Smooth halogen-free low-smoke flame-retardant cable material and preparation method thereof

A low-smoke, flame-retardant and smooth technology, which is applied in the field of cable materials, can solve the problems of affecting the mechanical properties of cable materials, poor dispersion of flame retardants, and high friction coefficients, so as to reduce the accumulation of die heads and improve smoothness Performance and surface gloss, effect of improving dispersion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

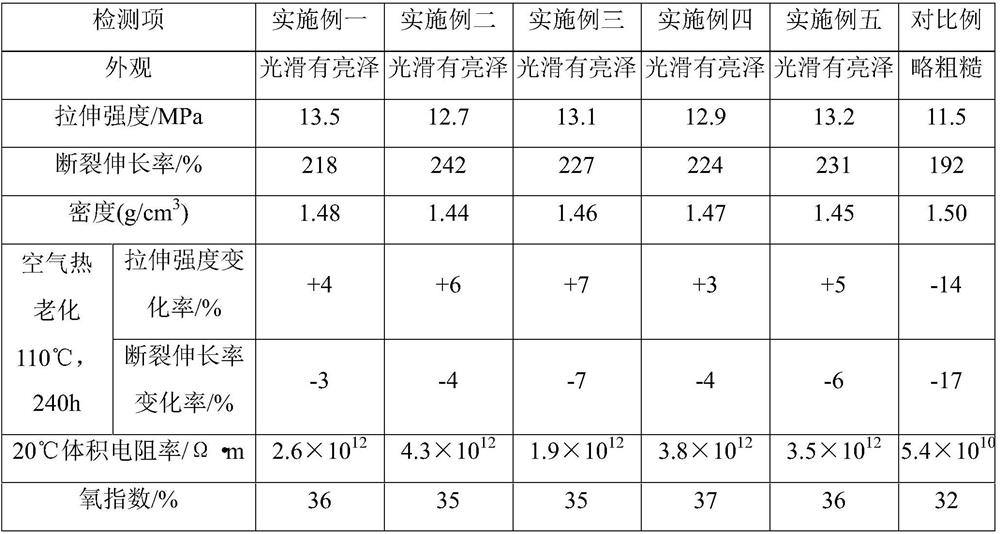

Examples

preparation example Construction

[0024] The invention provides a method for preparing a smooth halogen-free low-smoke flame-retardant cable material and the cable material prepared therefrom. The preparation method includes the following steps:

[0025] S1. Prepare a highly dispersible flame retardant, which is a nano aluminum hydroxide flame retardant. The present invention prepares highly dispersed flame retardant and comprises the following steps:

[0026] S101. Add excessive ammonia solution to the aqueous aluminum chloride solution to react to obtain a colloid, and use distilled water to wash the colloid to remove Cl - , to obtain aluminum hydroxide colloid.

[0027] S102, performing a hydrothermal reaction on the washed colloid, and reacting under the conditions of a pressure of 40-60 MPa and a temperature of 250-350° C. to obtain an aluminum hydroxide gel. Wherein, the hydrothermal reaction uses water as the reaction medium, the filling degree is 80-90%, the reaction time is 5.5-6.5h, the particle si...

Embodiment 1

[0032] This example provides a method for preparing a smooth halogen-free low-smoke flame-retardant cable material and the cable material prepared therefrom. The preparation method includes the following steps:

[0033] S1, prepare highly dispersible flame retardant, preparation method is as follows:

[0034] S101. Gradually add ammonia water to the aluminum chloride aqueous solution to an excessive amount, and react to form a colloid. The reaction equation is as follows: AlCl 3 +3NH 4 OH→Al(OH) 3 ↓+3NH 4 Cl, separate the colloid generated by the reaction from the solvent, wash the separated colloid repeatedly with distilled water, remove the chloride ions carried on the colloid, and obtain the aluminum hydroxide colloid.

[0035] S102, carry out hydrothermal reaction to the aluminum hydroxide colloid obtained in S101, use water as the reaction medium, the filling degree is 80%, react at a pressure of 40 MPa and a temperature of 350° C. for 5.5 hours, after the reaction, ul...

Embodiment 2

[0040] The difference between the present embodiment and the first embodiment mainly lies in that in the hydrothermal reaction of S102, the filling degree is 90%, and the reaction is carried out for 6.5 hours under the environment of the pressure of 60 MPa and the temperature of 250°C. In the freeze-drying process of S103, first cool the aluminum hydroxide gel to 2°C, then place it in an environment of -40°C and a pressure of 13.5Pa for 3h, then reduce the pressure to 1.5Pa, and keep it at -60°C for 10h , heat the powder to 25°C to obtain a highly dispersible flame retardant. In S2, the added slip agent accounted for 0.05% by mass of the mixture, and then the mixture was placed in a sound field with a frequency of 25 Hz and a power of 2600 W for ultrasonic treatment.

[0041] In S3, the raw material consumption of weighing is as follows: the mixture that the S2 of 170kg makes, the polyolefin resin of 100kg, the antioxidant of 1.5kg and the lubricant of 2kg, the polyolefin resi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com