Method for removing Cl <-> in zirconium oxide powder

A technology of zirconia powder and zirconium salt is applied in the field of preparation of zirconia ceramic powder, which can solve the problems of large water consumption and hard agglomeration of powder.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

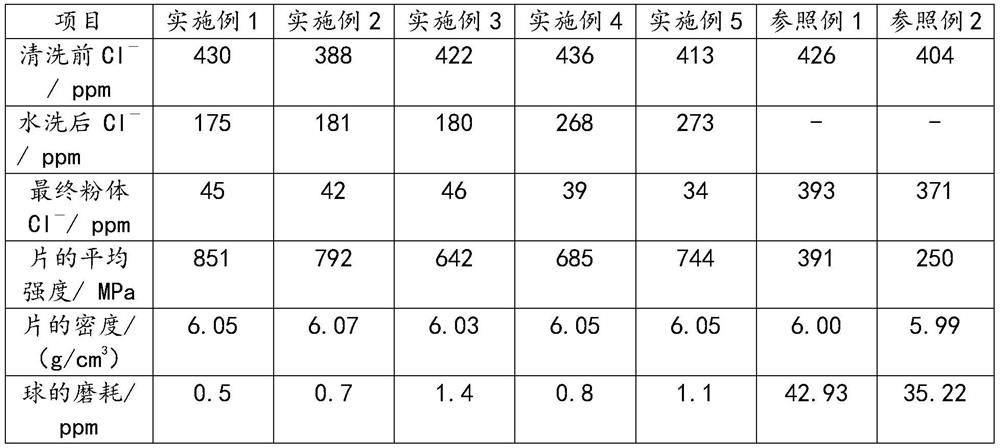

[0035] First prepare 2000L of 2mol / L zirconium oxychloride solution with deionized water as the solvent, and add 3mol% yttrium oxide into the solution, while stirring and heating to 75°C, so that the zirconium salt is fully dissolved in water, and a clear Acidic zirconium oxychloride solution, cooled to room temperature and filtered for use; then configure ammonia solution with the same concentration as the zirconium salt solution, cooled to room temperature for use; based on the precipitation method, slowly carry out the zirconium oxychloride solution and ammonia solution and then adjust the pH value of the solution to be about 7.5, then continue to add ammonia solution, adjust the pH value to 9.5, then stir for 30 minutes, and leave to stand to obtain a slurry; then repeatedly wash the prepared slurry with water 3 times, At this time, Cl in the slurry - The content is 430ppm, and then the slurry is made into a filter cake by means of pressure filtration, and then the filter ...

Embodiment 2

[0038] First prepare 2000L of 2mol / L zirconium carbonate solution with deionized water as the solvent, and add 3mol% yttrium oxide into the solution, stir and heat to 55°C at the same time, so that the zirconium salt is fully dissolved in water, and a clear acidic carbonate solution is obtained. Zirconium solution, cooled to room temperature and filtered for use; then configure ammonia solution with the same concentration as the zirconium salt solution, cooled to room temperature for use; based on the precipitation method, slowly mix the zirconium carbonate solution and ammonia solution to adjust the solution The pH value is about 7.0, continue to add ammonia solution, adjust the pH value to 9, then stir for 30min, and make the slurry after standing; then the prepared slurry is repeatedly washed with water 4 times, at this time, the Cl in the slurry - The content is 388ppm, and then the slurry is made into a filter cake by means of pressure filtration, and then the filter cake ...

Embodiment 3

[0040] First prepare 2000L of 2mol / L zirconium nitrate solution with deionized water as a solvent, and add 8mol% yttrium oxide into the solution, while stirring and heating to 65°C, so that the zirconium salt is fully dissolved in water, and clear acidic nitric acid is obtained Zirconium solution, cooled to room temperature and filtered for use; then configure an ammonia solution with the same concentration as the zirconium salt solution, and cool to room temperature for use; based on the precipitation method, slowly mix the zirconium nitrate solution and ammonia solution to adjust the solution The pH value of the solution is about 7.2, continue to add ammonia solution, adjust the pH value to 9.6, then stir for 38min, and make a slurry after standing (that is, colloidal hydroxide precipitation); then the prepared slurry is washed with water repeatedly 3 times, at this time the Cl in the slurry - The content is 422ppm, and then the slurry is made into a filter cake by means of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com