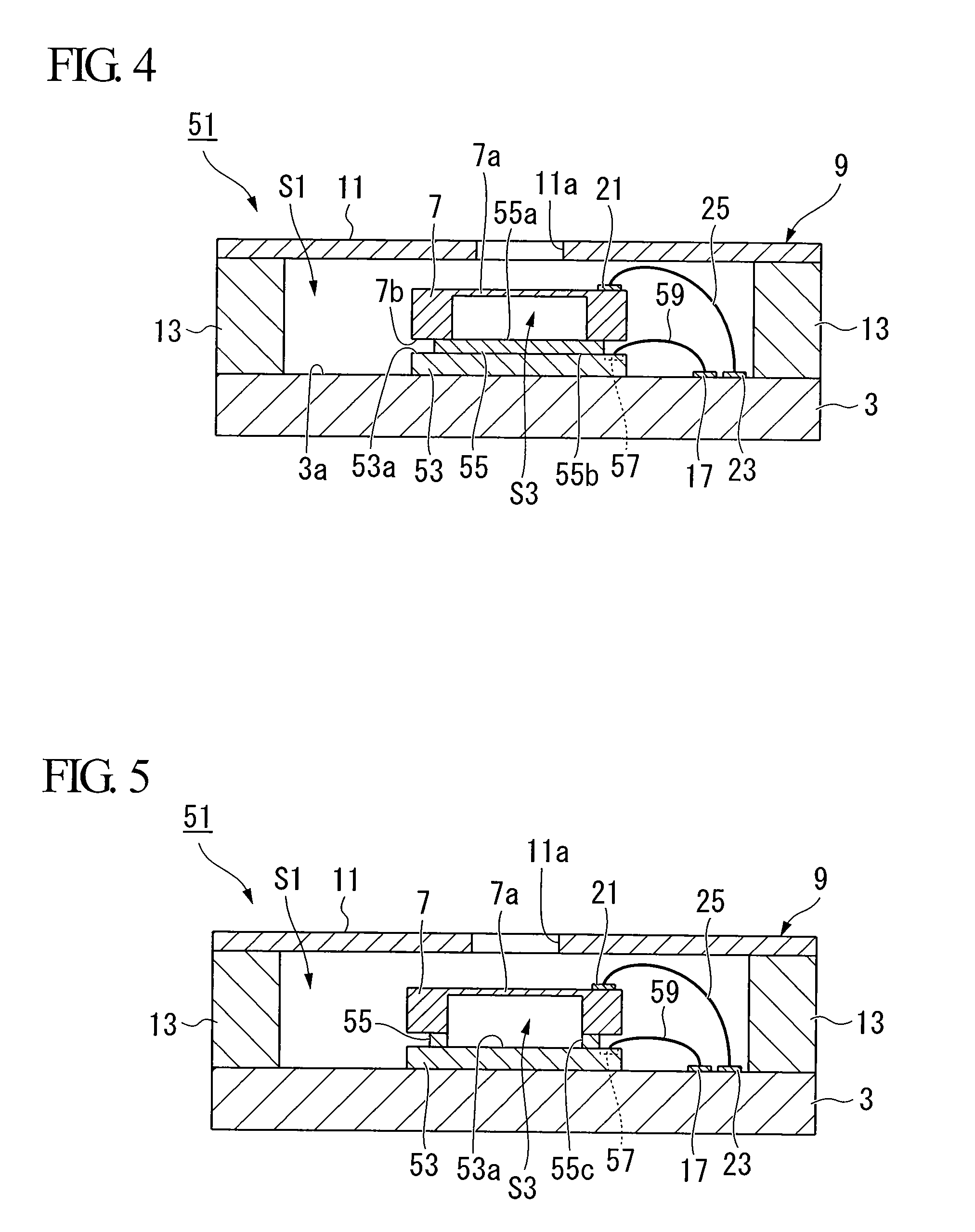

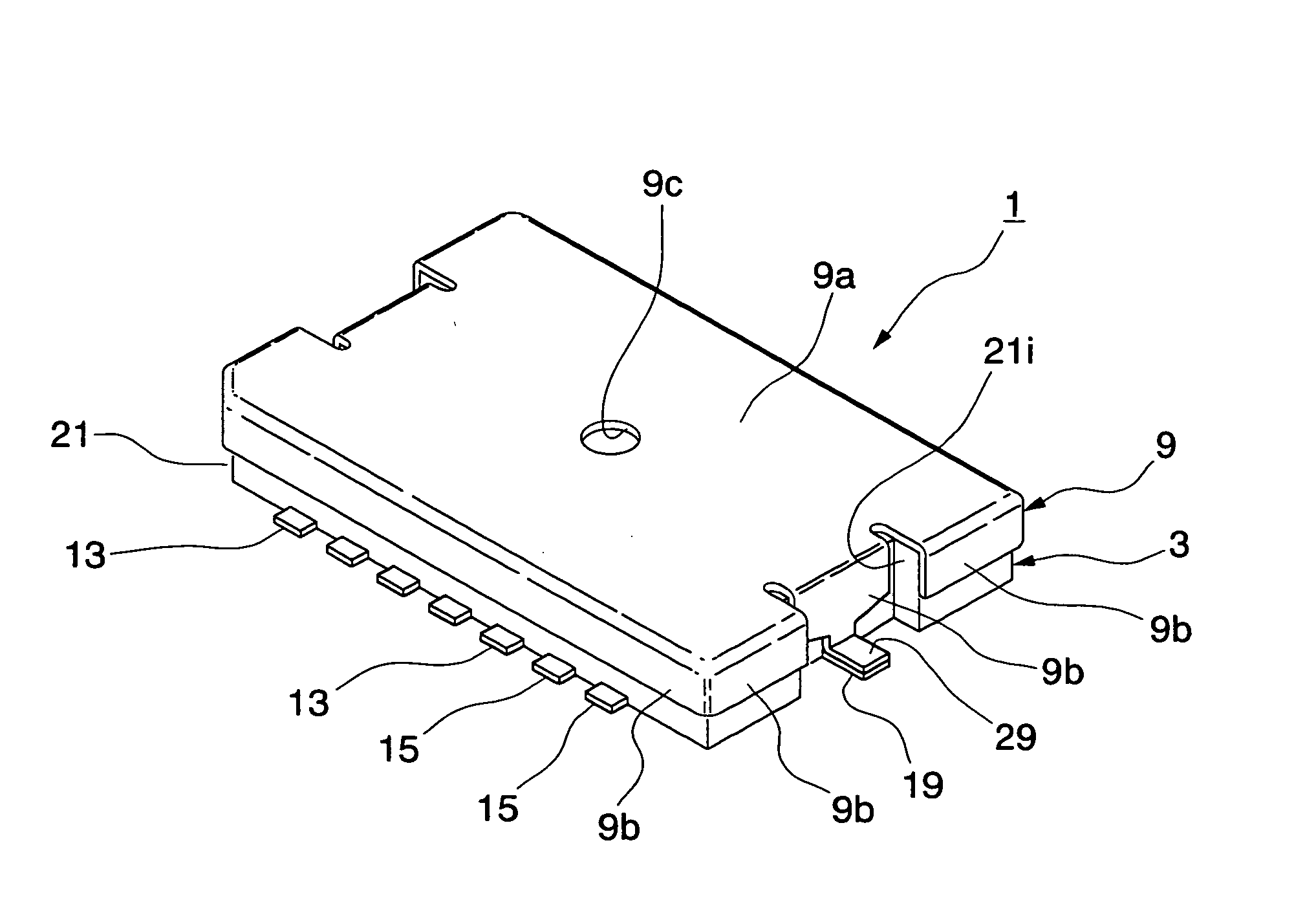

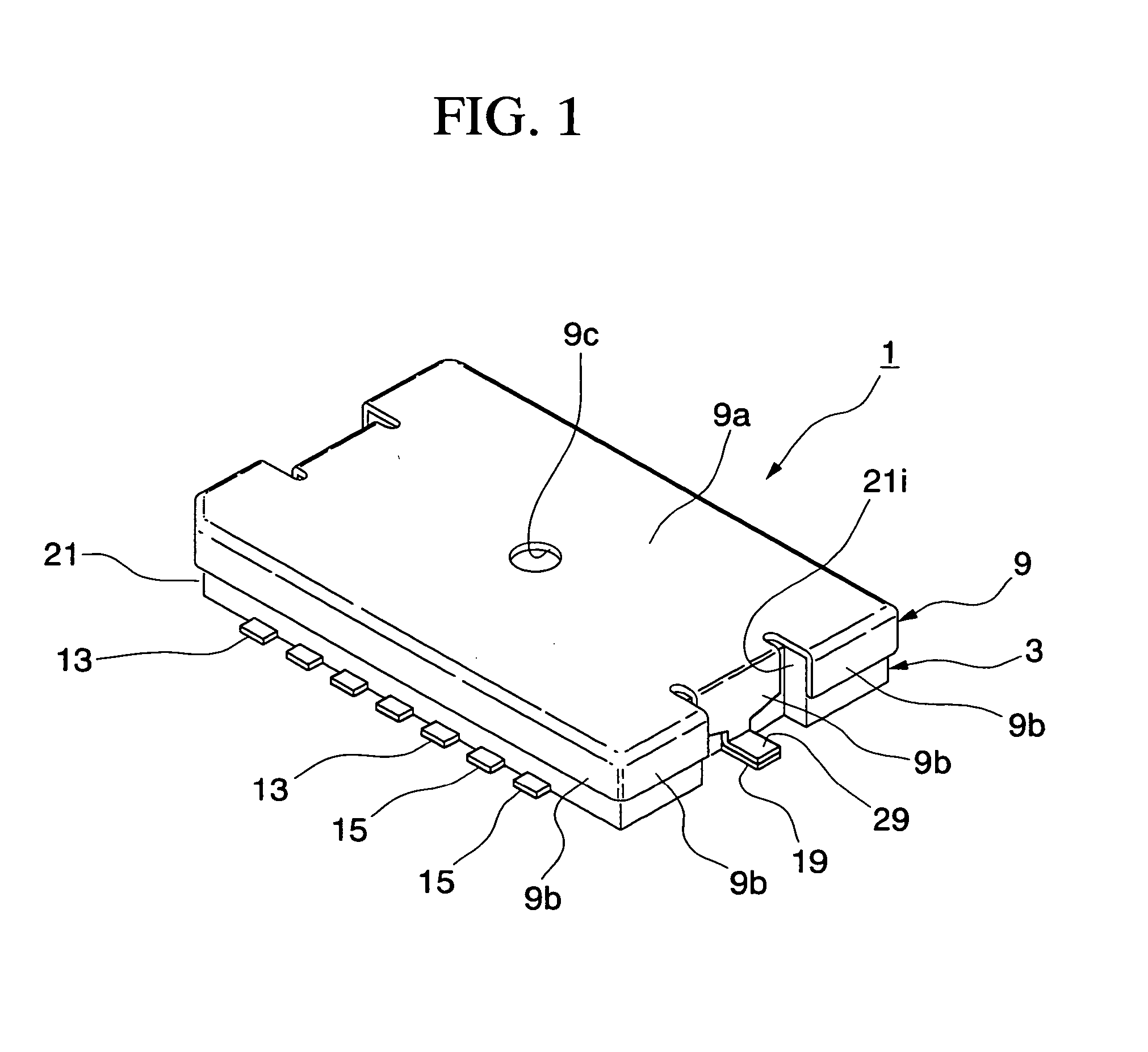

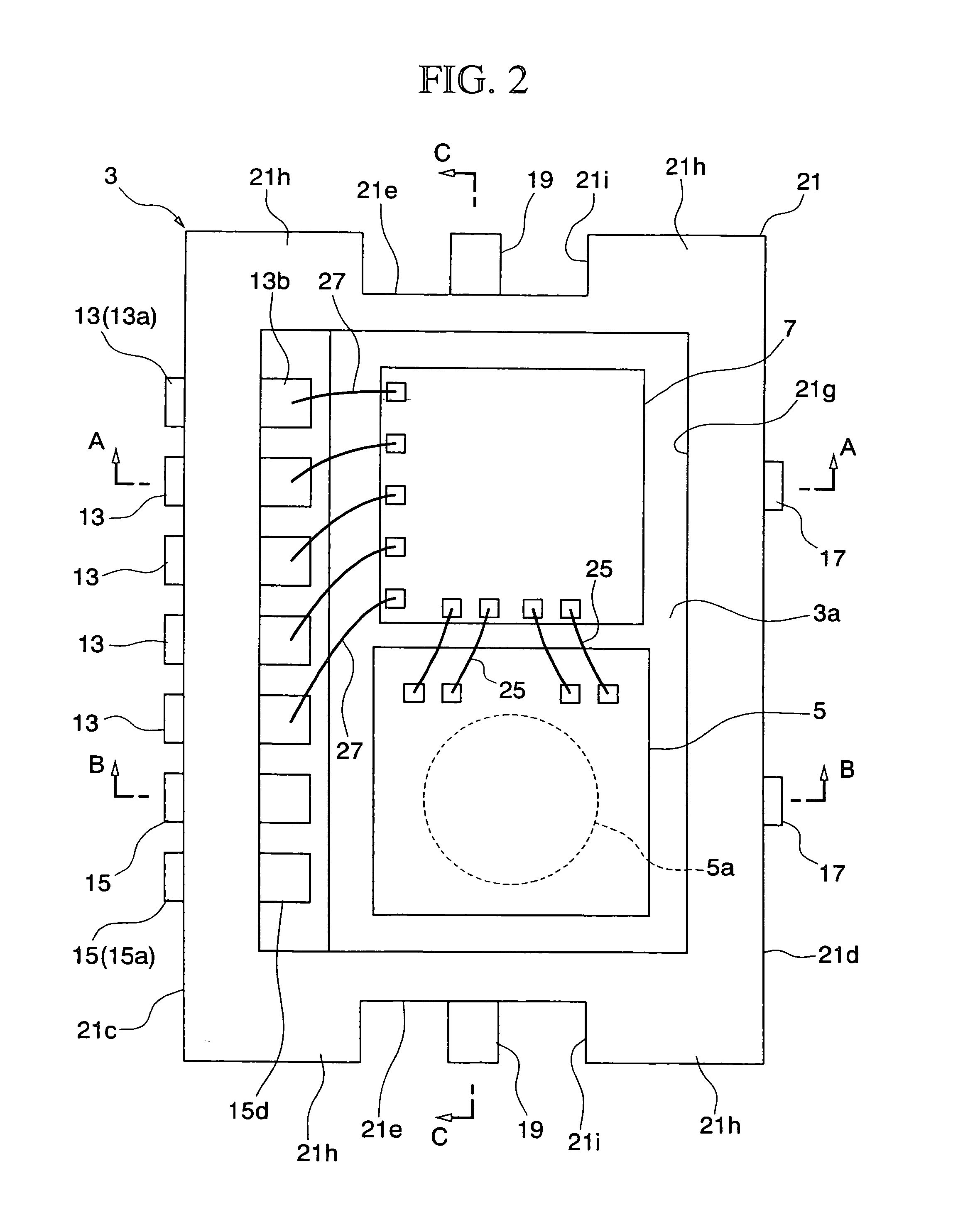

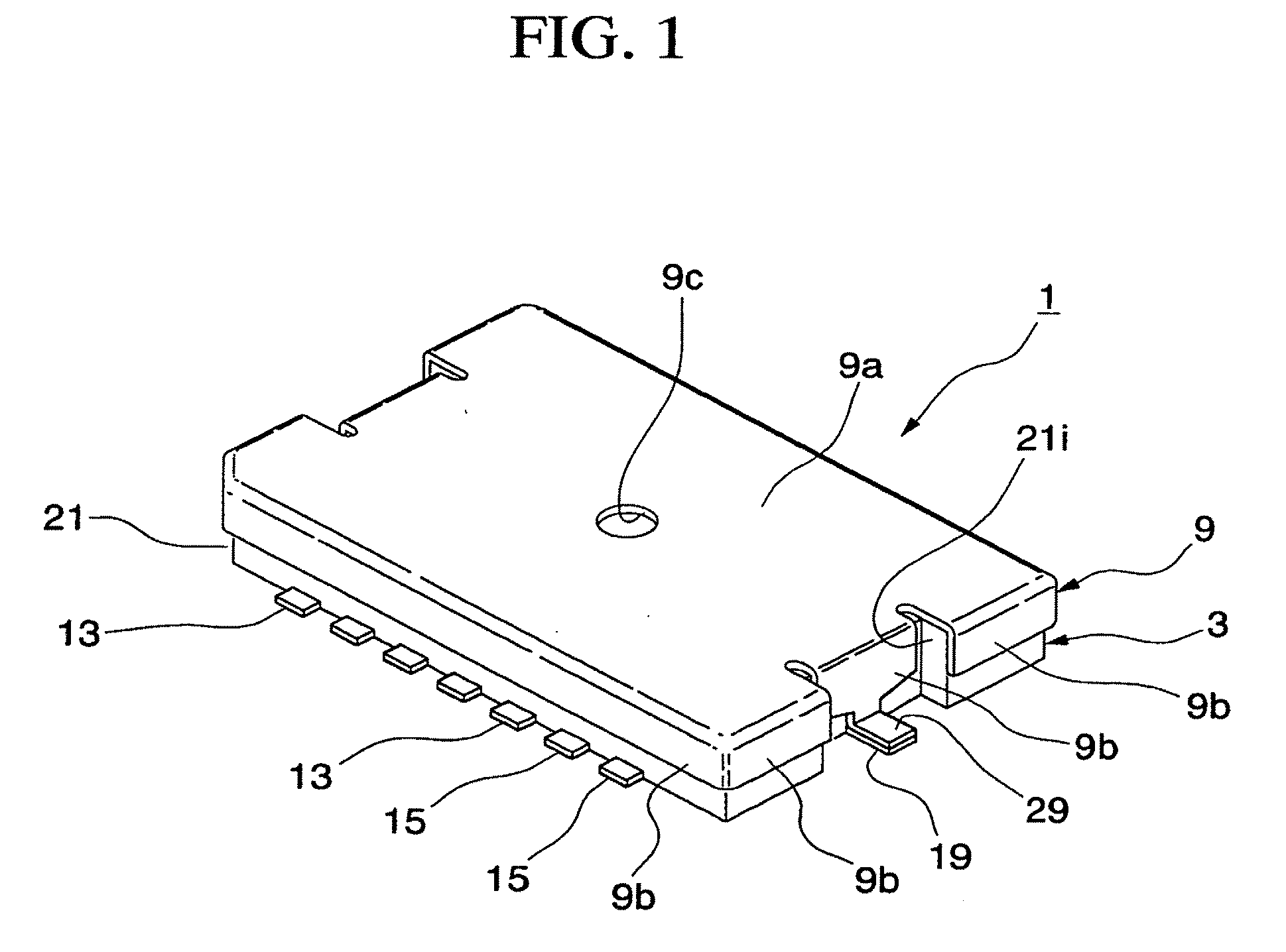

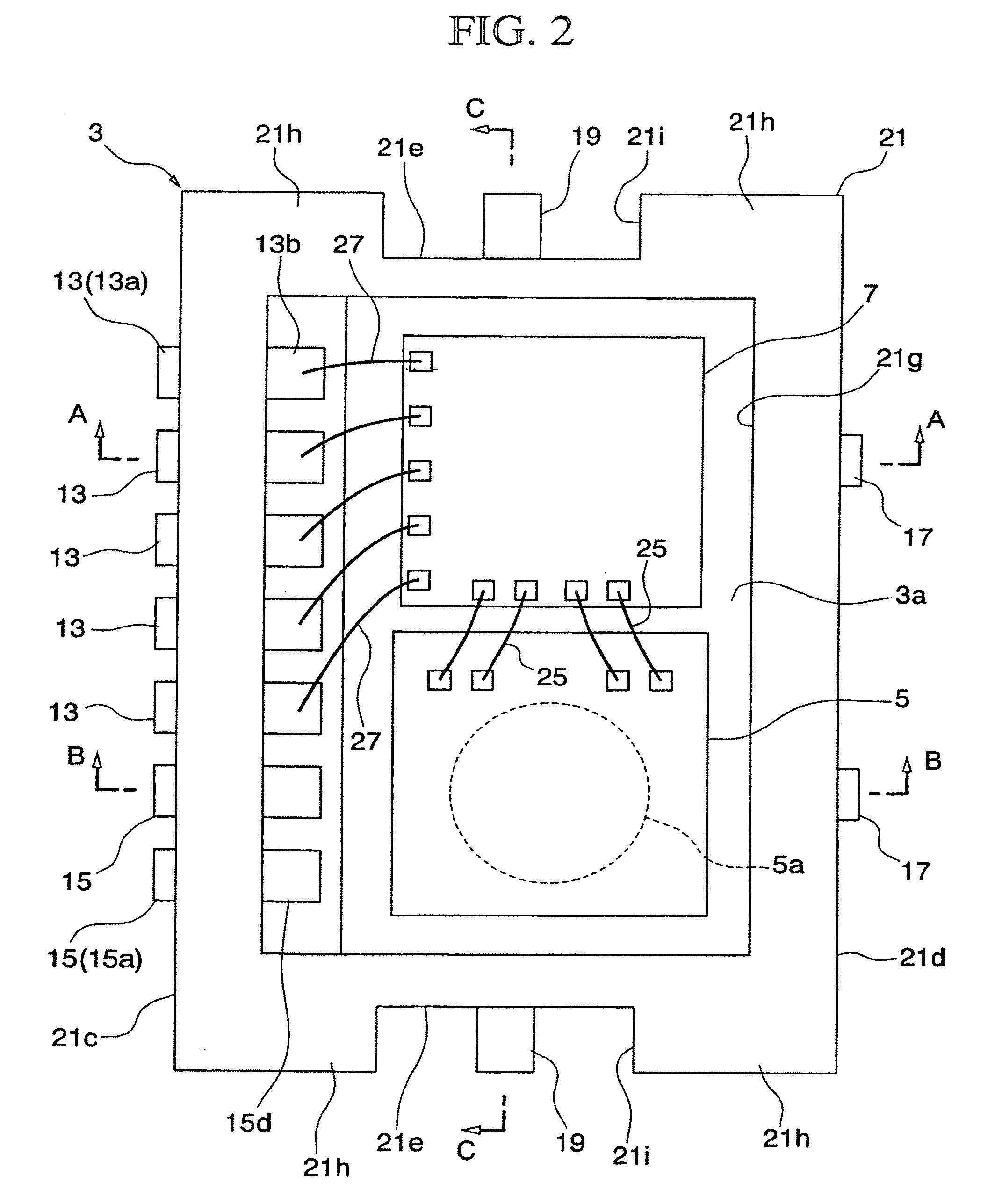

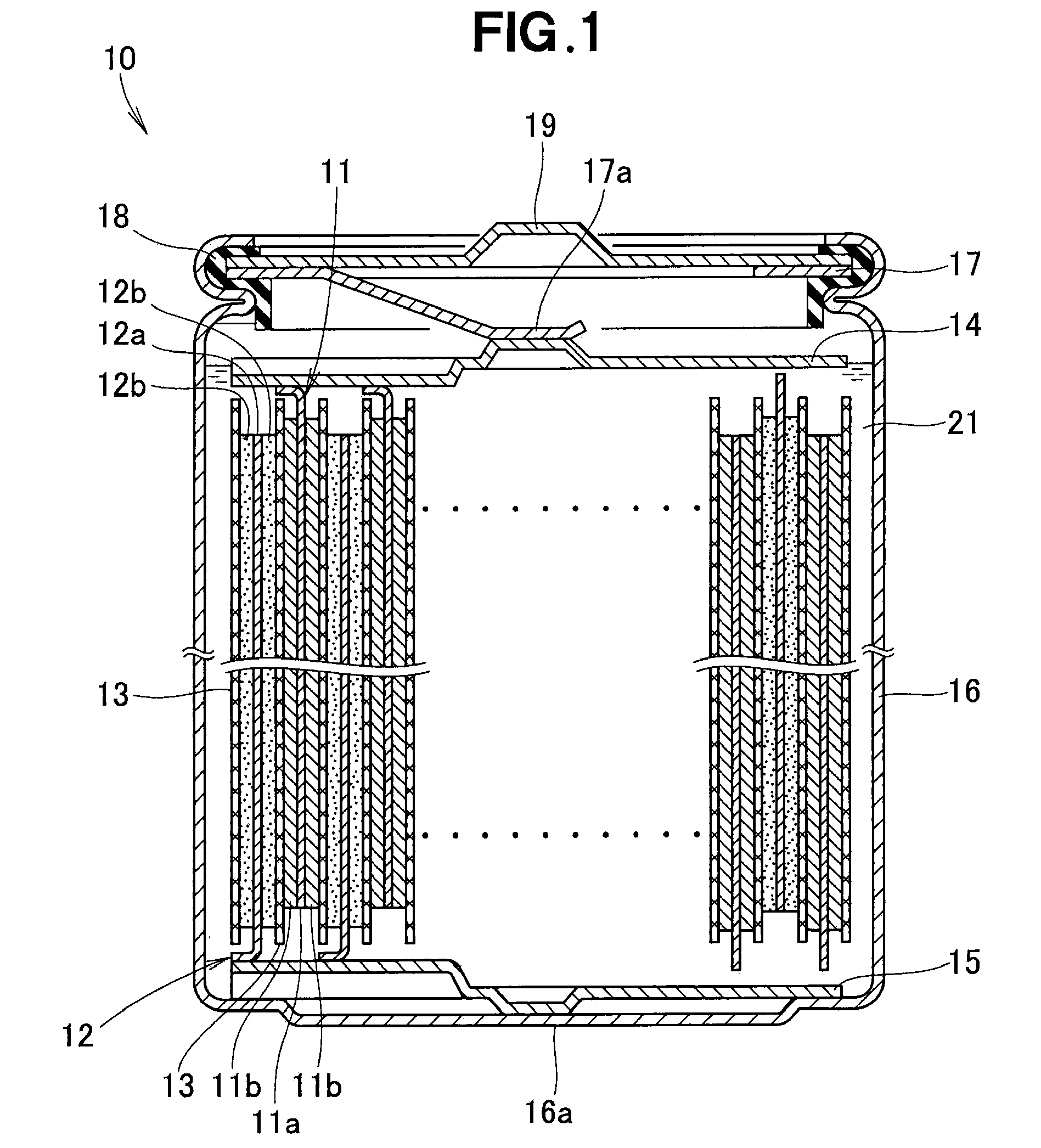

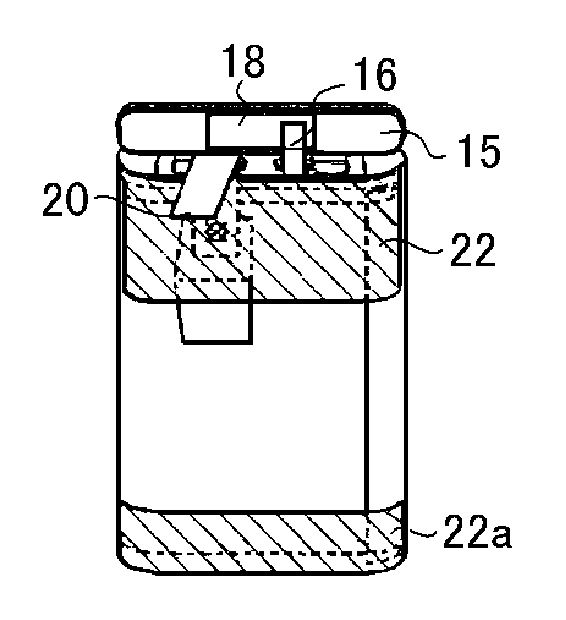

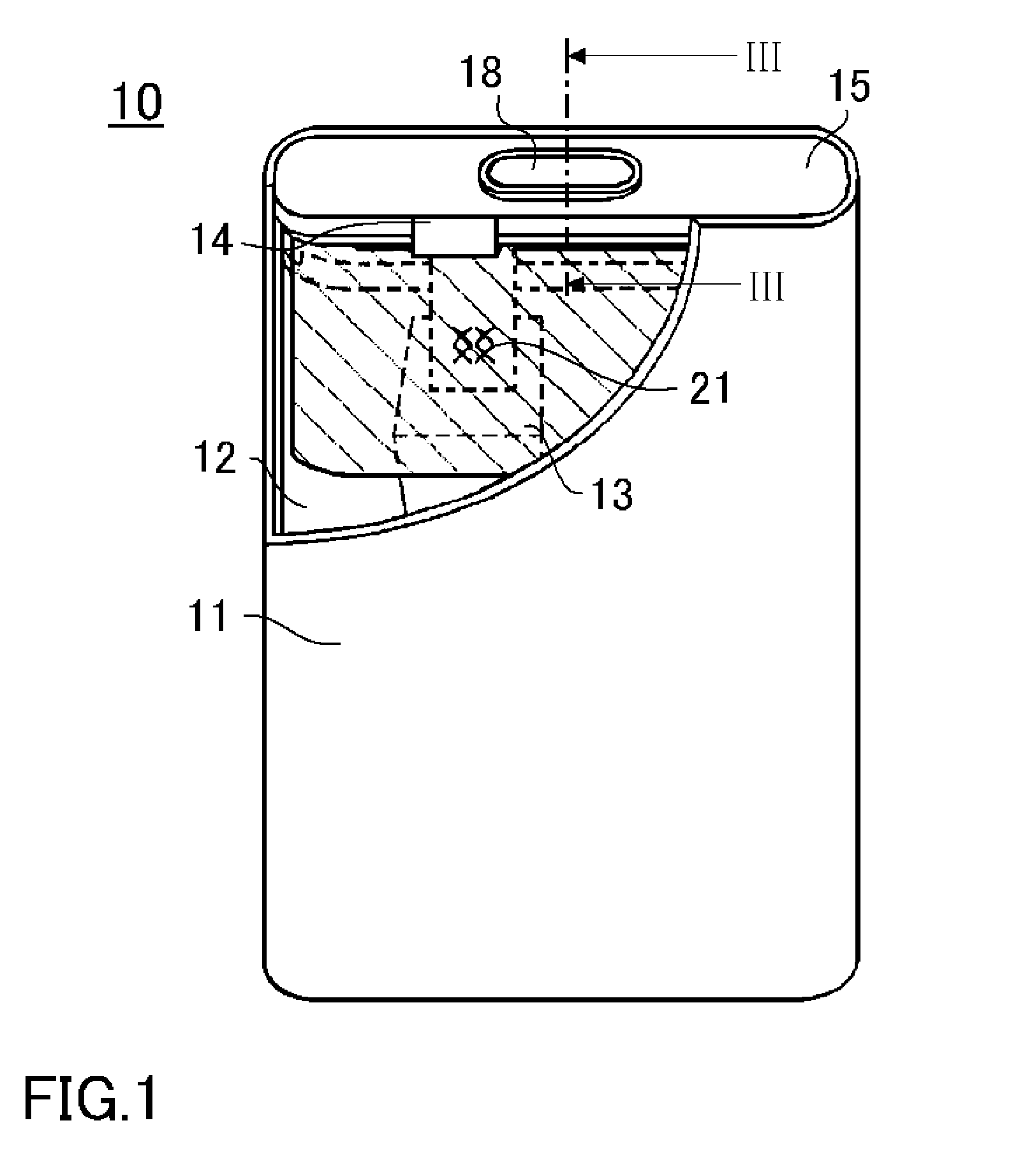

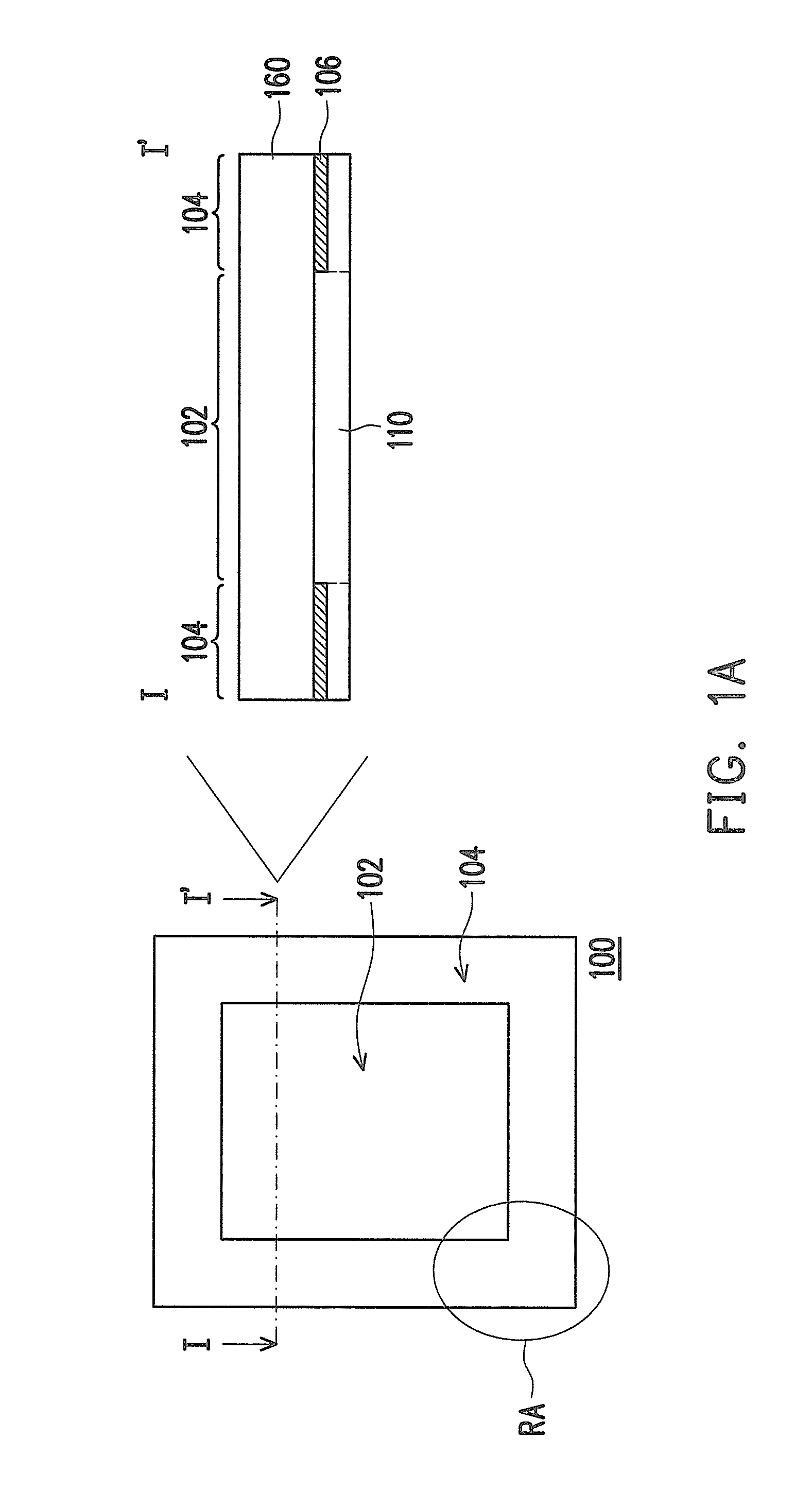

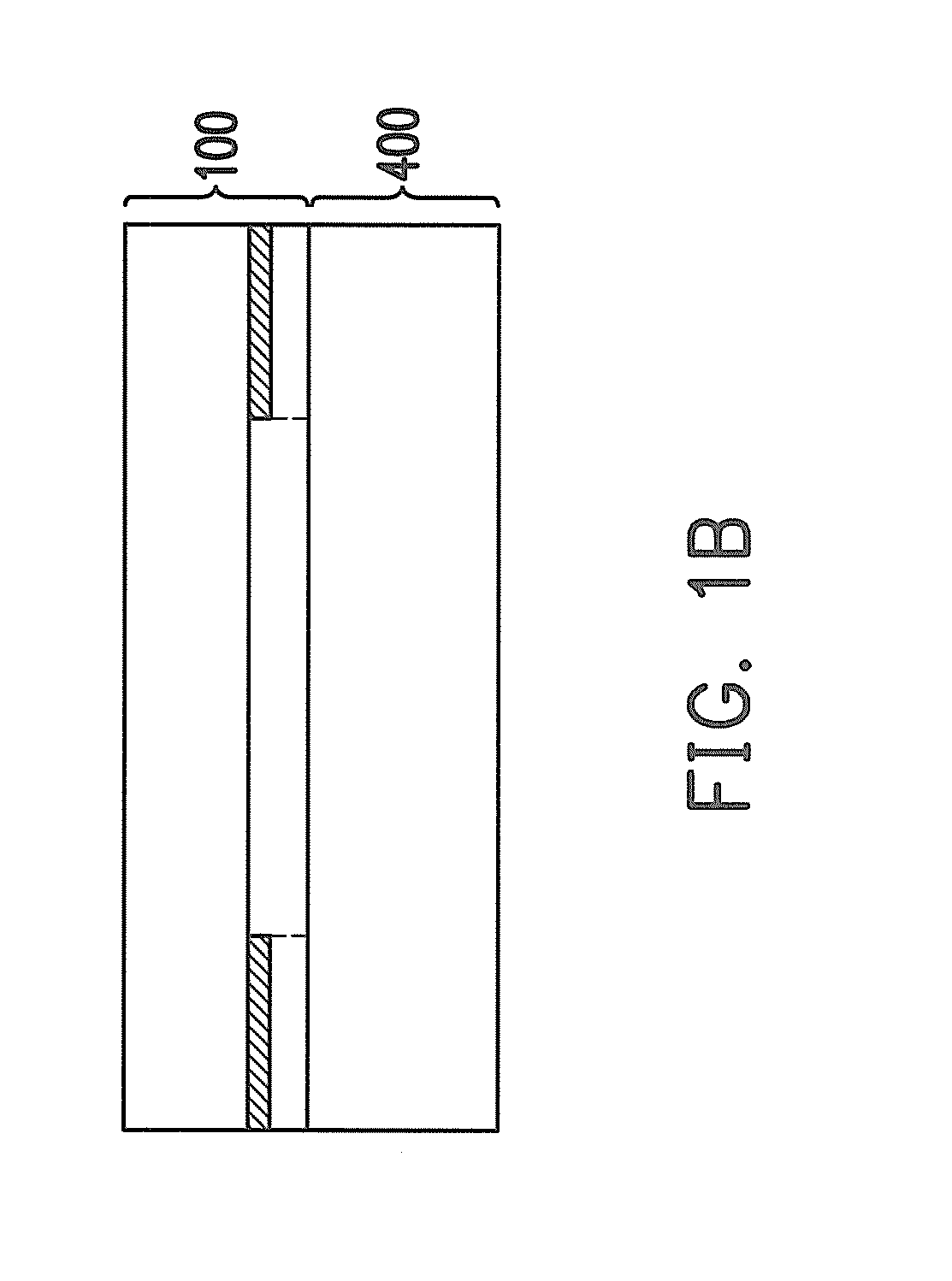

Semiconductor device

InactiveUS20070158826A1Reduced easeFormed with easeMicrophonesLoudspeakersDevice materialSemiconductor chip

A semiconductor device includes a substrate, a semiconductor chip having a diaphragm, which vibrates in response to sound pressure variations, and a circuit chip that is electrically connected to the semiconductor chip so as to control the semiconductor chip, wherein the semiconductor chip is fixed to the surface of the circuit chip whose backside is mounted on the surface of the substrate. Herein, a plurality of connection terminals formed on the backside of the semiconductor chip are electrically connected to a plurality of electrodes running through the circuit chip. A ring-shaped resin sheet is inserted between the semiconductor chip and the circuit chip. The semiconductor chip and the circuit chip vertically joined together are stored in a shield case having a mount member (e.g., a stage) and a cover member, wherein connection terminals of the circuit chip are exposed to the exterior via through holes of the stage.

Owner:YAMAHA CORP

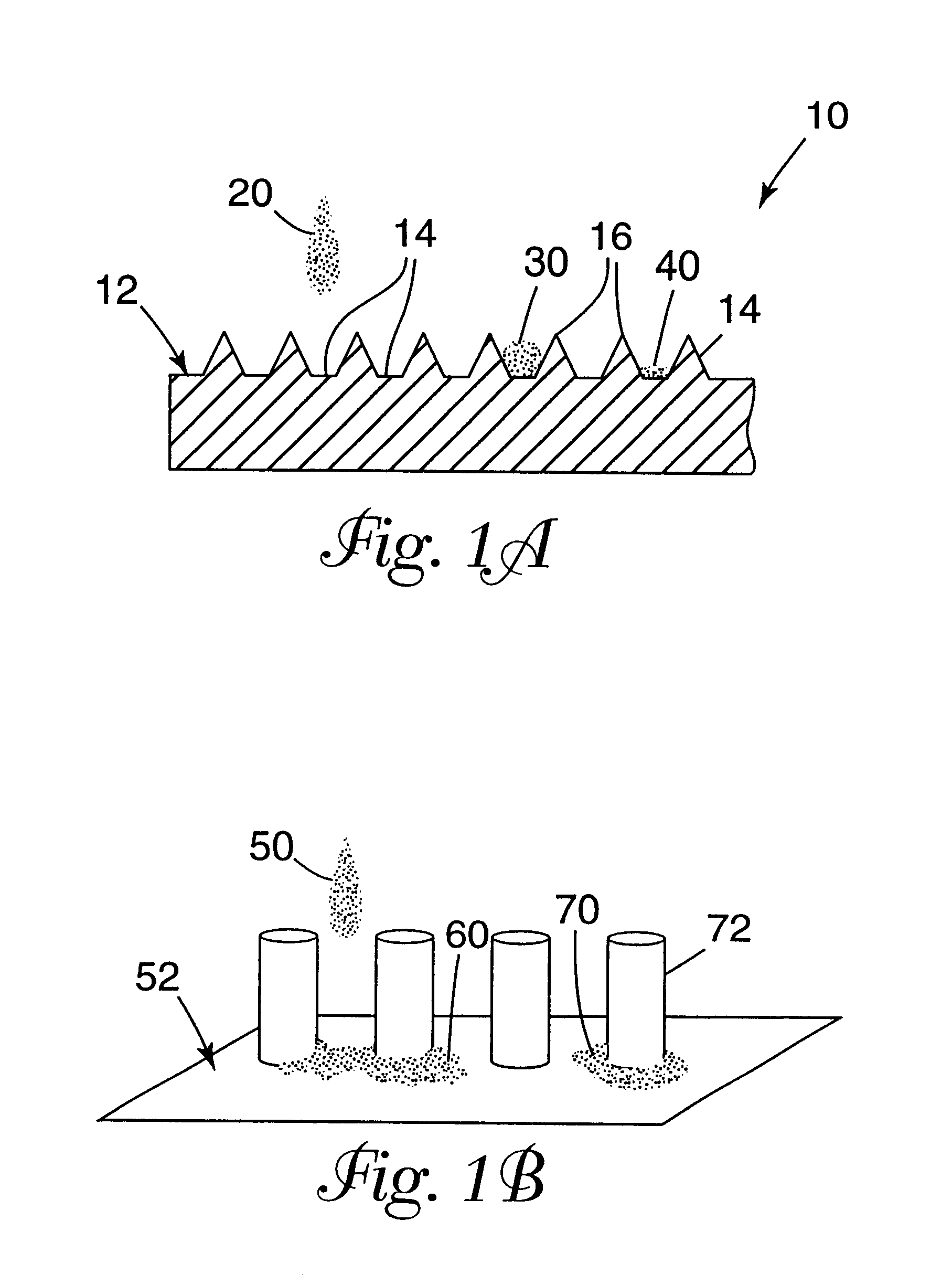

Random microembossed receptor media

InactiveUS6649249B1Form with easePrevention of feathering and bleedingAdditive manufacturing apparatusDecorative surface effectsWaxBiological fluid

