Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

51results about How to "Reduce the secondary grain distance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

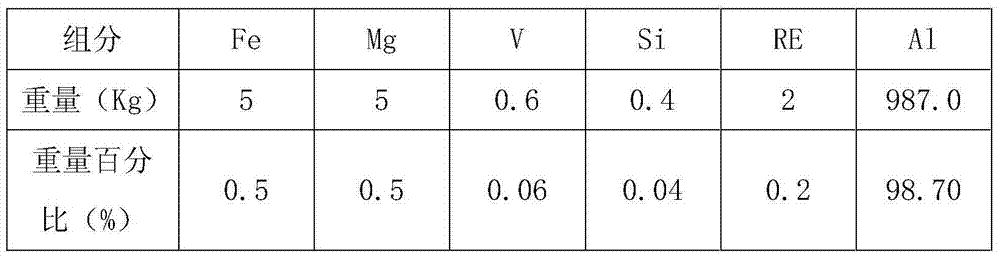

Preparation method for graphene rare earth aluminum alloy high-conductive material

ActiveCN107099708AReduce the degree of reunionLow densityConductive materialMetal/alloy conductorsRare earthConductive materials

The invention discloses a preparation method for a graphene rare earth aluminum alloy high-conductive material. The method comprises the following steps: adding aluminum scrap, silicon calcium alloy, copper aluminum alloy, zinc aluminum alloy, magnesium ingot, rare earth aluminum alloy and graphene into a smelting furnace for smelting; performing ladle analysis, thereby acquiring an aluminum alloy solution; casting and rolling the aluminum alloy solution, thereby acquiring aluminum alloy; performing homogenization treatment on the aluminum alloy; performing ageing treatment, thereby acquiring the graphene rare earth aluminum alloy high-conductive material. According to the preparation method for the graphene rare earth aluminum alloy high-conductive material, provided by the invention, the technical parameters are reasonably set, the graphene structure is optimized and the overall performance of the aluminum alloy is effectively improved, so that the acquired graphene rare earth aluminum alloy high-conductive material has excellent electric conductivity, heat resistance, arc altitude resistance and mechanical properties.

Owner:ANHUI NANYANG NEW MATERIAL TECH CO LTD

Silicon-and-magnesium-containing aluminum alloy sheet for air-conditioning radiator and preparation method of silicon-and-magnesium-containing aluminum alloy sheet

The invention relates to a silicon-and-magnesium-containing aluminum alloy sheet for an air-conditioning radiator. The silicon-and-magnesium-containing aluminum alloy sheet comprises the following chemical elements by mass percent: 0.25-0.35% of Si, 0.48-0.55 of Mg, 0.01-0.02 of Cr, 0. 05-0.15 of Fe, 0.01-0.03 of Ti, 0.01-0.03 of Cu, 0.005-0.02 of La, and the balance being Al. The aluminum alloy sheet provided by the invention has high strength and toughness, is added with lanthanum, the composition undercooling is carried out during gold casting, crystal grains are refined, a secondary crystal spacing is reduced, gas and inclusions in an alloy are reduced, and an inclusion tends to be nodulized, the surface tension of a melt can also be reduced, the mobility is increased, and ingots are favorably cast. According to a production method provided by the invention, the phenomena of layering, peeling, bubbling and cracking of aluminum alloy are reduced, and the yield is improved; a refining agent has a good refining effect, so that the pores and slag inclusion phenomena are obviously reduced.

Owner:ANHUI TIANXIANG AIR CONDITIONING SCI & TECH CO LTD

High-strength graphene and rare-earth aluminium alloy

The invention discloses a high-strength graphene and rare-earth aluminium alloy. The grapheme and rare-earth aluminium alloy comprises an aluminium alloy matrix and graphene. The composition of the aluminium alloy matrix comprises, by mass, 1.2-1.8% of Cu, 0.18-0.25% of Si, 0.08-0.2% of Cr, 0.6-0.8% of Mg, 0.1-0.2% of Mn, 0.3-0.4% of Fe, 0.3-0.5% of Zn, 0.02-0.06% of Ti, 0.1-0.2% of V, 0.1-0.2% of Ni, 0.04-0.07% of Mo, 0.05-0.12% of Zr, 0.04-0.08% of Nd, 0.04-0.06% of La, 0.03-0.05% of Ce, and the balance Al. The high-strength graphene and rare-earth aluminium alloy has good mechanical properties such as strength, toughness and the like.

Owner:ANHUI NANYANG NEW MATERIAL TECH CO LTD

Metal coating used for improving corrosion resistance of spring and preparing method of metal coating

InactiveCN105463446AHigh strengthImprove antioxidant capacityHeat inorganic powder coatingNiobiumCobalt

The invention discloses a metal coating used for improving corrosion resistance of a spring and a preparing method of the metal coating. The metal coating comprises, by mass percent, 0.02-0.04% of carbon, 3.1-3.3% of magnesium, 8.5-8.8% of chromium, 4.5-4.7% of vanadium, 8.5-8.9% of nickel, 2.3-2.5% of cobalt, 0.2-0.5% of niobium, 0.1-0.3% of arsenic, 0.7-0.9% of molybdenum, 0.02-0.04% of tungsten, 2.2-2.5% of selenium, 3.2-3.5% of titanium, 2.6-2.8% of bismuth, 1.5-1.8% of sodium, 2.7-2.9% of neodymium, 2.3-2.8% of promethium, 5.2-5.4% of erbium, 4.2-4.5% of samarium, 7.2-7.5% of assistant and the balance iron.

