Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

259 results about "Slurry viscosity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Slurry Viscosity can be defined as the product of dynamic viscosity of slurry, the liquid (Ul) and relative viscosity (Ur). It can be expressed relatively to the viscosity of a liquid phase. The unit of slurry viscosity is (Pa.s) because the relative viscosity is dimensionless and dynamic viscosity of slurry has a unit of (Pa.s).

Layered lithium-nickel-based compound oxide powder and its production process

ActiveUS20050158546A1High bulk densityGood rate characteristicsElectrode thermal treatmentSolid electrolyte cellsLiquid mediumNickel compounds

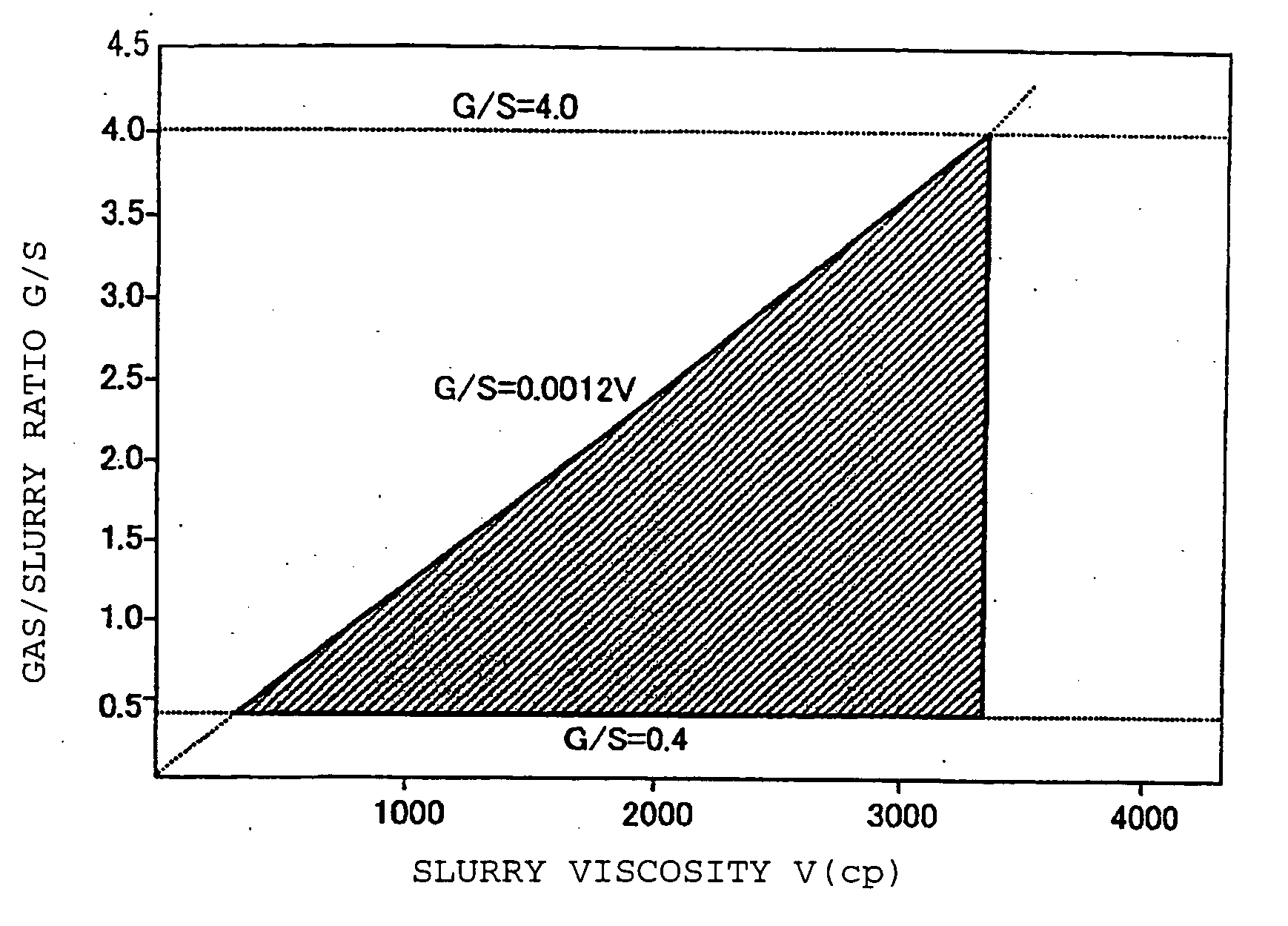

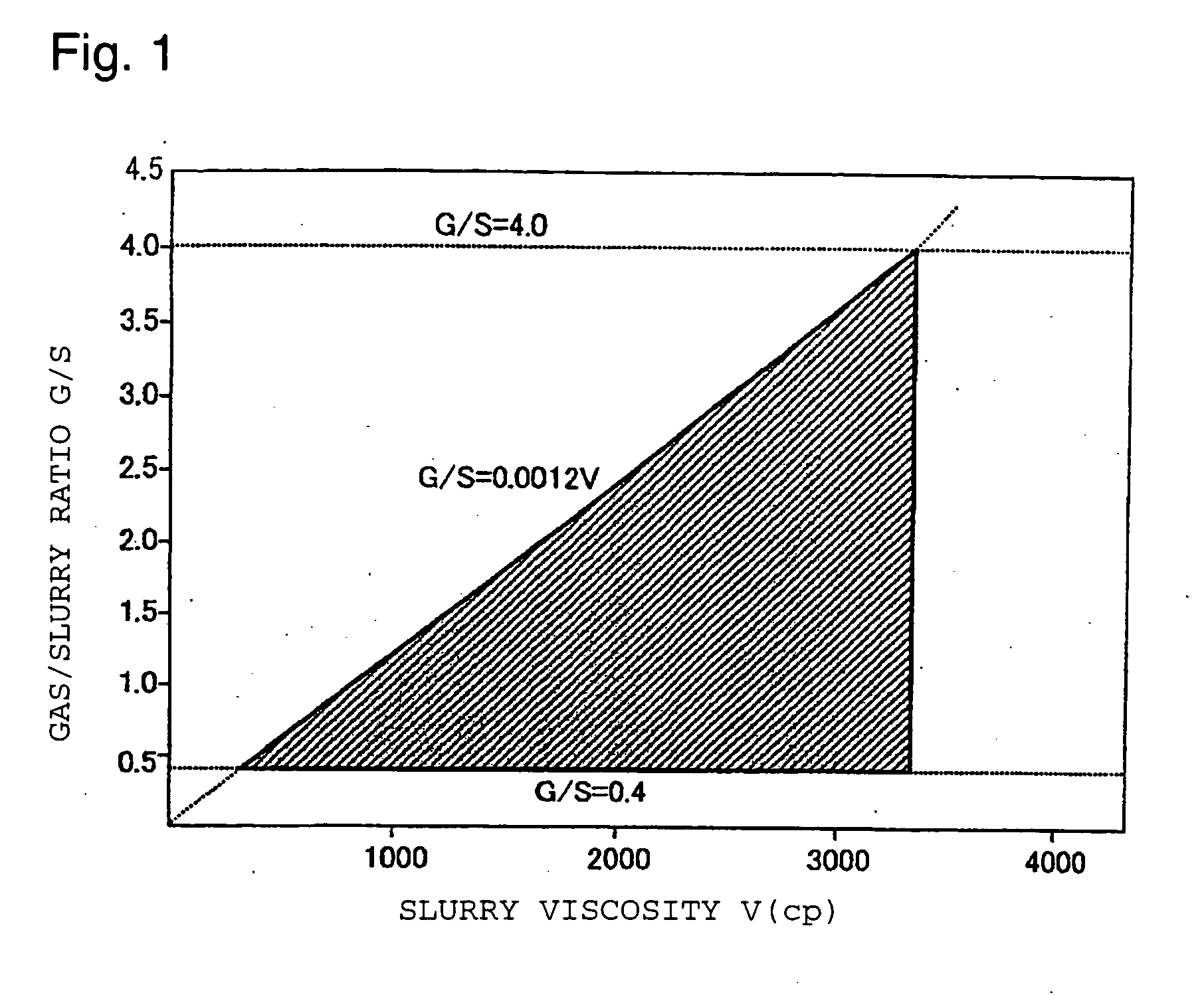

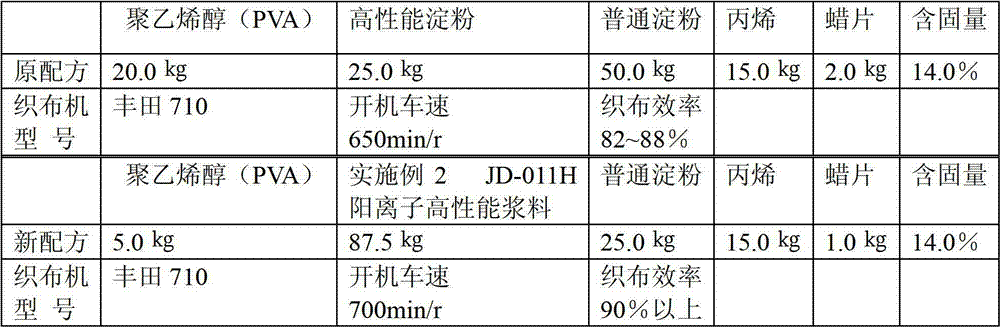

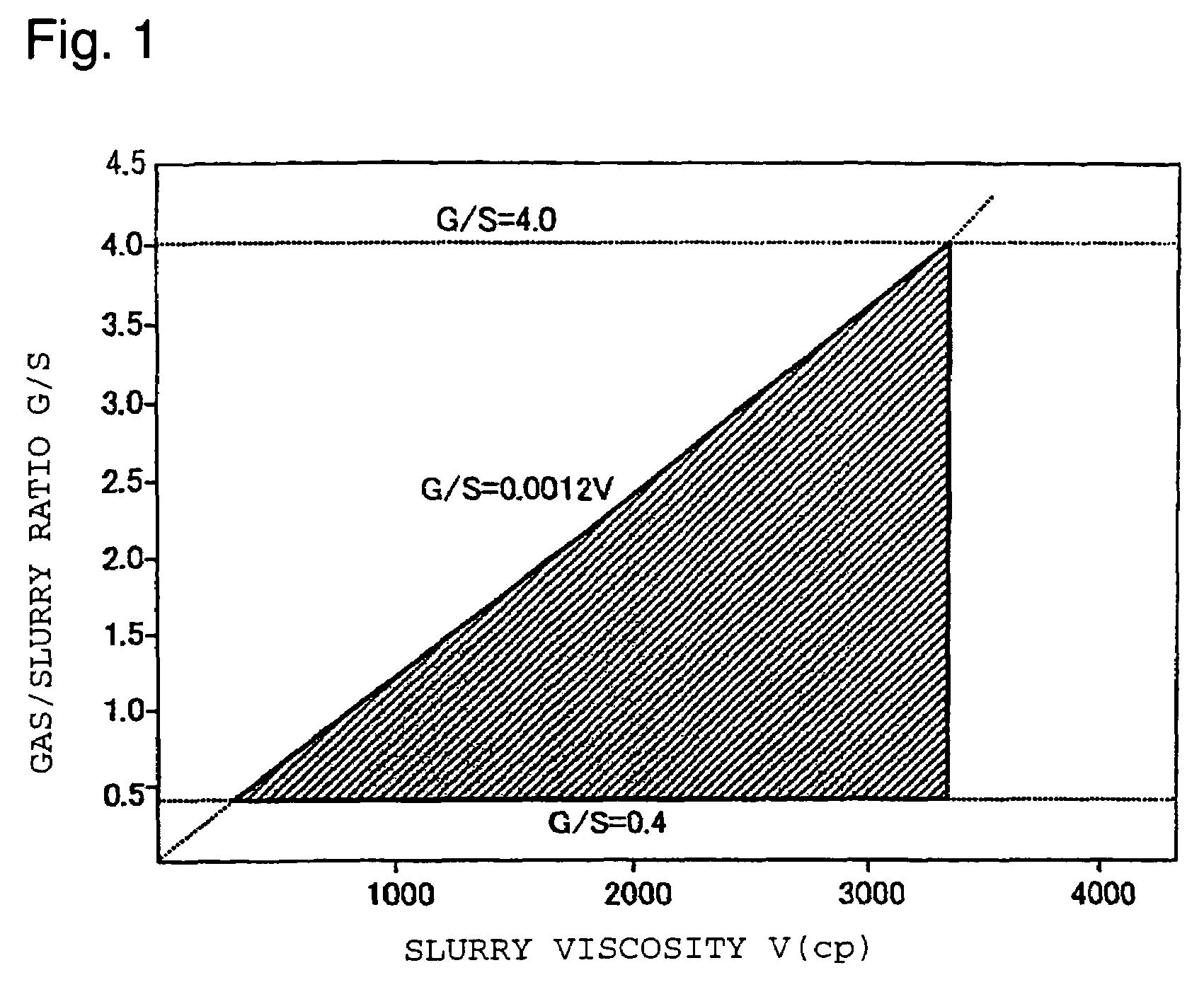

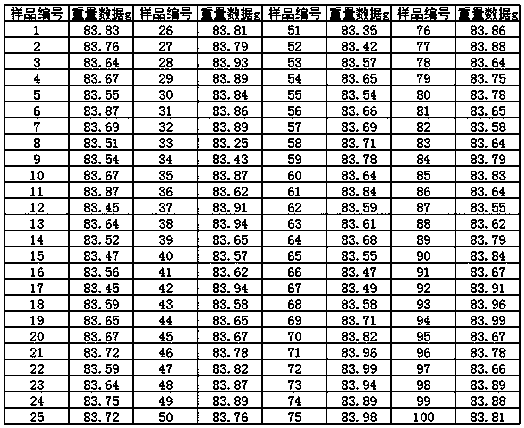

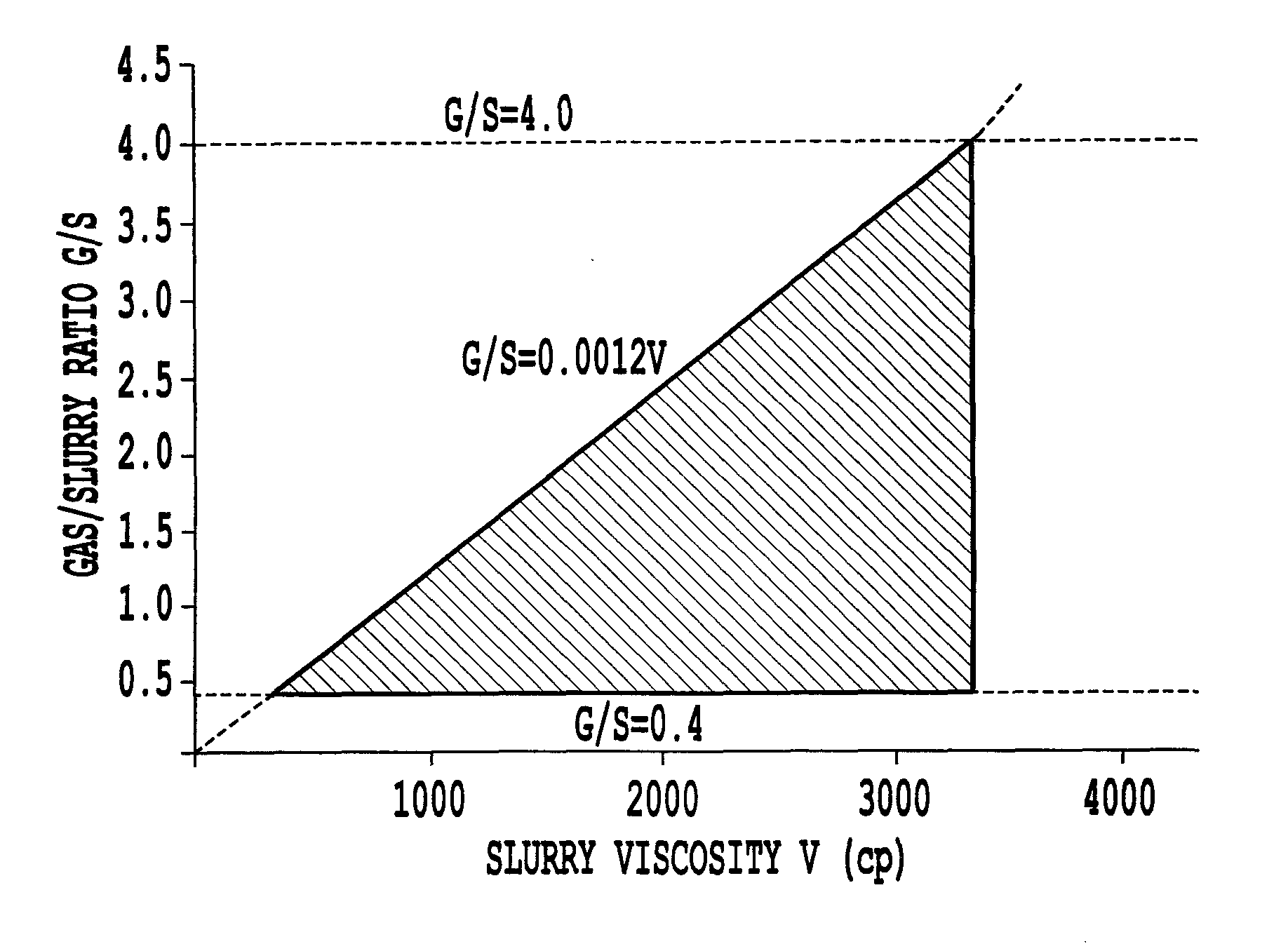

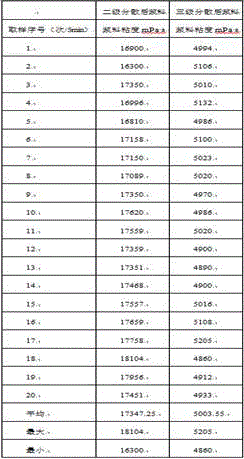

A layered lithium-nickel-based compound oxide powder for a positive electrode material for a high density lithium secondary cell, capable of providing a lithium secondary cell having a high capacity and excellent in the rate characteristics also, is provided. A layered lithium-nickel-based compound oxide powder for a positive electrode material for a lithium secondary cell, characterized in that the bulk density is at least 2.0 g / cc, the average primary particle size B is from 0.1 to 1 μm, the median diameter A of the secondary particles is from 9 to 20 μm, and the ratio A / B of the median diameter A of the secondary particles to the average primary particle size B, is within a range of from 10 to 200. In production of a layered lithium-nickel-based compound oxide powder, which comprises spray drying a slurry having a nickel compound and a transition metal element compound capable of substituting lithium other than nickel, dispersed in a liquid medium, followed by mixing with a lithium compound, and firing the mixture, the spray drying is carried out under conditions of 0.4≦G / S≦4 and G / S≦0.0012 V, when the slurry viscosity at the time of the spray drying is represented by V (cp), the slurry supply amount is represented by S (g / min) and the gas supply amount is represented by G (L / min).