A receptor medium with a sheet having a random microembossed imaging surface as one major surface thereof. The receptor medium can receive jettable materials, which include inks, adhesives, biological fluids, chemical assay reagents, particulate dispersions, waxes, electrically, thermally, or magnetically modifiable materials, and combinations thereof. The random microembossed medium unexpectedly solves such common inkjet printing problems as feathering, banding, and mudcracking in inkjet printing systems by controlling how an inkjet drop contacts and dries on an inkjet receptor medium and also Moire' effects. Clear lines of demarcation between adjoining colors of a pigmented inkjet image graphic can be obtained without creation of the Moire' effects. Methods of making and using the inkjet receptor medium are also disclosed.

Owner:3M INNOVATIVE PROPERTIES CO

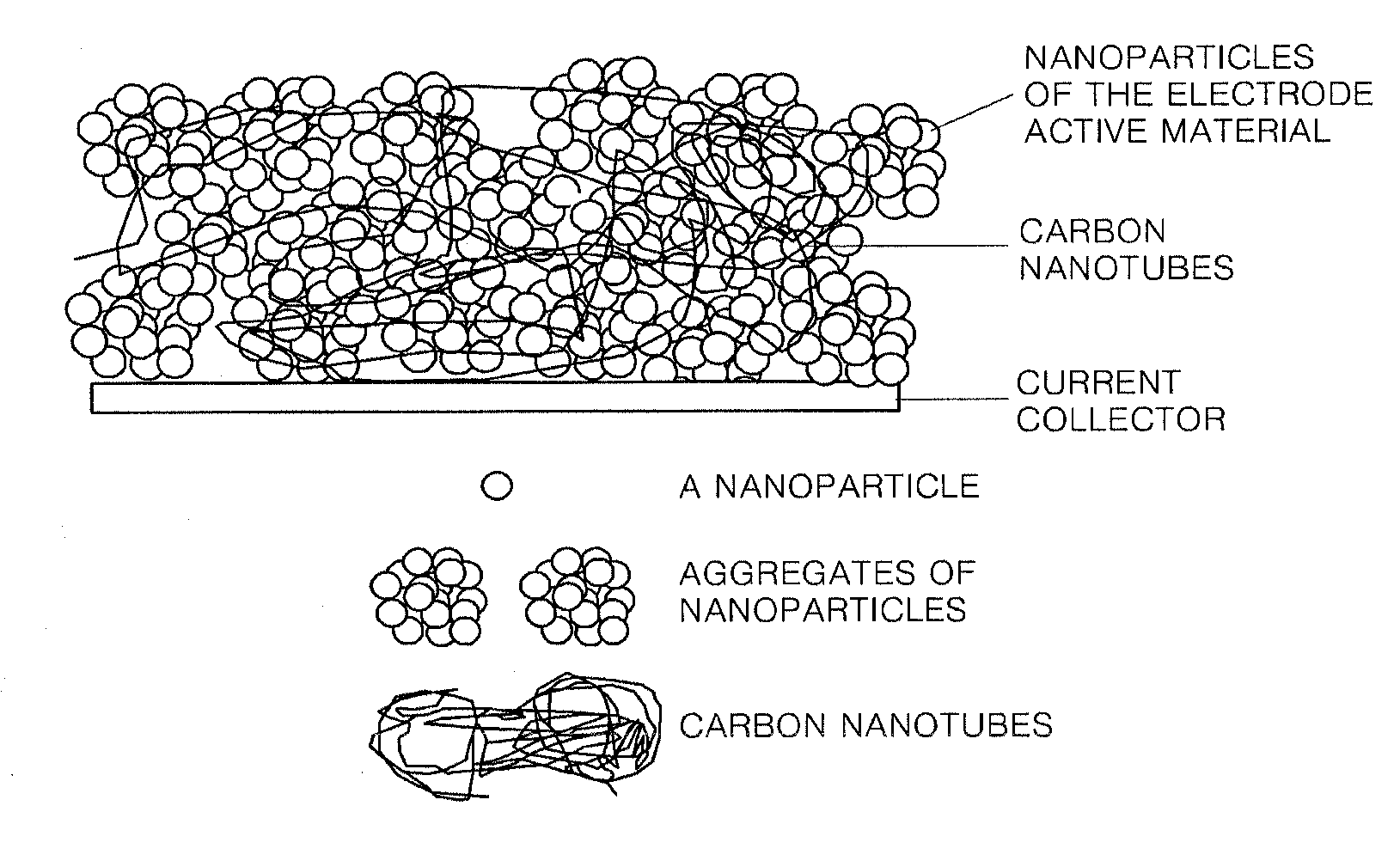

Composites of self-assembled electrode active material-carbon nanotube, fabrication method thereof and secondary battery comprising the same

InactiveUS20120107683A1High strengthRaise transfer toMaterial nanotechnologyElectric discharge heatingPower flowCharge carrier

A composite of electrode active material including aggregates formed by self-assembly of electrode active material nanoparticles and carbon nanotubes, and a fabrication method thereof are disclosed. This composite is in the form of a network in which at least some of the carbon nanotubes connect two or more aggregates that are not directly contacting each other, creating an entangled structure in which a plurality of aggregates and a plurality of carbon nanotube strands are intertwined. Due to the highly conductive properties of the carbon nanotubes in this composite, charge carriers can be rapidly transferred between the self-assembled aggregates. This composite may be prepared by preparing a dispersion in which the nanoparticles and / or carbon nanotubes are dispersed without any organic binders, simultaneously spraying the nanoparticles and the carbon nanotubes on a current collector through electrospray, and then subjecting the composite material formed on the current collector to a heat treatment.

