Method for preparing graphene-quantum-dot-doped organic-solvent-resistant ultrafiltration membrane, ultrafiltration membrane prepared by method and application of ultrafiltration membrane

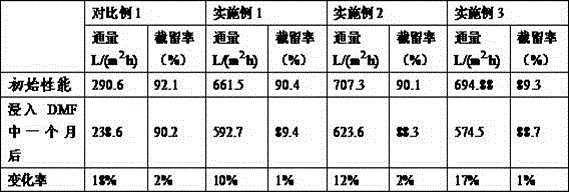

A technology of graphene quantum dots and resistance to organic solvents, applied in the field of membrane separation, can solve the problems of insufficient stability of ultrafiltration membranes, and achieve the effects of outstanding substantive features, high water flux and rejection rate, and high resistance to organic solvents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Preparation of graphene quantum dots:

[0048] Step I: Heat anhydrous citric acid to 150-300°C, drop the obtained molten citric acid into sodium hydroxide solution after 20-40 minutes, and then adjust the pH to 7 with hydrochloric acid solution;

[0049] Step II: The solution obtained in step I is separated by an ultrafiltration membrane with a molecular weight cut-off of 50,000 Daltons, and the resulting filtrate is collected; then the obtained filtrate is separated by a nanofiltration membrane with a molecular weight cut-off of 300 Daltons, and continuously added to the nanofiltration retentate Deionized water, the conductivity of the nanofiltration filtrate is less than 20 μs / cm, and the concentrated nanofiltration retentate is the graphene quantum dot solution. It has been determined that the graphene quantum dot nanoparticles contain functional groups such as carboxyl groups and phenolic hydroxyl groups. The particle diameter of the graphene quantum dot nanoparticl...

Embodiment 2

[0053] The preparation of graphene quantum dots is the same as in Example 1. Mix polyimide and DMF evenly, add graphene quantum dots to the casting solution to prepare a casting solution with a mass fraction of 20%, in which the mass fraction of graphene quantum dots is 1%; Stir for 6 hours, then centrifuge at 2000r / min for 20 minutes to defoam at a high speed; pour the prepared casting solution on the polyester non-woven fabric, control the height of the scraper to scrape at room temperature to form a film, and form a coating with a thickness of 120 μm; Evaporate the scraped coating in the air for 20 seconds, and then immerse it in deionized water at 30°C for 20 minutes. At this time, the high molecular polymer in the casting solution undergoes gel phase inversion and precipitates on the surface of the non-woven fabric to form a film. It is cross-linked 2h in the ethylenediamine / isopropanol cross-linking agent solution agent of 2.4% that above-mentioned phase conversion becom...

Embodiment 3

[0056] The preparation of graphene quantum dots is the same as in Example 1. Polyimide, polyethylene glycol 400, graphene quantum dots and DMF were uniformly mixed to prepare a casting solution with a mass concentration of PI of 20%, wherein the mass fraction of graphene quantum dots was 1%, and the concentration of polyethylene glycol 400 The mass fraction is 4%; mechanically stir the casting solution at 55°C for 6h, then let it stand at a constant temperature of 55°C for 24h, and then degas it by high-speed centrifugation at 1500r / min for 30min; pour the defoamed casting solution on On the polyester non-woven fabric, control the height of the scraper to scrape the film at room temperature to form a coating with a thickness of 120 μm; evaporate the scraped coating in the air for 10 seconds, immerse it in deionized water for 20 minutes, then take it out and rinse it clean After immersion in isopropanol for 24h, take it out for use; put the above-mentioned film soaked in isopro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com