Method for preparing nano flyash zeolite

A technology for fly ash zeolite and fly ash is applied in the field of preparation of fly ash synthetic zeolite to achieve the effects of eliminating environmental damage, saving costs and being easy to operate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

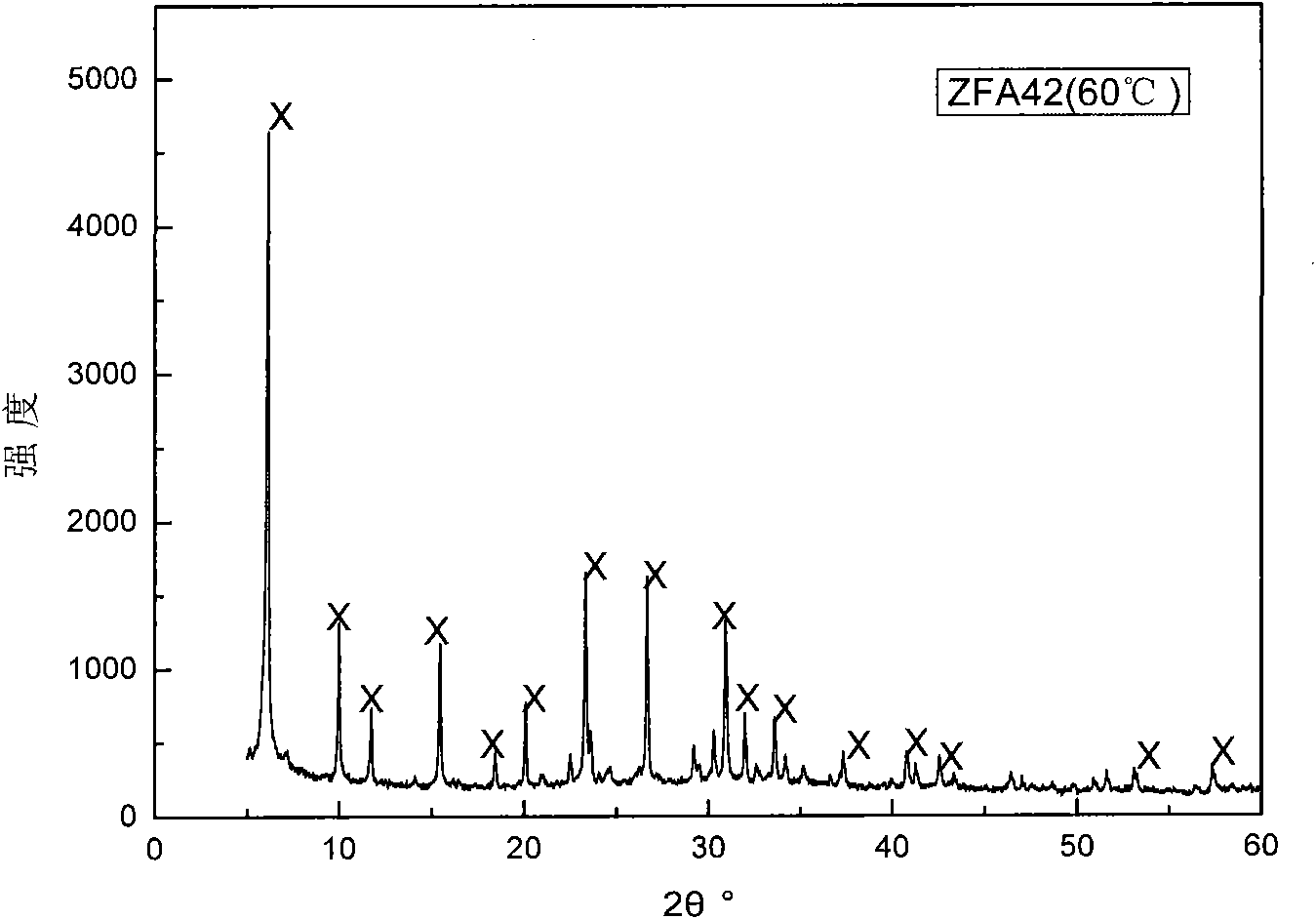

[0017] Accurately Weighing Amorphous SiO 2 and Al 2 O 3 5g of power plant fly ash with a content of 45.46% and 26.38%, respectively, was uniformly mixed with 5g of NaOH and then placed in a muffle furnace for calcination at 500°C for 1.5h to obtain clinker. 80 ml of concentrated seawater with a salinity of 42‰ was added to the obtained clinker, and the mixture was stirred at room temperature for 24 hours to obtain a silica-alumina gel. The prepared silica-alumina gel was hydrothermally reacted at 60 °C for 72 hours, and after the reaction, solid-liquid separation was carried out, washed with water to near neutrality, and dried to obtain a sample, which was characterized by X-ray diffraction. The obtained zeolite was NaX type zeolite. X-ray diffraction See attached picture. The average particle diameter of the obtained zeolite was measured to be 77.5 nm. The cation exchange capacity of the product determined by the ammonium acetate method was 394.0642 mmol / 100g, figure 1 T...

