Three-dimensional aluminum oxide fiber woven part reinforced aluminum oxide composite material based on aqueous slurry impregnation process and preparation method of three-dimensional aluminum oxide fiber woven part reinforced aluminum oxide composite material

A technology of alumina fiber and composite materials, which is applied in the field of continuous fiber reinforced ceramic matrix composite materials, and can solve problems such as long cycle time, fiber chemical damage, and complicated process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

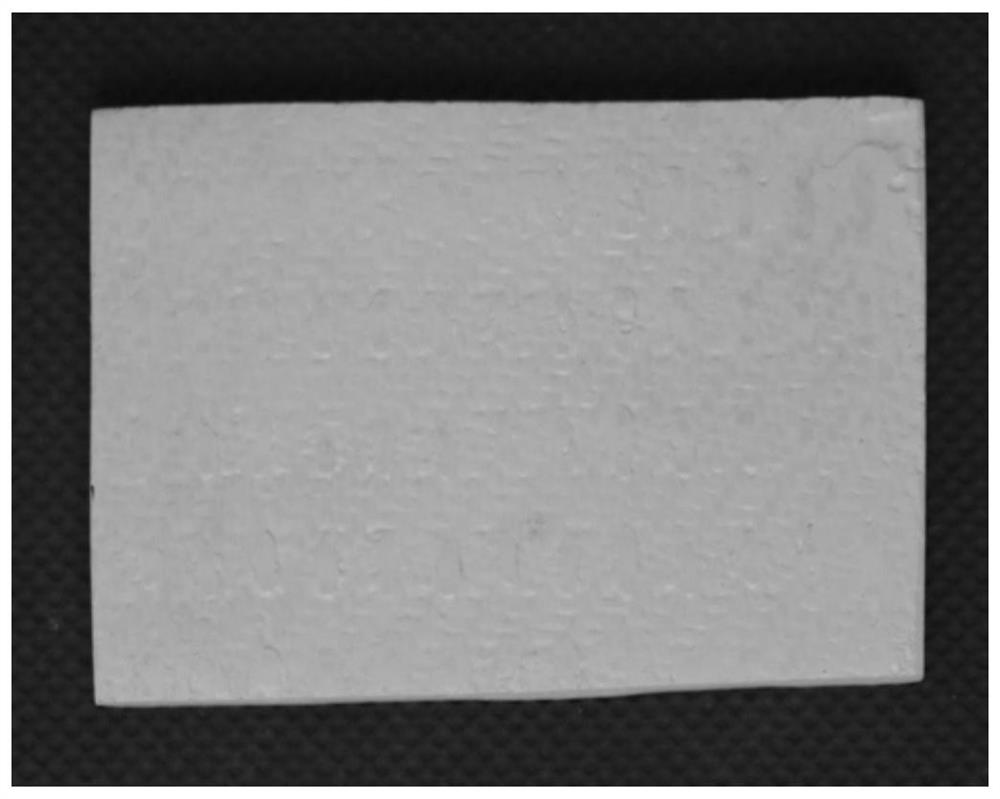

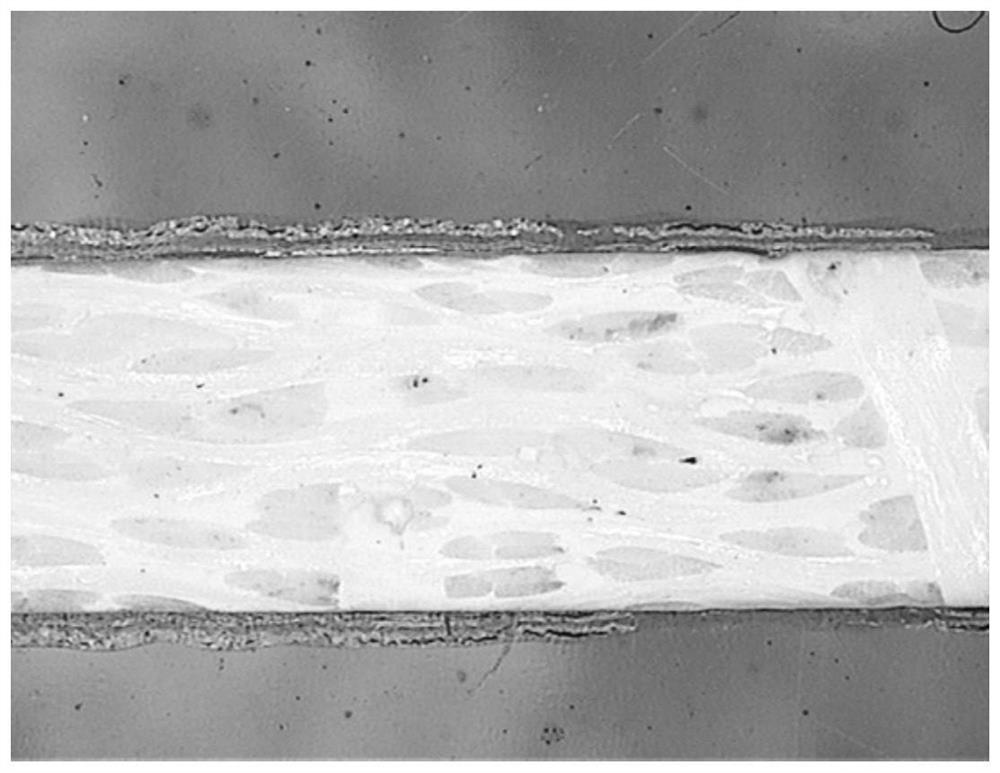

[0030] A three-dimensional alumina fiber braid reinforced alumina composite material based on the water-based slurry impregnation process. The porosity of the composite material is 21%. The composite reinforcement phase is a continuous alumina fiber braid, and the braid is stitched with fiber cloth. The mass content of alumina in the alumina fiber is 72%, and the fiber volume fraction in the composite material is 40%; the alumina matrix of the composite material is impregnated-dried-sintered multiple times through a high solid content, low viscosity water-based alumina powder slurry After the process is completed, the solid content of the aqueous alumina powder slurry is 30vol%, the slurry viscosity is 6mPa⋅s, the pH is 4.1, and the Zeta potential is 63mV.