Owner:SUZHOU CITY WUZHONG DISTRICT XUKOU FENGSHOU MACHINERY PARTS FACTORY

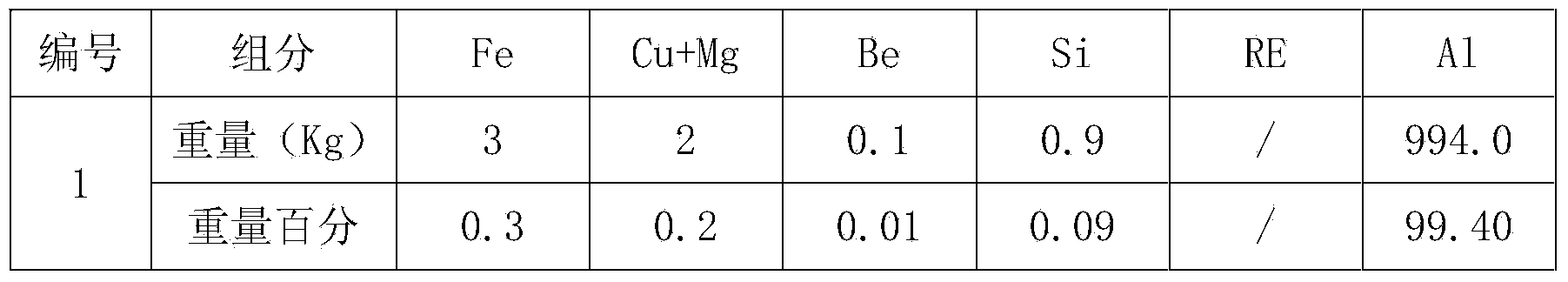

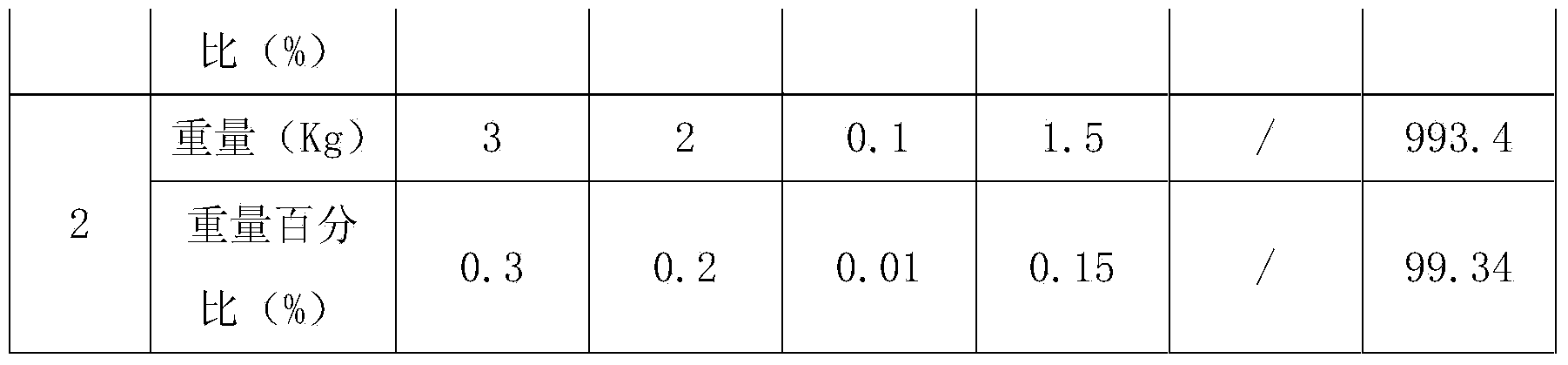

Al-Fe-Cu-Mg-Be alumium alloy for automobile wire and wiring harness therefore

PendingCN103725930AHigh mechanical strengthImprove tensile propertiesNon-insulated conductorsMetal/alloy conductorsSurface finishUltimate tensile strength

The invention discloses an Al-Fe-Cu-Mg-Be alumium alloy for an automobile wire and a preparation method thereof, and an automobile wiring harness prepared by the preparation method. The Al-Fe-Cu-Mg-Be alumium alloy for the automobile wire comprises the following components: 0.2-1.4wt% of Fe, 0.01-0.5wt% of Cu+Mg, 0.001-0.2wt% of Be, and the balance of Al and inevitable impurities. According to the invention, Fe element is added so that the mechanical strength and the tensile property of the alloy can be improved; Fe is also capable of obviously improving the high-temperature creep resistance and the fatigue resistance of the alloy; the addition of Cu+Mg is capable of improving the strength and the high-temperature creep property and the fatigue resistance of the alloy; Be is capable of improving the smelting quality of the alloy and the compactness of the surface oxide film, so that good-quality castings good in surface smoothness, high in strength and improved in ductility can be obtained; Be is also capable of improving the fluidity of the alloy so that the fluidity of the melt is improved, and can further improve the tensile strength and the limit of yielding of the alloy.