Embodiment 2

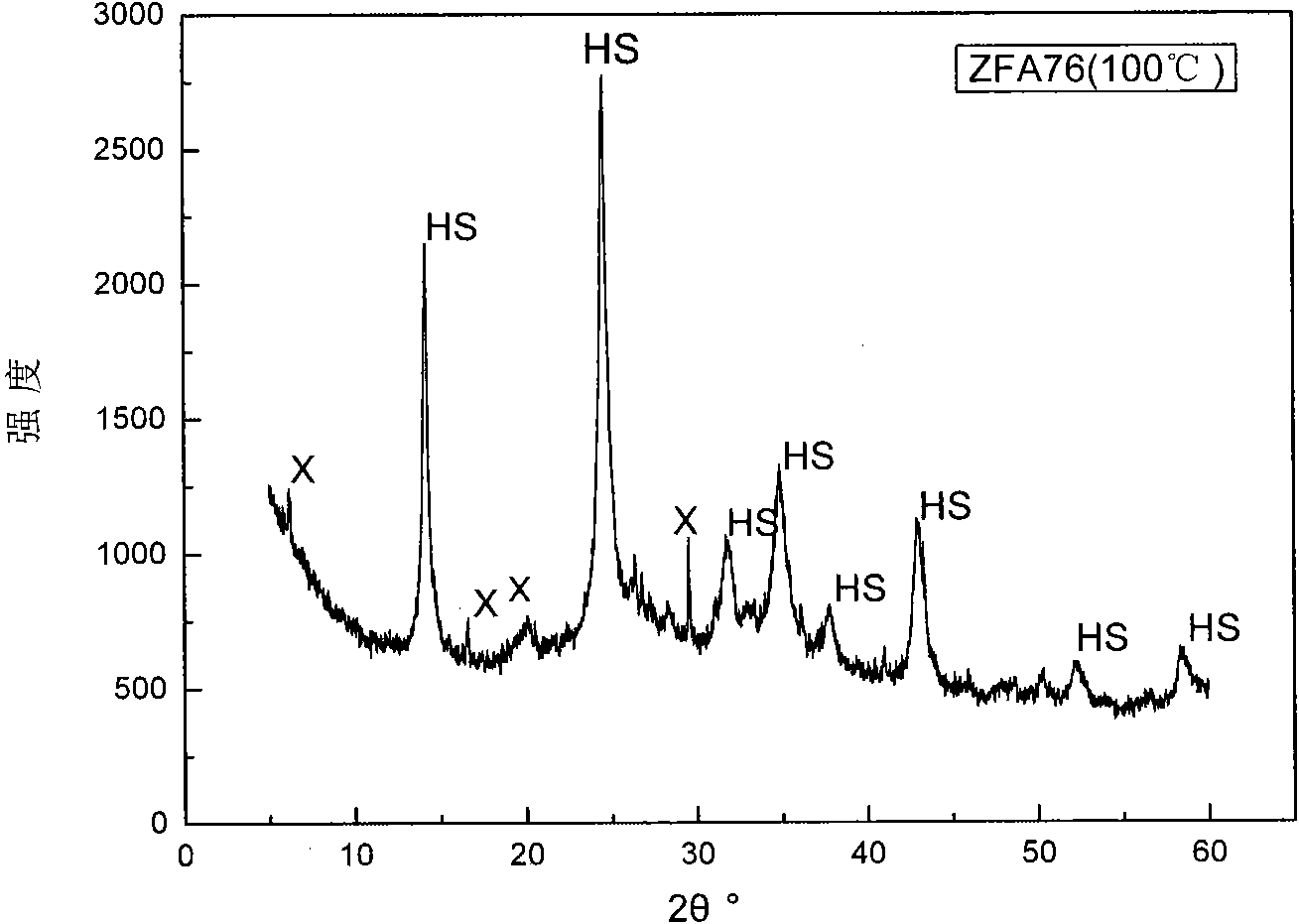

[0019] Accurately Weighing Amorphous SiO 2 and Al 2 O 3 5g of power plant fly ash with a content of 45.46% and 26.38% respectively, mixed with 6g of NaOH and placed in a muffle furnace for calcination at 550°C for 2h to obtain clinker. Add 55ml of concentrated seawater with a salinity of 76‰ to the clinker, and stir at room temperature for 24h to obtain silica-alumina gel. The prepared silica-alumina gel was placed in a polyethylene-lined stainless steel reactor, sealed and crystallized under autogenous pressure at 100 °C for 6 h, and then subjected to solid-liquid centrifugation, and repeatedly washed with deionized water until the pH value of the filtrate was reached. about neutral. The washed product was placed in an oven, dried at 80° C. for 12 hours, and ground into powder. X-ray diffraction characterization analysis shows that the product is a mixture of NaX-type zeolite and hydroxysodalite, and the X-ray diffraction pattern is shown in the accompanying drawing. The...