Owner:KOREA INST OF SCI & TECH

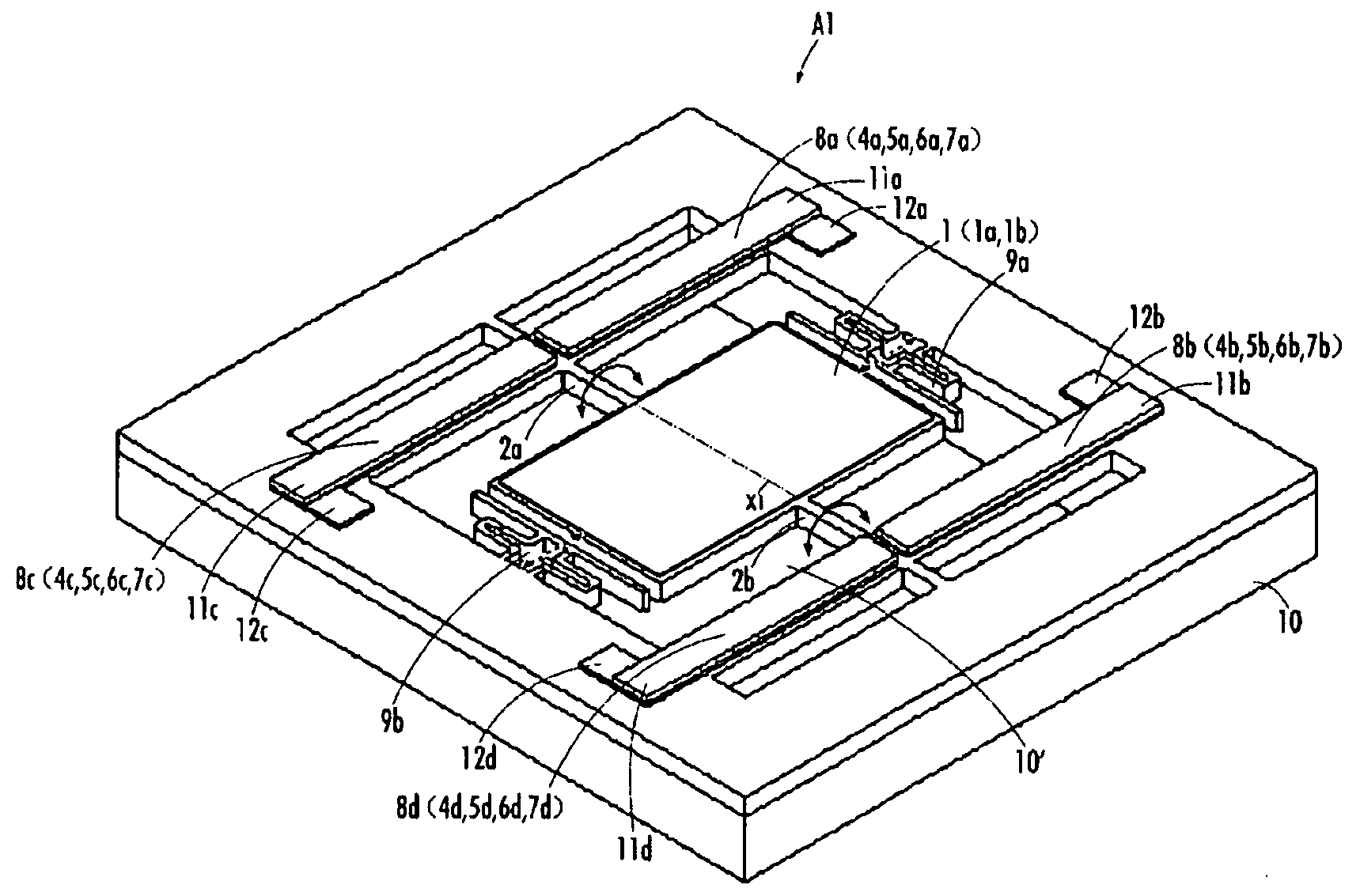

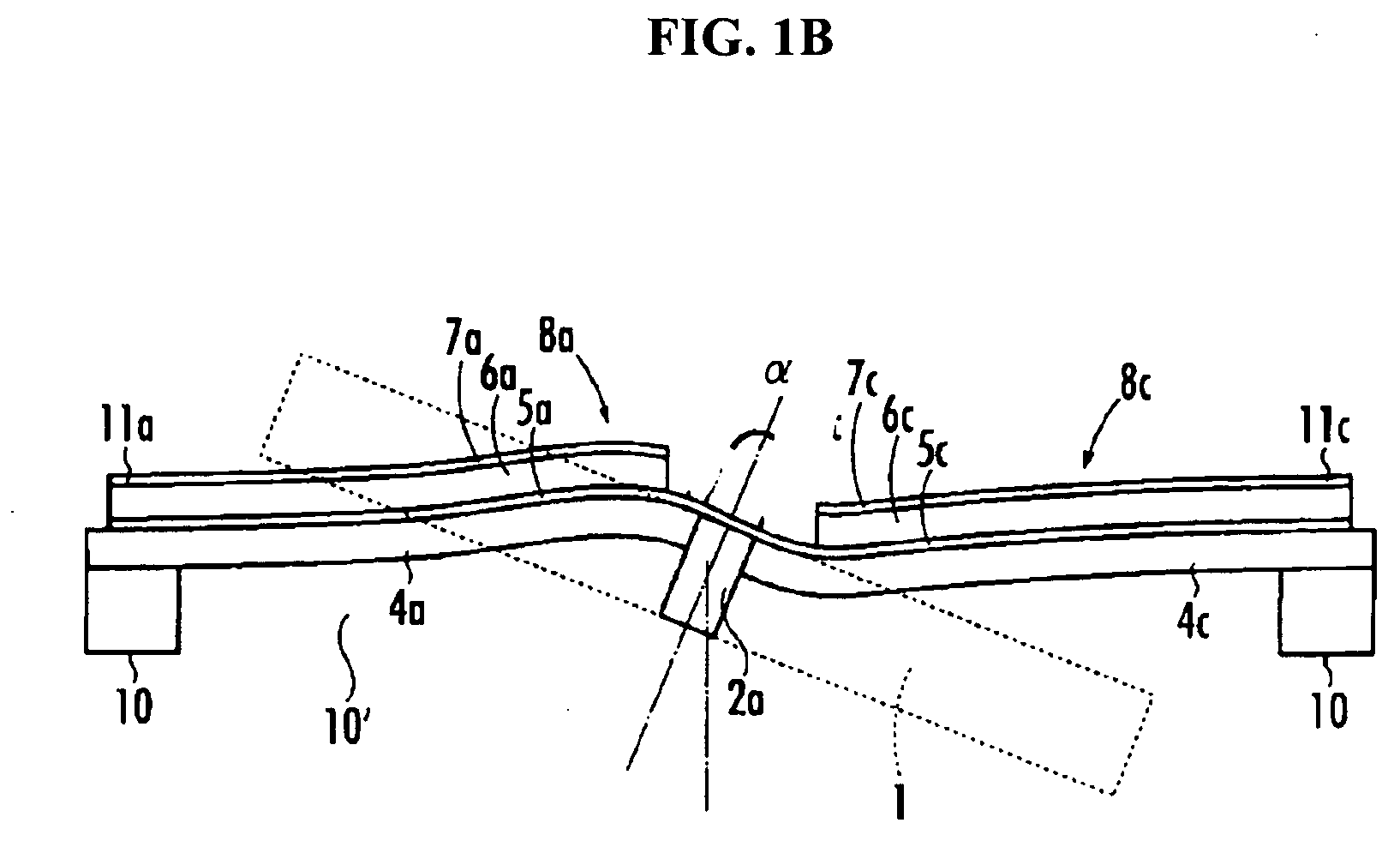

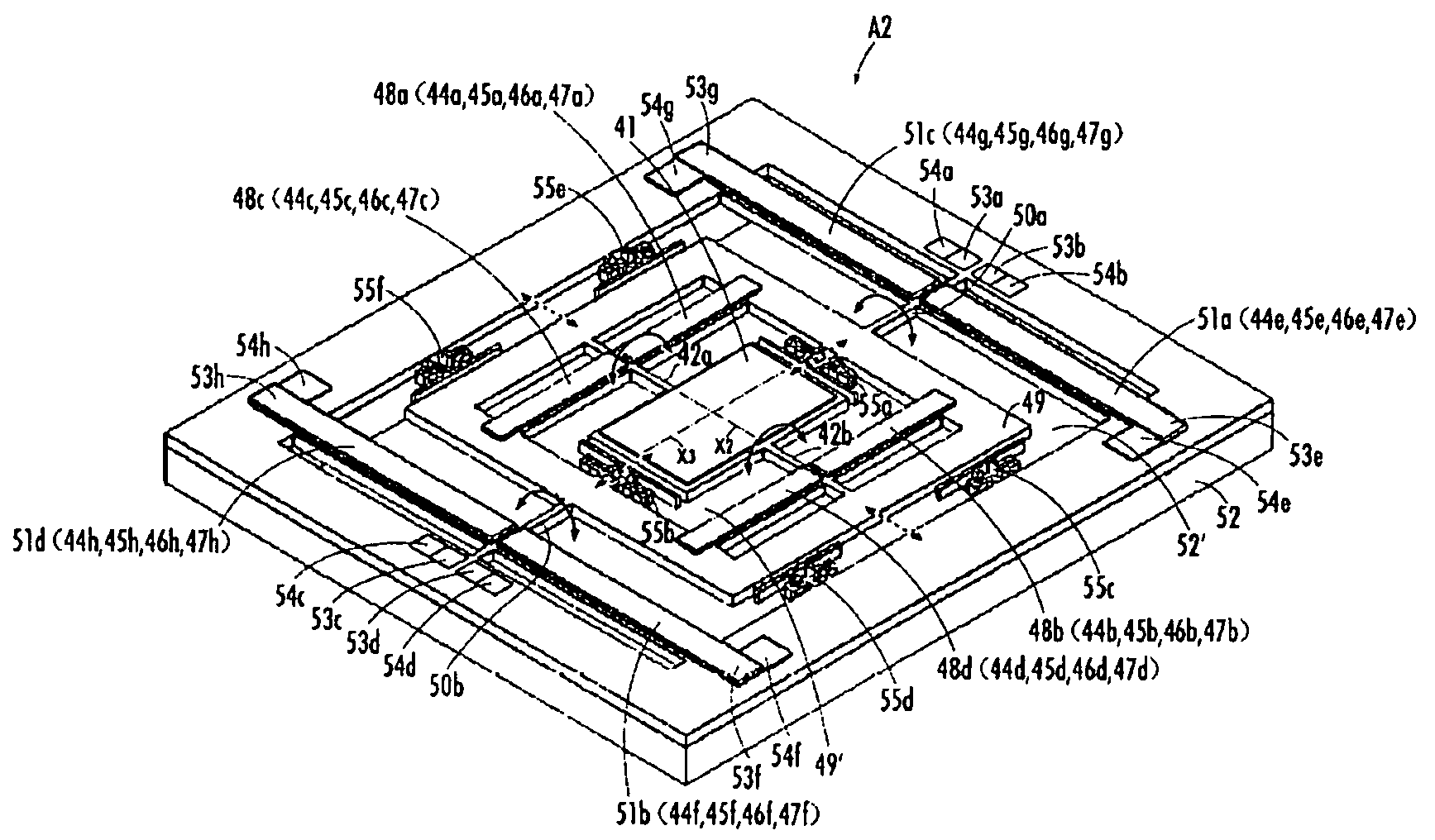

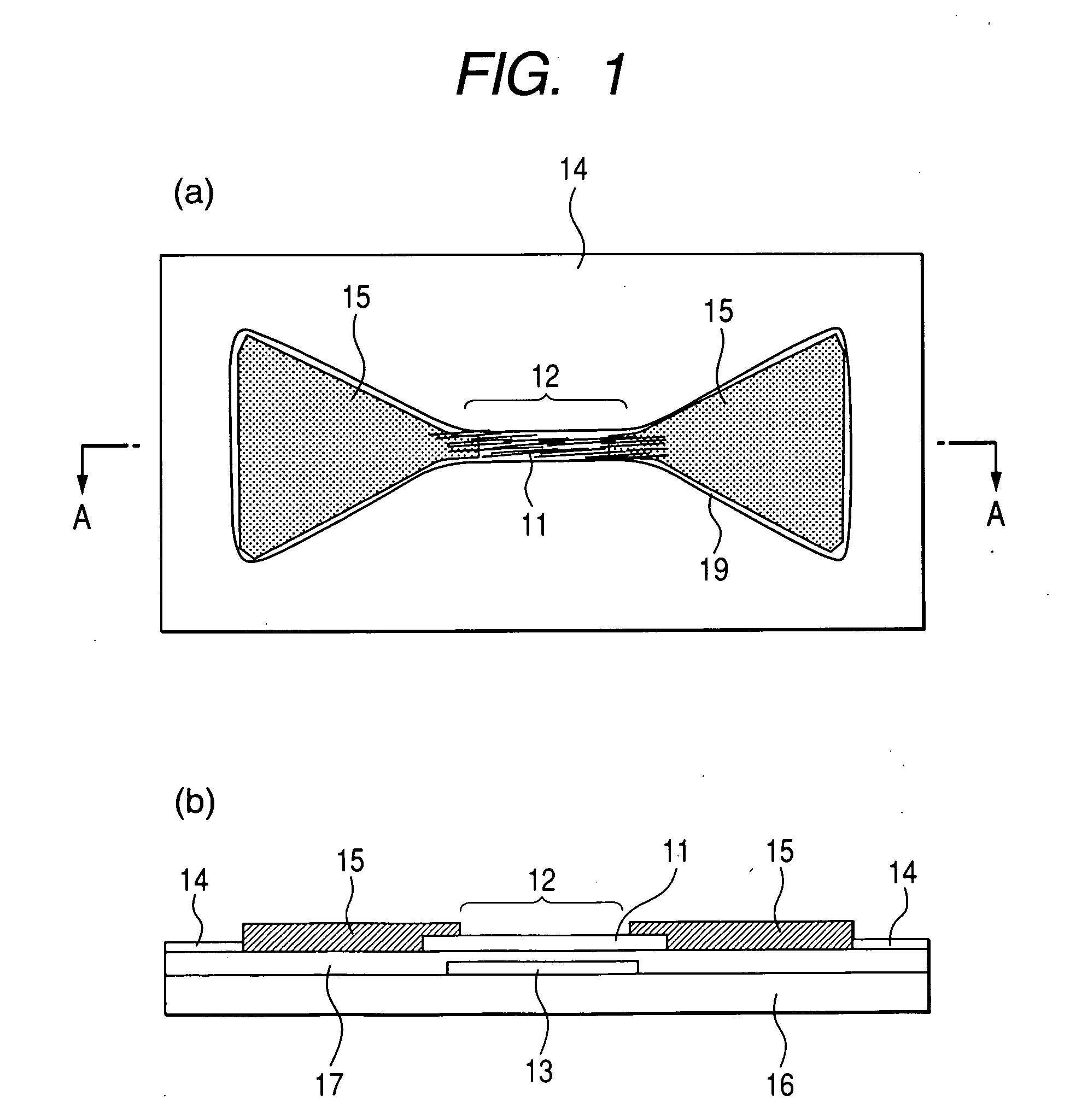

Optical deflector

ActiveUS20090180167A1Improve deflection performanceImprove scan performancePiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive/magnetostrictive devicesPiezoelectric cantileverEngineering

An optical deflector includes a mirror having a reflective plane; a torsion bar extending outwardly from a side of said mirror; a support surrounding said mirror; a piezoelectric cantilever including a supporting body and a piezoelectric body formed on the supporting body, one end of said piezoelectric cantilever being connected to said torsion bar, the other end of the piezoelectric cantilever being connected to said support, said piezoelectric cantilever, upon application of a driving voltage to the piezoelectric body, exhibiting a bending deformation due to piezoelectricity so as to rotate said torsion bar, thereby rotarily driving said mirror through said torsion bar; and an impact attenuator connected to said support, the impact attenuator being disposed in a gap between said mirror and said support.