[0031] This embodiment also provides a method for preparing a three-dimensional alumina fiber braided reinforced alumina composite material based on an aqueous slurry impregnation process, including the following steps:

...

Embodiment 2

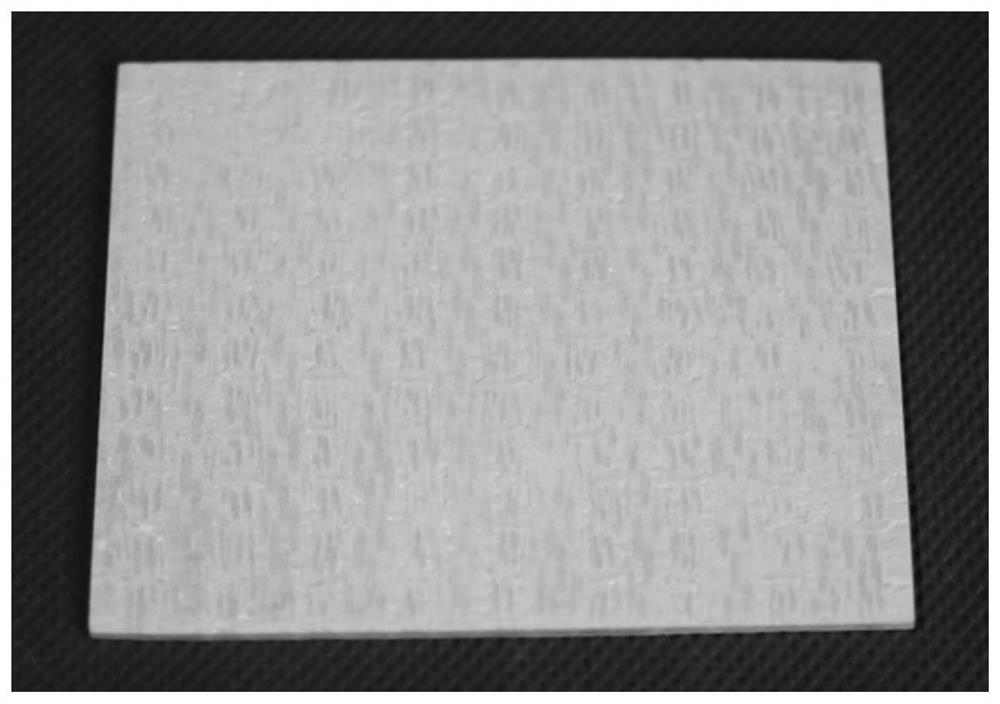

[0038] A three-dimensional alumina fiber woven piece reinforced alumina composite material based on the water-based slurry impregnation process. The porosity of the composite material is 25%. The composite material reinforcement phase is a continuous alumina fiber woven piece, and the woven piece is stitched with fiber cloth. The mass content of alumina in the alumina fiber is 99%, and the fiber volume fraction in the composite material is 42%; the alumina matrix of the composite material is impregnated-dried-sintered multiple times through a high solid content, low viscosity water-based alumina powder slurry After the process is completed, the solid content of the water-based alumina powder slurry is 40vol%, the viscosity of the slurry is 28mPa⋅s, the pH is 4.3, and the Zeta potential is 67mV.

[0039] This embodiment also provides a method for preparing a three-dimensional alumina fiber braided reinforced alumina composite material based on an aqueous slurry impregnation proc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com