Method for preparing spinnable polysiloxane ceramic precursor for SiC fibers

A technology of ceramic precursors and polysiloxane, which is applied in the fields of fiber chemical characteristics, textiles and papermaking, can solve the problem of high cost, and achieve the effect of high ceramic yield, low cost and high production yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

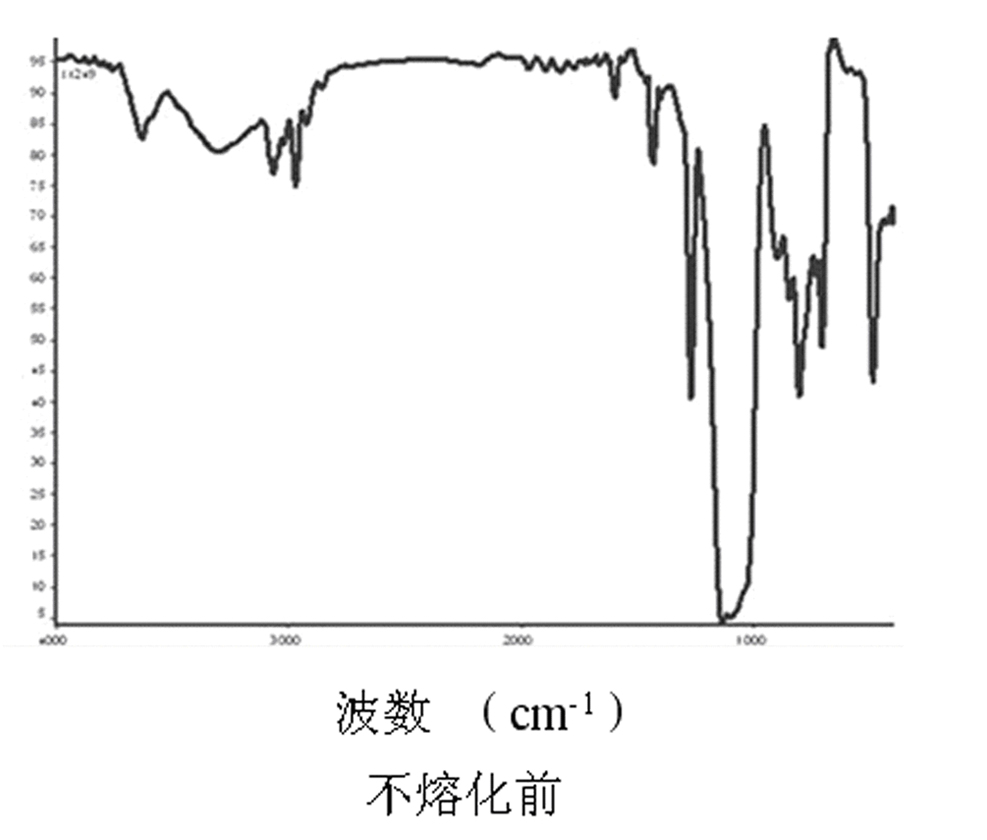

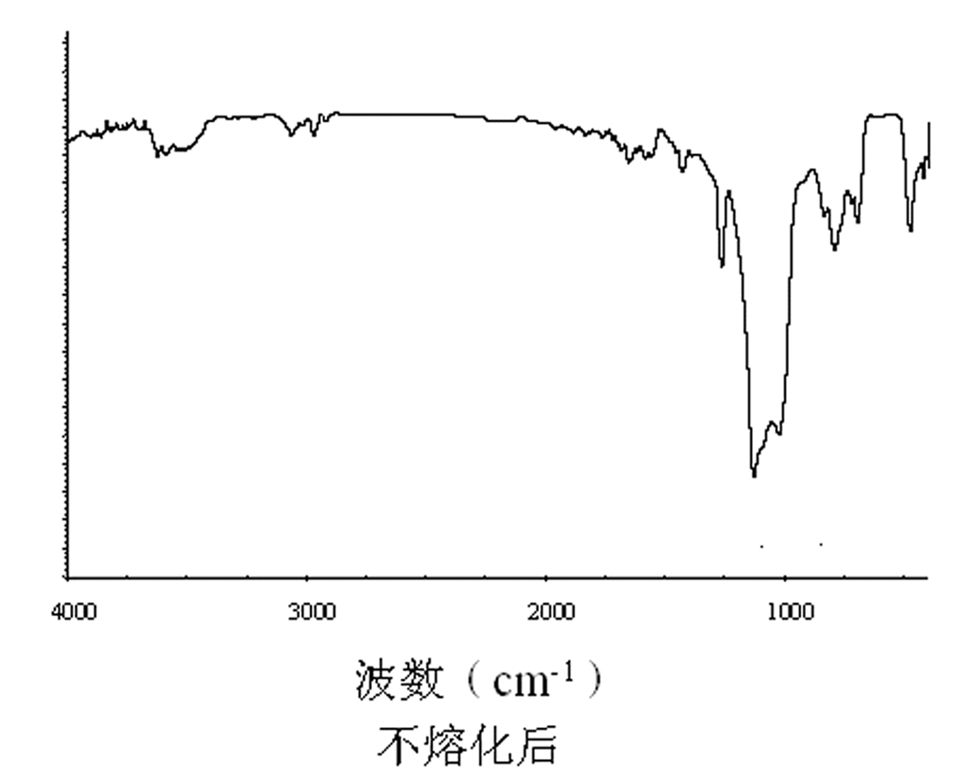

Image

Examples

Embodiment 1

[0020] (1) Add 16g of xylene, 12g of methyltrichlorosilane, 8g of dimethyldichlorosilane, and 2g of tetramethyldichlorodisiloxane into a three-necked flask; 2 Atmosphere protection, slowly (heating speed: 2°C / min) heat up to 82°C, then keep constant temperature, while mechanically stirring, stirring speed is 120r / min, then dropwise add potassium hydroxide aqueous solution (the mass ratio of potassium hydroxide to water is 3:10 ), the dropping rate was controlled at 3g / min, and the total amount of dropping was 104g; after the dropping was completed, it was kept at a constant temperature of 82°C for 12h; The siloxane xylene solution was taken out; (4) The xylene solvent was removed by vacuum distillation at 70°C for 1 h to obtain 15.6 g of hard white solid polysiloxane precursor (sample marked A1).

Embodiment 2

[0022] (1) 16g xylene, 12g methyltrichlorosilane, 8g dimethyldichlorosilane, 2g tetramethyldichlorodisiloxane are added to a three-necked flask; (2) vacuumize and feed N 2 Protect the atmosphere, slowly raise the temperature (heating rate is 2°C / min) to 70°C, then keep