Owner:ANHUI JOY SENSE CABLE

Preparation method for graphene rare earth aluminum alloy high-conductivity material cable

ActiveCN107230508AReduce primary silicon particle sizeImproved resistance to adverse effects caused by corrosionConductive materialApparatus for manufacturing conducting/semi-conducting layersMagnesiumHigh intensity

The invention discloses a preparation method for a graphene rare earth aluminum alloy high-conductivity material cable. Aluminum alloy is obtained by performing smelting on waste aluminum, silicon-calcium alloy, copper-aluminum alloy, zinc-aluminum alloy, magnesium ingot, rare earth aluminum alloy and graphene; and next, heat treatment is performed, and then the graphene rare earth aluminum alloy high-conductivity material cable is obtained by processing. According to the preparation method for the graphene rare earth aluminum alloy high-conductivity material cable provided by the invention, through reasonable setting of the technological parameters and optimization of the graphene structure, the overall performance of the aluminum alloy is improved effectively, so that the obtained graphene rare earth aluminum alloy high-conductivity material cable has the advantages of high intensity, plasticity, conductivity, heat resistance, resistance to fatigue under flexing, and processing performance and the like.

Owner:ANHUI NANYANG NEW MATERIAL TECH CO LTD

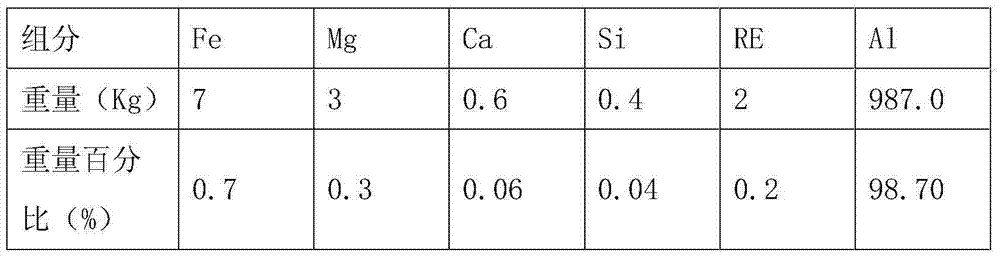

High-strength aluminum magnesium alloy for security door panels and heat treatment method of high-strength aluminum magnesium alloy

The invention discloses a high-strength aluminum magnesium alloy for security door panels. The aluminum magnesium alloy comprises the following components by mass percent: 0.12-0.32% of iron, 0.09-0.12% of silicon, 0.05-0.11% of copper, 0.32-0.46% of manganese, 4.7-5.5% of magnesium, 0.05-0.1% of zinc, 0.25-0.41% of titanium, 0.05-0.15% of zirconium, 0.12-0.18% of lanthanide, 0.001-0.005% of sodium, 0.001-0.003% of beryllium, less than or equal to 0.15% of impurities and the balance of aluminum, wherein the lanthanides comprise the following chemical components by mass percent: 13-17% of Nd, 0-18% of Ce, 8-14% of Er, 0-9% of Pr, 0-4% of Pm, 0-5% of Dy and the balance of La. Through the components, the decay resistance of the aluminum alloy can be improved; through a technology for heating processing, the processing cost can be reduced, the processing cycle can be shortened, the corrosion resistance and the welding performance of the aluminum alloy can be improved and the product quality can be improved.

Owner:SUZHOU SHENLONG DOORS & WINDOWS

Engine steering bracket processing process

InactiveCN107858561AImprove corrosion resistanceReduce gasMetallic material coating processesRare-earth elementHolmium

The invention discloses an engine steering bracket processing process. A blank is selected, and the blank comprises the following components of, in percentage by mass, 0.05-0.06% of C, 0.5-1% of Mn, 0.5-0.8% of Ni, 2-4% of Cr, 0.4-0.6% of Nb, 0.1-0.2% of Si, 0.1-0.12% of N, 0.2-0.5% of Fe, 1.5-2.0% of Mg, less than or equal to 0.2% of Cu, less than or equal to 0.015% of s, less than or equal to 0.025% of p, 0.3-0.5% of Mo, 2-4% of Al, 0.3-0.5% of Ti, 0.02-0.03% of B, 0.0018-0.0022% of v, 0.1-0.3% of composite rare earth, 0.2-0.4% of rare earth elements and the balance Al; and the composite rare earth comprises the following components of, in percentage by weight, 13-15% of cerium, 15-18% of praseodymium, 5-8% of holmium, 8-10% of gadolinium, 8-10% of gadolinium and the balance lanthanum, and the sum of all the components of the composite rare earth is 100%.

