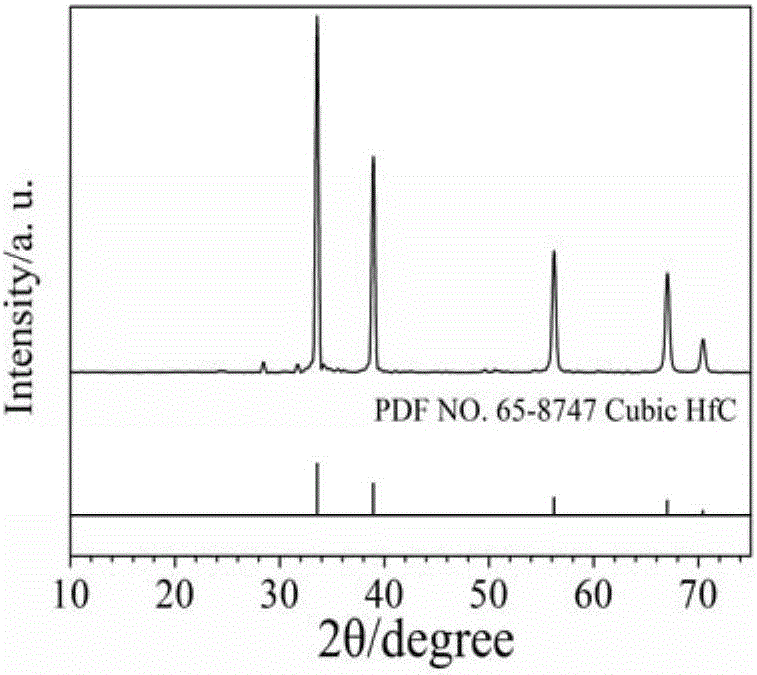

Method for preparing superhigh temperature carbonized hafnium ceramic nano-powder

A nano-powder, hafnium carbide technology, applied in the field of materials, can solve problems such as product agglomeration, and achieve the effects of improving sintering performance, convenient operation, simple and easy-to-control process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A preparation method of ultra-high temperature hafnium carbide ceramic nanopowder, adopting the following steps:

[0027] (1) Weigh a certain amount of analytically pure anhydrous sucrose and evenly disperse it in deionized water, stir it magnetically for 20 minutes to obtain a uniform and transparent sucrose solution, control its concentration to 0.02g / ml, and then add 0.05wt% polyethylene to it Pyrrolidone (PVP K30) and cetyltrimethylammonium bromide (CTAB) mixed template, the purity of the above-mentioned raw materials ≥ 99.5%, continue magnetic stirring for 20min, control the mass ratio of PVP K30 and CTAB in the above solution to be (9 : 1), and finally obtain a uniform and transparent precursor solution;

[0028] (2) Pour the precursor solution into a hydrothermal kettle with a Teflon lining. The hydrothermal kettle in the present embodiment is a 50ml Teflon-lined water tank produced by Shanghai Yanzheng Experimental Instrument Co., Ltd. Heat the kettle, the fill...

Embodiment 2

[0032] A preparation method of ultra-high temperature hafnium carbide ceramic nanopowder, adopting the following steps:

[0033] (1) Weigh a certain amount of analytically pure anhydrous sucrose and evenly disperse it in deionized water, stir it magnetically for 30 minutes to obtain a uniform and transparent sucrose solution, control its concentration to 0.08g / ml, and then add 0.1wt% polyethylene to it Pyrrolidone (PVP K30) and cetyltrimethylammonium bromide (CTAB) mixed template agent, continue magnetic stirring for 30 minutes, control the mass ratio of PVP K30 and CTAB in the above solution to (4:1), and finally obtain a uniform and transparent the precursor solution;

[0034] (2) Pour the precursor solution into a hydrothermal kettle with a Teflon lining, the filling degree is controlled at 55%, seal the hydrothermal kettle, put it into an electric blast drying oven, and adjust the appropriate temperature for reaction . The hydrothermal temperature is controlled at 170°C,...

Embodiment 3

[0038] A preparation method of ultra-high temperature hafnium carbide ceramic nanopowder, adopting the following steps:

[0039] (1) Weigh a certain amount of analytically pure anhydrous sucrose and evenly disperse it in deionized water, stir it with magnetic force for 40min to obtain a uniform and transparent sucrose solution, control its concentration to 0.1g / ml, then add 0.2wt% polyethylene to it Pyrrolidone (PVP K30) and cetyltrimethylammonium bromide (CTAB) mixed template agent, continue magnetic stirring for 40min, control the mass ratio of PVP K30 and CTAB in the above solution to (7:3), and finally obtain a uniform and transparent the precursor solution;

[0040] (2) Pour the precursor solution into a Teflon-lined hydrothermal kettle, control the filling degree at 60%, seal the hydrothermal kettle, put it into an electric blast drying oven, and adjust the appropriate temperature for reaction . The hydrothermal temperature is controlled at 180°C, the pressure is 10MPa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com