High-sensitivity alcohol-sensitive gas sensor, preparation method thereof, and preparation method of mesoporous SnO2 material

A gas sensor, mesoporous technology, applied in nanotechnology, analytical materials, instruments, etc. for materials and surface science, can solve the problems of grain agglomeration, poor crystal quality and thermal stability, and achieve increased contact area, Avoidance of impurities and structural defects, effect of short response-recovery time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

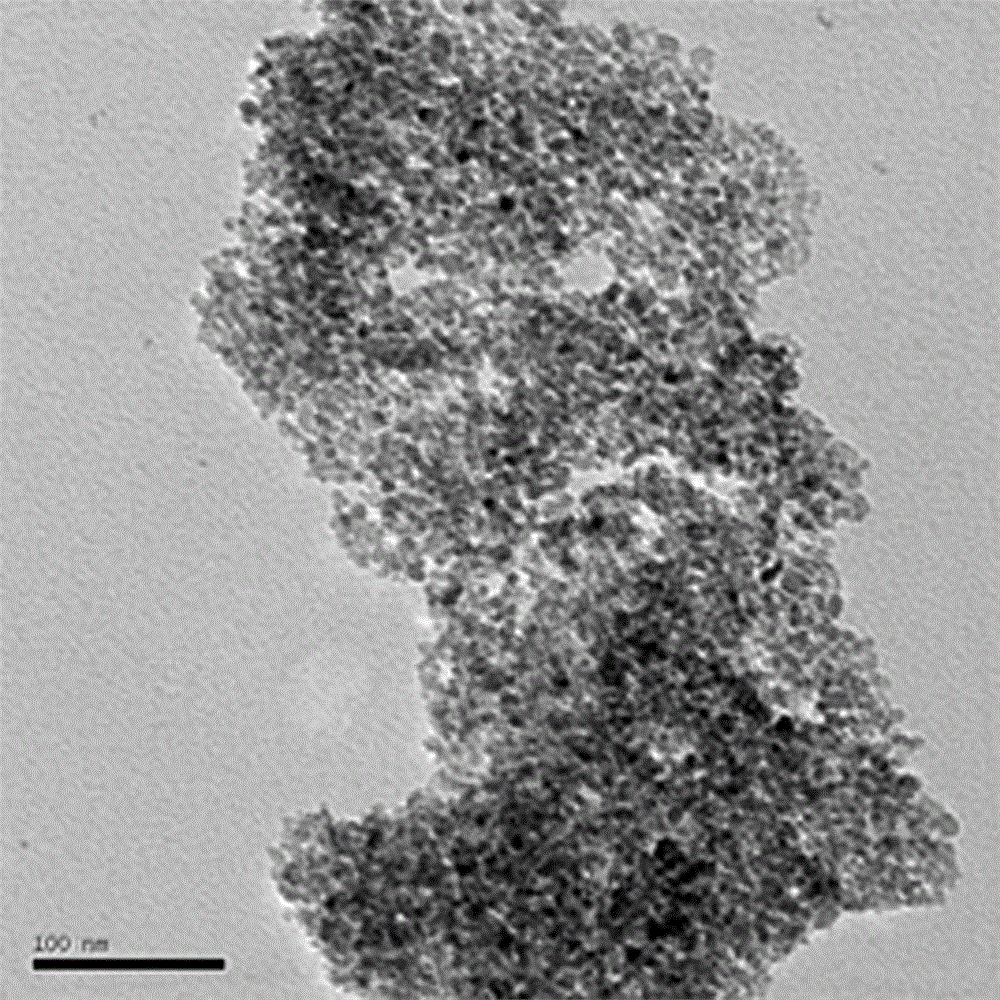

[0044] In the present invention, CTAB and dodecylamine are used as templates, and SnC l4 ·5H 2 O as tin source, mesoporous SnO was synthesized by a combination of double-template method and hydrothermal method 2 nanomaterials.

[0045] Mesoporous SnO 2 The specific preparation method of nanomaterial preparation is:

[0046] (1) Dissolve 3.1g of CTAB in 40mL of water and stir in a water bath at 40°C to obtain a surfactant solution.

[0047] (2) Add 0.11 g of dodecylamine into the surfactant solution, and stir until the solution is uniform.

[0048] (3) Add 1.05g of ammonia water with a mass percentage of 25% to 20mL of water to make an ammonia solution.

[0049] (4) Add the aqueous ammonia solution prepared in (3) into the mixture of the surfactant solution and dodecylamine prepared in (2), stir evenly, and continue stirring for 2 hours to obtain a template solution.

[0050] (5) Add 10.5g of SnC l4 ·5H 2 O was dissolved in 80 mL of water and added dropwise to the templ...

Embodiment 2

[0055] Mesoporous SnO 2 The specific methods of nanomaterials are:

[0056] (1) Dissolve 3.1g of CTAB in 40mL of water and stir in a water bath at 40°C to obtain a surfactant solution.

[0057] (2) Add 0.11 g of dodecylamine into the surfactant solution, and stir until the solution is uniform.

[0058] (3) Add 2.1g of 25% ammonia by mass to 20mL of water to make an ammonia solution.

[0059] (4) Add the aqueous ammonia solution prepared in (3) into the mixture of the surfactant solution and dodecylamine prepared in (2), stir evenly, and continue stirring for 2 hours to obtain a template solution.

[0060] (5) Add 10.5g of SnC l4 ·5H 2 O was dissolved in 80 mL of water and added dropwise to the template solution to obtain a white slurry-like solution, and magnetic stirring was continued for 3 h.

[0061] (6) React the white slurry-like solution prepared in (5) under high pressure at 160°C for 12 hours, cool, filter, and wash repeatedly with deionized water and absolute eth...

Embodiment 3

[0065] Mesoporous SnO 2 The specific methods of nanomaterials are:

[0066] (1) Dissolve 3.1g of CTAB in 40mL of water and stir in a water bath at 40°C to obtain a surfactant solution.

[0067] (2) Add 0.11 g of dodecylamine into the surfactant solution, and stir until the solution is uniform.

[0068] (3) Add 3.05g of ammonia water with a mass percentage of 25% to 20mL of water to make an ammonia solution.

[0069] (4) Add the aqueous ammonia solution prepared in (3) into the mixture of the surfactant solution and dodecylamine prepared in (2), stir evenly, and continue stirring for 2 hours to obtain a template solution.

[0070] (5) 10.5gSnC l4 ·5H 2 O was dissolved in 80 mL of water and added dropwise to the template solution to obtain a white slurry-like solution, and magnetic stirring was continued for 3 h.

[0071] (6) React the white slurry-like solution prepared in (5) under high pressure at 160°C for 12 hours, cool, filter, and wash repeatedly with deionized water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com