High-purity high-sintering active indium tin oxide mixed powder preparation method

A technology of indium tin oxide and mixed powders, which is applied in the preparation of high-end ITO targets, the preparation of indium tin oxide mixed powders, high sintering activity, and high-purity mixed oxide powders, which can solve the problem of low sintering activity and frequent agglomeration , Unsatisfactory dispersion of ITO powder and other problems, to achieve the effect of reducing serious agglomeration and preventing coagulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This embodiment provides a method for preparing a high-purity, highly sinterable indium tin oxide mixed powder, which includes the following steps:

[0033] (1) Prepare the composite dispersant solution, after the dispersants are completely dissolved in water, then mix together;

[0034] (2) Take SnCl 4 ·5H 2 O crystals were added to deionized water, stirred and dissolved, and the composite dispersant solution was added to obtain SnCl 4 solution;

[0035] (3) Keep stirring continuously, add ammonia water to SnCl 4 In the solution, a white precipitated precursor is generated;

[0036] (4) Move the precursor into a titanium alloy-lined autoclave for hydrothermal reaction;

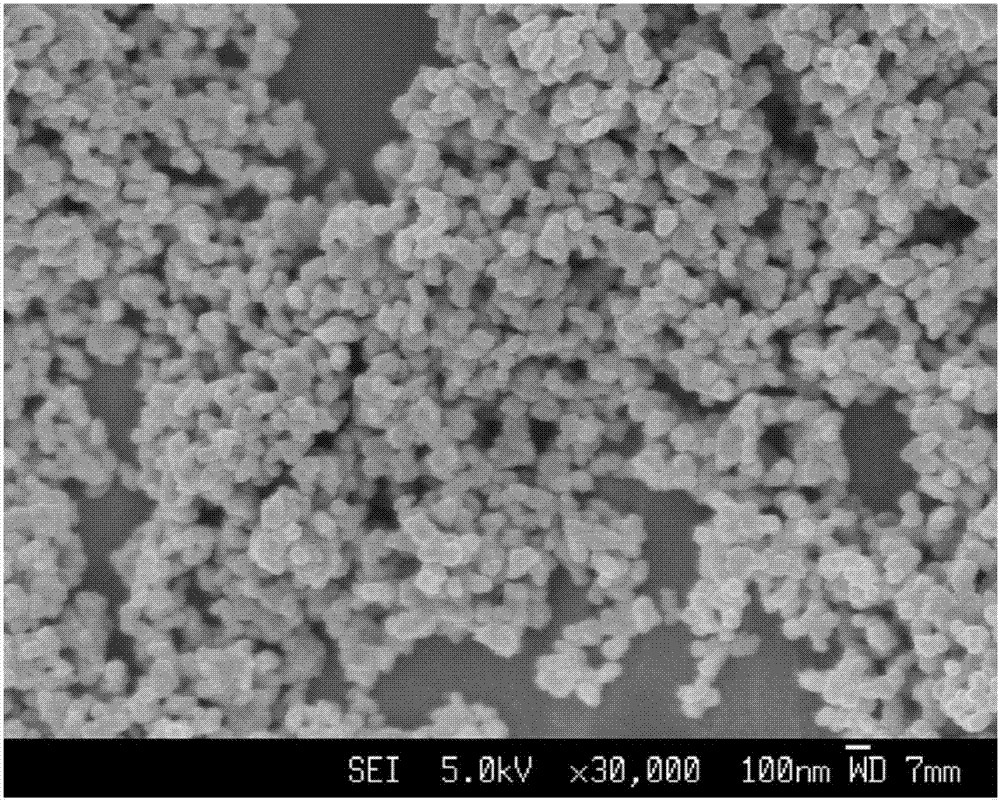

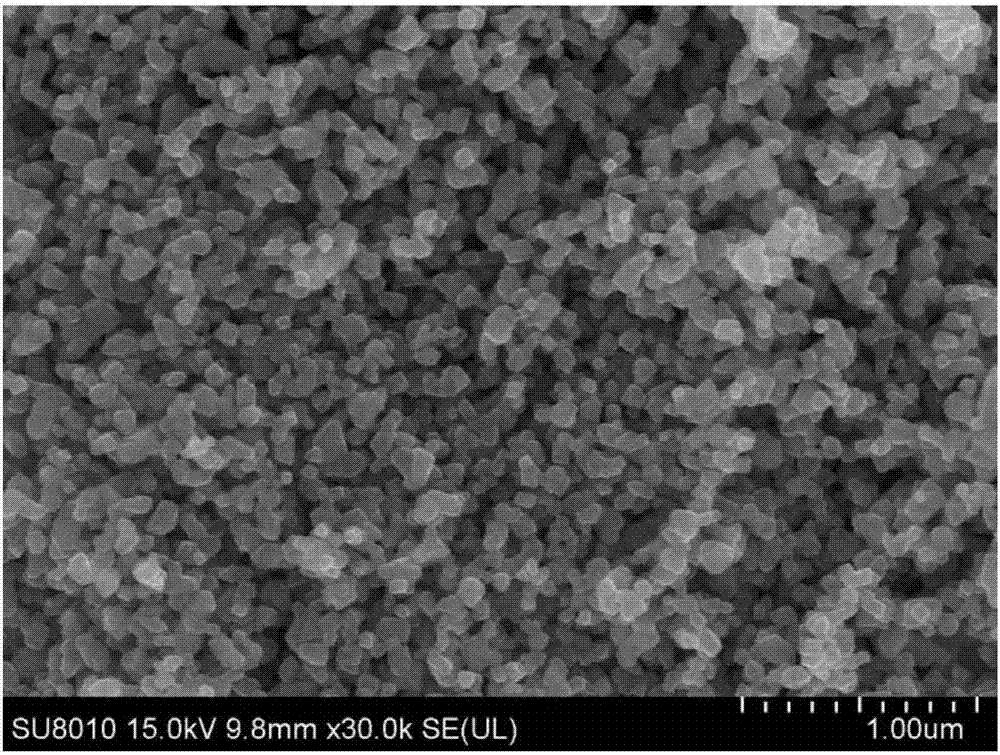

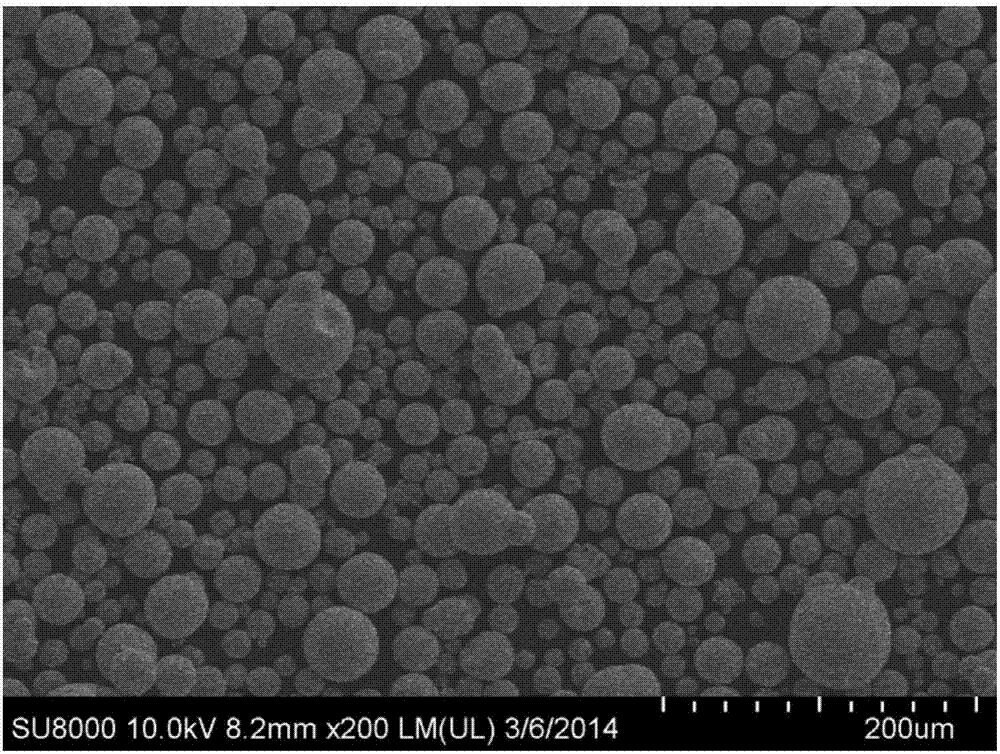

[0037] (5) After the hydrothermal reaction is over, take it out from the reaction kettle after natural cooling, and wash it repeatedly with deionized water until there is no Cl - In the presence of ions, after drying, heat treatment at 600°C for 3 hours, SnO can be obtained 2 Nano powder ( figu...

Embodiment 2

[0051] This embodiment provides a method for preparing a high-purity, highly sinterable indium tin oxide mixed powder, which includes the following steps:

