In-situ ceramization type anti-oxidant resin, resin matrix and ceramic material, as well as preparation method of resin

A technology of anti-oxidation and ceramicization, applied in the field of composite materials, to achieve the effect of convenient operation, good compatibility and simple curing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0084] Embodiment 1, preparation PBSCN-1-1 resin

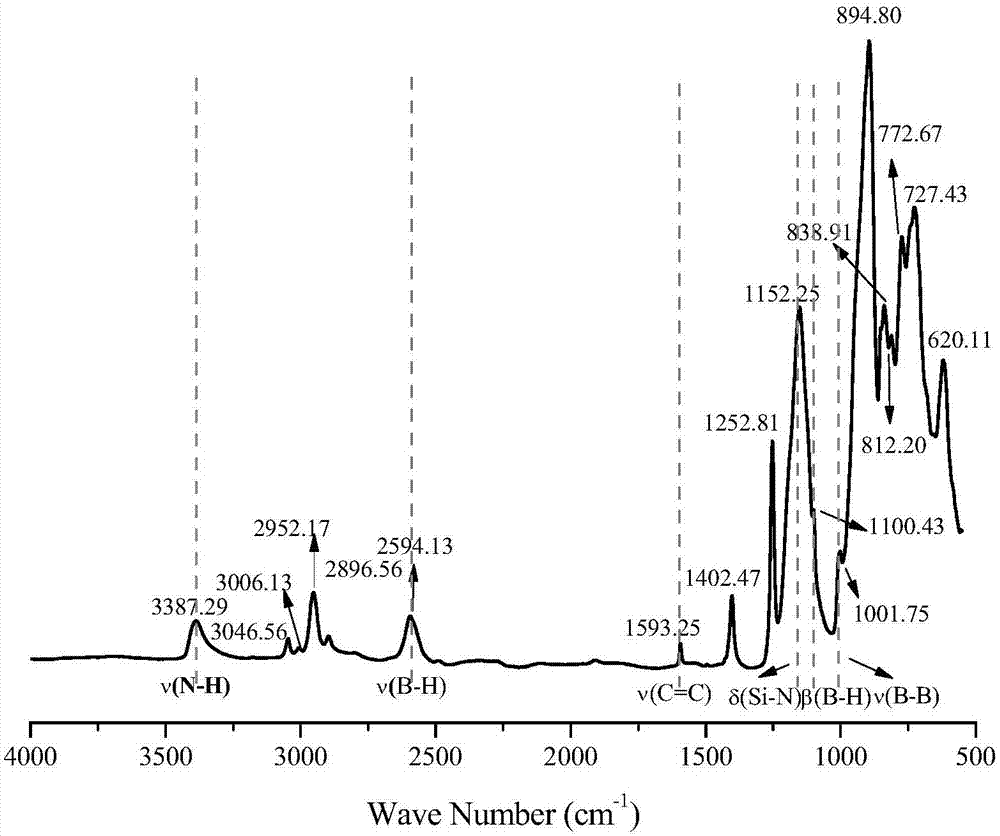

[0085] Take 85 g of silazane resin 1 (structure shown in formula V) and put it into a 250 ml three-necked flask, and install a magnet and a thermometer. Heating in an oil field, heating up while stirring, until the temperature of the system reaches 80°C. Take by weighing 15g of carborane monomer (structure as shown in IV), quickly add to the flask, increase the stirring force, keep heating, wait for the resin system to be homogeneous and then insulate and stir for 60min, finally obtain PBSCN-1-1 resin, its Infrared spectrum such as figure 1 shown.

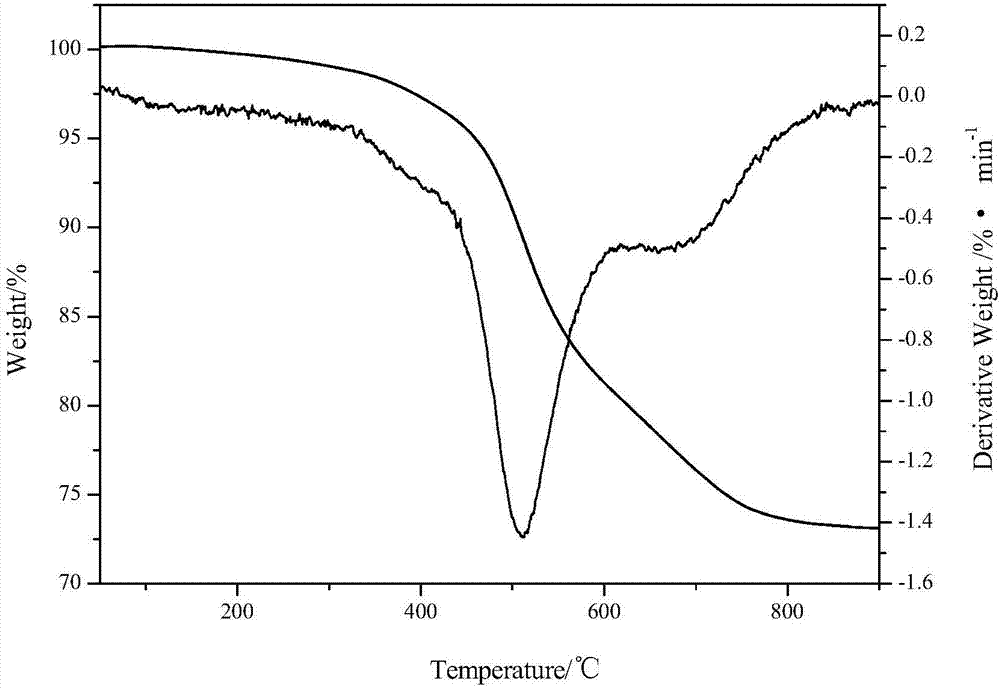

[0086] Prepare the resin matrix (resin cured product) according to the curing system of (140°C, 3h)+(180°C, 3h)+(240°C, 2h). Use N 2 TGA under air atmosphere characterizes its heat resistance performance, the heating rate is 10°C / min, and the temperature range is 25-900°C. Test results such as image 3 as shown, image 3 The PBSCN-1-1 resin prepared for the embodiment of the...

