A preparation method of high-purity, highly sintering active indium tin oxide mixed powder

A technology of indium tin oxide and mixed powder, which is applied in the preparation of indium tin oxide mixed powder, high-end ITO target material, and high sintering activity field, which can solve the problem of many agglomerations, low sintering activity, and unsatisfactory dispersion of ITO powder and other problems to achieve the effect of preventing coagulation and reducing serious agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This embodiment provides a method for preparing a high-purity, highly sinterable indium tin oxide mixed powder, which includes the following steps:

[0033] (1) Prepare the composite dispersant solution, after the dispersants are completely dissolved in water, then mix together;

[0034] (2) Take SnCl 4 ·5H 2 O crystals were added to deionized water, stirred and dissolved, and the composite dispersant solution was added to obtain SnCl 4 solution;

[0035] (3) Keep stirring continuously, add ammonia water to SnCl 4 In the solution, a white precipitated precursor is generated;

[0036] (4) Move the precursor into a titanium alloy-lined autoclave for hydrothermal reaction;

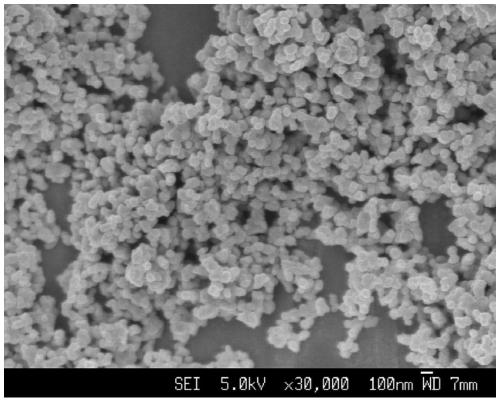

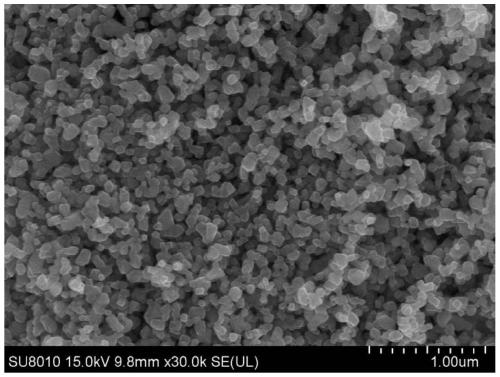

[0037] (5) After the hydrothermal reaction is over, take it out from the reaction kettle after natural cooling, and wash it repeatedly with deionized water until there is no Cl - In the presence of ions, after drying, heat treatment at 600°C for 3 hours, SnO can be obtained 2 Nano powder ( figu...

Embodiment 2

[0051] This embodiment provides a method for preparing a high-purity, highly sinterable indium tin oxide mixed powder, which includes the following steps:

[0052] (1) Prepare the composite dispersant solution, after the dispersants are completely dissolved in water, then mix together;

[0053] (2) Take SnCl 4 ·5H 2 O crystals were added to deionized water, stirred and dissolved, and the composite dispersant solution was added to obtain SnCl 4 solution;

[0054] (3) Keep stirring continuously, slowly drip ammonia water into SnCl 4 In the solution, a white precipitated precursor is generated;

[0055] (4) Move the precursor into a titanium alloy-lined autoclave for hydrothermal reaction;

[0056] (5) After the hydrothermal reaction is over, take it out from the reaction kettle after natural cooling, and wash it repeatedly with deionized water until there is no Cl - Drying without ions, after heat treatment at 600°C for 3 hours, SnO 2 Nano powder;

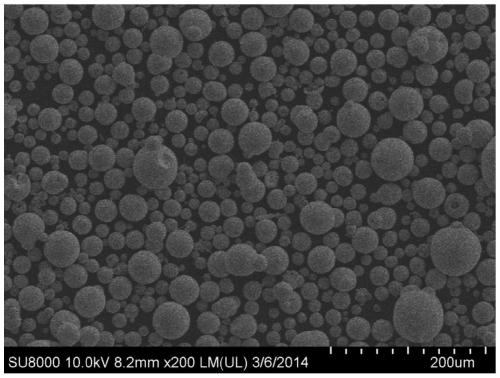

[0057] (6) Dissolve m...

Embodiment 3

[0070] This embodiment provides a method for preparing a high-purity, highly sinterable indium tin oxide mixed powder, which includes the following steps:

[0071] (1) Prepare the composite dispersant solution, after the dispersants are completely dissolved in water, then mix together;

[0072] (2) Take SnCl 4 ·5H 2 O crystals were added to deionized water, stirred and dissolved, and the composite dispersant solution was added to obtain SnCl 4 solution;

[0073] (3) Keep stirring continuously, add ammonia water to SnCl 4 In the solution, a white precipitated precursor is generated;

[0074] (4) Move the precursor into a titanium alloy-lined autoclave for hydrothermal reaction;

[0075] (5) After the hydrothermal reaction is over, take it out from the reaction kettle after natural cooling, and wash repeatedly with deionized water until Cl - Ions do not exist, after drying, 600 ° C, 3h heat treatment, get SnO 2 Nano powder;

[0076] (6) Dissolve metal In into concentrate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com