Owner:MITSUBISHI CHEM CORP

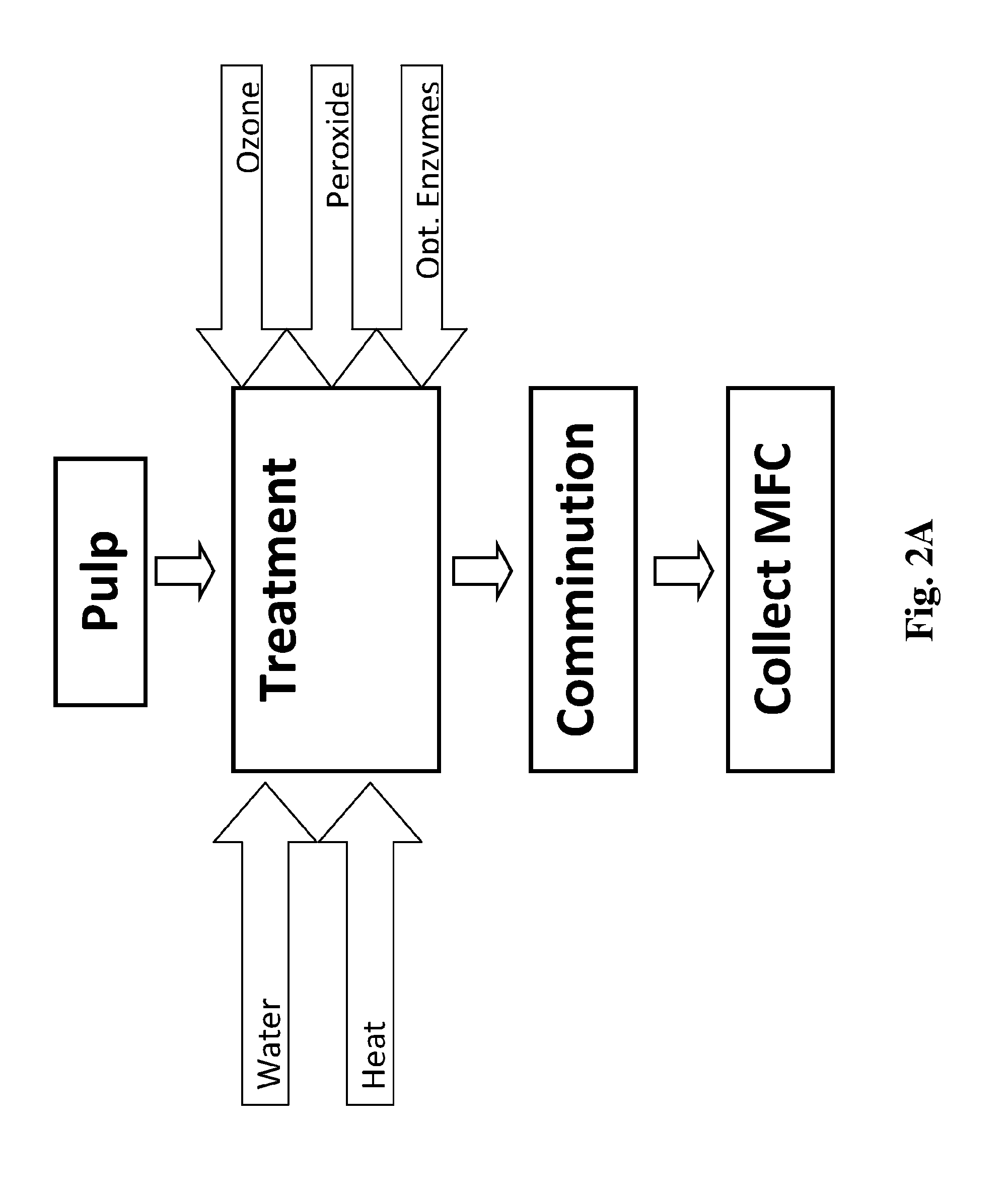

Energy Efficient Process for Preparing Nanocellulose Fibers

ActiveUS20150167243A1Improve efficiencyWeaken energySpecial paperPaper after-treatmentDepolymerizationNanofiber

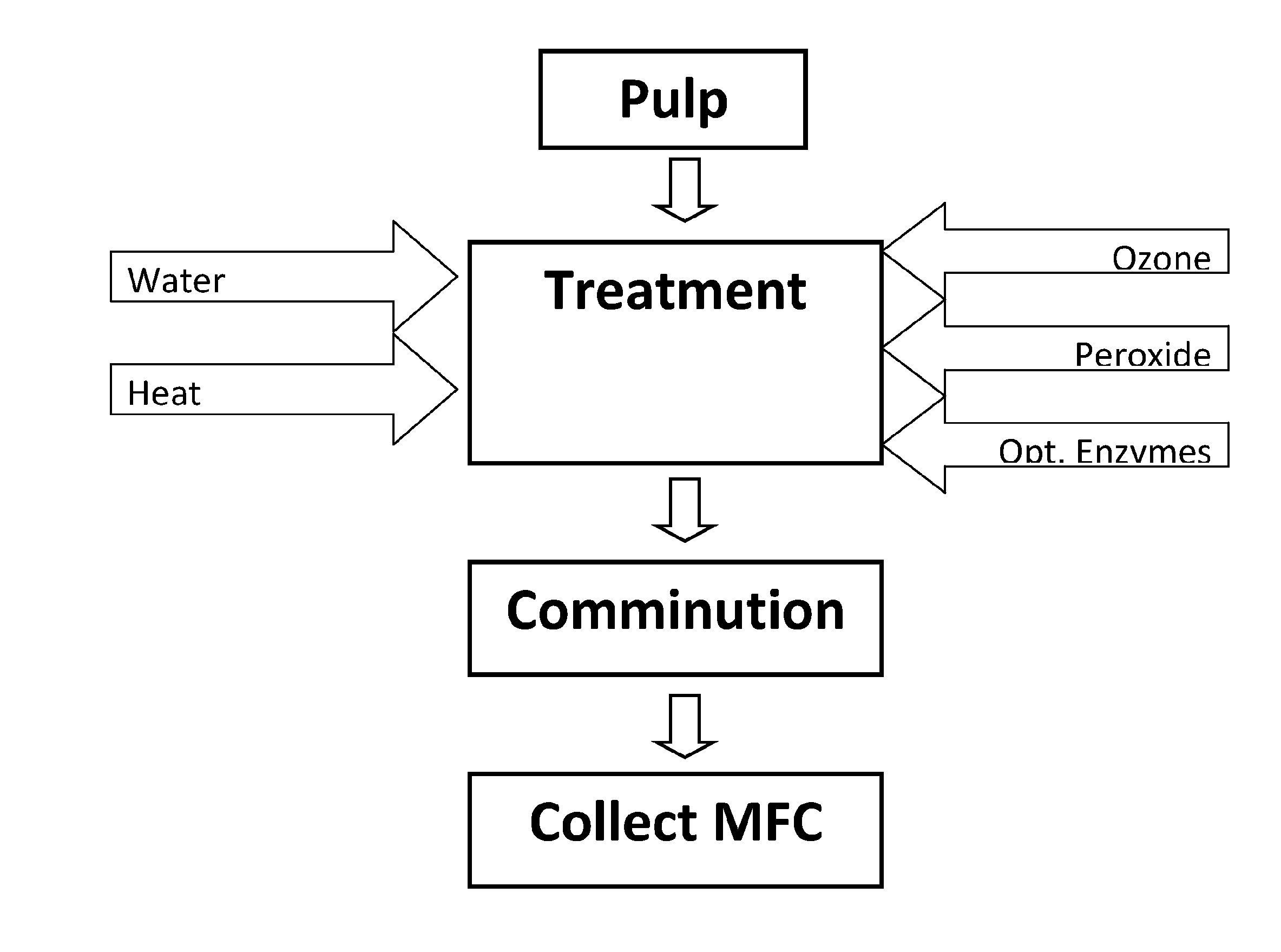

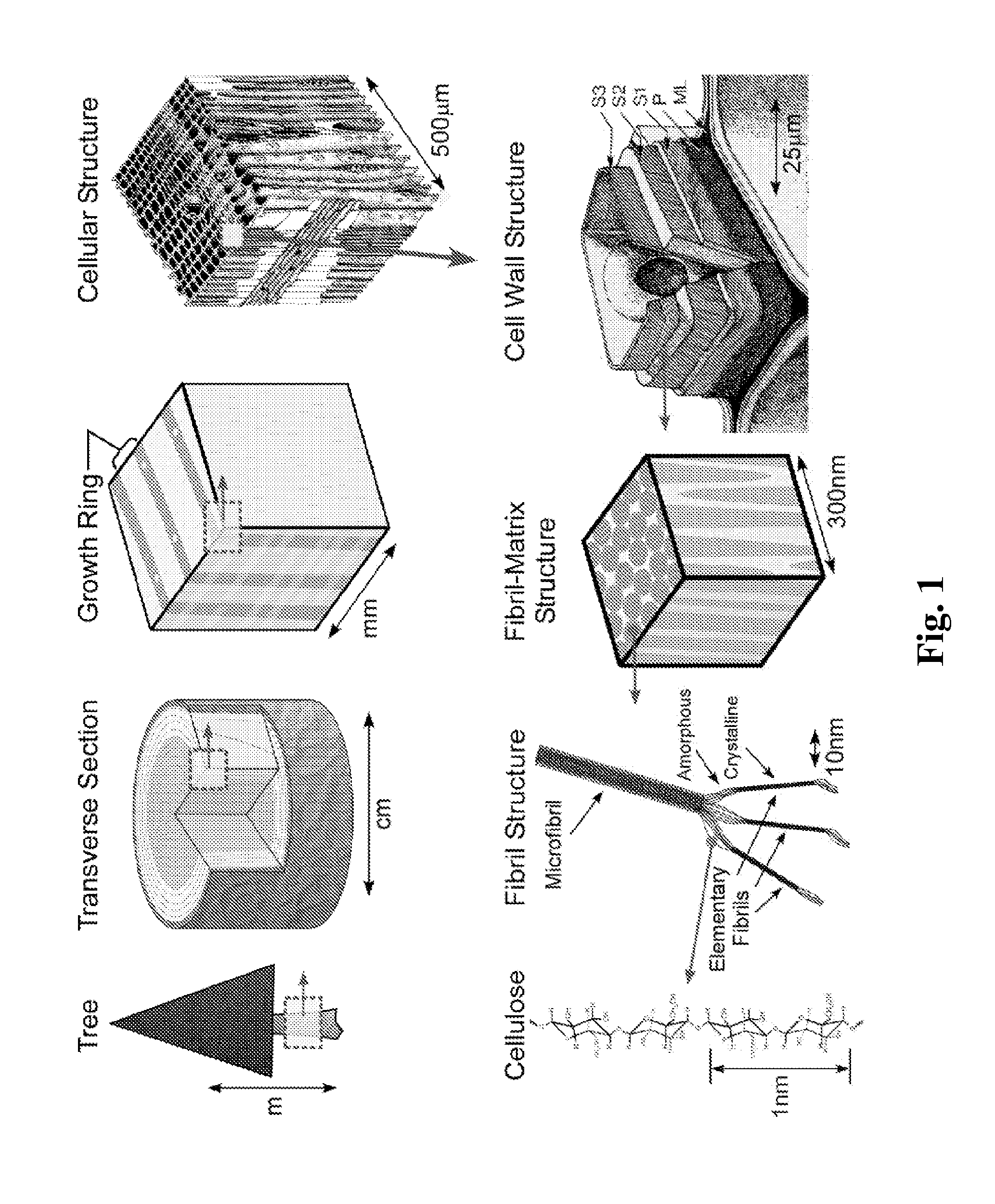

A scalable, energy efficient process for preparing cellulose nanofibers is disclosed. The process employs a depolymerizing treatment with one or both of: (a) a relatively high charge of ozone under conditions that promote the formation of free radicals to chemically depolymerize the cellulose fiber cell wall and interfiber bonds; or (b) a cellulase enzyme. Depolymerization may be estimated by pulp viscosity changes. The depolymerizing treatment is followed by or concurrent with mechanical comminution of the treated fibers, the comminution being done in any of several mechanical comminuting devices, the amount of energy savings varying depending on the type of comminuting system and the treatment conditions. Comminution may be carried out to any of several endpoint measures such as fiber length, % fines or slurry viscosity.