Owner:STANLEY ELECTRIC CO LTD

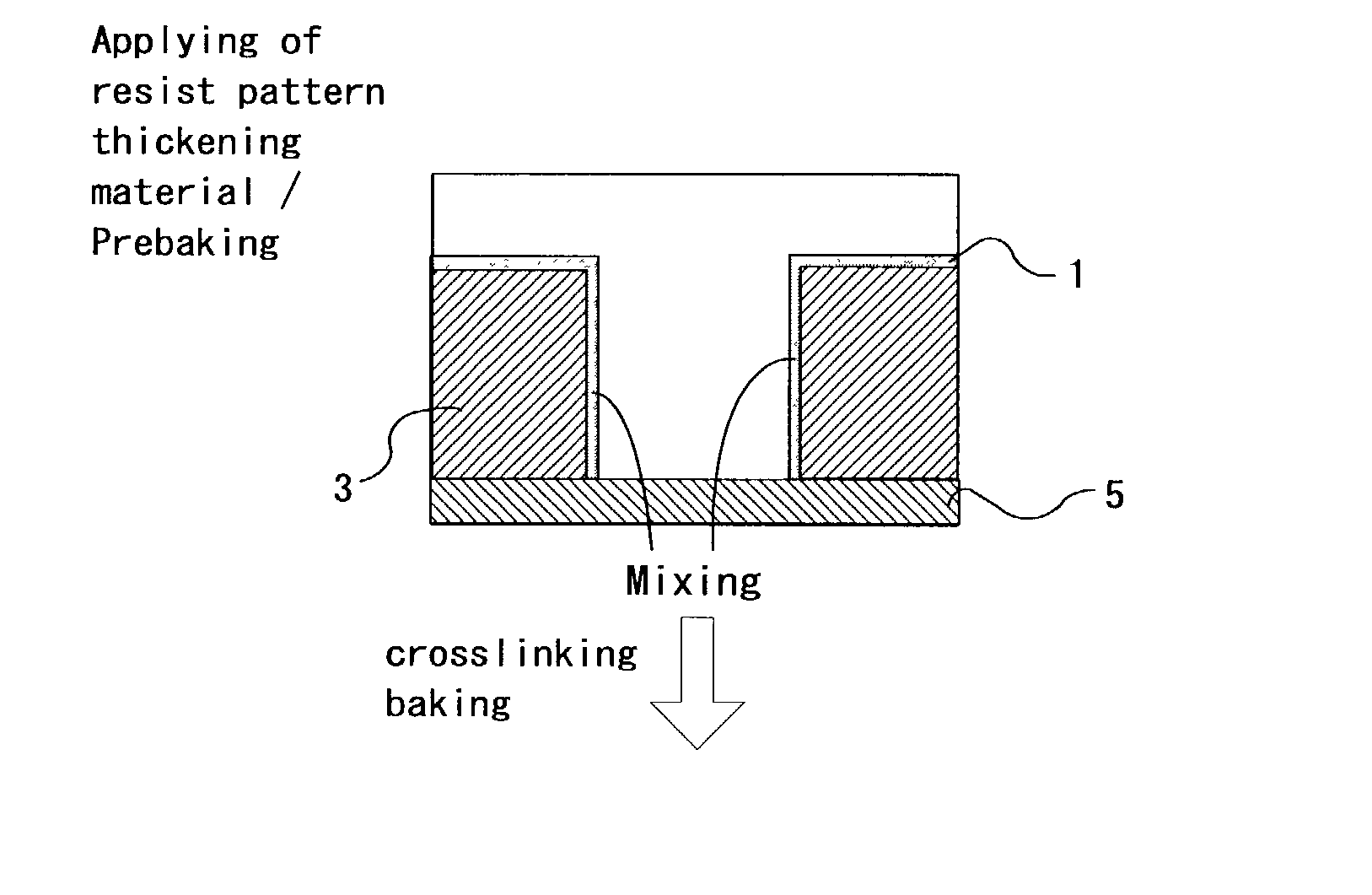

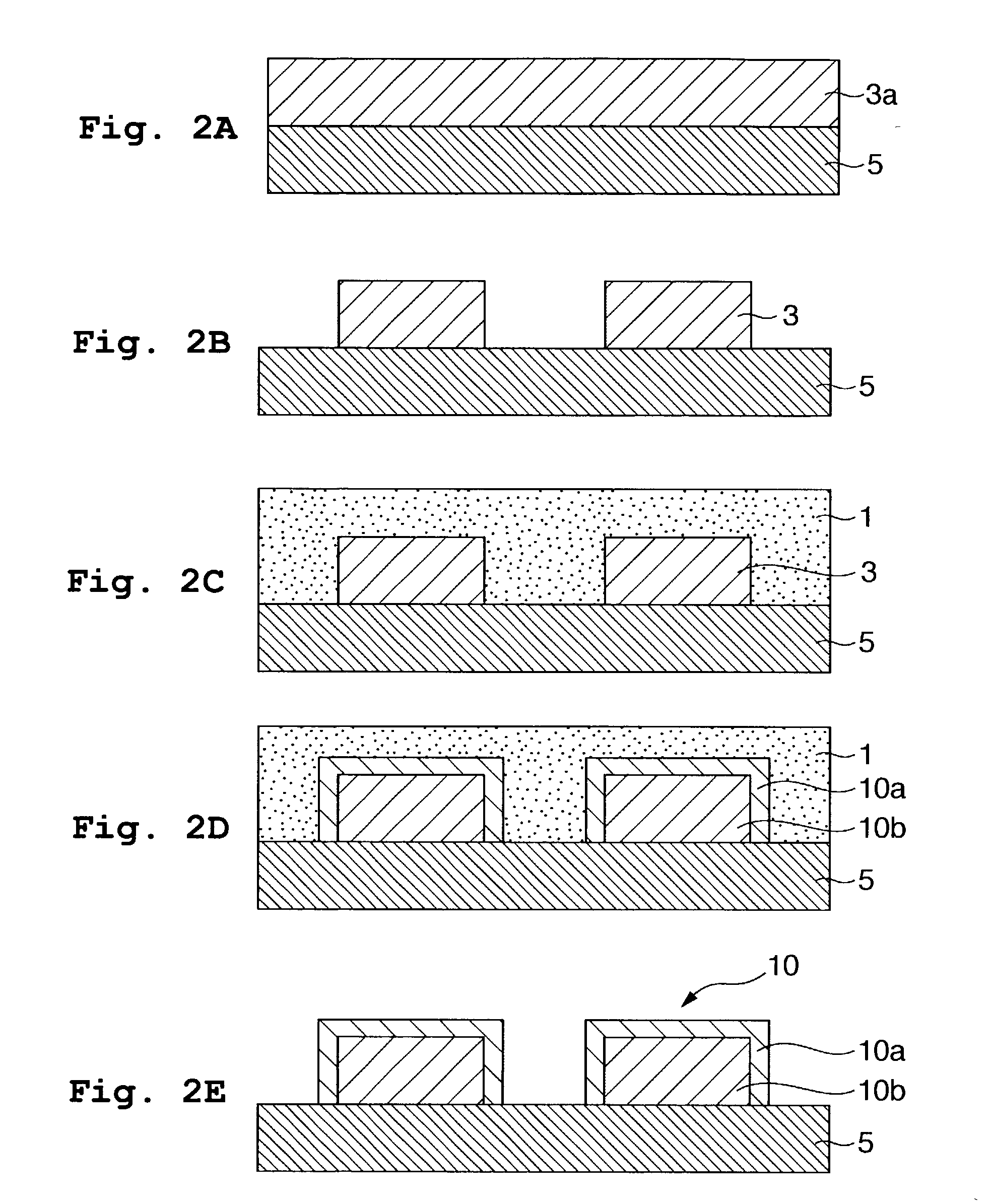

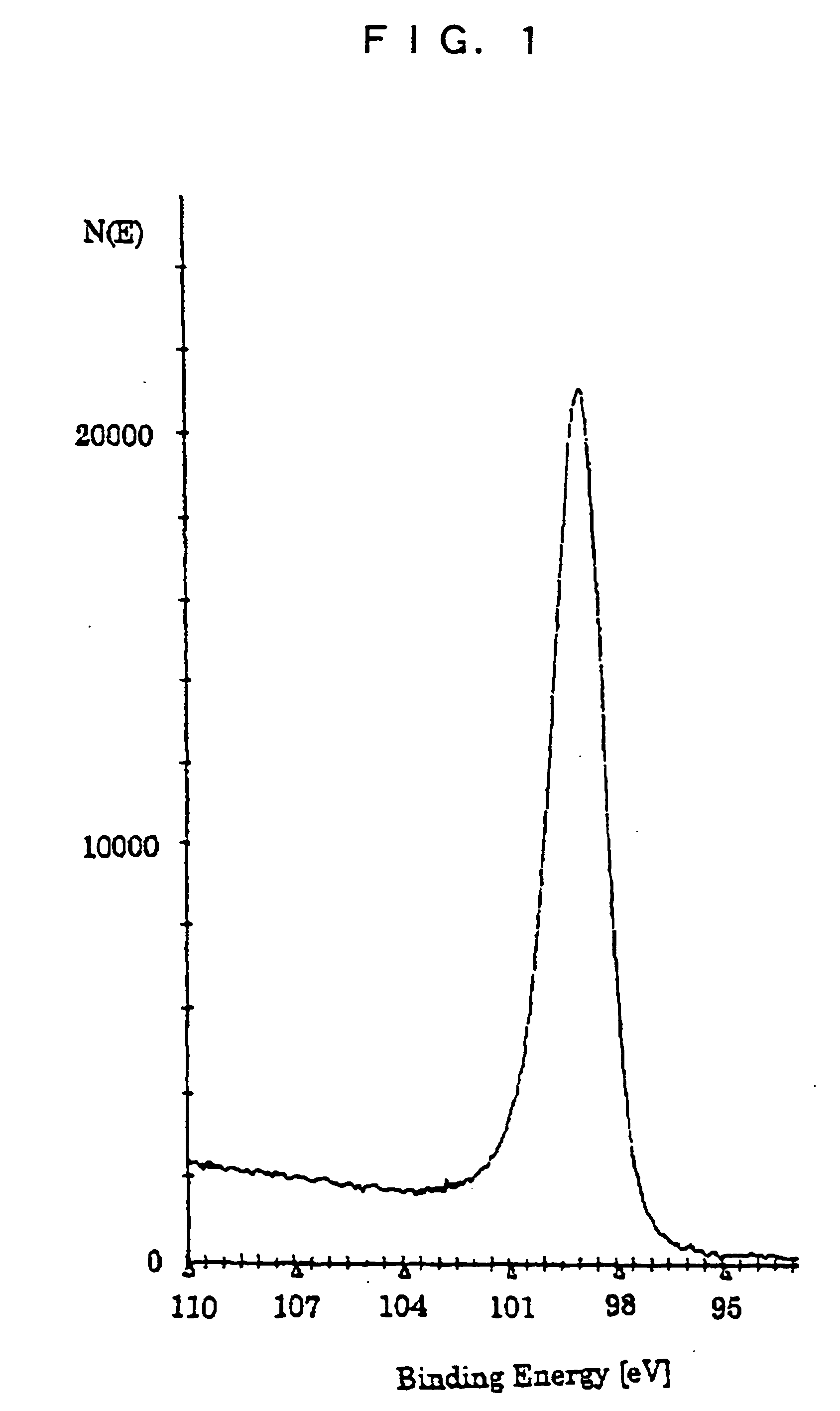

Resist pattern thickening material, resist pattern and forming process thereof, and semiconductor device and manufacturing process thereof

InactiveUS20030157801A1Simple structureImprove the immunityConstruction of head windingsDecorative surface effectsResistSurface layer

A resist pattern thickening material has resin, a crosslinking agent and a compound having a cyclic structure, or resin having a cyclic structure at a part. A resist pattern has a surface layer on a resist pattern to be thickened with etching rate (nm / s) ratio of the resist pattern to be thickened the surface layer of 1.1 or more, under the same condition, or a surface layer to a resist pattern to be thickened. A process for forming a resist pattern includes applying the thickening material after forming a resist pattern to be thickened on its surface. A semiconductor device has a pattern formed by the resist pattern. A process for manufacturing the semiconductor device has applying, after forming a resist pattern to be thickened, the thickening material to the surface of the resist pattern to be thickened, and patterning the underlying layer by etching, the pattern as a mask.

Owner:FUJITSU LTD

Semiconductor device

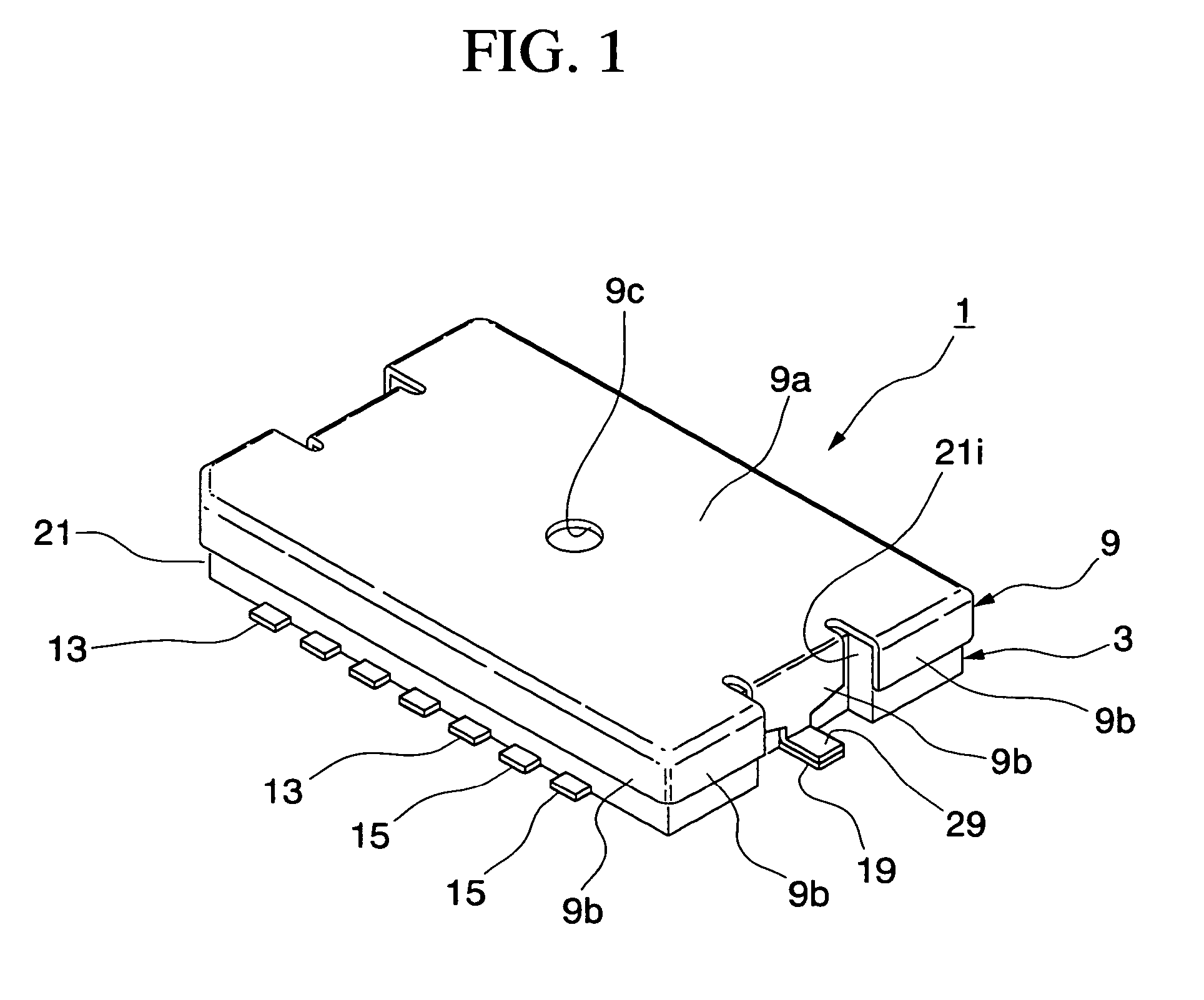

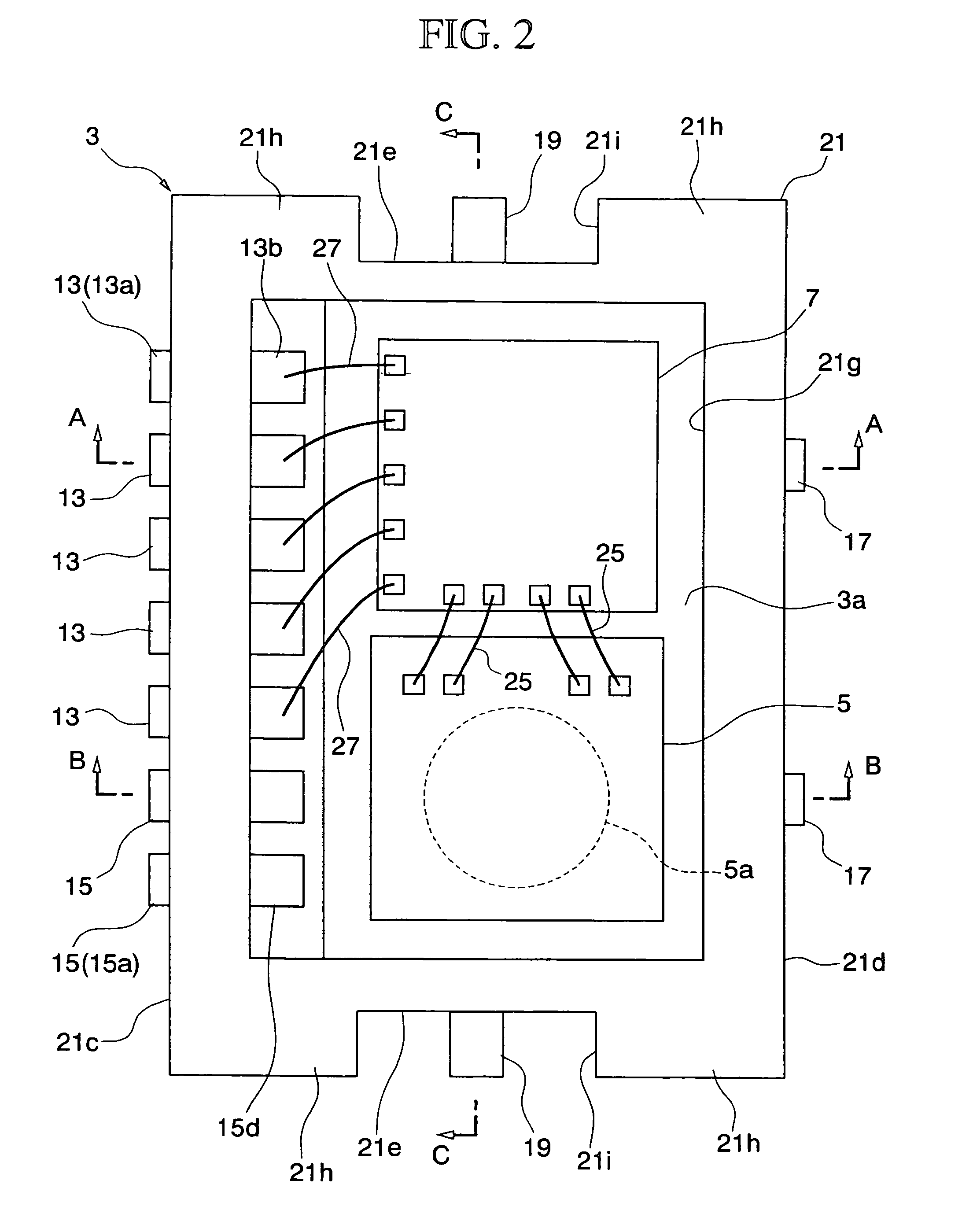

ActiveUS20070210392A1Formed with easeSemiconductor/solid-state device detailsSolid-state devicesDevice materialSemiconductor sensor

A semiconductor device is designed such that a semiconductor sensor chip having a diaphragm for detecting pressure variations based on the displacement thereof is fixed onto the upper surface of a substrate having a rectangular shape, which is covered with a cover member so as to form a hollow space embracing the semiconductor sensor chip between the substrate and the cover member. Herein, the substrate is sealed with a molded resin such that chip connection leads packaging leads are partially exposed externally of the molded resin; the chip connection leads are electrically connected to the semiconductor sensor chip and are disposed in line along one side of the semiconductor sensor chip; and the packaging leads are positioned opposite the chip connection leads by way of the semiconductor sensor chip. Thus, it is possible to downsize the semiconductor device without substantially changing the size of the semiconductor sensor chip.

Owner:INFINEON TECH AG

Semiconductor device

InactiveUS20090096041A1Formed with easeSemiconductor/solid-state device detailsFluid pressure measurement by electric/magnetic elementsSemiconductor chipSemiconductor sensor

A semiconductor device is designed such that a semiconductor sensor chip having a diaphragm for detecting pressure variations based on the displacement thereof is fixed onto the upper surface of a substrate having a rectangular shape, which is covered with a cover member so as to form a hollow space embracing the semiconductor sensor chip between the substrate and the cover member. Herein, the substrate is sealed with a molded resin such that chip connection leads packaging leads are partially exposed externally of the molded resin; the chip connection leads are electrically connected to the semiconductor sensor chip and are disposed in line along one side of the semiconductor sensor chip; and the packaging leads are positioned opposite the chip connection leads by way of the semiconductor sensor chip. Thus, it is possible to downsize the semiconductor device without substantially changing the size of the semiconductor sensor chip.

Owner:YAMAHA CORP

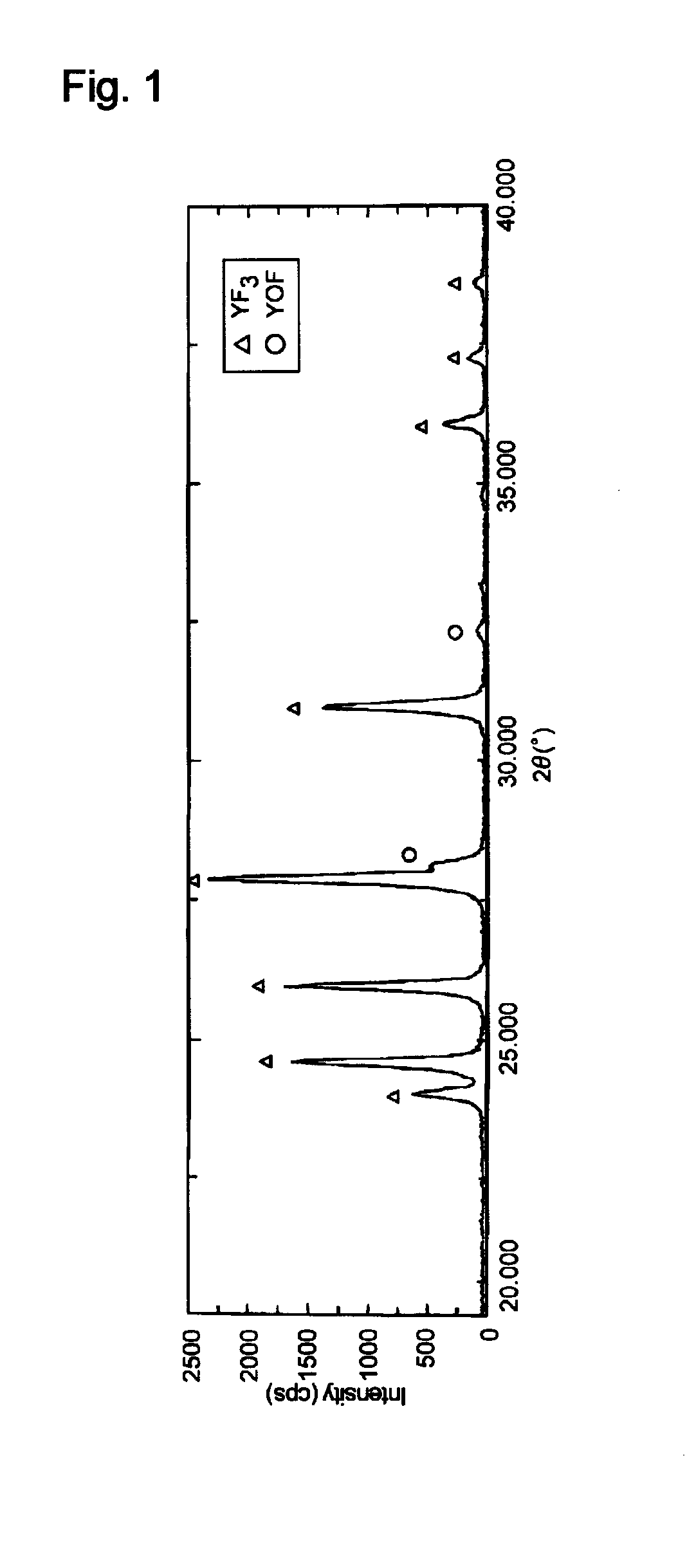

Thermal spray material and process for preparing same

ActiveUS20150096462A1Smooth thermal spray coatingFormed with easeMolten spray coatingRare earth metal compoundsRare-earth elementThermal spraying

A thermal spray material includes granules of an oxyfluoride of yttrium (YOF). The granules may contain a fluoride of yttrium (YF3). The granules preferably have an oxygen content of 0.3 to 13.1 mass %. The granules preferably have a fracture strength of 0.3 MPa or more and less than 10 MPa. Part of yttrium (Y) of the granules may be displaced with at least one rare earth element (Ln) except yttrium, the molar fraction of Ln relative to the sum of Y and Ln being preferably 0.2 or less.

