Hydrocracking method for increasing quality of refined diesel oil

A technology for hydrocracking and refining diesel oil, which is applied in the fields of hydrotreating process, petroleum industry, and hydrocarbon oil treatment to achieve the effects of improving refining effect, reducing reaction temperature, and saving cold hydrogen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

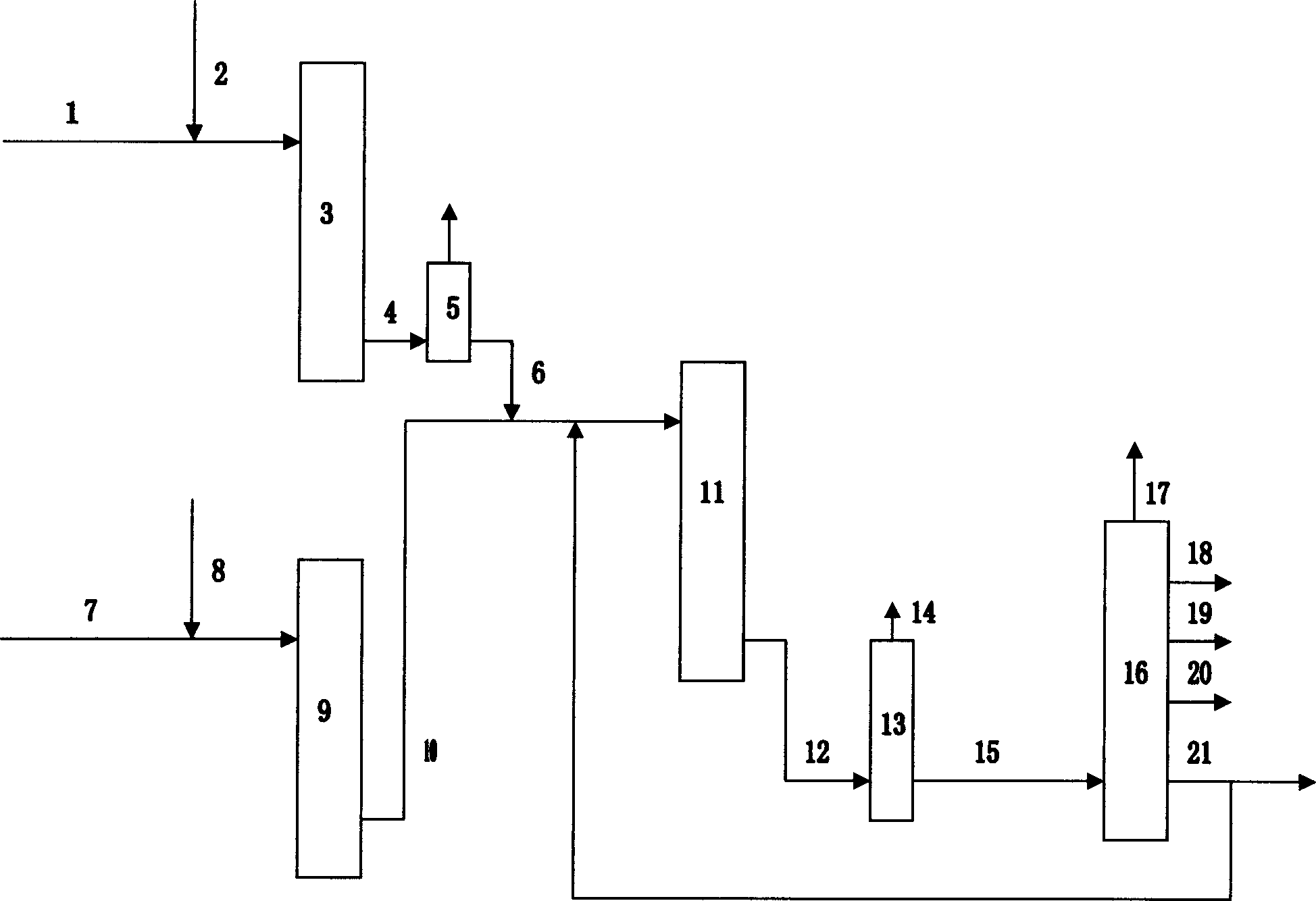

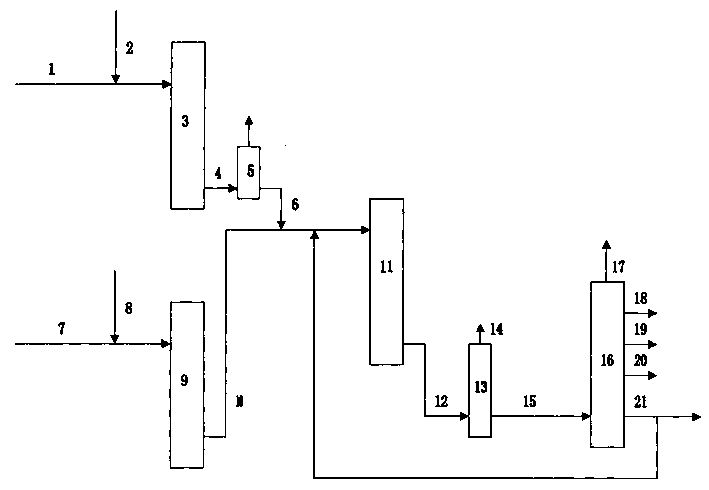

Method used

Image

Examples

Embodiment 1~2

[0016] First, the low-quality mixed diesel oil enters the medium-pressure hydrodesulfurization reactor, and the refined diesel oil is obtained through hydrogenation reaction. See Table 1 below.

[0017] Example 1

Example 2

Raw oil properties

Density, g / cm 3

0.8273

0.9035

59.7

35.2

Sulfur content, μg / g

988

6200

Nitrogen content, μg / g

1200

1500

Hydrodesulfurization process conditions

catalyst

FH-98

FH-5

pressure, MPa

7.0

6.8

temperature, ℃

300

320

Airspeed, h -1

1.5

1.5

Hydrogen oil volume ratio

1000∶1

1000∶1

Refined Diesel Properties

Sulfur content, μg / g

300

200

Nitrogen content, μg / g

100

300

62

40

Aromatic content, m%

35.0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com