Owner:UNIVERSITY OF MAINE

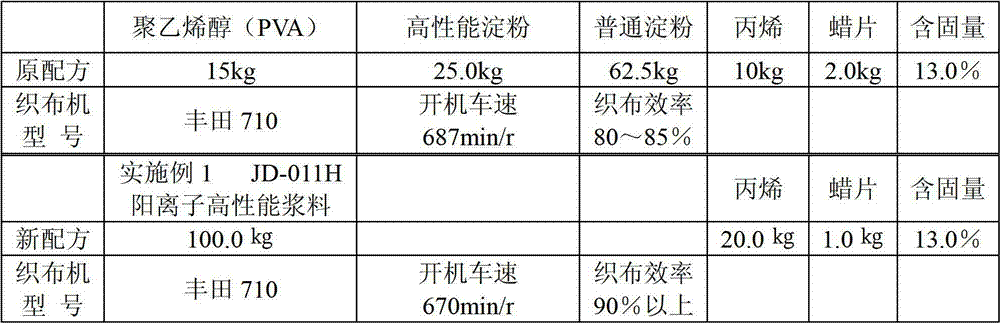

Cation high performance slurry

The invention discloses cation high performance slurry. The slurry is formed by commixture reaction of raw materials including corn starch, sodium hydroxide, trimethylamine hydrochloride and persulfate with the following quality content: 80-95% of the corn starch, 1-10% of the sodium hydroxide, 1-15% of the trimethylamine hydrochloride, and 0.1-15% of persulfate. The cation high performance slurry has the advantages of strong adhesive force, good film formation property, tenacious chorion and good elasticity, the flexibility (anti-fatigue property) is improved by 3-4 times compared with common modified starch slurry, the cation high performance slurry has good wear-resisting property and ageing resistance, and a serous fluid has good liquidity and stable viscosity under an I normal temperature condition; and the slurry contains no polyvinyl alcohol, when a spinning purified cotton yarn is subjected to a sizing process, a variety with 60 yarns with common compactness can be processed without polyvinyl alcohol, when sash cotton or purified cotton yarn with more than 60 yarns is subjected to sizing process, little polyvinyl alcohol or no polyvinyl alcohol is used, desizing is easy, waste water of serous fluid is easy to process, pollution of the waste water to the environment is small, and zero-pollution discharge in the production process is realized.

Owner:YIXING JUNDA SLURRY TECH

Layered lithium nickel composite oxide powder and process for producing the same

ActiveCN1698223AHigh bulk densityImprove featuresSecondary cellsActive material electrodesLiquid mediumNickel compounds

A layered lithium-nickel-based compound oxide powder for a positive electrode material for a high density lithium secondary cell, capable of providing a lithium secondary cell having a high capacity and excellent in the rate characteristics also, is provided. A layered lithium-nickel-based compound oxide powder for a positive electrode material for a lithium secondary cell, characterized in that the bulk density is at least 2.0 g / cc, the average primary particle size B is from 0.1 to 1 mum, the median diameter A of the secondary particles is from 9 to 20 mum, and the ratio A / B of the median diameter A of the secondary particles to the average primary particle size B, is within a range of from 10 to 200. In production of a layered lithium-nickel-based compound oxide powder, which comprises spray drying a slurry having a nickel compound and a transition metal element compound capable of substituting lithium other than nickel, dispersed in a liquid medium, followed by mixing with a lithium compound, and firing the mixture, the spray drying is carried out under conditions of 0.4<=G / S<=4 and G / S<=0.0012 V, when the slurry viscosity at the time of the spray drying is represented by V (cp), the slurry supply amount is represented by S (g / min) and the gas supply amount is represented by G (L / min).

Owner:MITSUBISHI RAYON CO LTD

Method to raise the solid content of catalytic cracking catalyst slurry

ActiveUS20080058197A1Maintains anti-frictionMaintains reactivity performanceCatalytic crackingMolecular sieve catalystsPseudoboehmiteMolecular sieve

A method for preparing cracking catalyst. The method comprises making catalyst slurry having a homogeneous distribution of molecular sieve slurry, pseudoboehmite, clay, inorganic acid and aluminum-containing binder; and subsequent spray drying. Inorganic acid is added prior to the addition of pseudoboehmite; addition of molecular sieve is added after the addition of inorganic acid; and a phosphatic dispersant is added during preparation. Compared to conventional methods of preparing FCC catalyst slurry, the inventive catalyst slurry viscosity is decreased and the fluidity thereof is improved, while catalyst anti-friction is maintained. The solid content of the FCC catalyst slurry can be increased to about 40% or more. The gel forming time is significantly reduced with increased productivity and decreased catalyst production cost. Meanwhile, the catalyst has high pore volume and improved micro-reactivity. Overall reactivity performance of the catalyst is also improved.

Owner:PETROCHINA CO LTD

Method of thick mash alcohol fermentation by using fresh cassava

ActiveCN101629189ARaise the initial total sugar contentIncrease profitBiofuelsFermentationAlcoholSlag

The invention relates to a method of thick mash alcohol fermentation by using fresh cassava, comprising the following steps: preparing fresh cassava which is pulverized for the first time into pulp; heating, liquefying and filtering; washing with hot water and filtering slag out; recycling residual sugar in a filtering slag, wherein filtrate obtained after filtering can be used for the first pulverization of the fresh cassava, the first filtrate can be used as pulverizing liquid in second pulverization of the fresh cassava. Slurry obtained after pulverization is used as row material of the thick mash alcohol fermentation, and the initial total sugar concentration reaches to 23.5-24.5 (g / 100mL); and after the procedures of liquefying, sterilization, saccharifying, fermentation, and the like, the obtained final fermentation mature raw spirit part reaches to more than 13.0(v / v). The invention completely uses the fresh cassava as raw material to ferment thick mash to produce alcohol, thereby effectively improving the initial total sugar concentration in the process of the thick mash alcohol fermentation by using the cassava, and solving the problems of big slurry viscosity, bad flowability, low mass transfer efficiency, and the like in the fermentation process. The invention has the advantages of simple process, energy saving, low cost, low waste material production, and the like,and is used for developing circular economy.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

Preparation method for low-reducing sugar red jujube powder

InactiveCN103719751AGuaranteed health functionMeet diverse needsFood ingredientsFood preparationBiotechnologyLactic acid bacterium

The invention belongs to the technical field of red jujube deep processing, and particularly relates to a preparation method for low-reducing sugar red jujube powder. The method comprises the following steps: based on a current process, inoculating desugaring strains for red jujube slurry, and performing fermentation and desugaring to realize the purpose of preparing the low-reducing sugar red jujube powder, wherein the desugaring strains adopts a composition formed by one or more of saccharomycetes, acetic bacteria or lactic acid bacteria at any proportion; the mass of each strain is about 10-15 percent of the slurry. During the desugaring and fermentation process, biological enzyme is preferentially added for enzymolysis. The red jujube powder contains the reducing sugar reduced by 80 percent compared with that in the raw materials of red jujubes, addition quantity of drying additives or auxiliary materials can be reduced to 10 percent due to the lower slurry viscosity. The method provided by the invention is low in cost, high in security, and simple, convenient and feasible in process, and has apparent economic and social benefits.

Owner:XINJIANG LOULAN MANOR JUJUBE IND

Layered lithium-nickel-based compound oxide powder and its production process

ActiveUS7309543B2Improve featuresIncrease in sizeElectrode thermal treatmentSolid electrolyte cellsLiquid mediumNickel compounds

Owner:MITSUBISHI CHEM CORP

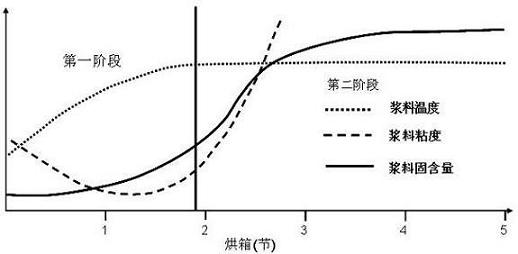

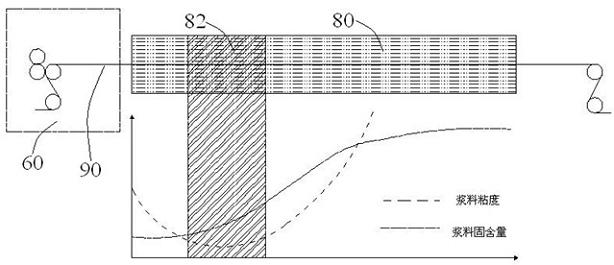

Preparation method of lithium ion battery cathode sheet, and film coating and drying apparatus

ActiveCN102306750AImprove performanceAchieve highly directional alignmentCell electrodesPretreated surfacesMagnetizationGraphite particle

The invention discloses a preparation method of a lithium ion battery cathode sheet. The method comprises steps that: a cathode slurry containing graphite is prepared and is coated on a substrate; slurry drying is carried out upon the coated substrate, and a magnetic field is applied on the slurry being dried during a phase when the viscosity of the slurry reaches the lowest point, such that (004) planes of graphite particles are perpendicular to the substrate plane; then the magnetic field is removed, and the slurry is continuously dried until the slurry turns solid. The invention also discloses a film coating and drying apparatus used for realizing the method. According to the invention, magnetization is carried out upon graphite during the drying phase when the viscosity of the slurry reaches the lowest point. Therefore, turning resistance is reduced, alignment consistency of the (004) planes of the graphite particles is improved. Also, when the graphite particles are turned, the slurry is instantly processed through a drying phase wherein the slurry solid content and the slurry viscosity are rapidly increased, such that high consistency on a graphite particle alignment direction is maintained, and highly-oriented alignment of graphite in the cathode sheet is realized.