Owner:苏州威斯道智能科技有限公司

Heat treatment method of aluminum magnesium alloy

ActiveCN105839036AEvenly heatedReduce temperature differenceRoom temperatureUltimate tensile strength

The invention relates to the technical field of heat treatment of alloy, in particular to a heat treatment method of aluminum magnesium alloy. The heat treatment method comprises the following steps: placing the aluminum magnesium alloy in a vacuum heat treatment furnace at first; controlling the temperature to be 490-510 DEG C along with the temperature of the furnace in a mode of heating and then cooling; cooling after insulation is finished; placing the aluminum magnesium alloy in an environment at the temperature of 360-380 DEG C and insulating for 1-2 hours; carrying out single-pass deformation at the insulating temperature, wherein deformation is 25-45%; then carrying out cold rolling, wherein the rolling speed is 0.08-0.25 m / s, and reduction in cold rolling is 30+ / -5%; and finally cooling the aluminum magnesium alloy in air until the temperature of the aluminum magnesium alloy reaches room temperature. The heat treatment method is simple to operate and easy to implement; and the machining time is shortened. The aluminum magnesium alloy treated by the method has the characteristics of dimensional stability, corrosion resistance, mechanical property and excellent extrusion performance, and further has the advantage that the strength of the aluminum magnesium alloy is reasonably matched with plasticity.

Owner:贵州航天风华精密设备有限公司

Anti-cracking low-temperature-resistant oil-immersed transformer shell

InactiveCN106756232AHigh strengthImprove antioxidant capacityTransformers/inductances casingsMetallic material coating processesRare-earth elementChemical composition

The invention discloses an anti-cracking low-temperature-resistant oil-immersed transformer shell, comprising a shell and an oil conservator arranged in the shell. The top of the shell communicates with the oil conservator through a pipeline, and the bottom of the shell also communicates with the oil conservator through another pipeline; the outer wall of the oil conservator is provided with cooling fins; the chemical composition of the alloy blank used in the cooling fins, by mass, are: 11.3-14.4% Al, 14.6-17.5% of Mg, 1.25-1.50% of Fe, 0.40-0.7% of Si, 0.01-0.10% of Cu, 1.5-1.7% of Mn, 1.4-2.0% of Zn, 0.10-0.25% of Zr, 1.10-3.12% of rare-earth element, less than 0.015% of impurity content, and the balance Ti; and the rare-earth element comprises, by weight, 15-18% of Gd, 3-5% of Pr, 7-9% of Dy, 12.5-12.8% of Ac, 15-20% of Nd, 11-13% of Sm, and the balance La.

Owner:SUZHOU CHENHENG WEAVING

Aluminum alloy for new energy automobile battery case and production process thereof

The invention relates to the metallurgy field, in particular to an aluminum alloy for a new energy automobile battery case and a production process thereof. By weight percent, the aluminum alloy product consists of elements of 3.4-5.1 of Zn, 2.3-2.7 of Mg, 1.7-1.9 of Cu, 0.3-0.8 of Fe, 0.1-0.4 of Mn, 0.1-0.3 of Si, 0.15-0.26 of Cr, 0.12-0.15 of Ti, the balance Al and inevitable impurities. The preparation process includes multiple procedures of refining, filtering, casting, calendaring, homogenization treatment, artificial aging, hot static pressure treatment and the like. The aluminum alloy sheet produced by using the production process is characterized by being high in tensile strength and yield strength, large in hardness and excellent in fatigue resistance, and is suitable for manufacture of the new energy automobile battery case.

Owner:山东创新精密科技有限公司

Stainless steel material for doors and windows

InactiveCN107058876AGood transverse yield strengthImprove plasticityAntifouling/underwater paintsPaints with biocidesRare-earth elementHigh intensity

The invention provides a stainless steel material for doors and windows. The material is prepared from a Fe element and modified chemical element impurities. The following modified chemical elements in percentage by mass are included: 0.05 to 0.11 percent of C, 0.5 to 1 percent of Mn, 0.21 to 0.24 percent of Si, 0.006 to 0.008 percent of P, 0.002 to 0.004 percent of S, 0.093 to 0.095 percent of Nb, 0.06 to 0.08 percent of V, 2.8 to 3.1 percent of Ti, 1.5 to 1.7 percent of Al, 0.001 to 0.006 percent of N, 0.0001 to 0.0002 percent of H, 0.05 to 0.07 percent of Cu, 7.4 to 15.2 percent of Cr, 8.1 to 11.3 percent of Ni, 0.23 to 0.25 percent of Mo, 0.21 to 0.23 percent of La, 0.04 to 0.08 percent of Sr, 0.05 to 0.1 percent of Th, 0.02 to 0.03 percent of Be, 0.05 to 0.08 percent of Zr, 0.0015 to 0.002 percent of B, and 0.06 to 0.09 percent of Re. According to the stainless steel material for doors and windows provided by the invention, the element contents in stainless steel are reasonably controlled, so that the obtained stainless steel is anti-corrosion and anti-erosion; and the rare earth element lanthanum is added, so that the high-strength anti-corrosion stainless steel for metal doors and windows are successfully obtained and has better transverse yield strength and high-ductility, the transverse tensile strength is larger than or equal to 450MPa, the transverse yield strength is larger than or equal to 240MPa, the transverse extension rate is larger than or equal to 30 percent, and the thickness-direction area reduction percentage is larger than or equal to 55 percent.