Owner:NIPPON YTTRIUM

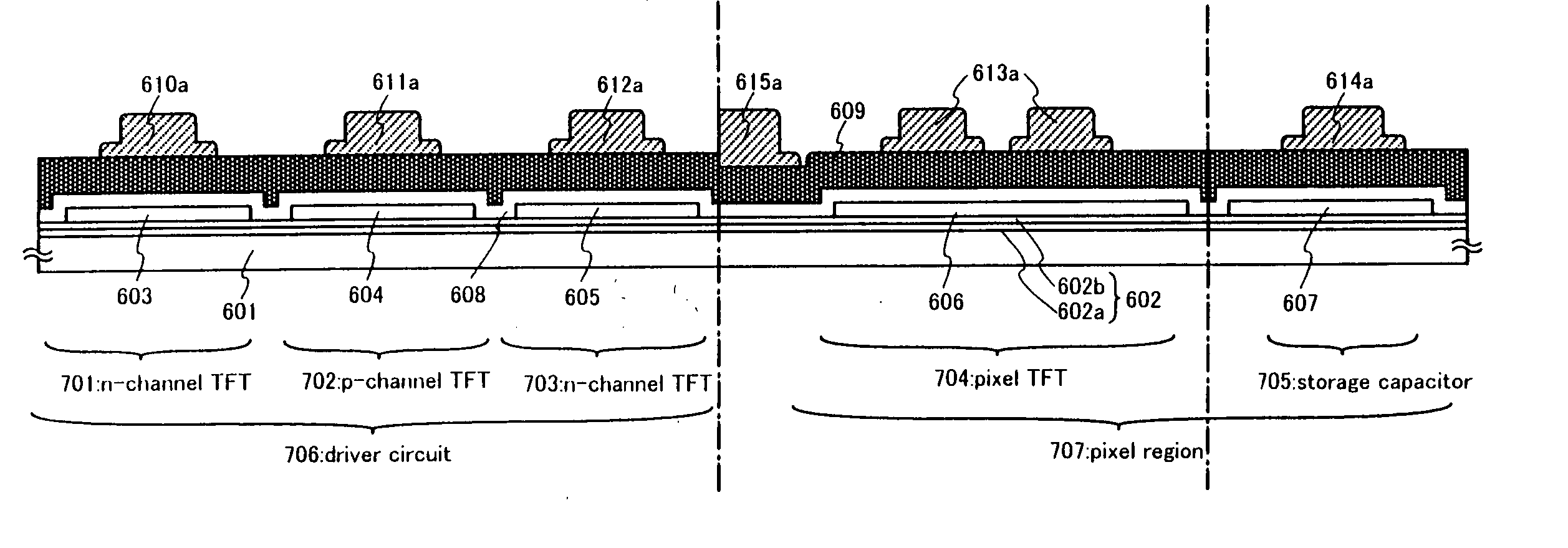

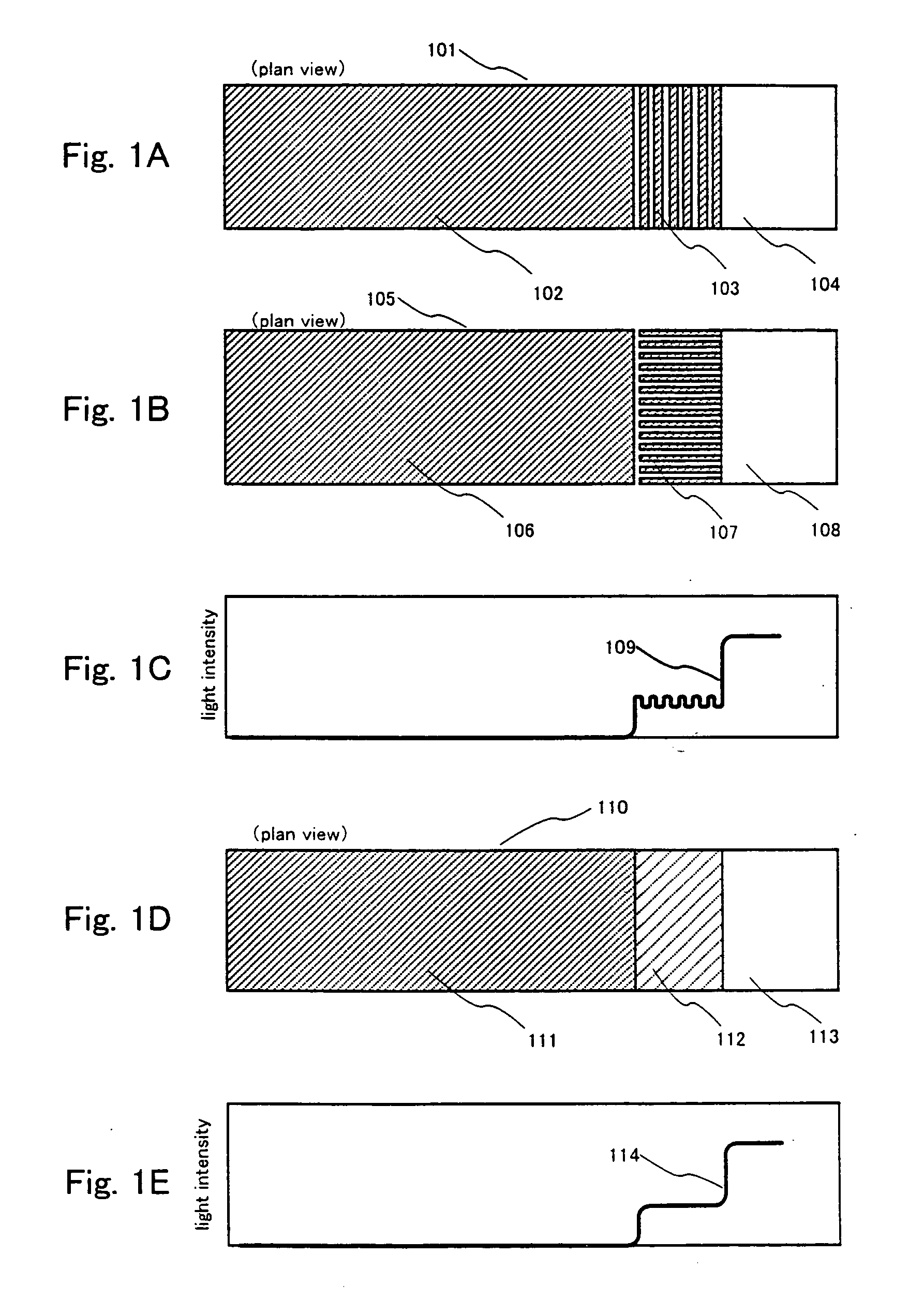

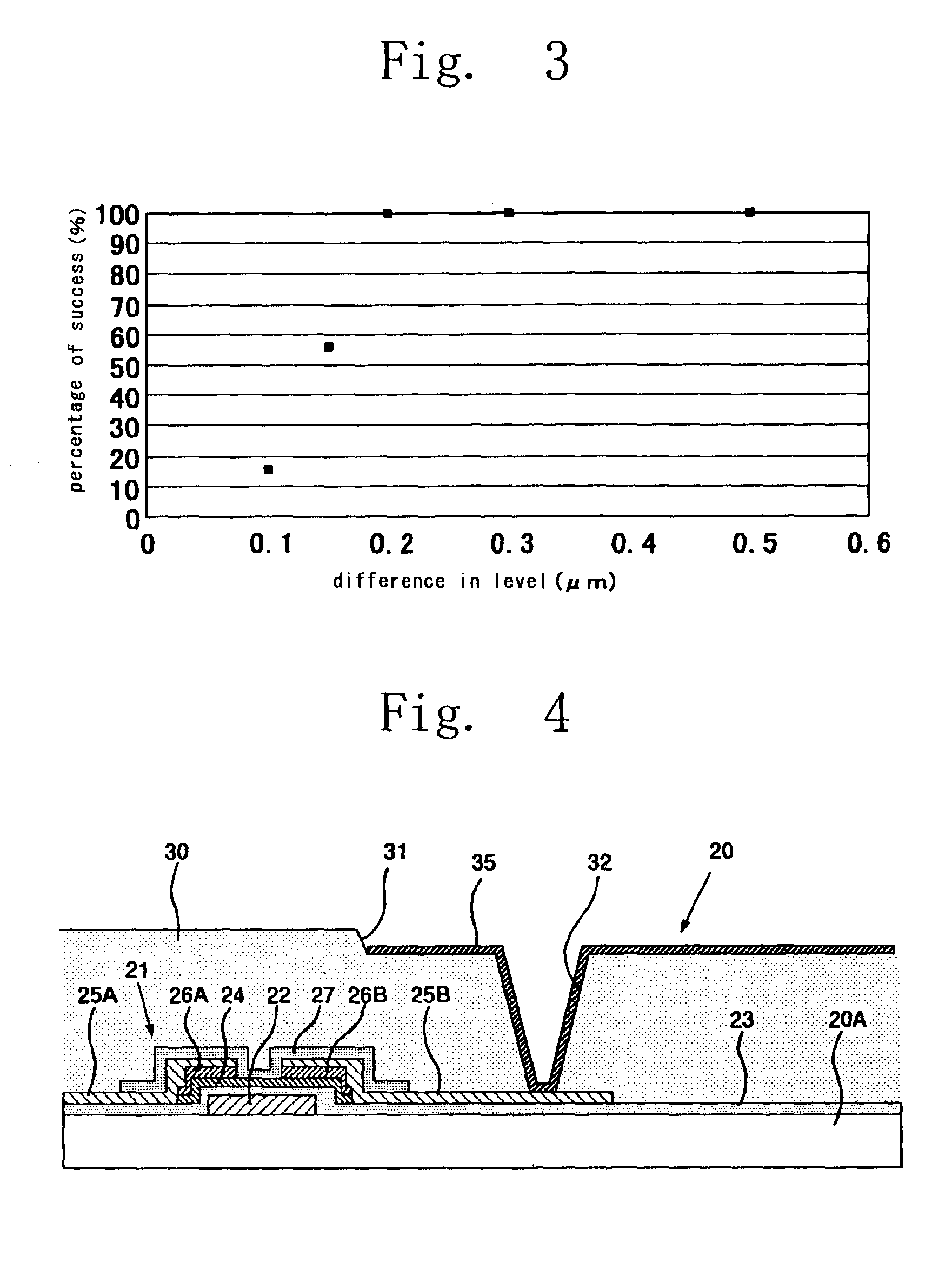

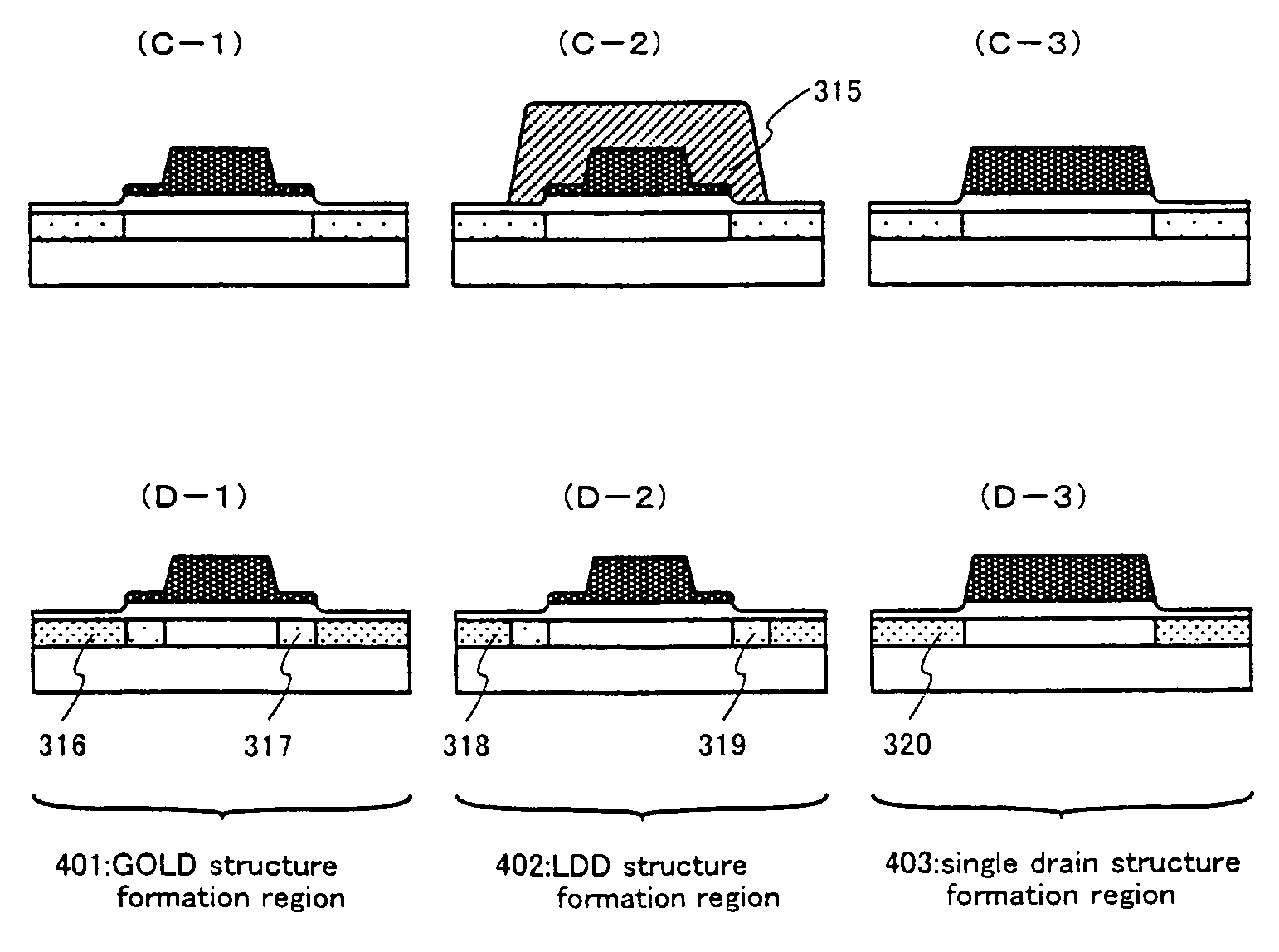

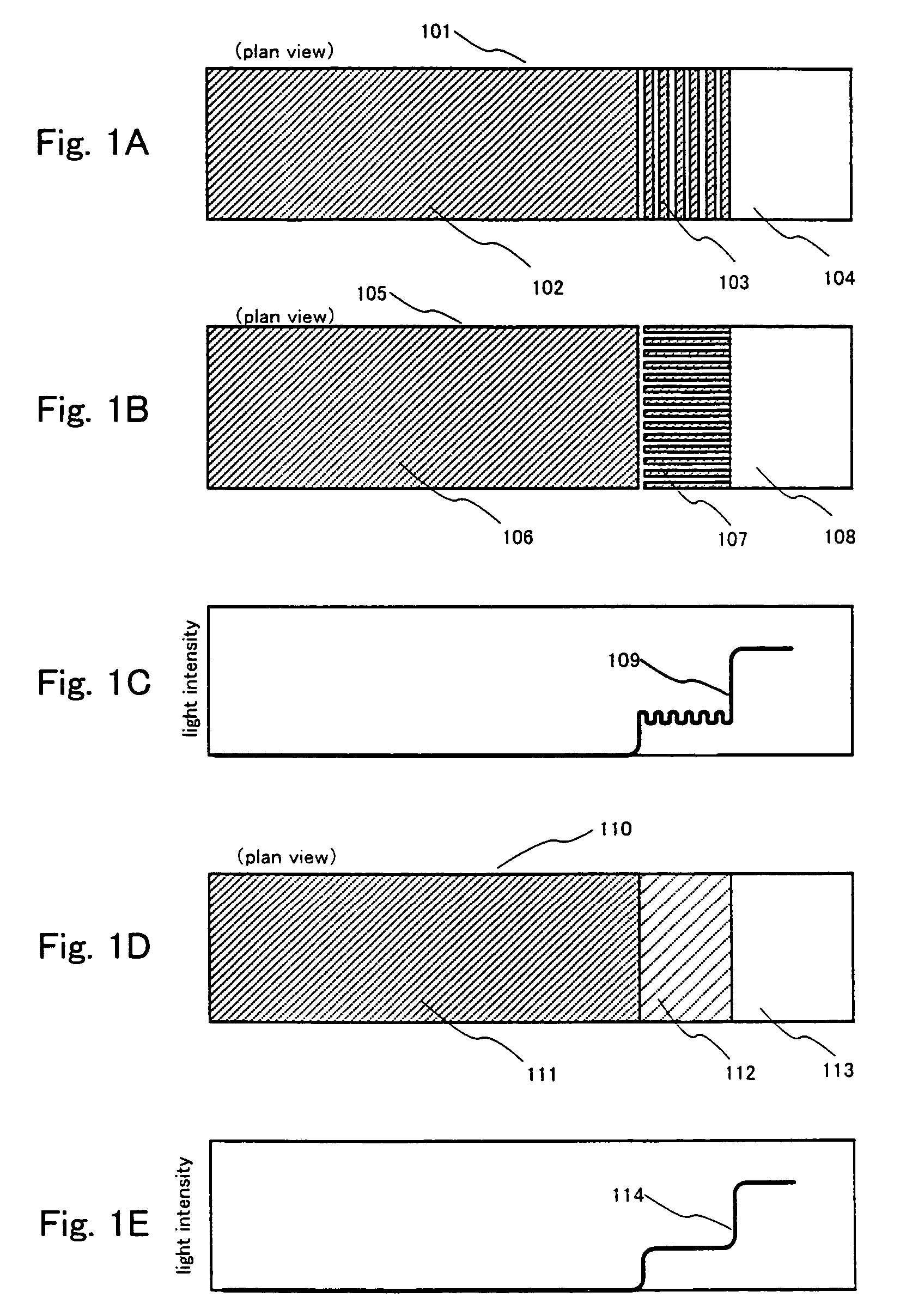

Method of manufacturing a semiconductor device

InactiveUS20060014335A1Reduce intensityReduce light intensityTransistorSolid-state devicesPhotolithographyIon implantation

Formation of LDD structures and GOLD structures in a semiconductor device is conventionally performed in a self aligning manner with gate electrodes as masks, but there are many cases in which the gate electrodes have two layer structures, and film formation processes and etching processes become complex. Further, in order to perform formation of LDD structures and GOLD structures only by processes such as dry etching, the transistor structures all have the same structure, and it is difficult to form LDD structures, GOLD structures, and single drain structures separately for different circuits. By applying a photolithography process for forming gate electrodes to photomasks or reticles, in which supplemental patterns having a function of reducing the intensity of light and composed of diffraction grating patterns or translucent films, are established, GOLD structure, LDD structure, and single drain structure transistors can be easily manufactured for different circuits through dry etching and ion injection process steps.

Owner:SEMICON ENERGY LAB CO LTD

Semiconductor device and manufacturing method therefor, circuit substrate, and electronic apparatus

InactiveUS6660545B2High reliability in electrical connectionSimple processSemiconductor/solid-state device detailsSolid-state devicesDevice materialSemiconductor chip

Owner:SAMSUNG ELECTRONICS CO LTD

Silane composition, silicon film forming method and solar cell production method

InactiveUS20060185712A1Increase the areaFormed with easeSilicon organic compoundsPV power plantsSilyleneSilanes

A silane composition for preparing a semiconductor thin films of a solar cell is disclosed. The silane composition contains a polysilane compound represented by the formula SinRm (n is an integer of 3 or more, m is an integer of n to (2n+2) and an m number of R's are each independently a hydrogen atom, alkyl group, phenyl group or halogen atom, with the proviso that when all the m number of R's are hydrogen atoms and m=2n, n is an integer of 7 or more), and at least one silane compound selected from cyclopentasilane, cyclohexasilane and silylcyclopentasilane.