Owner:DONGGUAN AMPEREX TECH

Synthesizing and using method of coal water slurry additive agent

InactiveCN101333469AImprove performanceSolve the shortcomings of high production costsLiquid carbonaceous fuelsMass ratioHydrolysis

The invention discloses a synthetic method for anthracene series coal water slurry additive, which comprises: sulfonation, hydrolysis, condensation and neutralization to crude anthracene. The crude anthracene and concentrated sulfuric acid are present in a mass ratio of 1:0.25 to 1, and the crude anthracene and formaldehyde are present in a mass ratio of 1:0.05 to 0.2; the sulfonation temperature is controlled at between 90 and 150DEG C, and the condensation temperature is controlled at between 100 and 120DEG C; and the sulfonation reaction time is 2 to 4h, and the hydrolysis time is 0.5 to 1h. A naphthalene sulphonic sodium formaldehyde polycondensate with the degree of polymerization ranging from 10 to 15 and average molecular weight of 2000 to 3500 is compounded with an anthracene series additive for being applied to coal water slurry preparation processes of different coal types, when the amount of the compound additive is 1 percent by weight of dry basis coal fines, the shear rate is kept at 100s<-1>, and when the slurry viscosity is 1200MPa.s, the coal water slurry with the concentration of 67.9 to 68.8 percent can be prepared, and the slurry has excellent stability. The combination of naphthalene sulphonic sodium formaldehyde polycondensate and anthracene series coal water slurry additive can prepare coal water slurry with excellent performance and reduce the production cost of additive in the meanwhile, and the compound additive has rather strong universality to the slurry making of different coal types.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

Polycarboxylic-acid concrete efficient water reducer with amide/imide structure and preparation method thereof

ActiveCN104371070AProcess operation is easy to controlPreparation and synthesis are safe and environmentally friendlyImideEnvironmental resistance

The invention provides a polycarboxylic-acid concrete efficient water reducer with an amide / imide structure. The polycarboxylic-acid water reducer prepared by employing the method has the advantages of being simple and easily controllable in technological operation, safe and environment-friendly in preparation synthesis, low in cost, energy-saving, consumption-reducing, substantial in water-reducing dispersing effect, high in storage stability, capable of reducing slurry viscosity under the condition of a low water-binder ratio, and the like. The polycarboxylic-acid water reducer has relatively good adaptability to different kinds of cement under the condition of low doping amount or low water-cement ratio, and helps to solve the problems that the raw material preparation cost of amide / imide type polycarboxylic acids is high, preparation conditions are severe and difficult to control, and the like.

Owner:JIANGSU SOBUTE NEW MATERIALS

Constant temperature ink conveyer

ActiveCN102211450AUniform and stable temperatureUniform and stable viscosityPrinting press partsBiochemical engineeringSolvent

The invention relates to a constant temperature ink conveyer, comprising an ink constant temperature tank, an ink distributor, an ink heat exchange tank, an ink recovering tank, an ink delivering pump, a stirrer and the like; depending on various heat exchange forms, the heat exchange forms of the ink conveyer can be a spiral type, a fin type and the like. The constant temperature ink conveyer has the characteristics of: stable and adjustable ink conveying temperature, which is beneficial for ensuring the quality of the printed products, relieving volatilization of solvent, stable ink slurry viscosity, and reducing the production cost. The technique of the constant temperature ink conveyer can be widely used to produce various new products, so that the industrial technique level is greatly improved.

Owner:中惠地热(荣成)有限公司

Environment-friendly low-viscosity high-strength polyurethane grouting lifting material and preparation method thereof

The invention discloses an environment-friendly low-viscosity high-strength polyurethane grouting lifting material and a preparation method thereof. The environment-friendly low-viscosity high-strength polyurethane grouting lifting material consists of a component A and a component B, wherein the component A mainly comprises composite polyether polyol, a low-viscosity epoxy resin compound, an amine catalyst, a foam stabilizing agent, water and a flame retardant; the component B mainly comprises an organic tin catalyst, polyisocyanate and the like. The ozone depletion potential of the environment-friendly low-viscosity high-strength polyurethane grouting lifting material disclosed by the invention is 0, the environment-friendly low-viscosity high-strength polyurethane grouting lifting material is clean and environment-friendly, and meanwhile has the characteristics of relatively low slurry viscosity, good flowbility, good groutability and the like, the rise time of the material can be controlled within 10-30 seconds, the foaming time of the material can be adjusted within 60-120 seconds, the foam appearance core density of the material can be within 50-80 kg / m<3>, the foams are uniform and dense, and the compression strength of the material is 0.45-0.70 MPa. Meanwhile as foams, rock and soil are all relatively good in adhesion property, the material is applicable to lifting mediation of buildings, traffic roads and projects under different geological conditions.

Owner:HEFEI UNIV OF TECH

Amide/imide structure polycarboxylate superplasticizer and preparation method thereof

ActiveCN107652405AProcess operation is easy to controlThe synthesis process is safe and environmentally friendlyImideSuperplasticizer

The invention discloses an amide / imide structure polycarboxylate superplasticizer and a preparation method thereof. The amide / imide structure polycarboxylate superplasticizer is synthesized by amidation / imidization of amine-terminated polyether to obtain polymerizable polyether amine, and then copolymerization reaction with active monomers. The preparation method of the polycarboxylate superplasticizer provided by the invention has the advantages of simple and easily controllable technological operation, safe and environment-friendly synthetic process, low cost, energy saving and consumption reduction. Also the obtained amide / imide structure polycarboxylate superplasticizer has the advantages of high water-reducing rate, good flowing retention performance, long storage period, significantreduction of slurry viscosity under a low water-binder ratio and the like, thus solving the problems of great difficulty, difficultly available raw materials, many side reactions, harsh conditions, high cost and the like in the amide / imide polycarboxylate synthesis process.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