Embodiment 3

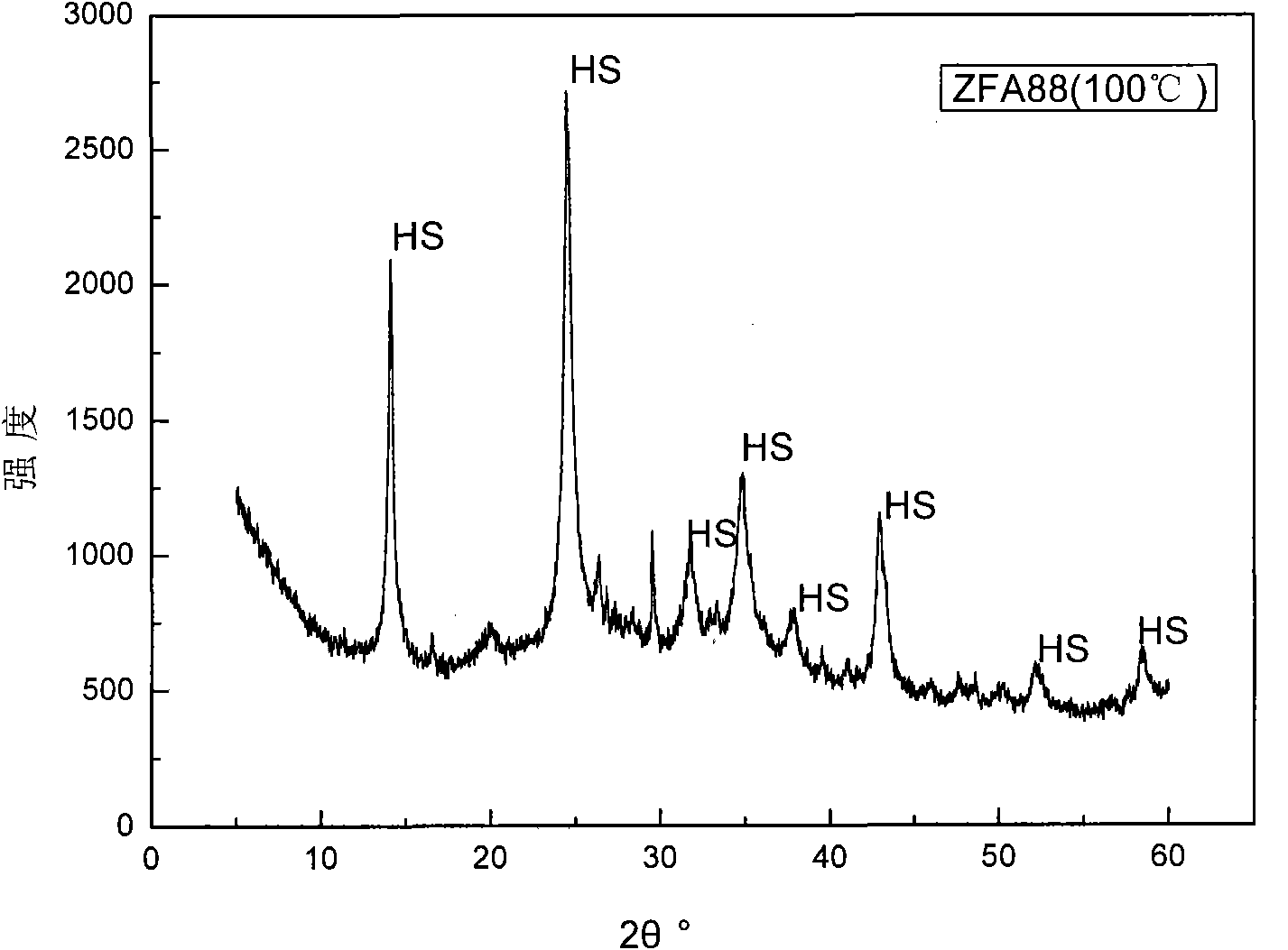

[0021] Accurately Weighing Amorphous SiO 2 and Al 2 O 3 10g of power plant fly ash with a content of 45.46% and 26.38% respectively, mixed with 12g of NaOH and calcined at 550°C for 2h in a muffle furnace to obtain clinker. Add 110 ml of concentrated seawater with a salinity of 88‰ to the clinker, and stir at room temperature for 24 hours to obtain silica-alumina gel. The prepared silica-alumina gel was placed in a polyethylene-lined stainless steel reactor, sealed and crystallized under autogenous pressure at 100 °C for 6 h, and then subjected to solid-liquid centrifugation, and repeatedly washed with deionized water until the pH value of the filtrate was reached. about neutral. The washed product was placed in an oven, dried at 80° C. for 12 hours, and ground into powder. X-ray diffraction analysis shows that the product is hydroxysodalite, the cation exchange capacity of the product is 262.4004mmol / 100g determined by ammonium acetate method, and the zeolite product is a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com