Embodiment 2

[0088] Embodiment 2, preparation PBSCN-1-2 resin

[0089] Take 71 g of silazane resin 1 (structure shown in V) and put it into a 250 ml three-necked flask, and install a magnet and a thermometer. Heating in an oil field, heating up while stirring, until the temperature of the system reaches 80°C. Weigh 29g of carborane monomer (structure as shown in IV), quickly add to the flask, increase the stirring force, keep heating, and keep stirring for 60min after the resin system is homogeneous, finally get PBSCN-1-2 resin.

[0090] Prepare the resin matrix (resin cured product) according to the curing system of (140°C, 3h)+(180°C, 3h)+(240°C, 2h). Use N 2 TGA under air atmosphere characterizes its heat resistance performance, the heating rate is 10°C / min, and the temperature range is 25-900°C. The cured product in N 2 T in air atmosphere d5 (The thermal decomposition temperature when the weight loss of the resin is 5%) is 391°C; the carbon residue rate at 900°C is 65.8%.

[009...

Embodiment 3

[0092] Embodiment 3, preparation PBSCN-2-1 resin

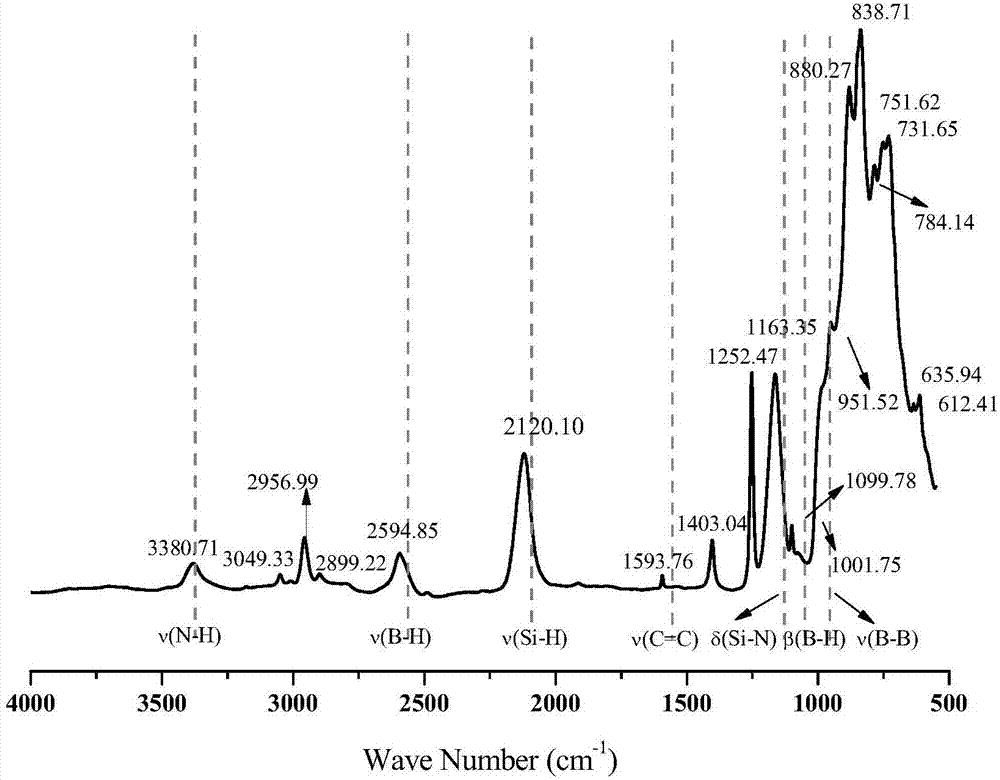

[0093] Take 85 g of silazane resin 2 (structure as shown in VI) and put it into a 250 ml three-necked flask, and install a magnet and a thermometer. Heating in an oil field, heating up while stirring, until the temperature of the system reaches 80°C. Take by weighing 15g of the carborane monomer (structure shown in IV), add it into the flask quickly, increase the stirring force, keep heating, and wait for the resin system to be homogeneous and then insulate and stir for 30min to finally obtain the PBSCN-2-1 resin. Infrared spectrum such as figure 2 shown.

[0094] According to the curing system of (140°C, 3h)+(180°C, 3h)+(240°C, 2h), the cured resin was prepared. Use N 2 TGA under air atmosphere characterizes its heat resistance performance, the heating rate is 10°C / min, and the temperature range is 25-900°C. The cured product in N 2 T in air atmosphere d5 (The thermal decomposition temperature when the weight loss of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| carbon residual rate | aaaaa | aaaaa |

| carbon residual rate | aaaaa | aaaaa |

| carbon residual rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com