Owner:合肥市旺友门窗有限公司

Preparing method of high-strength aluminum alloy material used for building door and window machining

The invention discloses a preparing method of high-strength aluminum alloy material used for building door and window machining. The aluminum alloy material comprises, by mass percent, 0.9% of silicon, 6.8% of copper, 0.3% of magnesium, 0.8% of iron, 0.8% of manganese, 0.35% of chromium, 0.15% of titanium, 0.07% of strontium, 0.3% of zirconium, 0.8% of boron, 0.1% of rhenium, 0.2% of rare earth and the balance raw material aluminum. Manganese and titanium are added for improving the high-temperature strength of alloy containing copper and silicon, the recrystallization process of the aluminumalloy can be prevented, the recrystallization temperature is increased, the recrystallization grains can be obviously refined, through adding of chromium and zirconium, recrystallization nucleation and growing can be obstructed, the alloy can be subjected to certain strengthening, the toughness of the alloy can be improved, stress corrosion cracking sensitivity can be reduced, strontium has the advantages of being long in metamorphic effective time, good in effect and reproducibility and the like, the casting ingot homogenizing time is reduced, the material mechanical property and plastic machining can be improved, the product surface roughness is improved, and hot rolling and cold rolling are smoothly carried out.

Owner:安徽博安门窗有限公司

Aluminum-plastic wood sectional material

InactiveCN107152213AImprove mechanical propertiesExtended service lifeWindow/door framesAnti-corrosive paintsLow-density polyethyleneFiber

The invention provides an aluminum-plastic wood profile, comprising a wood-plastic layer and an aluminum alloy layer; the wood-plastic layer is composed of the following raw materials in parts by weight: 10-30 parts of sarin resin, 5-15 parts of plant fiber powder, wood powder 40-50 parts, 20-40 parts of polyurethane foam powder, 5-15 parts of inorganic filler, 3-10 parts of flame retardant, 1-3 parts of lubricant, 0-2 parts of antioxidant, ethylene-vinyl acetate copolymer 2-7 parts of mixture with ethylene-acrylic acid copolymer, 1-3 parts of cold resistance agent M711, 1-2 parts of light stabilizer GW-540, 5-15 parts of inorganic filler, 3-10 parts of flame retardant, 1 part of lubricant ‑5 parts, 1‑3 parts of colorant, 3‑10 parts of bentonite, 20‑40 parts of low density polyethylene. In the present invention, the wood-plastic layer and the aluminum alloy layer are used in combination, and the advantages and disadvantages of the wood-plastic layer and the aluminum alloy layer are complemented. Weather resistance, wear resistance and other properties, in the natural environment, aluminum-plastic wood profiles have good mechanical properties, are not easy to age, and have a long service life.

Owner:合肥市旺友门窗有限公司

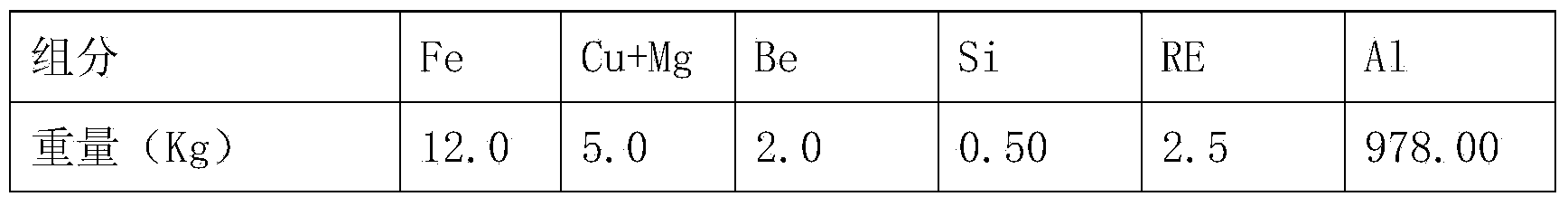

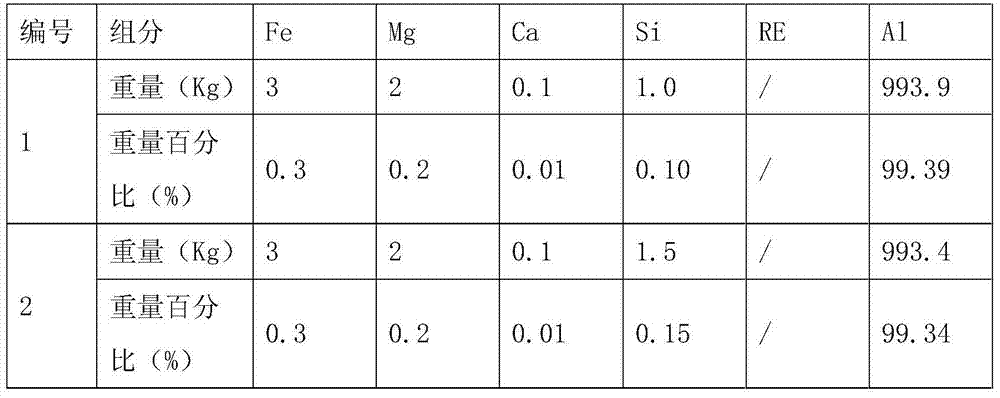

Al-Fe-Mg-Ca aluminum alloy for automobile wire and wire harness thereof

PendingCN103757488AOvercoming processabilityOvercoming creep resistanceMetal/alloy conductorsUltimate tensile strengthImpurity

The invention discloses an Al-Fe-Mg-Ca aluminum alloy for an automobile wire, a preparation method thereof and an automobile wire harness prepared by using the Al-Fe-Mg-Ca aluminum alloy. The Al-Fe-Mg-Ca aluminum alloy for the automobile wire comprises the following components: 0.2-1.4wt% of Fe, 0.01-0.5wt% of Mg, 0.001-0.2wt% of Ca and the balance of Al and inevitable impurities. According to the Al-Fe-Mg-Ca aluminum alloy disclosed by the invention, by adding Fe, the mechanical strength and tensile properties of the alloy can be improved, and Fe can also obviously improve the high-temperature creep resistance and improve the anti-fatigue performance of the alloy; by adding Mg, the strength and high-temperature creep property of the alloy can be improved, and the anti-fatigue performance can be improved; by adding Ca, the electrical conductivity of the alloy can be improved.

