Antibacterial toughened polyethylene film and preparation method thereof

A polyethylene film and toughening technology, applied in the field of polyethylene film, can solve the problems of reducing the toughness, strength and mechanical properties of polyethylene film materials, reducing the continuity of amorphous structure regions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

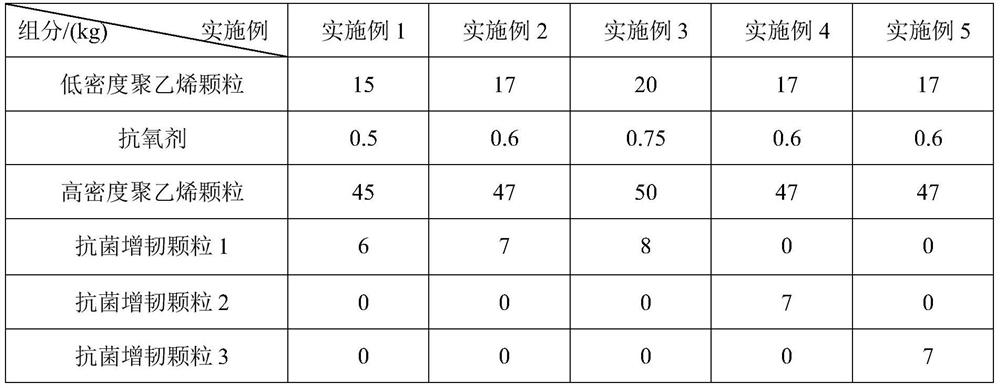

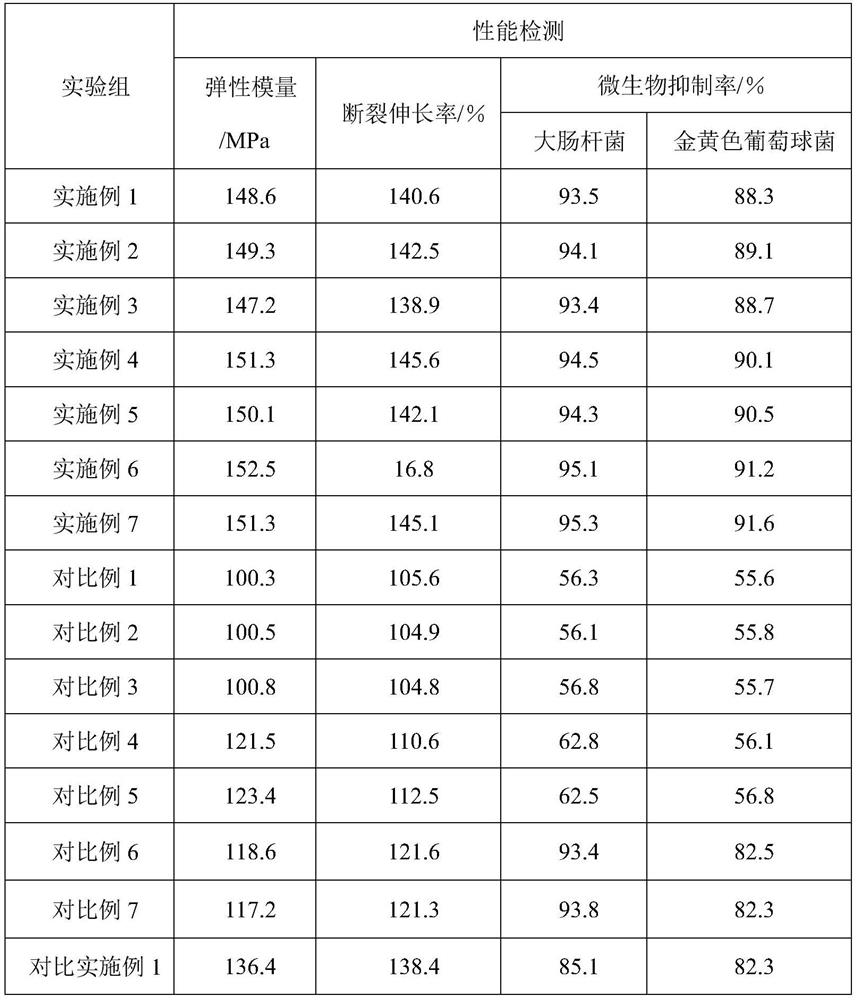

Examples

preparation example Construction

[0037] In the second aspect, the present application provides a method for preparing an antibacterial and toughened polyethylene film. The preparation steps of the antibacterial and toughened polyethylene film include: S1. The tough particles are stirred and mixed in a high-speed stirring device, and the mixed material is collected; S2, the mixed material is placed in a twin-screw extruder, and the temperature of the first zone to the seventh zone of the twin-screw extruder is adjusted to 140°C and 170°C in sequence , 170°C, 170°C, 170°C, 170°C, 160°C, extrude and granulate at a speed of 55r / min and collect the extruded particles; S3, then stir and mix the extruded particles with high-density polyethylene particles and place In the blown film machine, adjust the temperature of the first zone, the second zone and the third zone of the blown film machine to 165°C, 180°C and 180°C in sequence, and the temperature of the extrusion die is 165°C, and the film can be produced by extru...

preparation example 1

[0054] Stir and mix zinc nitrate and aluminum nitrate according to the Zn:Al molar ratio of 3:1, collect the mixed particles and add them to deionized water, adjust the solution concentration to 0.3mol / L, take the metal oxide sol with the same molar mass as aluminum nitrate , stir and mix the solution with a metal oxide sol with a particle size of 20nm to collect the matrix liquid, adjust the pH of the matrix liquid to 8.5, and then keep stirring at 35°C for 24h, filter and collect the filter cake, and dry at 75°C for 6h. Prepare antibacterial and toughened particles; add antibacterial and toughened particles to 0.85mol / L sodium hydroxide solution, stir and mix and let stand for 15h, then centrifuge at 2500r / min for 10min, remove the lower layer of precipitate and rinse with deionized water for 3 After that, vacuum freeze-dry to prepare alkali-treated antibacterial and toughened particles 1.

preparation example 2

[0056] Stir and mix zinc nitrate and aluminum nitrate according to the Zn:Al molar ratio of 3:1, collect the mixed particles and add them to deionized water, adjust the solution concentration to 0.3mol / L, take the metal oxide sol with the same molar mass as aluminum nitrate , stir and mix the solution with a metal oxide sol with a particle size of 20nm to collect the matrix liquid, adjust the pH of the matrix liquid to 8.5, and then keep stirring at 45°C for 24h, filter and collect the filter cake, and dry at 80°C for 7h. Prepare antibacterial and toughened particles; add antibacterial and toughened particles to 1mol / L sodium hydroxide solution, stir and mix and let stand for 17h, then centrifuge at 2750r / min for 12min, remove the lower layer of precipitate and rinse it with deionized water 4 times Afterwards, vacuum freeze-drying to prepare alkali-treated antibacterial and toughened particles 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com