Owner:JSR CORPORATIOON

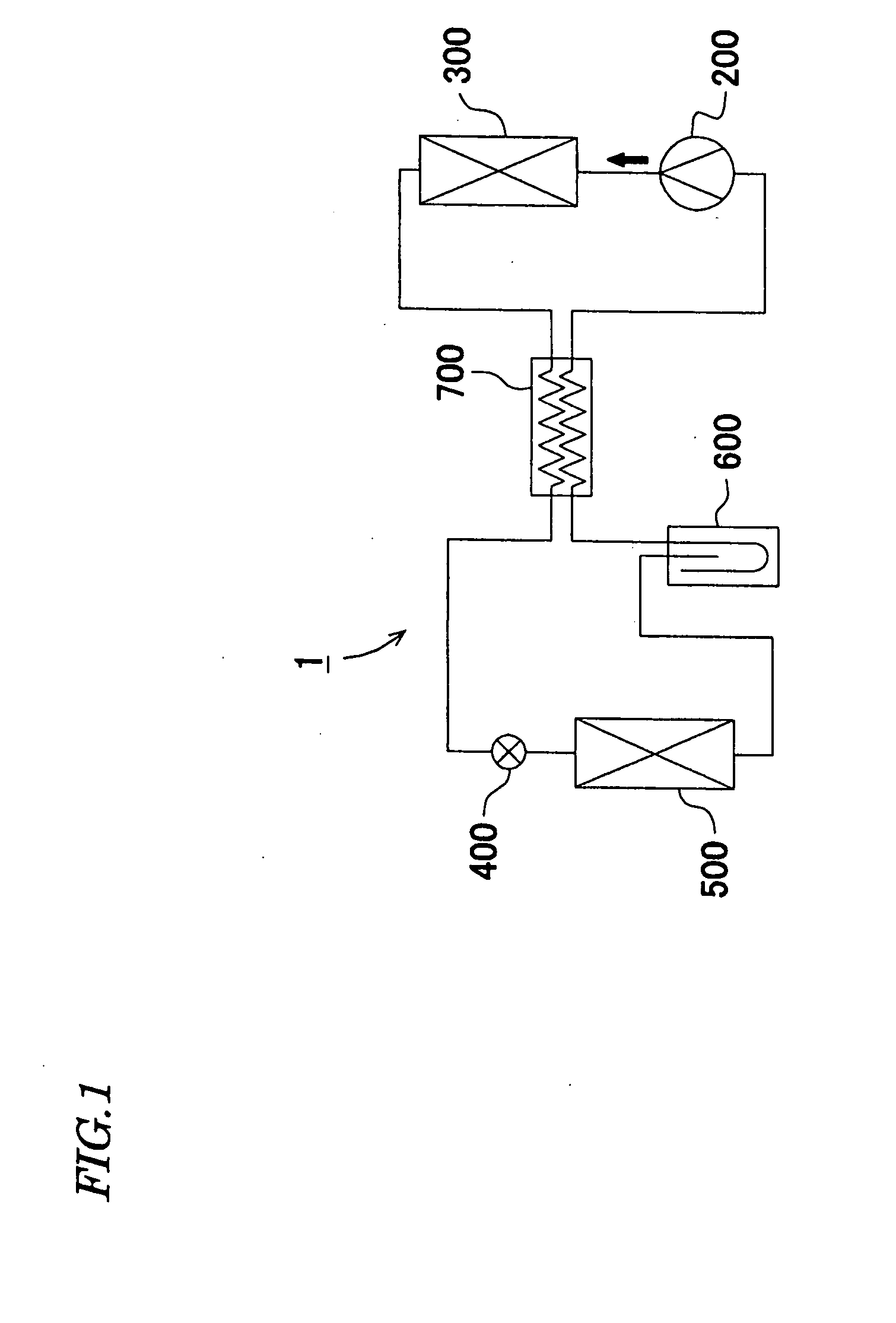

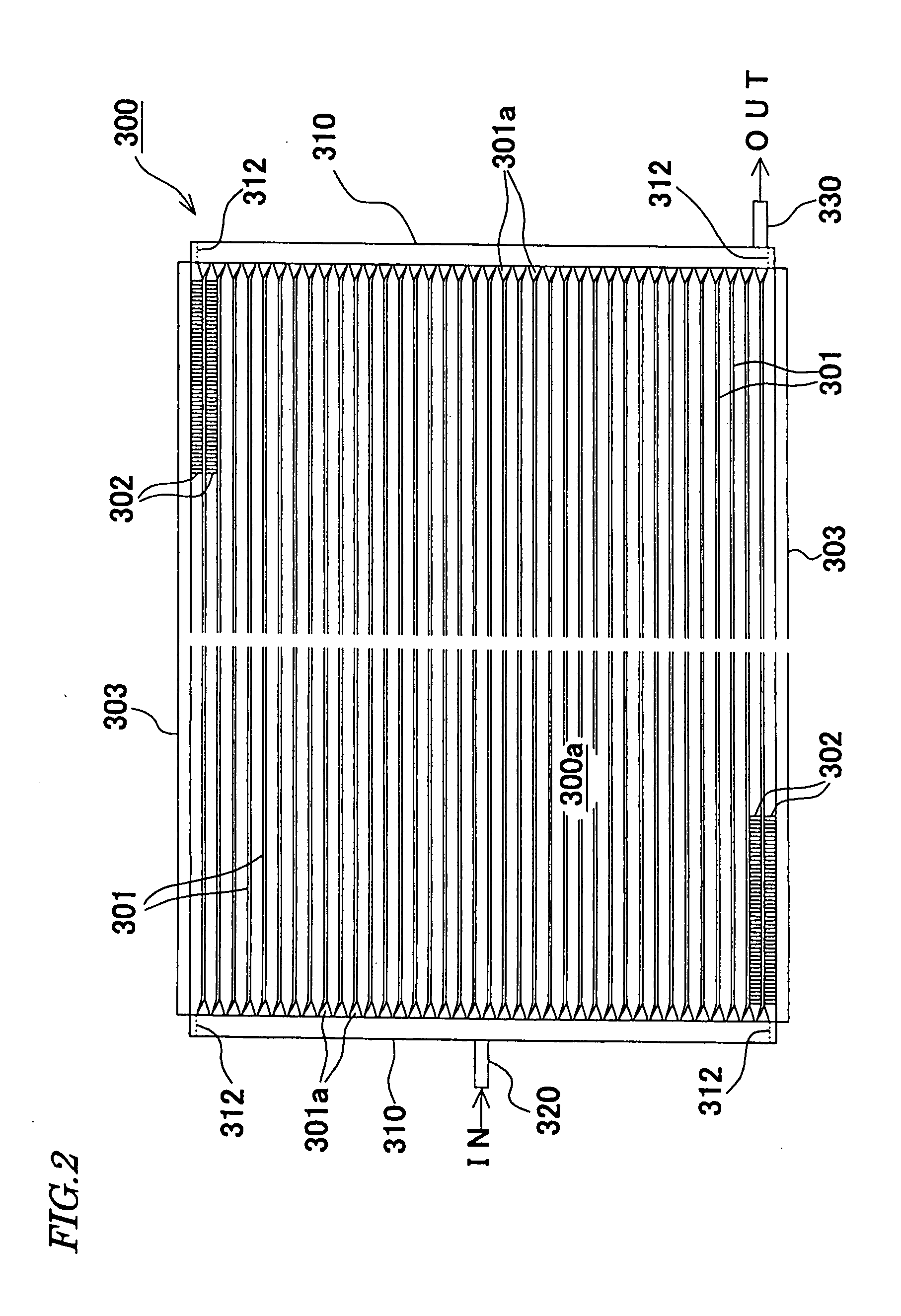

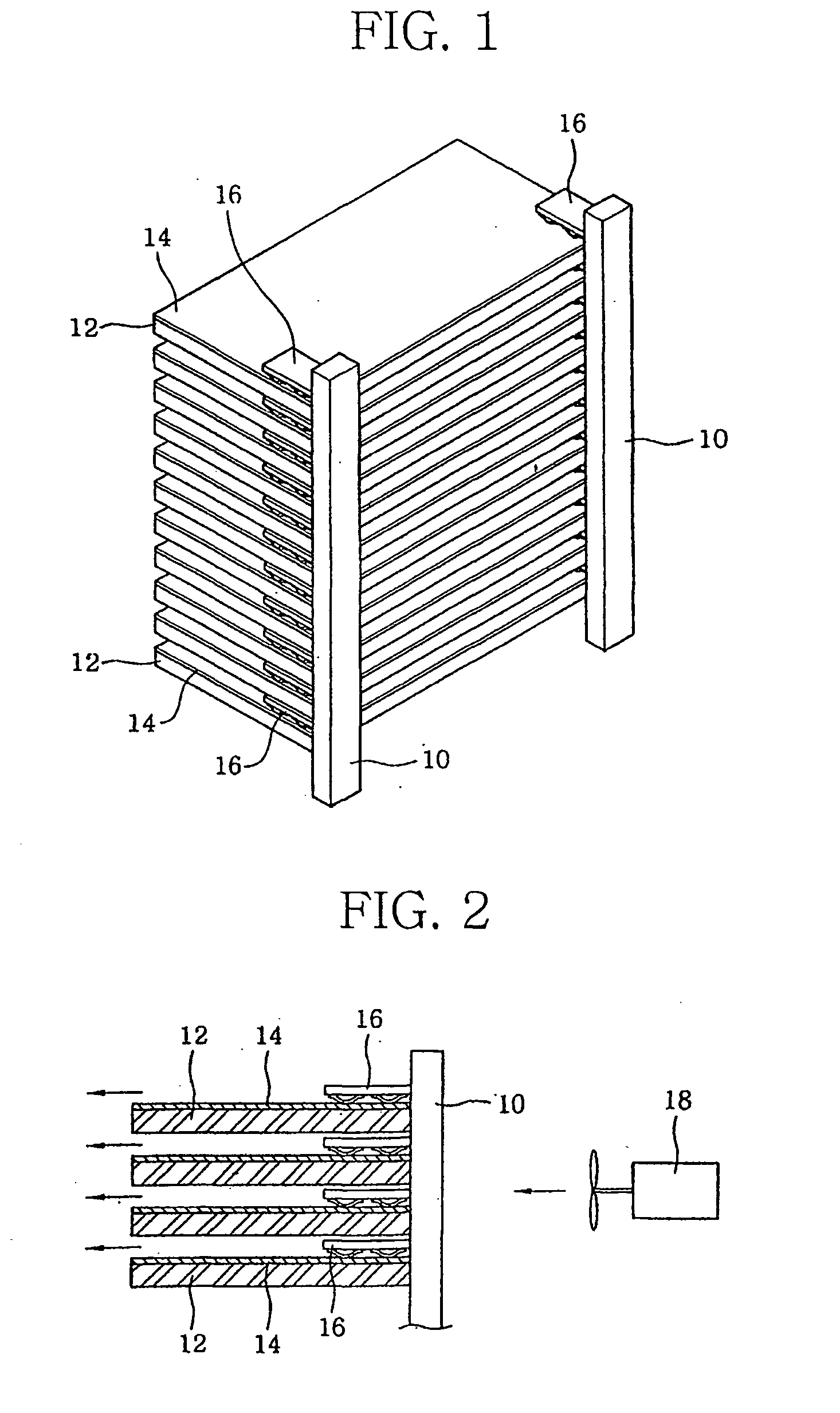

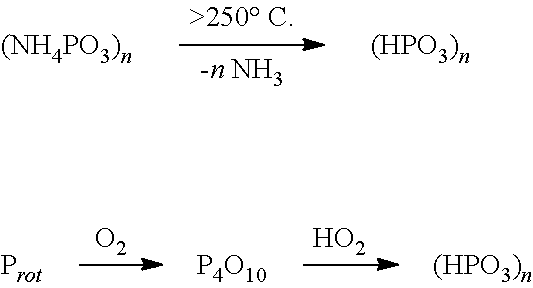

Heat exchanger and tube for heat exchanger

InactiveUS20050011637A1Efficient assemblySmall volume of tankStationary conduit assembliesHeat exchanger casingsEngineeringRefrigeration

A heat exchanger and its tubes, wherein the heat exchanger includes a core 300a, having a lamination of flat tubes 301 for flowing a refrigerant and corrugated fins 302, and tanks 310 having slots for insertion of the ends of tubes, the core is configured to have the flat surfaces of the tubes in parallel with the airflow direction, and the tubes have their ends 301a twisted in the width direction by 90° with respect to the airflow direction. A heat exchanger for a supercritical refrigeration cycle has tanks 310a, 310c displaced in a direction orthogonal to the airflow direction on one side of plural cores 300a, 300b which are overlaid in the airflow direction, and an inlet 320 and an outlet 330 for the refrigerant are oriented toward the windward side or the downwind side of the airflow direction.

Owner:ZEXEL VALEO CLIMATE CONTROL CORP SAITAMA

Optical deflector

ActiveUS7605965B2Effective avoidanceSacrificing performancePiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive/magnetostrictive devicesPiezoelectric cantileverEngineering

An optical deflector includes a mirror having a reflective plane; a torsion bar extending outwardly from a side of said mirror; a support surrounding said mirror; a piezoelectric cantilever including a supporting body and a piezoelectric body formed on the supporting body, one end of said piezoelectric cantilever being connected to said torsion bar, the other end of the piezoelectric cantilever being connected to said support, said piezoelectric cantilever, upon application of a driving voltage to the piezoelectric body, exhibiting a bending deformation due to piezoelectricity so as to rotate said torsion bar, thereby rotarily driving said mirror through said torsion bar; and an impact attenuator connected to said support, the impact attenuator being disposed in a gap between said mirror and said support.

Owner:STANLEY ELECTRIC CO LTD

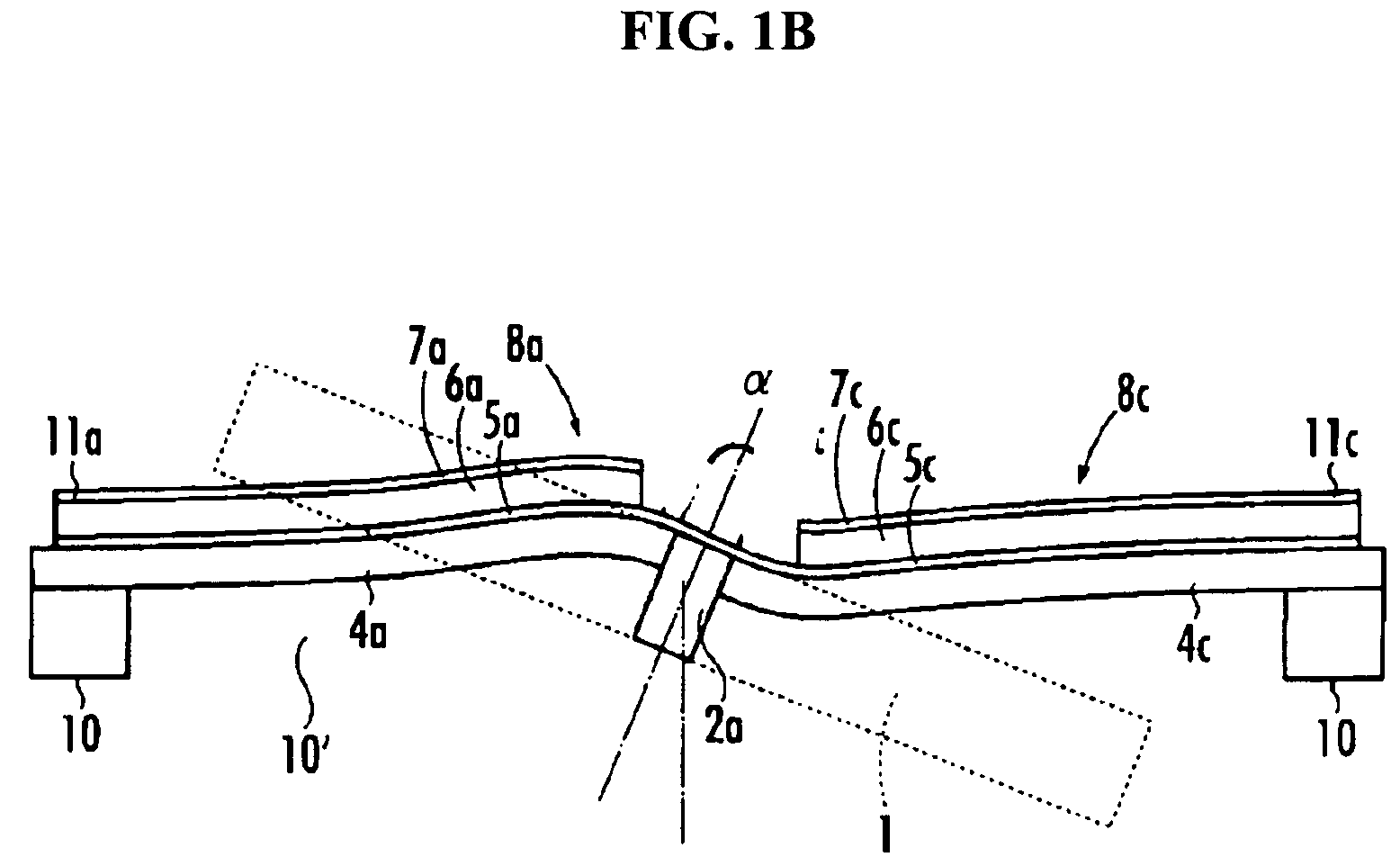

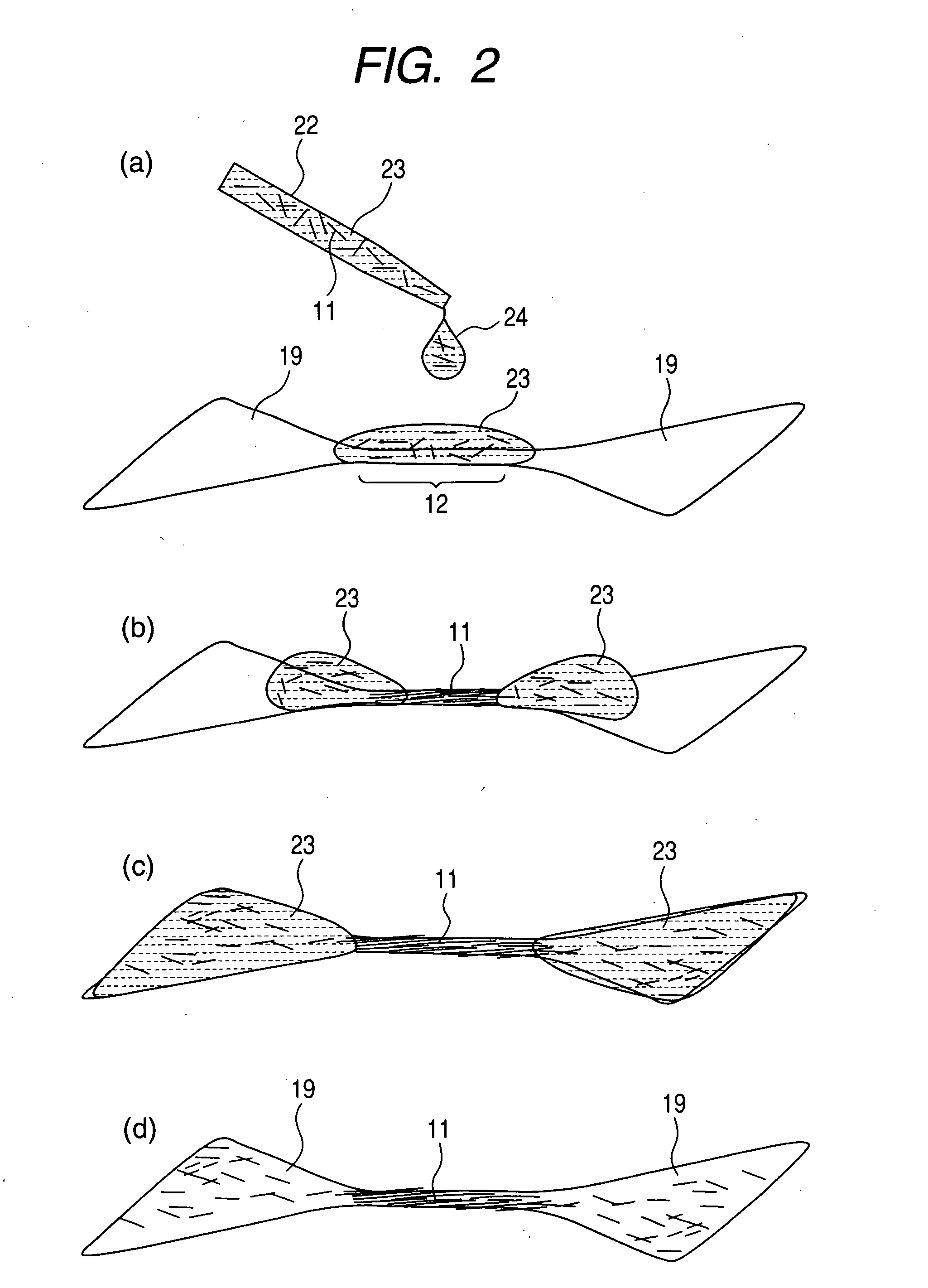

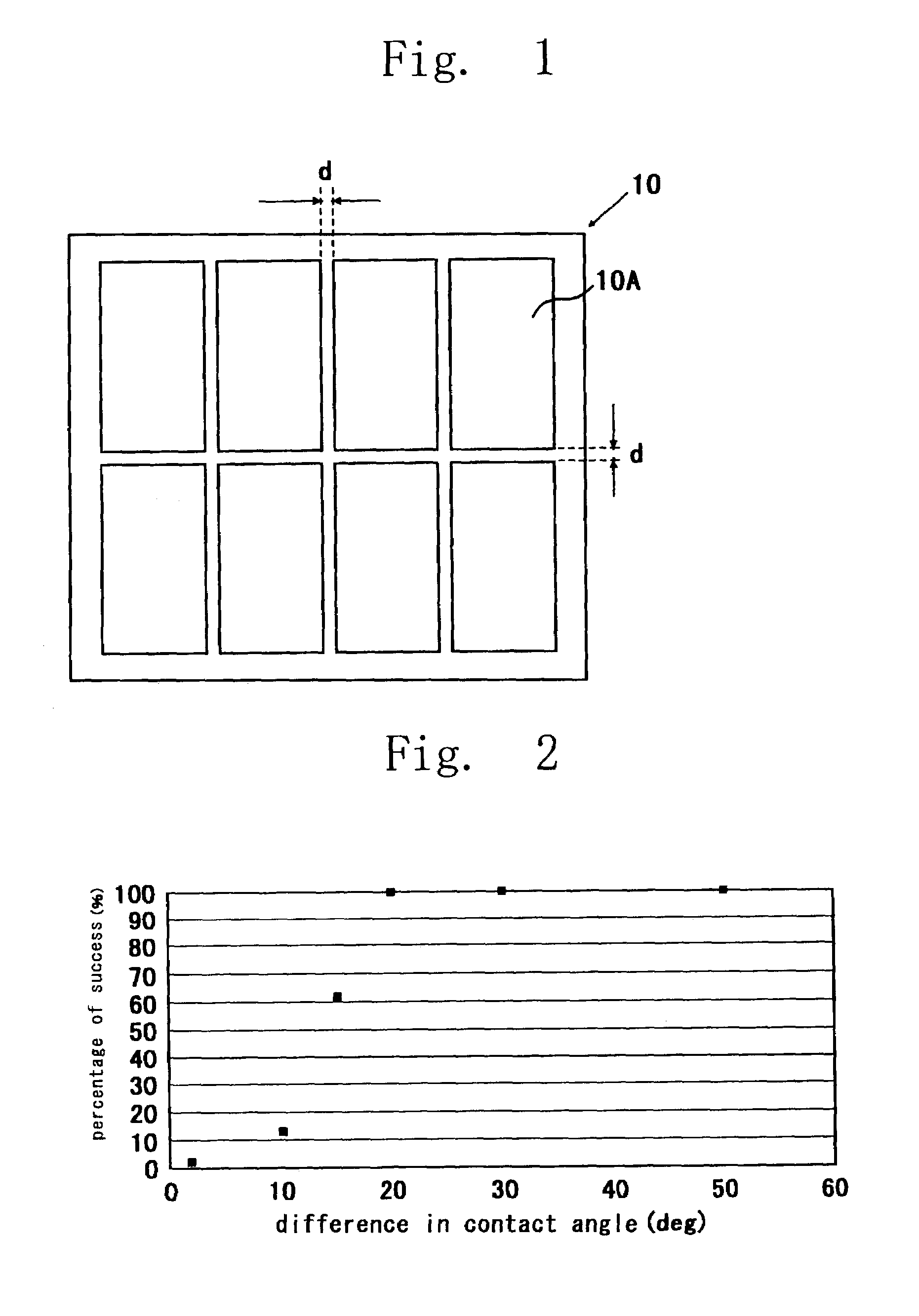

Field effect transistor and its manufacturing method

InactiveUS20060110847A1Improve mobilityEnhancing the orientation of channel moleculesSolid-state devicesSemiconductor/solid-state device manufacturingNanowireSpontaneous movements

To provide a method of easily producing TFT in which the orientation of channel molecules or wires is enhanced, compared with conventional type organic TFT at a low price, a lyophilic TFT pattern encircled by a lyophobic area is formed on a substrate, spontaneous movement is made in a droplet containing organic molecules or nanowires dropped in a channel region by characterizing the form of the pattern, and the organic molecules or the nanowires are oriented in the channel region by the movement.

