Nanocrystal with core-shell structure and preparation method thereof

A technology of nano-crystal and core-shell structure, applied in crystal growth, chemical instruments and methods, single crystal growth, etc., can solve problems such as the inability to control crystal shape and crystal plane, and achieve the effect of clear crystal shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

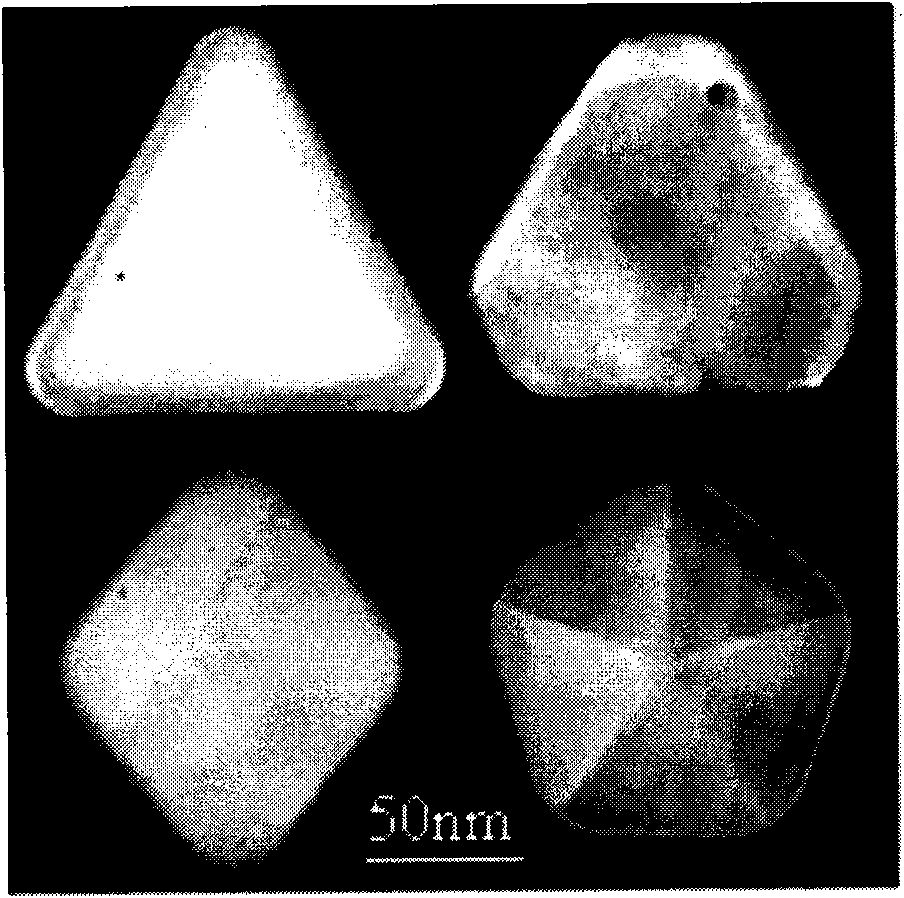

[0063] In this example, various shapes of gold-core-silver-shell structures with thinner silver shells were prepared. These shapes include triangles (attached Figure 2a ), hexagon (with Figure 2b ), Pentagram (attached Figure 2c ), octahedral shape (attached Figure 2d )Wait.

[0064] Concrete preparation method comprises the following steps:

[0065] 1) Get the ethylene glycol solution of 20ml of 0.1M chloroauric acid and 20ml of 1M polyvinylpyrrolidone, and fully mix each other according to the molar ratio of [chloroauric acid] / [polyvinylpyrrolidone] 1 / 10 to obtain the reactant mixed solution 1 ;

[0066] 2) Take 20ml of 0.1M AgNO 3 And 20ml of 1M polyvinylpyrrolidone nitrogen-dimethylformamide solution, according to [AgNO 3 ] / [polyvinylpyrrolidone] molar ratio 1 / 10, [AgNO 3 ] / [AuCl] molar ratio 1 is fully mixed with each other to obtain a reactant mixed solution 2;

[0067] 3) The mixed solution 1 is transferred into a microwave reactor, and after the microwave ...

Embodiment 2

[0070] In this example, various shapes of gold / silver core-shell nanocrystal structures with thicker silver shells were prepared. The cross-sectional shapes of these crystal structures include triangles (attached Figure 3a ), hexagon (with Figure 3b ), Pentagram (attached Figure 3c ). The crystal also has an octahedral shape (attached Figure 3d )Wait. Concrete preparation method comprises the following steps:

[0071] 1) Get the ethylene glycol solution of 20ml of 0.1M chloroauric acid and 20ml of 1M polyvinylpyrrolidone, and fully mix each other according to the molar ratio of [chloroauric acid] / [polyvinylpyrrolidone] 1 / 10 to obtain the reactant mixed solution 1 ;

[0072] 2) Take 20ml of 0.9MAgNO 3 and 20ml of 9M polyvinylpyrrolidone nitrogen, nitrogen-dimethylformamide solution, according to [AgNO 3 ] / [polyvinylpyrrolidone] molar ratio 1 / 10, [AgNO 3 ] / [auric acid chloride] in a molar ratio of 9 is fully mixed with each other to obtain a reactant mixed solution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com