Catalytic rearrangement preparation method of polycarbosilane

A technology of polycarbosilane and carbosilane, which is applied in the field of catalytic synthesis of polycarbosilane, can solve the problems of lower production cost, low reaction temperature, and good product quality, and achieve high ceramic yield, high reaction rate, and guaranteed product quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0047] Preparation example 1 (preparation of raw material LPS)

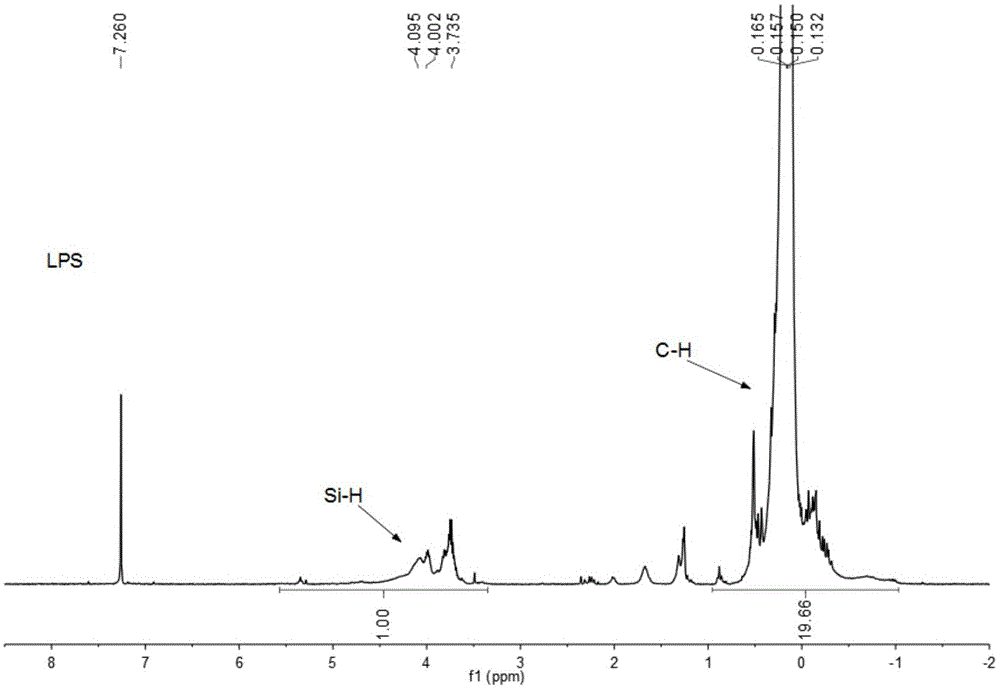

[0048] Add 1200g of solid PDMS powder into a 3L three-necked flask, vacuumize nitrogen or argon to replace the air three times, protect the argon flow, heat to 390-420°C with an electric heating mantle, and pyrolyze and distill to obtain about 1080g of colorless and transparent liquid silane (LPS), which 1 H-NMR, 29 Si-NMR, GC-MS and FTIR were as Figure 1-3 and Figure 10 (a) shown. These characterization results show that LPS is a complex mixture composed of more than 20 silane-carbosilane rings and a small number of linear small molecules, and its molecular structure can be determined by [(SiMe 2 ) 0.7 (CH 2 SiMeH) 0.3 ]express.

Embodiment 1

[0055] Experimental steps: (1) Vacuumize the atmospheric cracking rearrangement synthesis system, replace high-purity nitrogen, repeat 3 times; (2) under the protection of high-purity nitrogen, put the LPS (190g) of Preparation Example 1 into the reaction device In, then under stirring, add 0.38g of B (C 6 f 5 ) 3 Catalyst (being 0.20wt% of LPS); (3) heating up, be warming up to 395 ℃ through 35h, and heat preservation reaction 5h, total reaction time is 40h; (6) cooling room temperature obtains crude product 131.89g, and crude product liter To 370°C, low molecular weight was removed by distillation; (7) cooled to room temperature to obtain 122.31g of the product.

[0056] The synthesis yield of the crude product of PCS in this embodiment is 69.4%, and the yield of the final product (PCS-S1) is 64.4%, and its thermogravimetric (TGA) curve is shown in Figure 11 , It can be seen that the ceramic yield is 70.5%. The melting point of PCS-S1 is 235-250°C. Depend on Figure 8...

Embodiment 2

[0059] Experimental steps: (1) Vacuumize the atmospheric cracking rearrangement synthesis system, replace high-purity nitrogen, repeat 3 times; (2) under the protection of high-purity nitrogen, put the LPS (190g) of Preparation Example 1 into the reaction device In, then under stirring, add 0.38g of B (C 6 f 5 ) 3 Catalyst (0.20wt% of LPS); (3) temperature program, 23.5h to 395°C, and heat preservation reaction for 4h, the total reaction time is 27.5h; (6) then distilled at 370°C to remove low molecular weight; (7 ) was cooled to room temperature to obtain product (PCS-S2) 113.05g (yield 59.5%), and its ceramic yield was 70.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com