Owner:HITACHI LTD

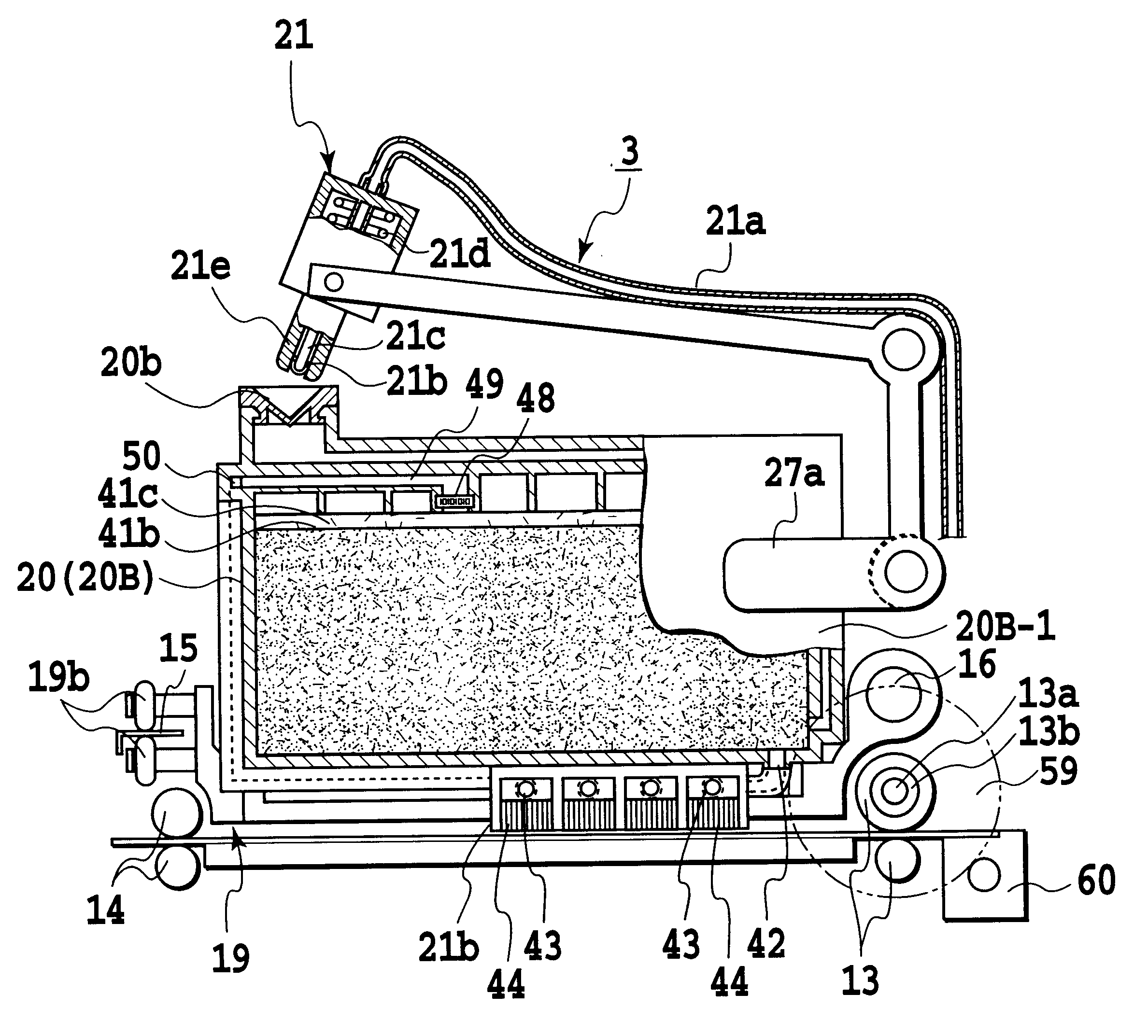

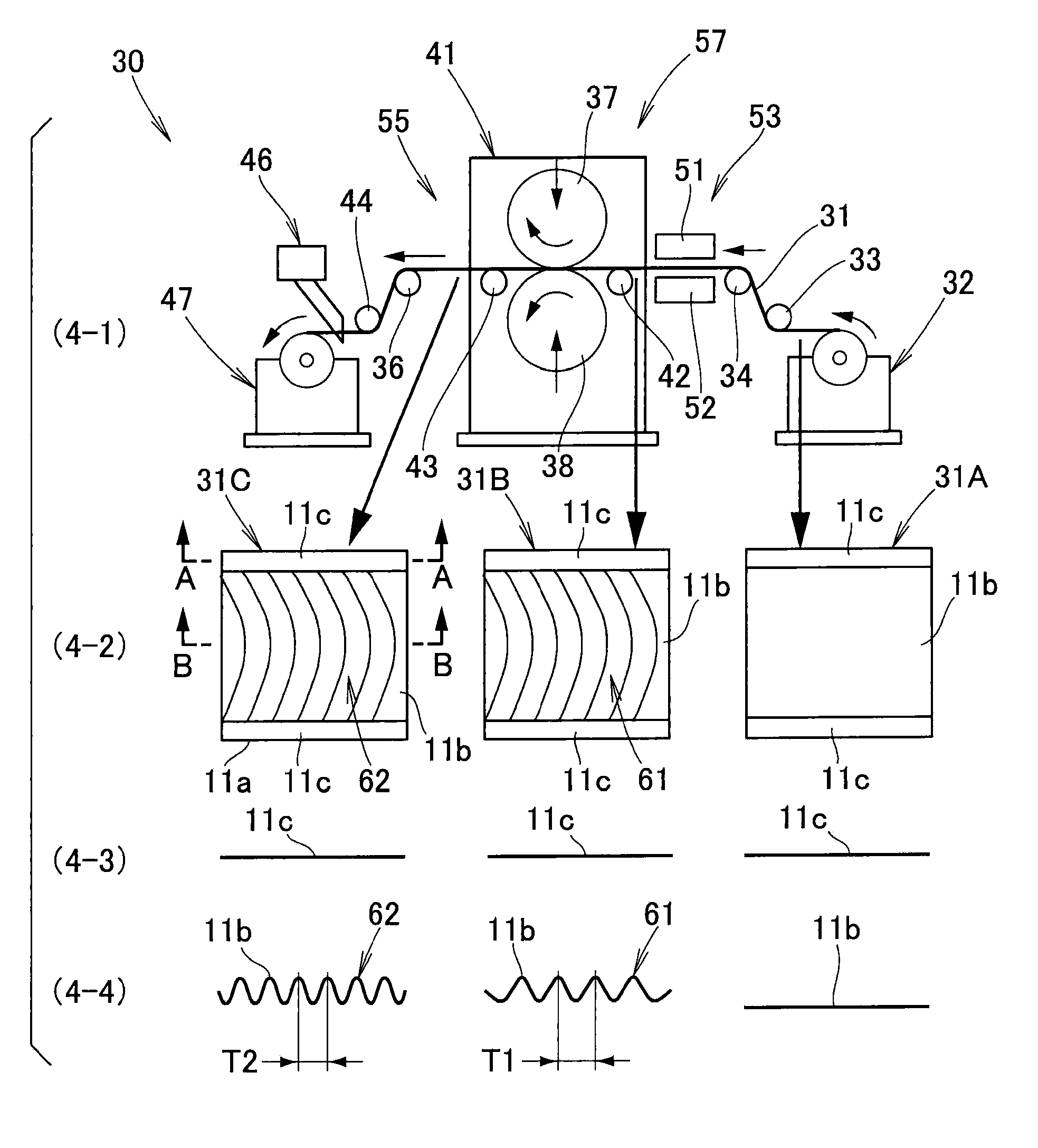

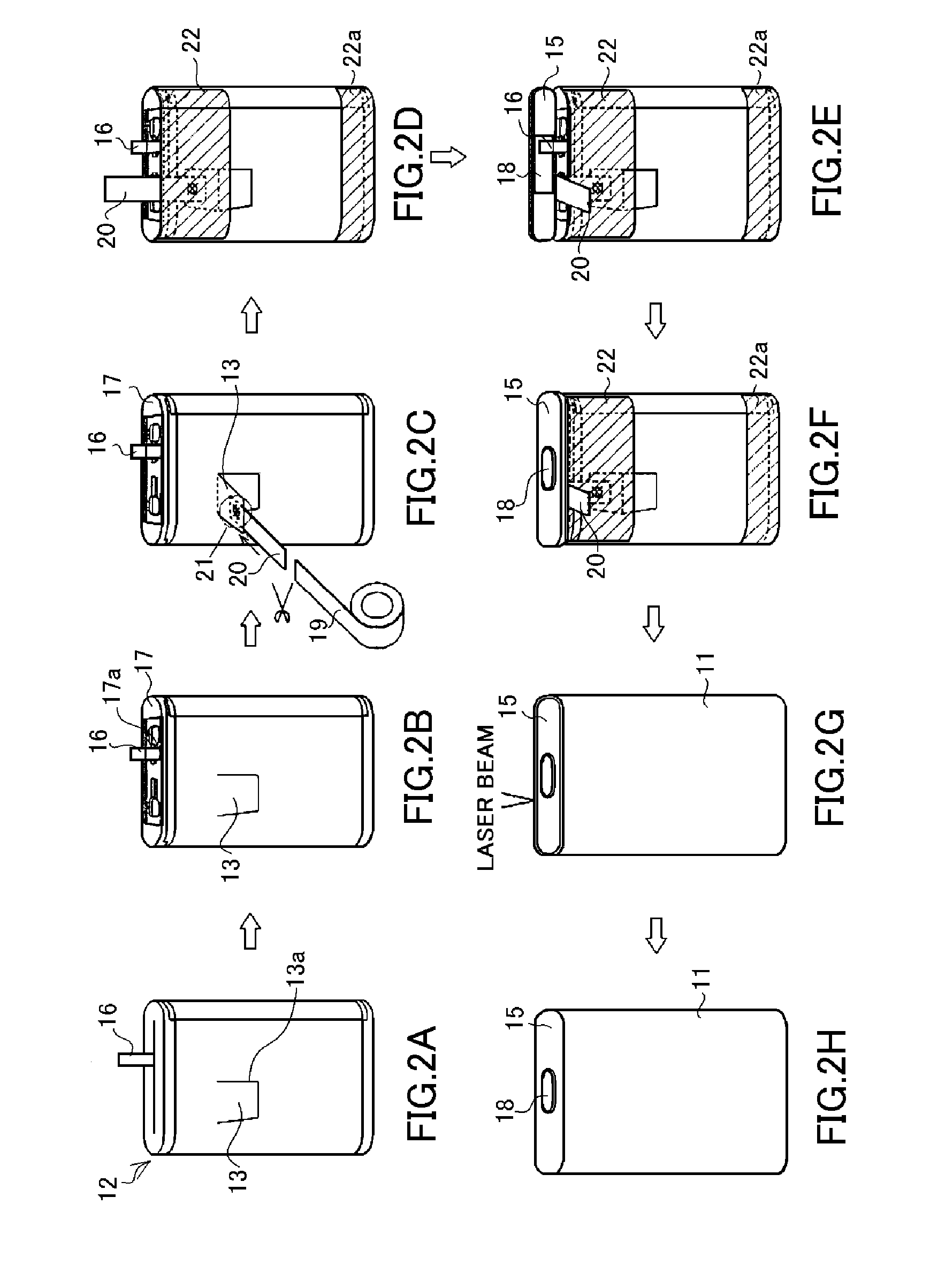

Battery manufacturing method and apparatus

InactiveUS20090100669A1Minimize thickness changeMinimize lowering of processing accuracyElectrode rolling/calenderingAssembling battery machinesElectrical and Electronics engineeringCurrent collector

For manufacturing a battery including positive and negative sheet electrodes formed from positive and negative electrode sheets each having active-material-coated portions on opposite surfaces, except for opposite surfaces of one side edge portion, of the sheet and non-active-material-coated portions on the opposite surfaces of the one side edge portion, a method includes: forming a succession of corrugations on each of the sheets, having the coated portions provided thereon, in a longitudinal direction of the sheet; roll-pressing each of the sheets having the corrugations formed thereon; constructing an electrode assembly of the positive and negative sheet electrodes with a separator interposed therebetween; and connecting current collectors to the non-coated portions of the sheet electrodes.

Owner:HONDA MOTOR CO LTD

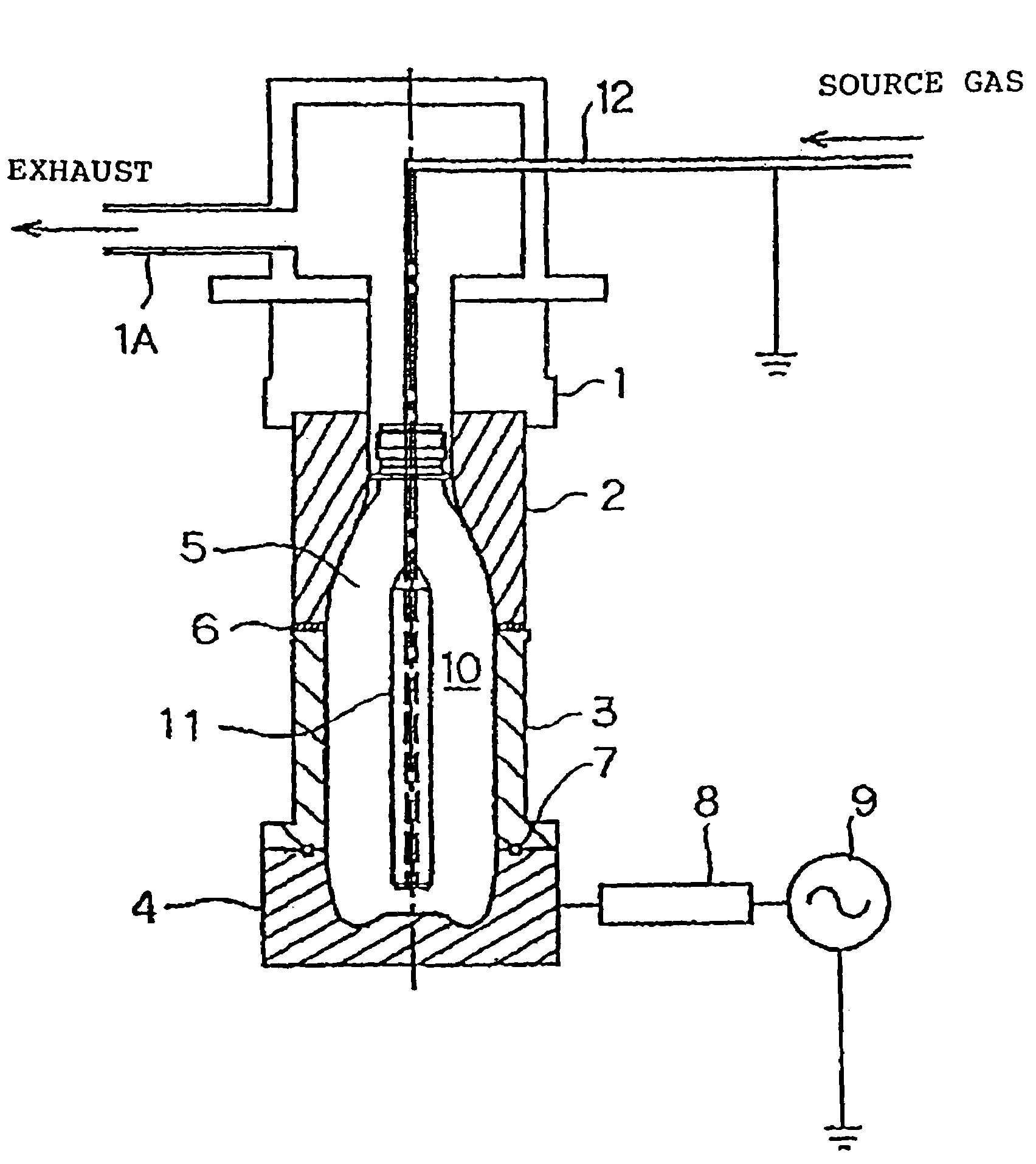

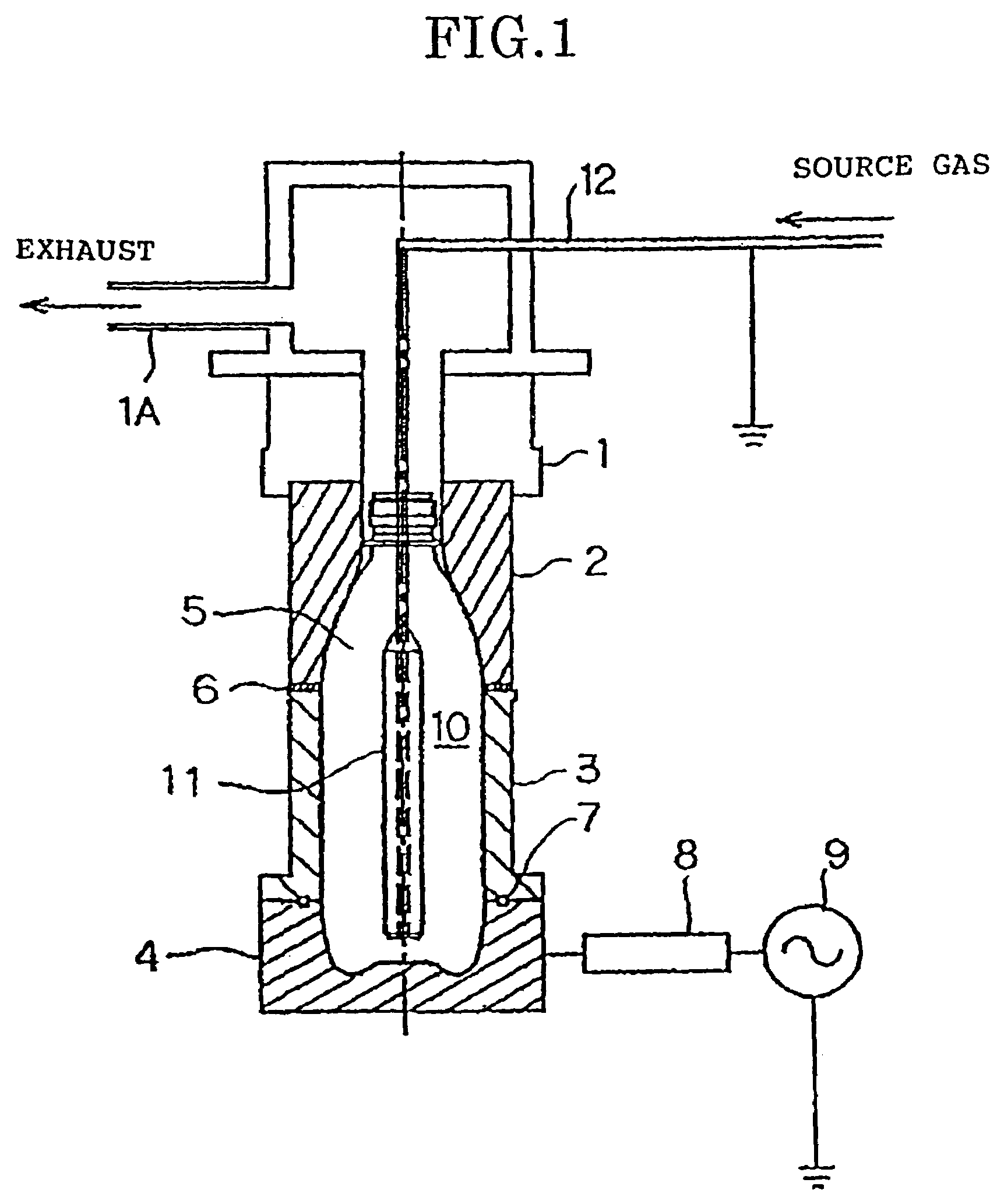

Plastic container for liquid medicine and method of storing and recovering liquid medicine

InactiveUS7029752B2Reduced activityReduce concentrationBottlesSynthetic resin layered productsDiamond-like carbonWater vapor

A plastic container for liquid medicine, which, concerning the effective components of liquid medicine, is capable of prevention of deterioration in quality due to mixing of oxygen and water vapor, prevention of variation in concentration due to water volatilization and moisture absorption, etc. A plastic container for liquid medicine, which is a plastic container internally coated with DLC (diamond-like carbon) film wherein water vapor permeability is 0–0.006 g / container / day and oxygen permeability is 0–0.011 ml / container / day, such properties being obtained by optimizing the three conditions, composition, density and film thickness of the DLC film.

Owner:MITSUBISHI SHOJI PLASTICS

Ion complex, coated product and coating method

InactiveUS6555225B1Inhibition of dissolutionMaintain stabilitySynthetic resin layered productsPharmaceutical containersOrganic solventWater insoluble

An ion complex which comprises a water-insoluble polyion (P) and a water-soluble polyion (A); and is insoluble in water and soluble in an aqueous organic solvent. Such an ion complex becomes a coating material which can preferably be used for coating of various ionic substances (e.g., substance having biological activity such as an anticoagulant property or an antibacterial property).

Owner:MEBIOL +1

Fuel hose

InactiveUS6467509B1Excellent to to permeationIncrease resistanceLayered productsHeat exhanger conduitsPolymer sciencePhenol

A fuel hose comprising a rubber layer and a fluororesin layer formed on the inner surface of the rubber layer, in which the adhesion to the fluororesin layer is improved by blending from 2 to 15 phr of a phenol-type resin with the rubber forming the rubber layer. Phenol resins of a specific polymeric structure are particularly preferred as the phenol-type resins. A fluororesin layer formed by melting a fluororesin and allowing it to adhere to the inner surface of the rubber layer by powder coating is particularly preferred. The provision of the fluororesin layer on the inner surface of the rubber layer enables simple and effective adhesion of the thinned fluororesin layer to the rubber layer.

Owner:SUMITOMO RIKO CO LTD

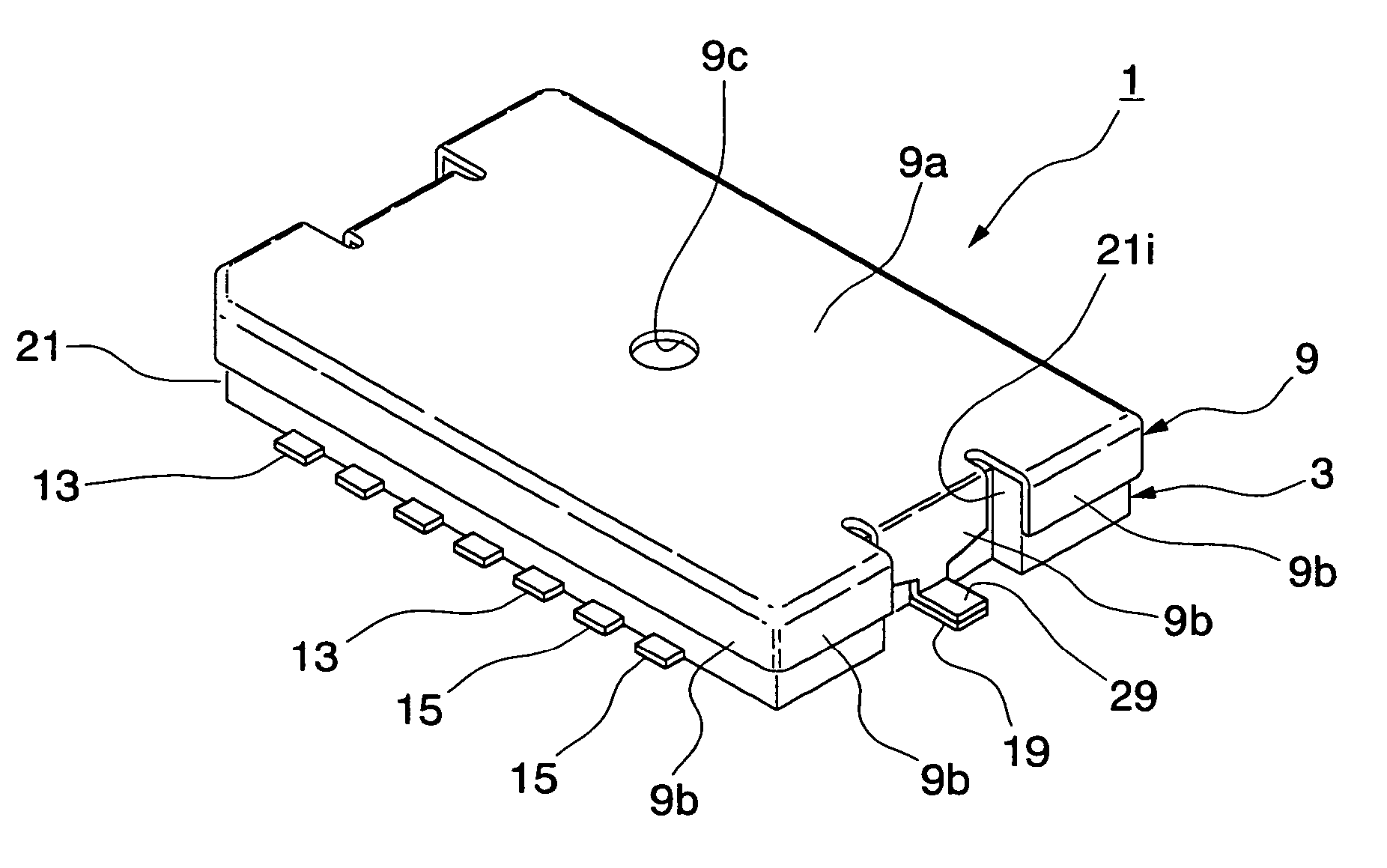

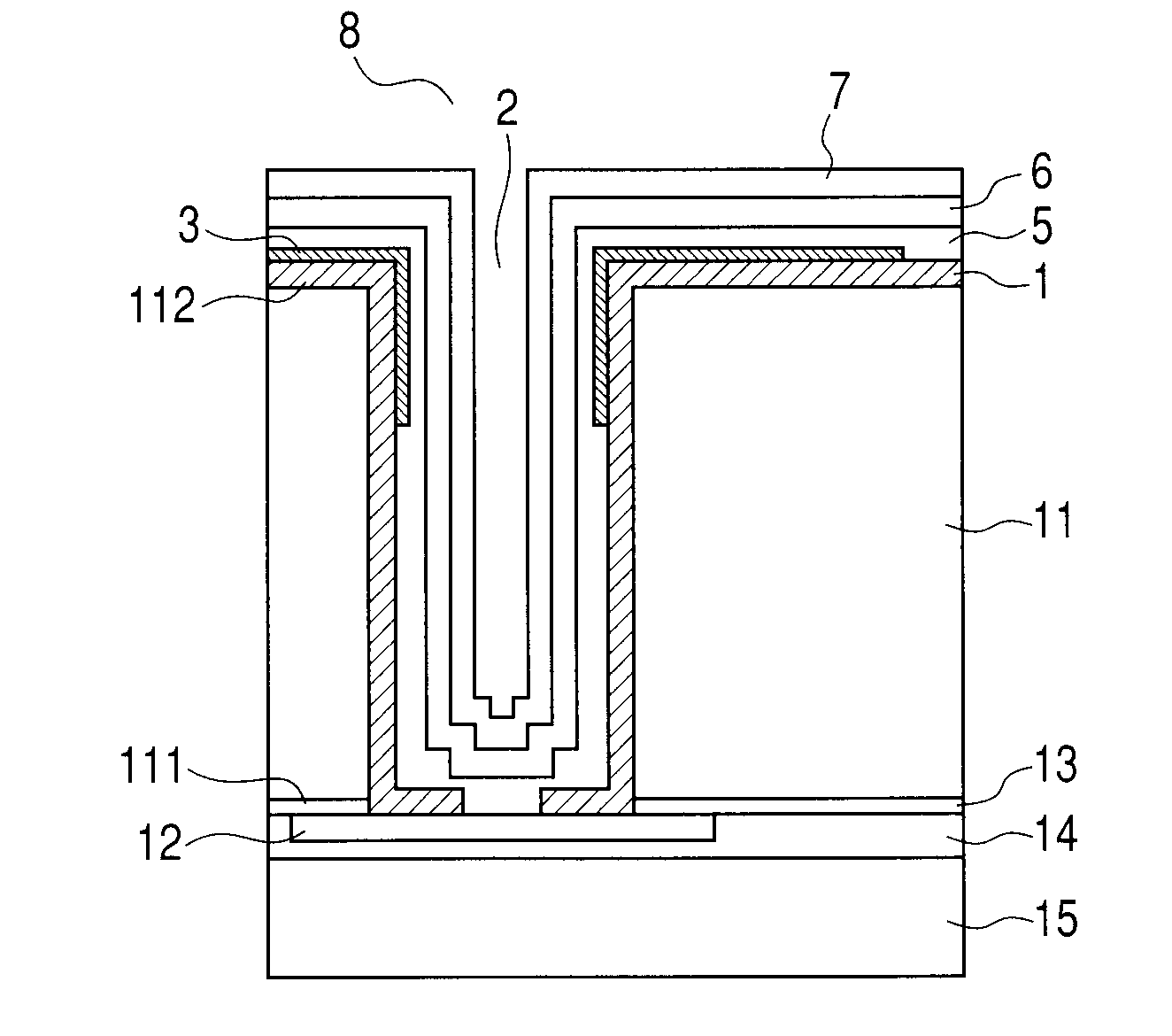

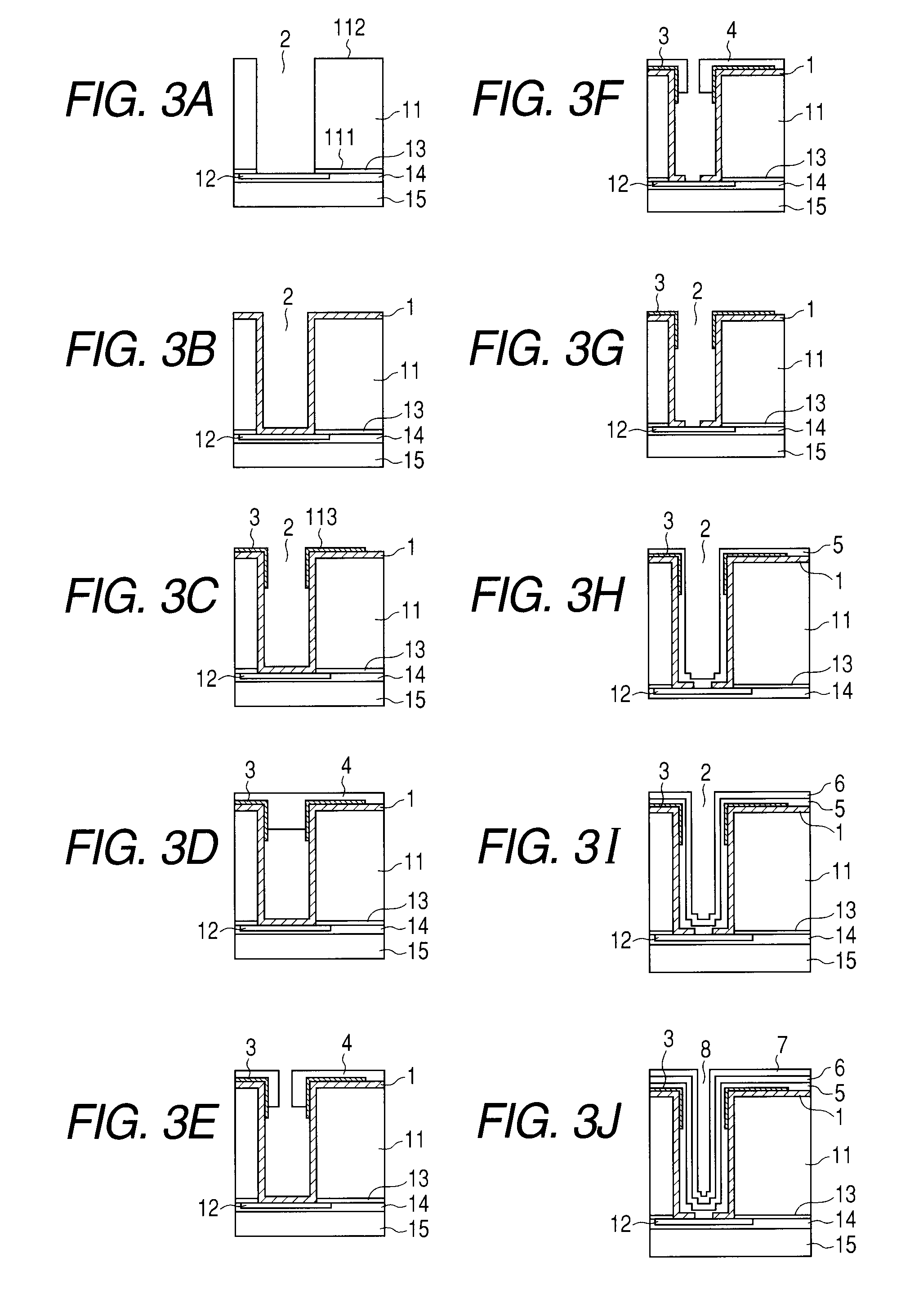

Semiconductor device

ActiveUS7560811B2Formed with easeSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipSemiconductor sensor

A semiconductor device is designed such that a semiconductor sensor chip having a diaphragm for detecting pressure variations based on the displacement thereof is fixed onto the upper surface of a substrate having a rectangular shape, which is covered with a cover member so as to form a hollow space embracing the semiconductor sensor chip between the substrate and the cover member. Herein, the substrate is sealed with a molded resin such that chip connection leads packaging leads are partially exposed externally of the molded resin; the chip connection leads are electrically connected to the semiconductor sensor chip and are disposed in line along one side of the semiconductor sensor chip; and the packaging leads are positioned opposite the chip connection leads by way of the semiconductor sensor chip. Thus, it is possible to downsize the semiconductor device without substantially changing the size of the semiconductor sensor chip.