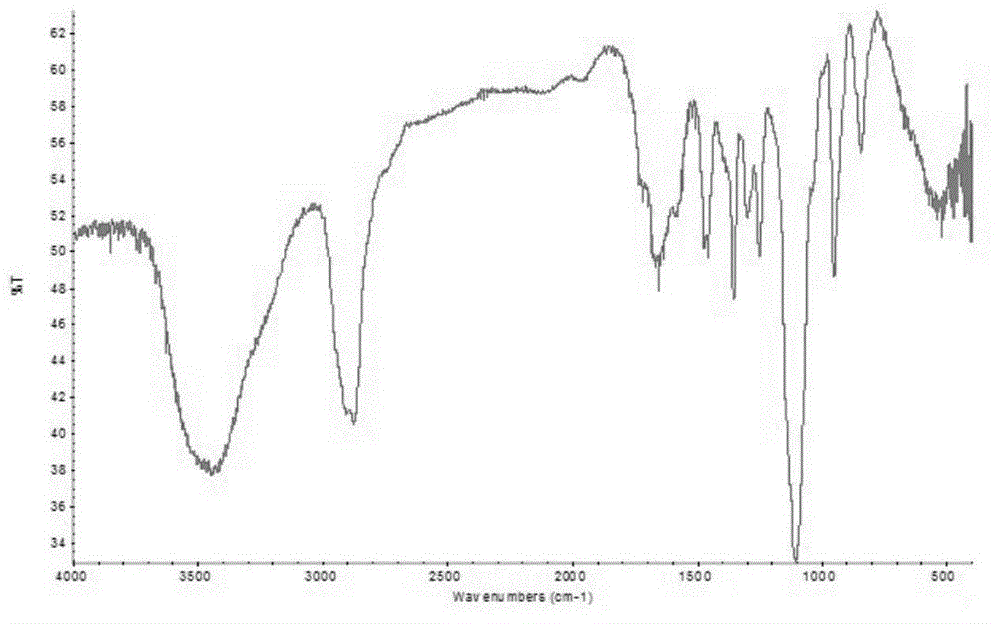

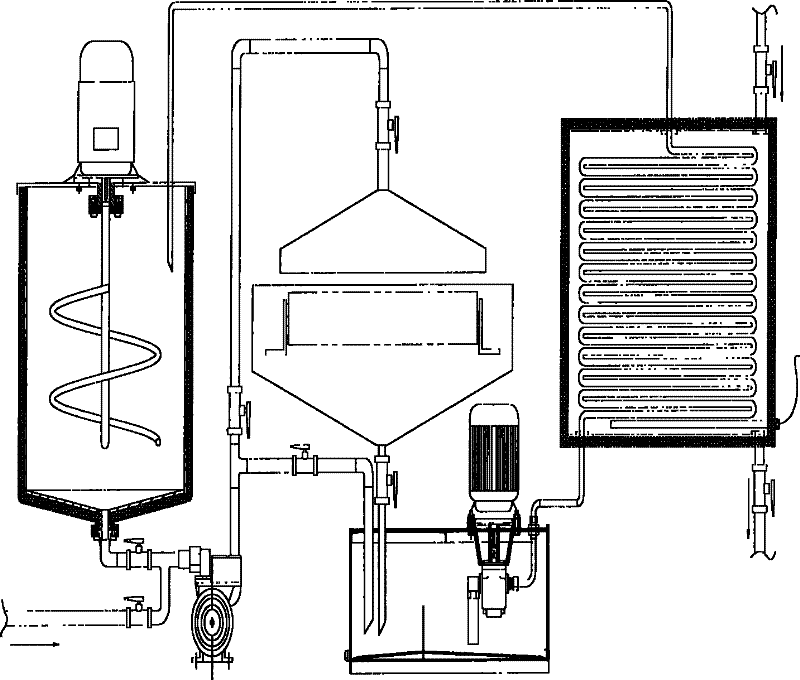

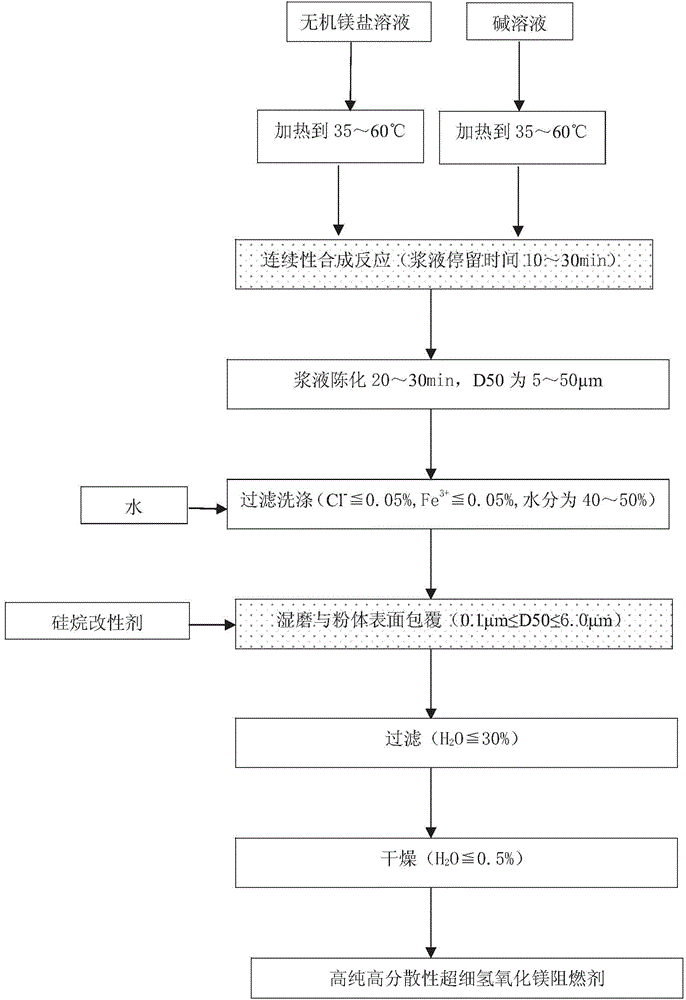

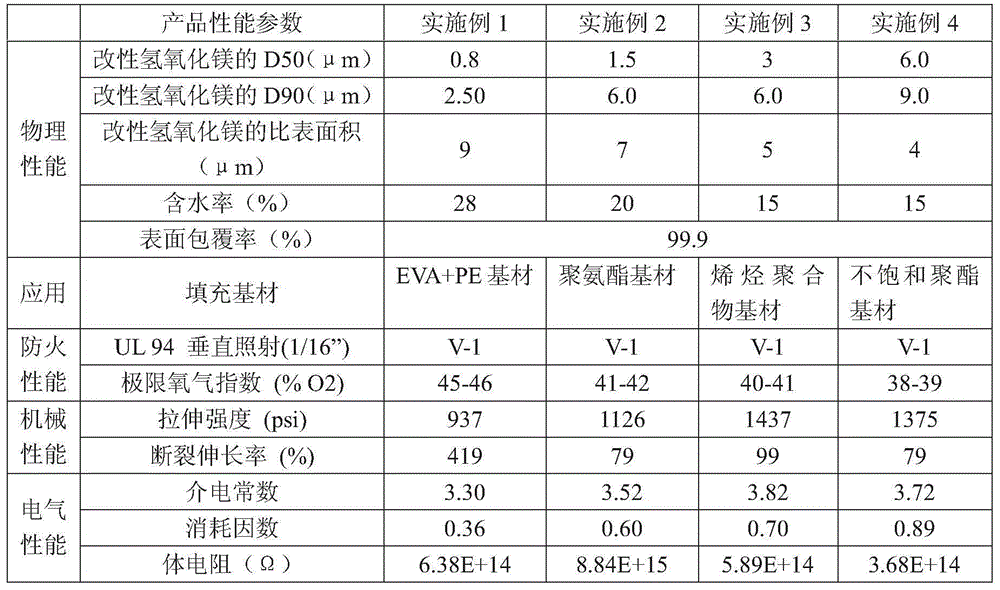

Method for preparing magnesium hydrate flame retardant

ActiveCN104592789AAddressing Purity IssuesSolve for uniformityPigment treatment with organosilicon compoundsPigment physical treatmentDispersityWet grinding

The invention discloses a method for integrally preparing a high-dispersity ultrafine magnesium hydroxide flame retardant, which comprises the following steps: continuously synthesizing high-purity magnesium hydroxide; and carrying out single cycle wet grinding and surface modification on magnesium hydroxide and integrally implementing particle size control and surface processing of the magnesium hydroxide flame retardant. According to the invention, the technical difficulties of control on purity, slurry viscosity, particle size, particle size distribution and specific surface area of the magnesium hydroxide flame retardant, the existence of the phenomena of secondary coagulation and bonding during the drying process and the like; a hydrophilic surface of magnesium hydroxide flame retardant powder is modified into a lipophilic surface, so that the intermiscibility and dispersity of the powder in a macromolecule polymeric material are improved, the influence of the high-dispersity ultrafine magnesium hydroxide flame retardant on the processing performance and the mechanical performance of a polymer product is reduced, and the comprehensive properties of the macromolecule polymer, such as flame retardance, processing, mechanics, electrics, are optimized.

Owner:江苏艾特克阻燃材料有限公司

Method for improving thermal stability of acetic ester starch slurry viscosity

InactiveCN101492509AOvercome the disadvantage of poor thermal stability of viscosityQuality improvementFibre treatmentCross-linkCompound (substance)

The invention relates to a method for improving viscosity thermal stability of acetic ester starch slurry, in particular to a method for improving viscosity thermal stability of starch slurry during the chemical processing and denaturation of cassava starch. The method comprises oxidization denaturation, esterification denaturation and cross-linking denaturation. After the oxidization denaturation and the esterification denaturation, sodium trimetaphosphate which accounts for 1 percent of the weight of the cassava starch is added, then the reaction lasts 5 hours at the room temperature, and during the reaction, sodium hydroxide solution with the concentration of 3 percent is used for remaining the pH value of the cassava starch slurry to be 9.0-9.2. The invention has the advantages that when the acetic ester starch slurry prepared according to the method of the invention is used, in comparison with the acetic ester starch slurry prepared through oxidization-esterification denaturation, the viscosity thermal stability is improved from 55.6 percent to 81 percent, the stability of sizing quality can be ensured, and the spinning production efficiency and the product quality can be improved.

Owner:DONGGUAN DONGMEI FOOD

Novel lithium ion battery homogenizing and stirring process

ActiveCN104201325AHigh viscosityHigh solid contentElectrode manufacturing processesSecondary cellsLithium iron phosphatePhysical chemistry

The invention discloses a novel lithium ion battery homogenizing and stirring process. The novel lithium ion battery homogenizing and stirring process comprises the following steps: feeding total dry powder prepared by fully mixing 1-5 parts by mass of conductive carbon powder, 90-100 parts by mass of an active substance-lithium iron phosphate, and 1-5 parts by mass of an adhesive-PVDF into a stirrer, sequentially stirring the dry powder so as to be in a paste manner, stirring the slurry, stirring with high viscosity, stirring by adjusting the viscosity so as to slurry and carrying out vacuum defoamation on the slurry. By virtue of the novel lithium ion battery homogenizing and stirring process, the content of solid in the slurry can be greatly increased; the slurry viscosity can be improved; the mixing time can be shortened; finally, the performance of the lithium ion battery can be greatly improved and the service life of the lithium ion battery can be greatly prolonged.

Owner:ZHEJIANG CASNOVO MATERIALS

Novel stirring process for positive electrode slurry of lithium ion battery

InactiveCN108619927AImprove dispersion uniformityReduce lossMixing methodsTransportation and packagingLow speedLithium-ion battery

The invention discloses a novel stirring process for the positive electrode slurry of a lithium ion battery. The process comprises the following steps: (1) preparation of conductive glue liquid; (2) infiltration of active substances; (3) normal-temperature low-speed forward and backward stirring; (4) vacuum high-speed stirring; and (5) adjustment of slurry viscosity and solid content and blankingto prepare the positive electrode slurry of the lithium ion battery. Compared with conventional wet mixing and dry mixing, the novel stirring process of the invention of the invention has the beneficial effects that the novel stirring process integrates the advantages of l wet mixing and dry mixing to a certain extent, and can improve the dispersion uniformity of the positive electrode slurry of the lithium ion battery, reduce the loss of stirring equipment and prolong the service life of the equipment.

Owner:SHENZHEN GPC ENERGY GRP CO LTD

Layered lithium-nickel-based compound oxide powder and its prodution process

InactiveUS20080182169A1Improve featuresIncrease in sizeElectrode thermal treatmentCobalt compoundsLiquid mediumNickel compounds

A layered lithium-nickel-based compound oxide powder for a positive electrode material for a high density lithium secondary cell, capable of providing a lithium secondary cell having a high capacity and excellent in the rate characteristics also, is provided.A layered lithium-nickel-based compound oxide powder for a positive electrode material for a lithium secondary cell, characterized in that the bulk density is at least 2.0 g / cc, the average primary particle size B is from 0.1 to 1 μm, the median diameter A of the secondary particles is from 9 to 20 μm, and the ratio A / B of the median diameter A of the secondary particles to the average primary particle size B, is within a range of from 10 to 200. In production of a layered lithium-nickel-based compound oxide powder, which comprises spray drying a slurry having a nickel compound and a transition metal element compound capable of substituting lithium other than nickel, dispersed in a liquid medium, followed by mixing with a lithium compound, and firing the mixture, the spray drying is carried out under conditions of 0.4≦G / S≦4 and G / S≦0.0012V, when the slurry viscosity at the time of the spray drying is represented by V (cp), the slurry supply amount is represented by S (g / min) and the gas supply amount is represented by G (L / min).

Owner:MITSUBISHI CHEM CORP

Method for preparing solar cell front silver paste slurry

InactiveCN107545941AModerate viscosityImprove the level ofNon-conductive material with dispersed conductive materialCable/conductor manufactureWater bathsSolar cell

The present invention relates to a kind of method of preparing solar cell positive silver paste slurry: 1, the preparation of silver powder: (1) ultrapure water dissolves silver nitrate, adds dispersant, adjusts pH to 3-5; (2) ultrapure water dissolves Reductant, adjust the pH to 3-5; (3) Add silver nitrate solution to the reducing agent solution for reaction at a temperature of 45-55°C, centrifuge to collect the precipitate after fully reacting; (4) Wash and dry the precipitate to obtain silver powder; II, Preparation of organic vehicle: Mix solvent, thickener and thixotropic agent, heat in a water bath at 75-85°C, stir to dissolve, let stand and cool to room temperature; III. Preparation of front silver paste: Now mix silver powder and glass powder evenly , then add the organic vehicle and mix evenly, and grind until the fineness reaches the required value. The slurry prepared by the invention has suitable viscosity, good leveling and thixotropy, good chemical stability, and long storage period. The prepared slurry has strong ability to penetrate the anti-reflection film, and the formed thick film has strong adhesion and good ohmic contact. , the resulting battery sheet should have good electrical properties.

