Aftertreatment method for doped nano-zirconia powder

A nano-zirconia, powder technology, applied in zirconia, nanotechnology, nanotechnology and other directions, can solve the problems of non-uniform sintering, affecting material properties, difficult to completely eliminate hard agglomeration, etc., and achieve high transparency and high density. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] First, prepare 3 moles of yttria stabilized nano-zirconia powder (3Y-TZP) into a slurry with a powder mass fraction of 80%, and use zirconia beads with a diameter of 1 mm and 0.3 mm as the grinding medium. The ratio of zirconium beads is 6:4, the speed of the sand mill is 2000r / min, and the grinding time is 2h. The slurry is sprayed into liquid ammonia to be condensed, and finally dried at a temperature of -10°C and a vacuum of 10 Pa until the moisture completely disappears to prepare nano-zirconia powder.

[0055] The obtained doped nano zirconia powder was tested, and the results are as follows:

[0056] Powder: D50 0.08um, D90 0.21um, D97 0.43um.

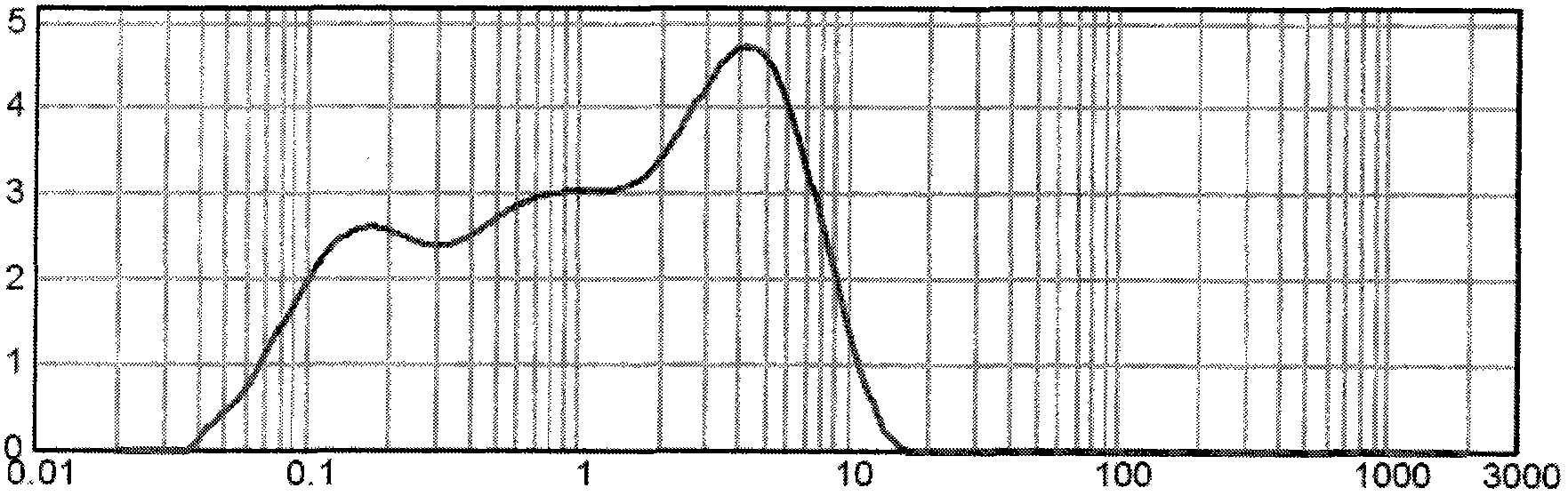

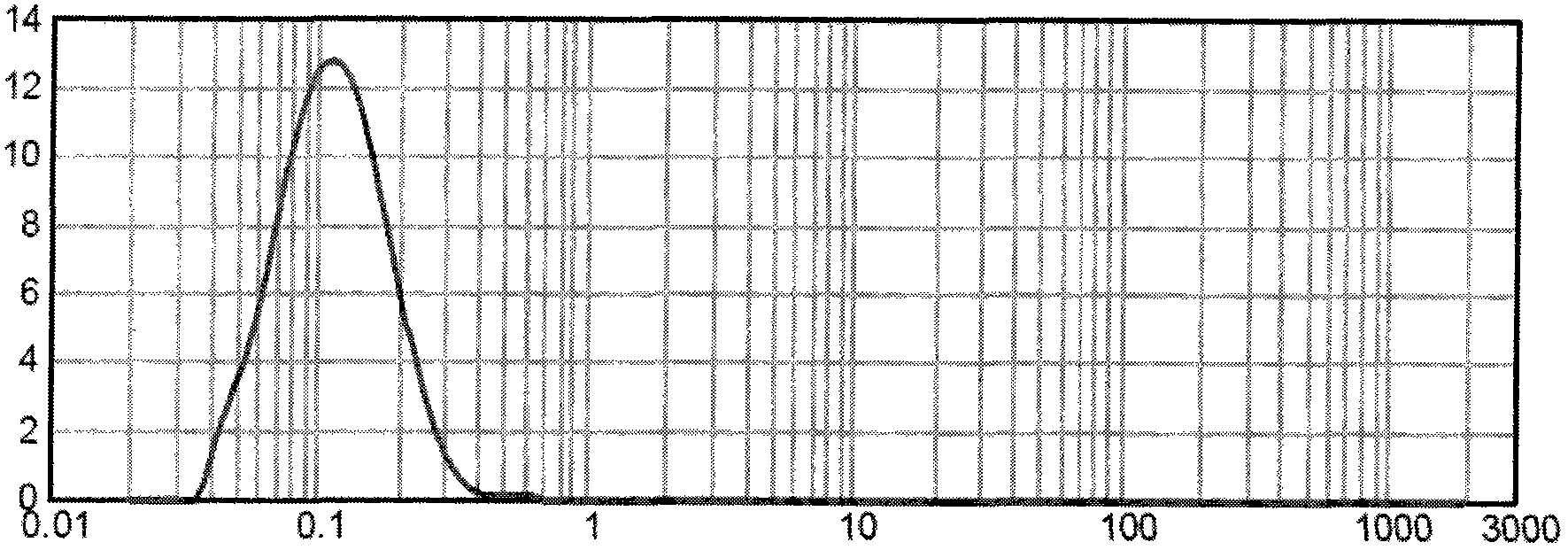

[0057] figure 1 with figure 2 They are the particle size distribution curves of the powder before and after the post-treatment method of the present invention. It can be clearly seen from the figure that the post-treatment method of the present invention completely eliminates the hard agglomeration existing in the original pow...

Embodiment 2

[0069] First, 4 moles of yttrium oxide stabilized nano zirconia powder (4Y-PSZ) is prepared into a slurry with a powder mass fraction of 25%, ultrasonic frequency is 40KHz, and treated for 4 hours, then the slurry is sprayed and condensed, and finally at -25 Drying at a temperature of ℃ and a vacuum of 6 Pa until the moisture completely disappears to prepare nano zirconia powder.