Owner:INFINEON TECH AG

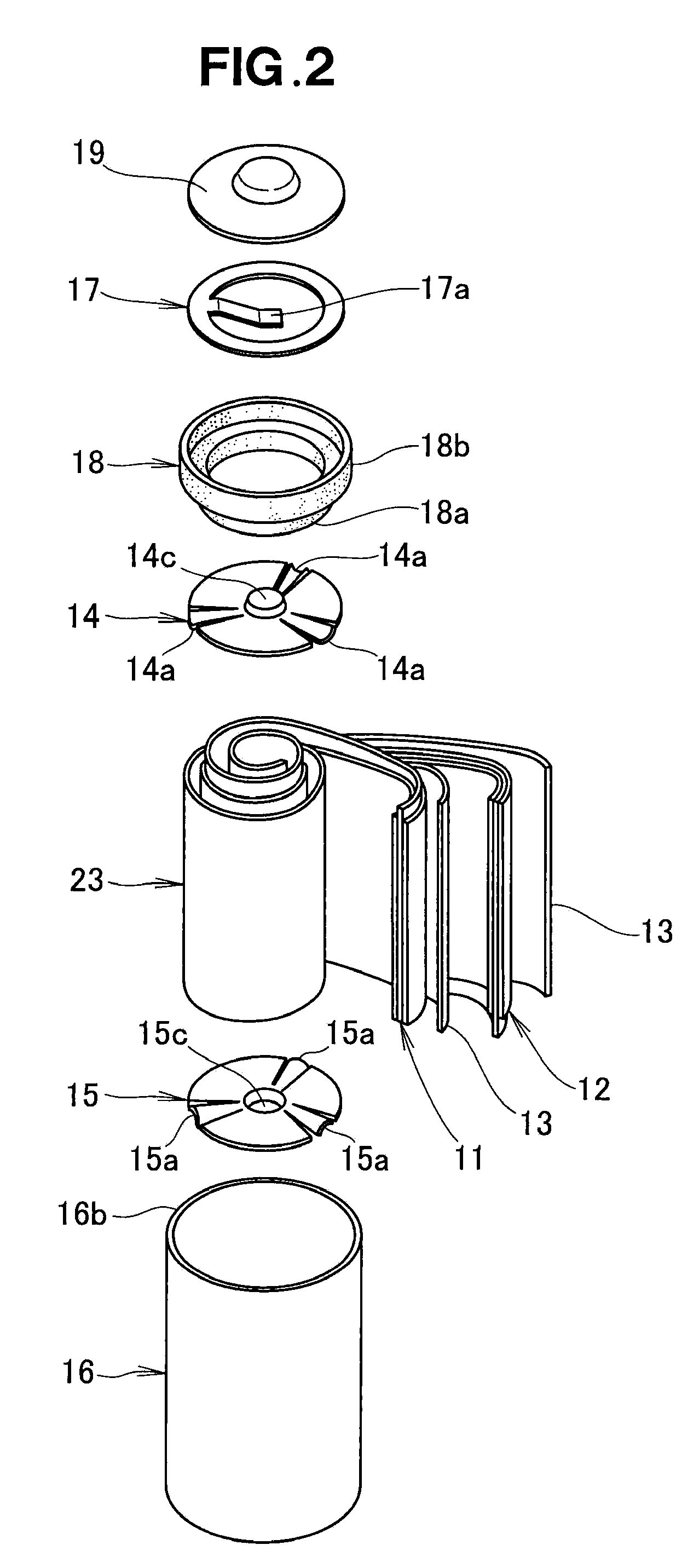

Terminal for sealed battery and manufacturing method therefor

InactiveUS20120058390A1Formed with easeImprove sealingSmall-sized cells cases/jacketsSecondary cellsEngineeringShape matching

A negative electrode terminal includes an outer terminal of a solid flat rivet shape and an inner terminal of a hollow flat rivet shape. A hollow axle portion of the inner terminal is inserted in a first insulating member, an opening bored in a sealing plate, and a second insulating member so as to be insulated from the sealing plate. A columnar axle portion of the outer terminal is inserted into the hollow axle portion of the inner terminal and crimped thereto, so that a radially bulge-deformed portion is formed in an intermediate portion of the columnar axle portion. The hollow axle portion deforms into a shape matching the radially bulge-deformed portion and is crimped to the columnar axle portion, and its tip is curling-formed to match a curved surface between a brim portion and the columnar axle portion of the outer terminal.

Owner:SANYO ELECTRIC CO LTD

Semiconductor apparatus manufacturing method and semiconductor apparatus

InactiveUS20100127403A1High yieldImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesResistEtching

There is provided a method of manufacturing the semiconductor apparatus, including: forming through-hole which penetrates a semiconductor substrate at a point that corresponds to a location of an electrode pad; forming an insulating film on a rear surface of the semiconductor substrate, including the interior of the through-hole; forming an adhesion securing layer from a metal or an inorganic insulator on a surface of the insulating film at least in an opening portion of the through-hole; forming a resist layer to serve as a mask in bottom etching on the adhesion securing layer; performing bottom etching to expose the electrode pad; removing the resist layer to obtain the insulating film free of surface irregularities that would otherwise have been created by bottom etching; forming a barrier layer, a seed layer, and a conductive layer by a low-temperature process; and performing patterning.

Owner:CANON KK

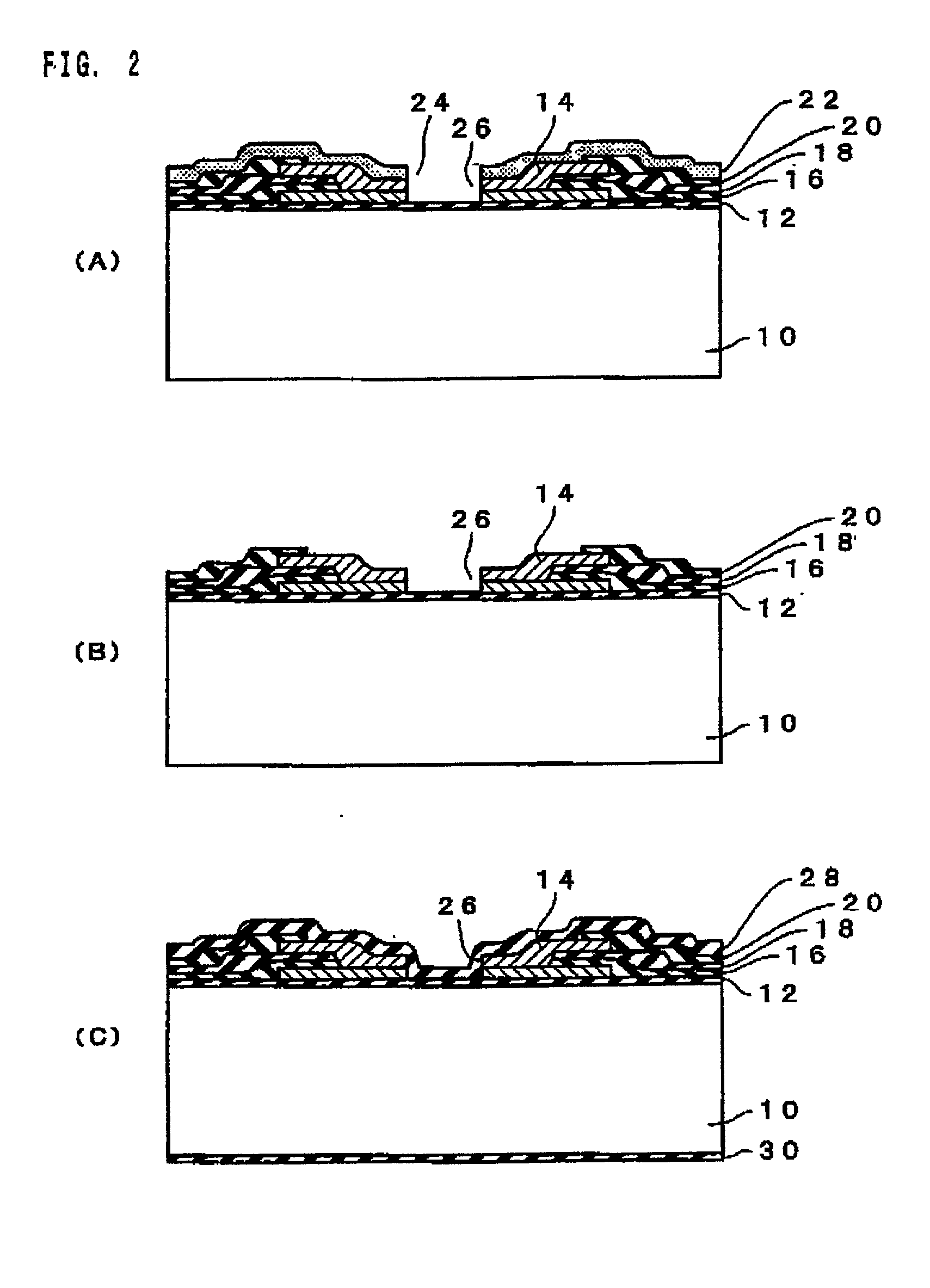

Radiation-sensitive resin composition, forming process for forming patterned insulation film, active matrix board and flat-panel display device equipped with the same, and process for producing flat-panel display device

InactiveUS6984476B2Less treatment stepFormed with easeVessels or leading-in conductors manufactureDiazo compound compositionsElectrical conductorRadiation sensitivity

The invention provides a radiation-sensitive resin composition, by which a patterned insulation film whose water repellency varies is easily formed with high precision, a process for forming a patterned insulation film using this composition, a display element and an flat-panel disply device using the composition, and a process for producing the flat-panel disply device.The resin composition comprises (A) an alkali-soluble copolymer, (B) a 1,2-quinonediazide compound and (C) a water-repellent siloxane resin in particular proportions. In the production process of the patterned insulation film, patterning exposure and development are conducted on a coating formed of the resin composition. The display element and flat-panel disply device are equipped with an interlayer insulation film formed by the resin composition. The production process of the flat-panel disply device comprises an interlayer insulation film-forming step including a treatment of patterning exposure exposing conductor layer-forming regions in an exposure that only surface layer portions are cured in one part thereof, and the whole in the thickness-wise direction thereof is cured in the other parts, and a conductor layer-forming step of forming conductor layers on the surface of the interlayer insulation film with a liquid material.

Owner:SHARP KK +1

Method of manufacturing a semiconductor device

InactiveUS7169656B2Transmittivity is loweredReduce intensityTransistorSolid-state devicesPhotolithographyIon implantation

Formation of LDD structures and GOLD structures in a semiconductor device is conventionally performed in a self aligning manner with gate electrodes as masks, but there are many cases in which the gate electrodes have two layer structures, and film formation processes and etching processes become complex. Further, in order to perform formation of LDD structures and GOLD structures only by processes such as dry etching, the transistor structures all have the same structure, and it is difficult to form LDD structures, GOLD structures, and single drain structures separately for different circuits. By applying a photolithography process for forming gate electrodes to photomasks or reticles, in which supplemental patterns having a function of reducing the intensity of light and composed of diffraction grating patterns or translucent films, are established, GOLD structure, LDD structure, and single drain structure transistors can be easily manufactured for different circuits through dry etching and ion injection process steps.

Owner:SEMICON ENERGY LAB CO LTD

Method for producing thin film heating element and heating device using same

InactiveUS20040099657A1Increase thermal resistanceLow thermal expansionLamination ancillary operationsHeater elementsThin film electrodeChemical composition

A method of producing a thin film heating element is provided which can be used in manufacturing a transparent thin film heating element of desired shape with an increased heat emission property and an excellent durability. Also provided is a heating device of the type incorporating the thin film heating element produced by this method. The inventive method comprises the steps of, applying heat- and oil-resistant ink on a predetermined surface area of a base element, allowing the ink to run dry, spraying conductive chemical composition on the base element to form a conductive thin heater film, removing the ink out of the base element, printing a thin film electrode leading to the thin heater film, and baking the base element into a thin film heating element.

Owner:PARK SUNG DON

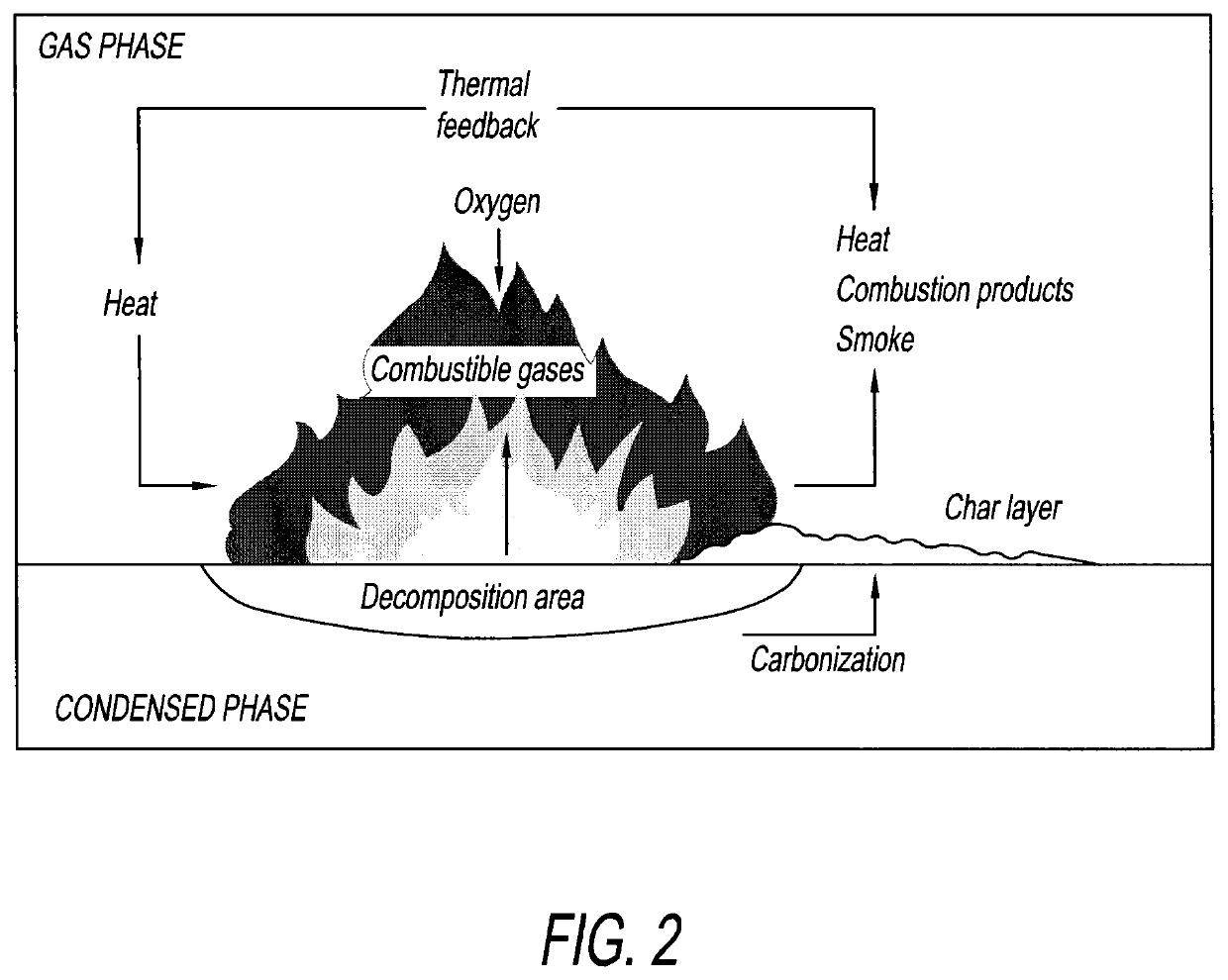

Flame retardant compositions and processes for preparation thereof

ActiveUS10752840B2Extended shelf lifeEasy to operateFireproof paintsPolymer scienceO-Phosphoric Acid

Owner:CHESTNUT SPRINGS LLC

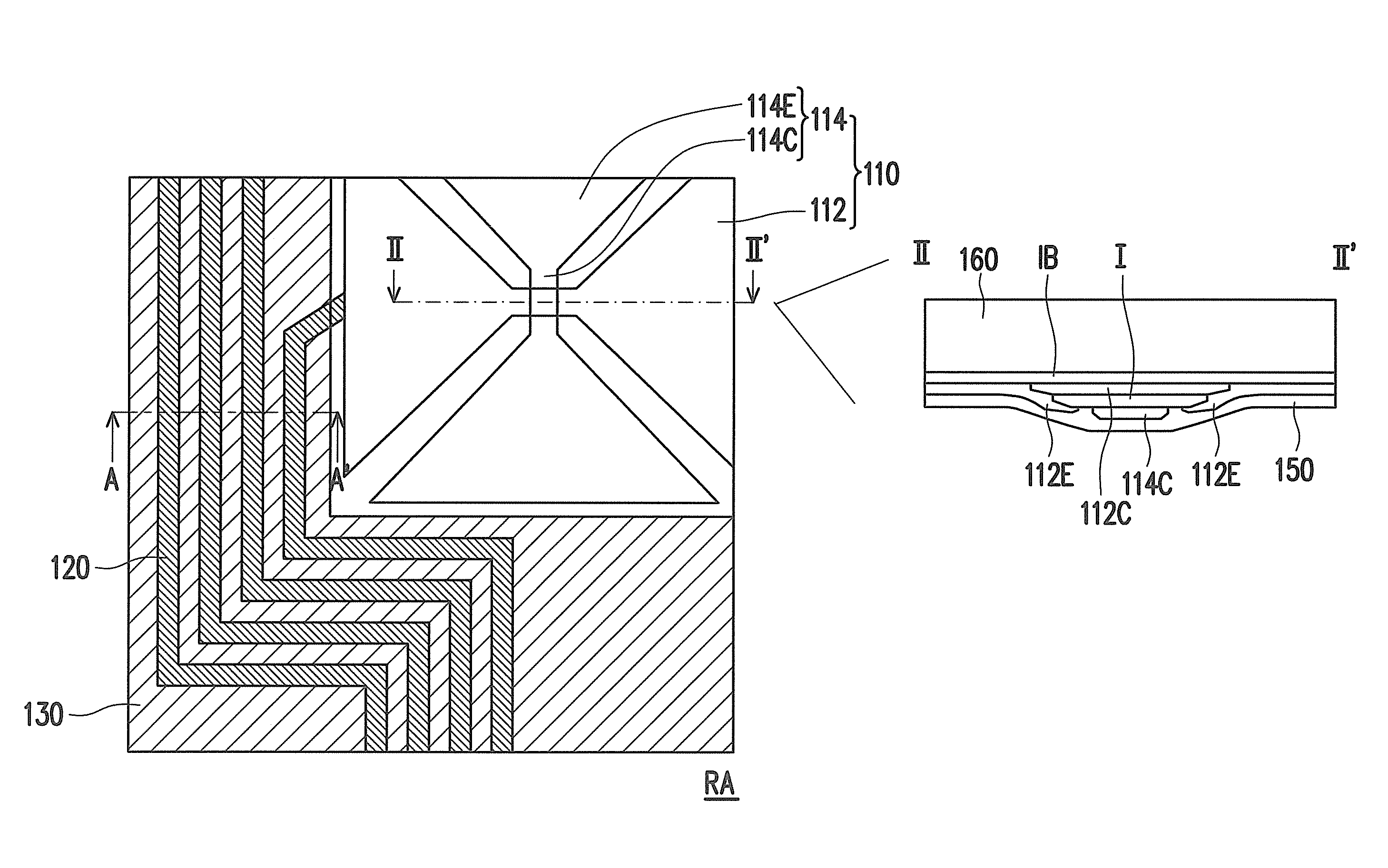

Touch panel and touch display panel

InactiveUS20120256851A1Satisfactory light shield effectLight shielding effectElectronic switchingInput/output processes for data processingTouch panelTransmission line

A touch panel has an active area and a peripheral area surrounding the active area. The touch panel includes a cover plate, a touch sensing element, a non-black color layer, transmission lines, a reflective pattern layer, and a protection layer. The touch sensing element is on the cover plate and in the active area. The non-black color layer is on the cover plate and in the peripheral area. The transmission lines at a side of the non-black color layer away from the cover plate and in the peripheral area electrically connect the touch sensing element. The reflective pattern layer is configured at the side of the non-black color layer away from the cover plate and at least located in a partial region of the peripheral area not covered by the transmission lines. The protection layer is configured at a side of the transmission lines away from the cover plate.

Owner:WINTEK CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com