Owner:扬中市润宇电力设备有限公司

Lithium ion battery slurry preparation apparatus and method thereof

ActiveCN106669520AEvenly dispersedViscosity consistency is well controlledTransportation and packagingMixer accessoriesBuffer tankConsistency control

The invention relates to a lithium ion battery slurry preparation apparatus. The lithium ion battery slurry preparation apparatus comprises a powder storage tank, a dry powder mixing and dispersing device, a solvent storage tank, a primary dispersion device, a buffer tank A, a secondary dispersion device, a buffer tank B, a third dispersion device, and a vacuum defoaming storage tank; the primary dispersion device, the buffer tank A, the secondary dispersion device, the buffer tank B, the third dispersion device and the vacuum defoaming storage tank are connected through the pipelines in order; the temperature-detecting devices are arranged on the secondary dispersion device and the third dispersion device; a beta-ray density detector and an on-line viscosity detector are arranged between the outlet of the secondary dispersion equipment and the buffer tank, and the beta-ray density detector and the on-line viscosity detector are arranged between the thrid dispersion equipment and the vacuum defoaming storage tank. The invention also relates to a method for preparing a lithium battery slurry by using the apparatus, the used apparatus has advantage of high production efficiency, the dispersion of the slurry is uniform, the slurry viscosity consistency can be better controlled, and the same batch of the slurry is basically controlled at + / -700 mPa.S.

Owner:SHANDONG GOLDENCELL ELECTRONICS TECH

Superfine Magnesium hydroxide powder, its preparing process and is combustible resin composition

InactiveCN1356361AHigh viscosityGood dispersionMagnesium hydroxidePigment physical treatmentBruciteFire retardant

To inexpensively provide magnesium hydroxide superior in a physical property, appearance when finely dispersed in a resin and being low cost by inhibiting the increase of slurry viscosity in wet pulverization, secondary coagulation and sticking in drying and by hydrophobicity treatment on the surface of the particle of the above hydroxide at the same time. SOLUTION: Natural brucite and / or calcined magnesia of 100 pts.wt. is mixed with a polycarboxylic acid-based dispersing agent of 0.01-20 pts.wt., a fatty acid metal salt of 0.01-20 pts.wt. and water of 10-1,000 pts.wt. The fine magnesium hydroxide powder of which the mean particle diameter is 10 micron or less is manufactured by the wet pulverization. The fine powder is mixed in a thermoplastic resin compound as a fire-resistant agent and / or a fire-resistant auxiliary agent.

Owner:AJINOMOTO CO INC

Horizontal type spiral centrifuge

InactiveCN102078844AStable pressureGood vibration reduction effectRotary centrifugesVibration attenuationFrequency conversion

The invention relates to a horizontal type spiral centrifuge, which is provided with a pressure-constant slurry overflow valve on the end of a slurry inlet pipe of a commonly used horizontal type centrifuge, so as to ensure the stable pressure of the slurry in a rotary drum, wherein a slurry and water separating valve is arranged on the end of a slurry outlet pipe, for solving the problem that the slurry viscosity and intensity of the slurry are influenced by washing the centrifuge with too much clean water; a specific compound vibration-attenuation base is arranged between a machine leg and a chassis, for solving the problem that the noise and the damaged parts are caused by the vibration of the centrifuge; a frequency-conversion control master motor or main and secondary motors are used for solving the problem that the demands on the rotation speed of the main and secondary motors are different on different lands; and a wireless remote sensing device is used for realizing the remote control and convenient operation.

Owner:朱士荣

High-capacity lithium ion battery positive electrode slurry and preparation method and application thereof

InactiveCN108878767AIncrease productivitySmall particle sizeElectrode manufacturing processesSecondary cellsCooking & bakingInternal resistance

The invention belongs to the technical field of lithium ion battery manufacturing, and particularly provides a preparation method of high-capacity lithium ion battery positive electrode slurry. The preparation method comprises the following steps that various raw materials are weighed and subjected to baking processing before use; polyvinylidene fluoride is dissolved into an N-methyl-2-pyrrolidonesolution with the weight 12-19 times of that of polyvinylidene fluoride, and after stirring and filtering are conducted, an adhesive solution A is obtained; a carbon nanotube solution is added into the adhesive solution A, and after the mixed solution is stirred to be uniform, a conducting adhesive solution B is obtained; the conducting adhesive solution B is added into a stirrer in twice, and stirring is conducted to obtain slurry C; ethyl alcohol is added into the slurry C, the slurry viscosity is adjusted with N-methyl-2-pyrrolidone, and after stirring is conducted, slurry D is obtained; and after the slurry D is subjected to processing of a high-speed dispersion machine, filtration processing and vacuum deformation processing, the final slurry is obtained. According to the preparationmethod, in the production process, preparation of the conducting adhesive solution B and preparation of the final slurry are conducted independently and synchronously, and the production efficiency of the positive electrode slurry is effectively improved; and a lithium ion battery prepared from the slurry is low in internal resistance, high in energy density and beneficial to exertion of the maximum gram capacity.

Owner:CALB CO LTD

Radial-structured tubular porous ceramic and preparation method thereof

InactiveCN108046828AEasy to operateLow equipment requirementsCeramicwareWater basedChemical industry

The invention discloses radial-structured tubular porous ceramic and a preparation method thereof, and belongs to the technical field of preparation of porous ceramic materials. Water-based ceramic slurry is prepared from ceramic powder as a raw material as well as a dispersing agent and a sintering aid, ball-milling, uniform mixing and degassing are performed on the slurry, then the slurry is fedinto a cooling mold for freezing, a frozen green body is placed in a freezer dryer for sublimation of ice layers, then the dried green body is sintered, the tubular porous ceramic which is radial from inside to outside is obtained, and intervals between the ice layers decrease gradually. Meanwhile, gradient change control of pore morphology and porosity of a product can be realized by changing conditions such as slurry viscosity, raw material particle size and the like. The operation is simple, equipment requirements are low, and the tubular porous ceramic is environmentally friendly. The prepared radial-structured tubular porous ceramic has wide application prospect in purification filter, thermal insulation, bio-medical treatment, electronic devices, aerospace, energy and chemical industry and other aspects.

Owner:XI AN JIAOTONG UNIV

Integrated detector for slurry viscosity and rock debris granularity

InactiveCN103076252AImprove automationImprove the level of intelligenceParticle size analysisMaterial weighingRational useInformatization

The invention discloses an integrated detector for slurry viscosity and rock debris granularity. The detector integrates a funnel viscosimeter with a granularity separation screen, implements sequential control automatically to complete screening, weighing and testing based on virtual type signal analyzing software and hardware technologies, and can analyze and figure out the slurry viscosity, the rock debris granularity and the distribution of the slurry and the rock debris. The detector can be directly installed near a well mouth, from which well-site drilling fluid returns to the ground, for sampling and real-time detection, and reflects valuable information about a drilling well and geology for the first time, thereby providing a basis for optimizing drilling parameters and using solid control system devices correctly and reasonably by a drilling crew. For instance, a drilling engineer can choose screens with different meshes according to particle sizes so as to improve a solid control screening effect, and the like. At the same time, the detector is one of indispensable sensing systems in an intelligent type vibrating screen working condition monitoring link. According to the detector, the funnel viscosimeter is modified simply and automatically, so that the measurement accuracy is increased; and technologies related to the vibrating screen are applied to the granularity detection, so that test automation is achieved and a requirement for well-site informatization is adapted.

Owner:周永干

Blended yarn sizing slurry mixing

The invention provides a slurry mixing method for the sizing of the blended yarn of natural color cotton fiber and apocynum fiber, wherein the main slurry is a merge of 1799PVA and PVA205MB with total alcoholysis, then is mixed with the converted starch, and is supplemented with penetrant and softening agent, the sizing surface is smooth and bright with little hair and the sizing film is flexible and abrasion-proof, in yarn leasing, the slurry dropping and broken ends are little and at the same time the slurry viscosity can be ensured to reduce the sizing control difficulty caused by the fluctuation of viscosity in the sizing process, the slurry quality is stable without rimple, the slurry viscosity can long be kept in a same level and the permeance and coverage rate are improved, the hair gluing and sizing film strength can be ensured and the weaving efficiency of the yarn on the weaver can be improved.