Owner:ANHUI JOY SENSE CABLE

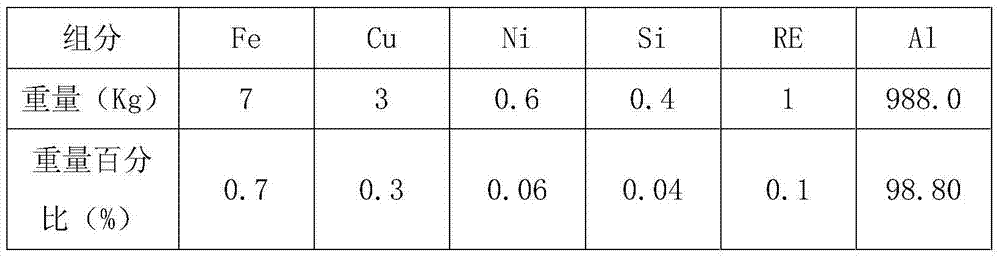

Al-Fe-Mg-Ni aluminum alloy for automobile wire and wire harness thereof

PendingCN103757487AOvercoming processabilityAchieving Lightweight IssuesMetal/alloy conductorsSurface tensionGrain boundary

The invention discloses an Al-Fe-Mg-Ni aluminum alloy for an automobile wire, a preparation method thereof and an automobile wire harness prepared by using the Al-Fe-Mg-Ni aluminum alloy. The Al-Fe-Mg-Ni aluminum alloy for the automobile wire comprises the following components: 0.2-1.4wt% of Fe, 0.01-0.5wt% of Mg, 0.001-0.2wt% of Ni and the balance of Al and inevitable impurities. According to the Al-Fe-Mg-Ni aluminum alloy disclosed by the invention, by adding Fe, the mechanical strength and tensile properties of the alloy can be improved, and Fe can also obviously improve the high-temperature creep resistance and improve the anti-fatigue performance of the alloy; by adding Mg, the strength and high-temperature creep property of the alloy can be improved, and the anti-fatigue performance can be improved; Ni has multiple effects of refining grains, filling a grain boundary of a matrix and forming a near-aluminum electric potential metal compound, and can obviously weaken the surface tension of a melt, reduce the viscosity of the melt and significantly improve the flowability of the melt and the mechanical properties of the alloy.

Owner:ANHUI JOY SENSE CABLE

Al-Fe-Cu-Ni aluminum alloy for automotive wire and wire harness thereof

PendingCN103757493AOvercoming processabilityOvercoming creep resistanceMetal/alloy conductorsUltimate tensile strengthMechanical property

The invention discloses an Al-Fe-Cu-Ni aluminum alloy for an automotive wire and a wire harness thereof. The Al-Fe-Cu-Ni aluminum alloy for the automotive wire comprises the following components by weight percent: 0.2 to 1.4wt% of Fe, 0.01 to 0.5wt% of Cu, 0.001 to 0.2wt% of Ni, and the balance being Al and inevitable impurities. According to the Al-Fe-Cu-Ni aluminum alloy, Fe element added improves the mechanical strength and the tensile property of the alloy, obviously improves the resistance to high temperature creep, as well as improves the antifatigue performance of the alloy; Cu added improves the alloy strength and high temperature creep performance as well as improves the antifatigue performance; and Ni realizes the effects of refining crystal grain, filling a matrix crystal boundary, forming a near aluminum potential metal compound, weakening the surface tension of a melt, reducing melt viscosity, as well as obviously improving melt fluidity and mechanical performance of the alloy.

Owner:ANHUI JOY SENSE CABLE

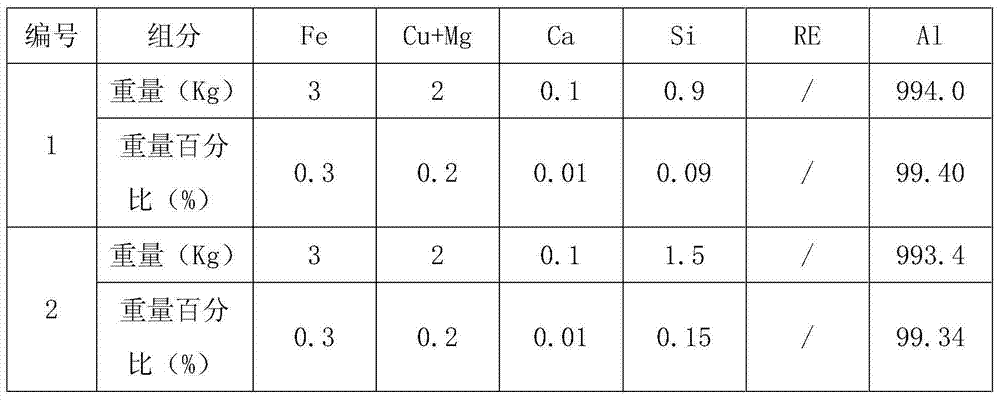

Al-Fe-Cu-Mg-Ca aluminum alloy for automotive wire and wiring harness thereof

PendingCN103757496AOvercoming processabilityAchieving Lightweight IssuesMetal/alloy conductorsFe elementAluminium alloy