[0052] (1) Prepare the composite dispersant solution, after the dispersants are completely dissolved in water, then mix them together; (2) Take SnCl 4 ·5H 2 O crystals were added to deionized water, stirred and dissolved, and the composite dispersant solution was added to obtain SnCl 4 solution;

[0053] (3) Keep stirring continuously, slowly drip ammonia water into SnCl 4 In the solution, a white precipitated precursor is generated;

[0054] (4) Move the precursor into a titanium alloy-lined autoclave for hydrothermal reaction;

[0055] (5) After the hydrothermal reaction is over, take it out from the reaction kettle after natural cooling, and wash it repeatedly with deionized water until there is no Cl - Drying without ions, after heat treatment at 600°C for 3 hours, SnO 2 Nano powder;

[0056] (6) Dissolve metal ...

Embodiment 3

[0069] This embodiment provides a method for preparing a high-purity, highly sinterable indium tin oxide mixed powder, which includes the following steps:

[0070] (1) Prepare the composite dispersant solution, after the dispersants are completely dissolved in water, then mix together;

[0071] (2) Take SnCl 4 ·5H 2 O crystals were added to deionized water, stirred and dissolved, and the composite dispersant solution was added to obtain SnCl 4 solution;

[0072] (3) Keep stirring continuously, add ammonia water to SnCl 4 In the solution, a white precipitated precursor is generated;

[0073] (4) Move the precursor into a titanium alloy-lined autoclave for hydrothermal reaction;

[0074] (5) After the hydrothermal reaction is over, take it out from the reaction kettle after natural cooling, and wash repeatedly with deionized water until Cl - Ions do not exist, after drying, 600 ° C, 3h heat treatment, get SnO 2 Nano powder;

[0075] (6) Dissolve metal In into concentrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com