the temperature constant, and at the same time carry out mechanical stirring, the stirring speed is 60r / min, and then dropwise add potassium hydroxide aqueous solution (the mass ratio of potassium hydroxide to water is 3: 10), the dropping rate is controlled at 3g / min, and the total amount of dropping is 102g; after the dropping is completed, keep at a constant temperature of 65°C for 6h; The polysiloxane xylene solution was taken out; (4) The polysiloxane xylene solution in the upper layer was distilled at 70°C for 1 h to remove the xylene solvent, and 10.8 g of white rubbery polysiloxane precursor (sample labeled A2).

Embodiment 3

[0024] (1) Add 16g of xylene, 12g of methyltrichlorosilane, 8g of dimethyldichlorosilane, and 2g of tetramethyldichlorodisiloxane into a three-necked flask; 2 Protect the atmosphere, slowly raise the temperature (heating rate is 1°C / min) to 90°C, then keep the temperature constant, and at the same time carry out mechanical stirring, the stirring speed is 240r / min, and then dropwise add potassium hydroxide aqueous solution (the mass ratio of potassium hydroxide to water is 3: 10), the dropping rate is controlled at 3g / min, and the total amount of dropping is 104g; after the dropping is completed, keep at a constant temperature of 90°C for 18h; The siloxane xylene solution was taken out; (4) The polysiloxane xylene solution in the upper layer was distilled at 70°C for 1 hour to remove the xylene solvent, and 14.3 g of hard white solid polysiloxane precursor (sample marked for A3).

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com