The invention discloses an Al-Fe-Cu-Mg-Ca alloy for an automotive wire, a preparation method thereof and a prepared automotive wiring harness, wherein the Al-Fe-Cu-Mg-Ca alloy for the automotive wire comprises the following components: 0.2-1.4wt% of Fe, 0.01-0.5wt% of Cu and Mg, 0.001-0.2wt% of Ca, and the balance of Al and inevitable impurities. The mechanical property and the tensile property of the alloy can be improved by adding an Fe element; the high-temperature creep resistance and the fatigue resistance of the alloy also can be obviously improved by the Fe; the strength and the high-temperature creep property of the alloy can be improved and the fatigue resistance can be improved by adding the Cu and Mg; the conductivity of the aluminum alloy can be improved by adding the Ca; meanwhile, the cutting property of the aluminum alloy can be improved, and removal of hydrogen in molten aluminum is facilitated.

Owner:ANHUI JOY SENSE CABLE

High-strength graphite rare earth aluminum alloy conductor

ActiveCN107017036AReduce the degree of reunionLow densityConductive materialMetal/alloy conductorsRare earthGraphite

The invention discloses a high-strength graphite rare earth aluminum alloy conductor. An aluminum alloy matrix comprises, by mass percentage, 0.05-0.08 of Y, 0.05-0.08 of Er, 0.01-0.03 of Pr, 1-1.5% of Cu, 0.15-0.2% of Si, 0.15-0.25% of Cr, 0.05-0.1% of Ca, 0.15-0.25% of Mn, 0.1-0.25% of Fe, 0.15-0.2% of Ni, 0.2-0.45% of Zn, 0.08-0.15% of Ti, 0.035-0.045% of Sr, 0.07-0.12% of Zr, with the balance being Al. The high-strength graphite rare earth aluminum alloy conductor presented by the invention has good mechanical properties, such as strength and toughness, and has good resistance to high temperature, impact resistance and electrical conductivity.

Owner:ANHUI NANYANG NEW MATERIAL TECH CO LTD

Treatment process of spinning vacuum silk boiling box

InactiveCN107955483AReduce gasReduce inclusionsAnti-corrosive paintsEpoxy resin coatingsRare-earth elementHolmium

The invention provides a treatment process of a spinning vacuum silk boiling box. Blanks comprise, in weight percent, 0.05-0,06% of C, 0.5-1% of Mn, 0.5-0.8% of Ni, 2-4% of Cr, 0.4-0.6% of Nb, 0.1-0.2% of Si, 0.1-0.12% of N, 0.2-0.5% of Fe, 1.5-2.0% of Mg, lower than or equal to 0.2% of Cu, lower than or equal to 0.015% of s, lower than or equal to 0.02% of p, 0.3-0.5% of Mo, 2-4% of Al, 0.3-0.5%of Ti, 0.02-0.03% of B, 0.0018-0.0022% of v, 0.1-0.3% of composite rare earth, 0.2-0.4% of rare earth elements and the balance Al. The composite rare earth comprises, in weight percent, 13-15% of cerium, 15-18% of praseodymium, 5-8% of holmium, 8-10% of gadolinium, 8-10% of yttrium and the balance lanthanum, and the sum of the weight percent of components of the composite rare earth is 100%.

Owner:苏州天亦辰针织有限公司

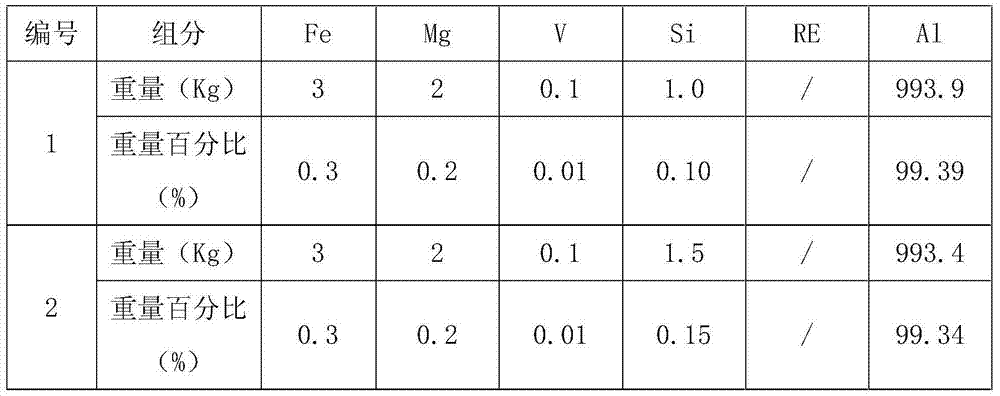

Al-Fe-Mg-V aluminum alloy for automotive wire and wiring harness prepared from aluminum alloy