Owner:SHENGHONG GRP CO LTD

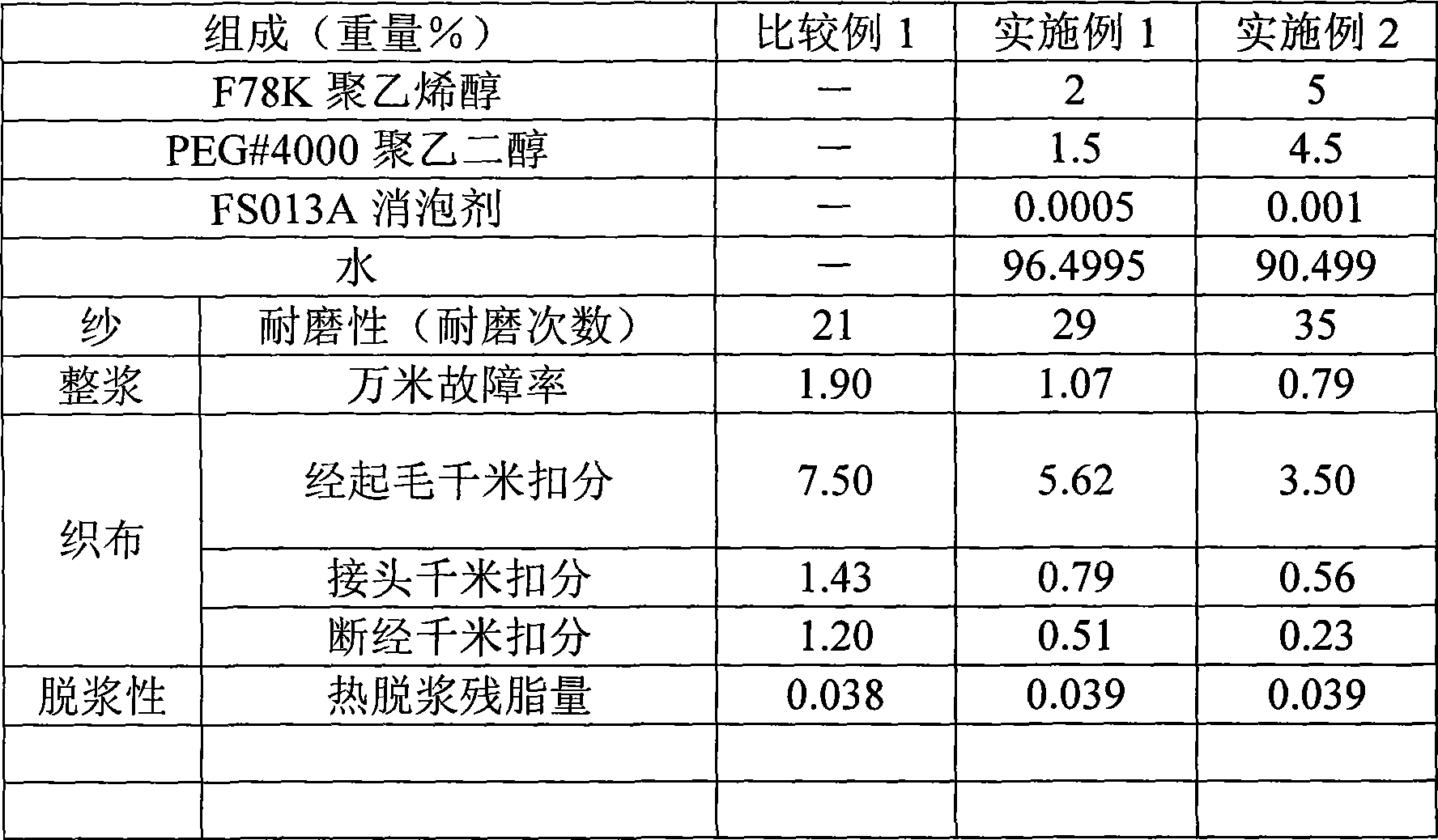

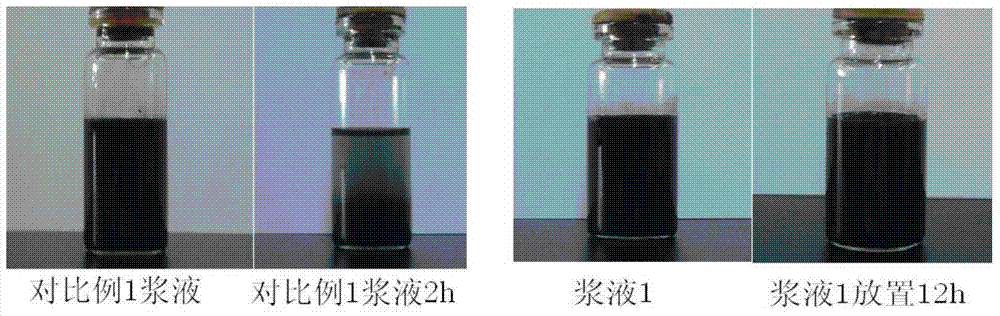

Slurry composition of glass fiber yarn and method for preparing same

The invention discloses a slurry composition of a glass fiber yarn and a method for preparing the same, and aims to provide a slurry composition of the glass fiber yarn, which has stable slurry viscosity without preservative, less compounding ingredients and good stability. The slurry composition of the glass fiber yarn comprises the following components in proportion by weight: 2 to 5 percent of polyvinyl alcohol, 1.5 to 4.5 percent of polyethylene glycol, 0.0005 to 0.0015 percent of antifoaming agent and the balance of water. The slurry composition of the glass fiber yarn can be widely applied in the filed of manufacturing glass fiber clothes.

Owner:珠海珠玻电子材料有限公司

Method for integrally preparing high-dispersity ultrafine magnesium hydroxide flame retardant

InactiveCN103665939ALow purityControl Particle UniformityMagnesium hydroxidePigment treatment with organosilicon compoundsDispersityFire retardant

The invention discloses a method for integrally preparing a high-dispersity ultrafine magnesium hydroxide flame retardant, which comprises the following steps: continuously synthesizing high-purity magnesium hydroxide; and carrying out single cycle wet grinding and surface modification on magnesium hydroxide and integrally implementing particle size control and surface processing of the magnesium hydroxide flame retardant. According to the invention, the technical difficulties of control on purity, slurry viscosity, particle size, particle size distribution and specific surface area of the magnesium hydroxide flame retardant, the existence of the phenomena of secondary coagulation and bonding during the drying process and the like; a hydrophilic surface of magnesium hydroxide flame retardant powder is modified into a lipophilic surface, so that the intermiscibility and dispersity of the powder in a macromolecule polymeric material are improved, the influence of the high-dispersity ultrafine magnesium hydroxide flame retardant on the processing performance and the mechanical performance of a polymer product is reduced, and the comprehensive properties of the macromolecule polymer, such as flame retardance, processing, mechanics, electrics, are optimized.

Owner:江苏艾特克阻燃材料有限公司

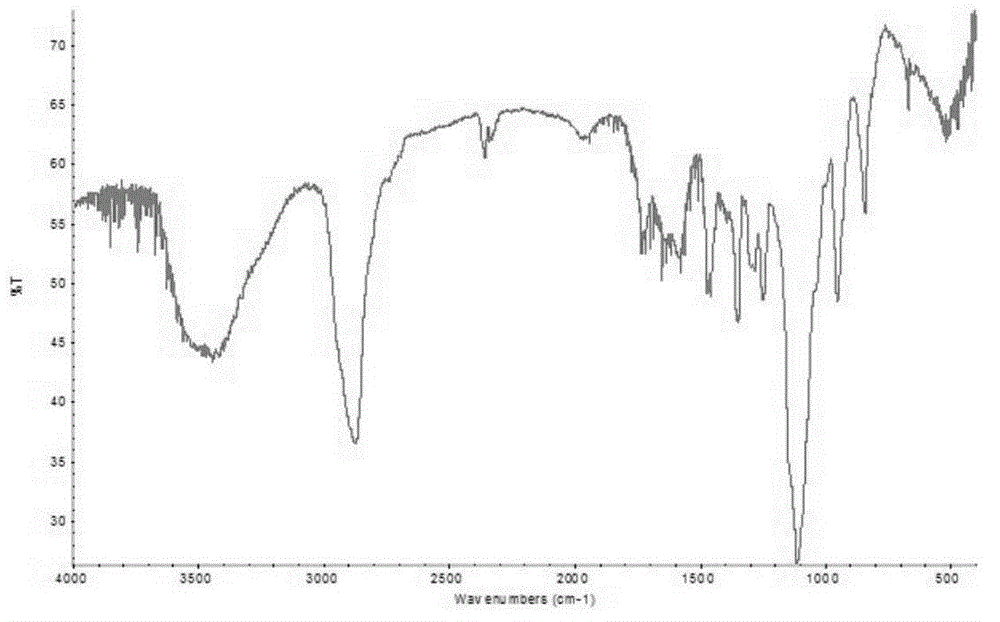

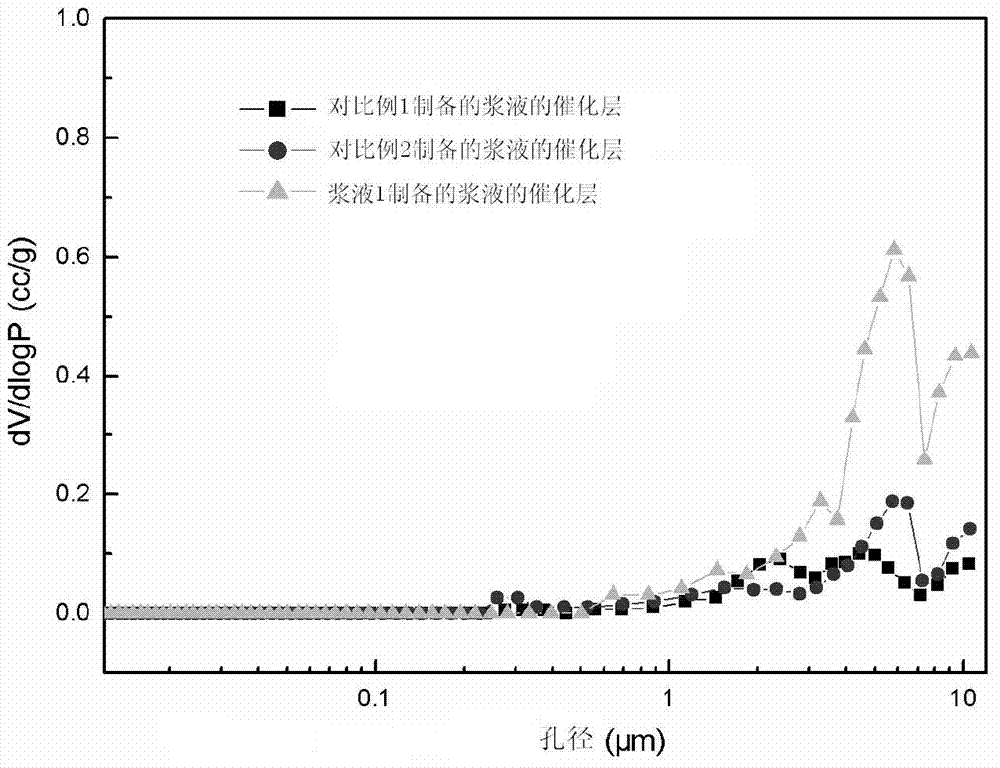

Fuel cell catalyst slurry and application thereof

InactiveCN104716342AViscosity is easy to controlControllable solid contentCell electrodesHigh current densityConductive polymer

The invention discloses a preparation method of proton exchange membrane fuel cell catalyst layer slurry, the catalyst slurry components include a catalyst, a conductive polymer and a solvent, the catalyst slurry viscosity is 100-1000 mPa.s, and the solid content is 10 to 50 wt%. By controlling the final viscosity and the solid content of the slurry, the slurry form and catalyst layer preparation efficiency and effect can be ensured. A catalytic layer electrode prepared from the slurry can be used for assembly of a proton exchange membrane fuel cell membrane electrode (MEA Membrane Electrode Assemble) and the pore size distribution is more conducive to the gas-liquid mass transfer, and is conducive to the improvement of the performance and stability of the battery in a high current density range.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com