Method for preparing high-performance filming water-base drilling fluid

A water-based drilling fluid, high-performance technology, used in drilling compositions, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with specific embodiment:

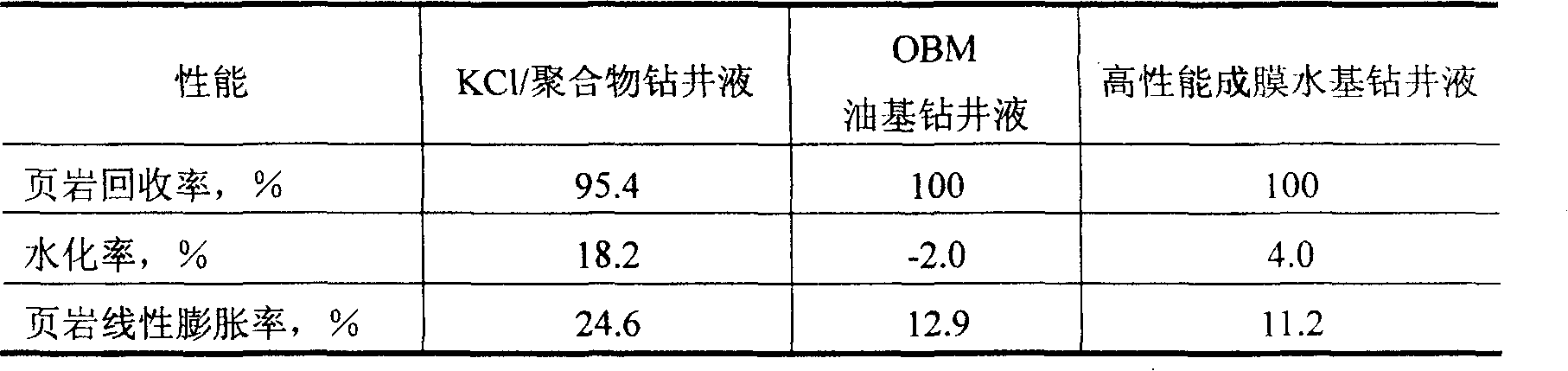

[0020] The preparation method of the high-performance film-forming water-based drilling fluid is as follows: by weight, it contains 10 parts of NaCl, 3 parts of PAC, 0.5 parts of XC, 1 part of KPAM, 8 parts of amino-based shale inhibitors, 4 parts of lubricants, and 8 parts of ingredients. Mix film agent, 1 part NaOH, and 90 parts water, and stir evenly to make high-performance film-forming water-based drilling fluid.

[0021] KCl / polymer drilling fluid formula is:

[0022] 10% NaCl aqueous solution + 3% PAC + 0.5% XC + 1% KPAM + 8% KCl + 4% lubricant + NaOH (adjust the pH value to 10.0);

[0023] The formula of oil-based drilling fluid is:

[0024] 80% 5# white oil + 20% CaCl 2 Aqueous solution + 5% primary emulsifier + 5% secondary emulsifier + 1% wetting agent + 2.5% fluid loss control agent + 2.5% organic soil + 1.25% alkalinity regulator

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com