Diamond polishing solution for rough polishing of silicon carbide wafers and preparation method

A technology of silicon carbide crystal and diamond, which is applied in the field of diamond polishing fluid and preparation for rough polishing of silicon carbide wafers, can solve problems such as difficulty in dispersion and limit the development of oily polishing fluid, and achieve easy cleaning, rich surface active groups, and improved utilization rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

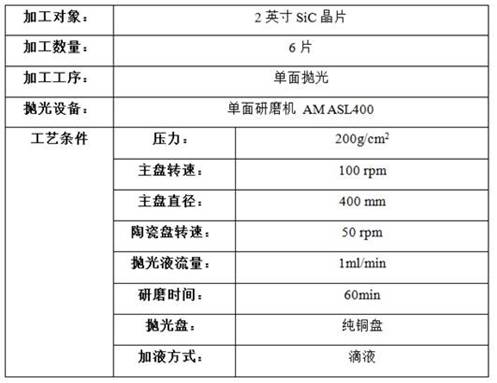

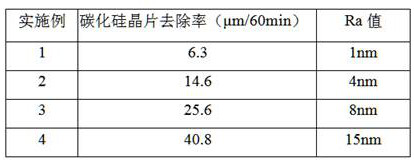

Examples

Embodiment 1

[0028] ① Weigh 300nm polycrystalline diamond powder and disperse it in water. The solid content of diamond powder in water is 5%. Ultrasonic dispersion is carried out at room temperature for 30 minutes under stirring. The speed of the machine is 1500rpm, the centrifugation time is 8min, and the coarse throwing is done 3 times to fully remove the oversized particles and hard aggregates in the dispersion;

[0029] ②Centrifugal dehydration of the dispersed liquid after throwing coarse to obtain a paste slurry with low water content, measure the water content of the paste slurry, and adjust the water content of the final paste slurry to 50%;

[0030] 3. Freeze-drying with a low-temperature freeze dryer 2. is the pasty slurry with a water content of 50% to obtain dry, loose, diamond abrasives without lumps;

[0031] ④Weigh 92 parts of C12-C15 mineral oil, 4 parts of dispersant KH550, 5 parts of diamond abrasive in ③, and ultrasonicate for 30-60min at room temperature under stirrin...

Embodiment 2

[0037] ① Weigh 700nm polycrystalline diamond powder and disperse it in water. The solid content of diamond powder in water is 6%. Ultrasonic dispersion is carried out at room temperature for 30 minutes under stirring. The speed of the machine is 750rpm, the centrifugation time is 5min, and the coarse throwing is done 3 times to fully remove the oversized particles and hard aggregates in the dispersion;

[0038] ②Centrifugal dehydration of the dispersed liquid after throwing coarse to obtain a paste slurry with low water content, measure the water content of the paste slurry, and adjust the water content of the final paste slurry to 60%;

[0039] 3. Freeze-drying with a low-temperature freeze dryer 2. is a paste slurry with a water content of 60% to obtain dry, loose, diamond abrasives without lumps;

[0040] ④ Weigh 90 parts of C12-C15 mineral oil, 3 parts of dispersant OFS-6341, 6 parts of diamond abrasive in ③, ultrasonically 30-60min at room temperature under stirring, ult...

Embodiment 3

[0046] ① Weigh 1 μm polycrystalline diamond powder and disperse it in water. The solid content of diamond powder in water is 7.5%. Ultrasonic dispersion is carried out at room temperature for 30 minutes under stirring. The speed of the machine is 200rpm, and the throwing time is 3 minutes for 3 times to fully remove the oversized particles and hard aggregates in the dispersion;

[0047] ②Centrifugal dehydration of the dispersed liquid after throwing coarse to obtain a paste slurry with low water content, measure the water content of the paste slurry, and adjust the water content of the final paste slurry to 75%;

[0048] 3. Freeze-drying with a low-temperature freeze dryer 2. is the pasty slurry with a water content of 75% to obtain dry, loose, diamond abrasives without lumps;

[0049] ④Weigh 89 parts of C12-C15 mineral oil, 2 parts of dispersant KH550, 8 parts of diamond abrasive in ③, and ultrasonicate for 30-60min at room temperature under stirring, ultrasonic power: 800KW...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com