[0070] The particle size analysis of the obtained doped nano-zirconia powder is as follows:

[0071] Powder: D500.09um, D900.28um, D970.50um.

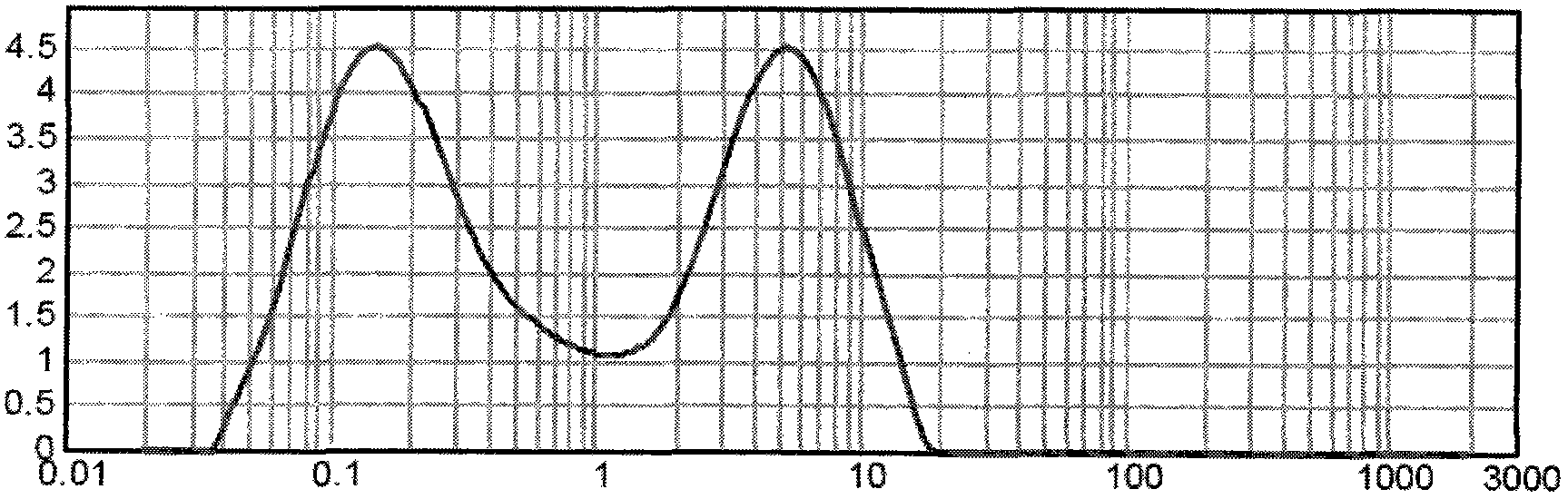

[0072] image 3 with Figure 4 These are the particle size distribution curves of the powder before and after the treatment in this embodiment. It can be clearly seen from the figure that the post-treatment method of the present invention completely eliminates the hard agglomeration existing in the original powder.

[0073] Using the powder obtained in this example, a ceramic material was prepared by the same molding and sintering process as in Example 1. Its perfor...

Embodiment 3

[0078] First, use 5 moles of yttria stabilized nano-zirconia powder (5Y-PSZ) with zirconia beads with a size of 0.5mm, 1mm, and 3mm as the grinding medium. The ratio of the three zirconia beads is 4:1::5. Ball ratio: 1:1.2, a slurry with a powder mass fraction of 20%, ball milling for 34 hours, then spray the slurry into liquid ammonia for condensation, and finally dry it at -40°C and a vacuum of 2Pa until The moisture is completely eliminated, and nano-zirconia powder is prepared.

[0079] The particle size analysis of the doped nano-zirconia powder is as follows:

[0080] Powder: D50 0.10um, D90 0.30um, D97 0.55um.

[0081] Figure 5 with Image 6 These are the particle size distribution curves of the powder before and after the treatment in this embodiment. It can be clearly seen from the figure that the post-treatment method of the present invention completely eliminates the hard agglomeration existing in the original powder.

[0082] Performance after sintering: Density after si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Three-point bending strength | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com