PendingCN103757486AOvercoming processabilityOvercoming creep resistanceMetal/alloy conductorsImpurityFe element

The invention discloses an Al-Fe-Mg-V aluminum alloy for an automotive wire, a preparation method of the Al-Fe-Mg-V aluminum alloy and a wiring harness prepared from the aluminum alloy. The Al-Fe-Mg-V aluminum alloy for the automotive wire comprises the following components in percentage by weight: 0.2%-1.4% of Fe, 0.01%-0.5% of Mg, 0.001%-0.2% of V and the balance being Al and inevitable impurities. According to the invention, the mechanical strength and tensile performance of the alloy can be improved by adding the Fe element, and Fe can further remarkably improve the high-temperature creep resistance and the anti-fatigue performance of the alloy; the strength and the high-temperature creep resistance of the alloy can be improved by adding Mg, and the anti-fatigue performance of the alloy can be improved; V has the effect of refining grains in a casting process and further has the effects of refining recrystallized structures and improving the recrystallization temperature.

Owner:ANHUI JOY SENSE CABLE

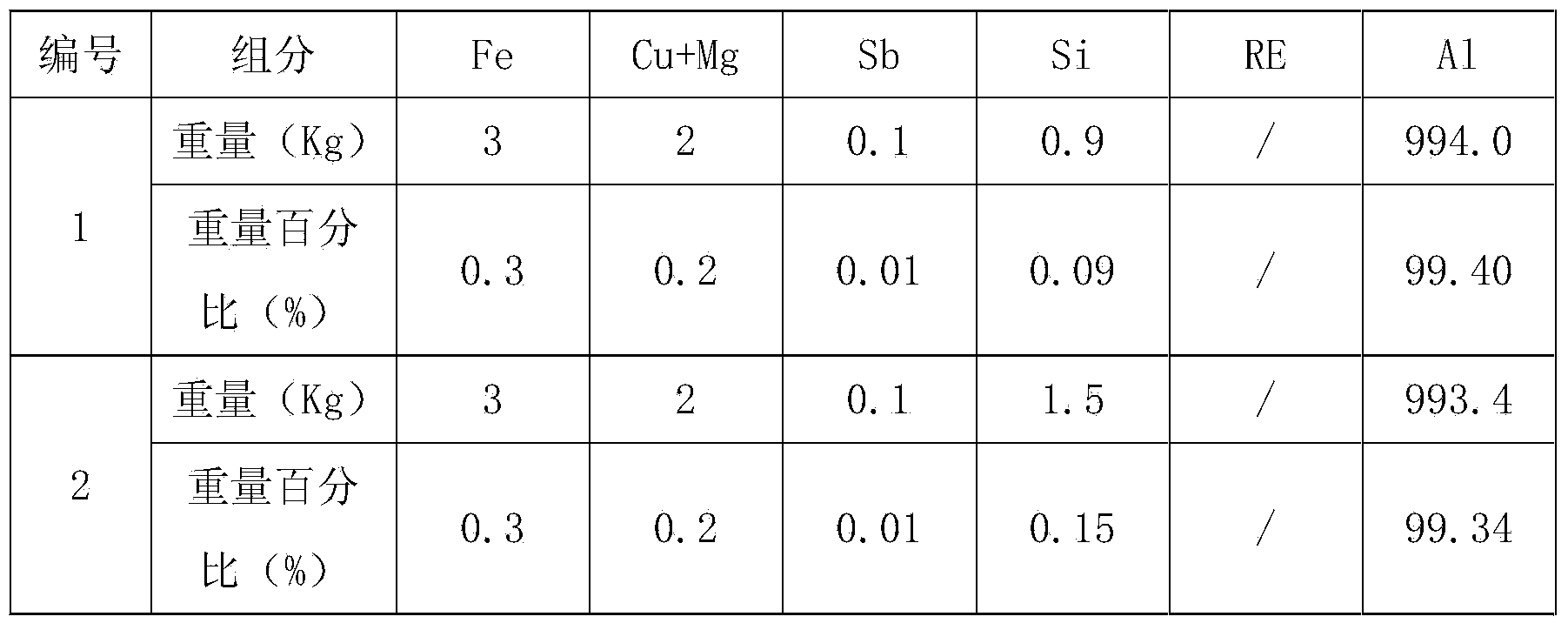

Al-Fe-Cu-Mg-Sb aluminum alloy for automotive wire and wiring harness made of aluminum alloy

ActiveCN103725929AOvercoming processabilityOvercoming creep resistanceManufacturing wire harnessesMetal/alloy conductorsFe elementAluminium alloy

The invention discloses an Al-Fe-Cu-Mg-Sb aluminum alloy for an automotive wire, a manufacturing method of the aluminum alloy, and a wiring harness made of the aluminum alloy. The Al-Fe-Cu-Mg-Sb aluminum alloy for the automotive wire comprises the following ingredients in percentage by weight: 0.2-1.4wt% of Fe, 0.01-0.5wt% of Cu and Mg, 0.001-0.2wt% of Sb, and the balance of Al and inevitable impurities. The mechanical strength and the tensile properties of the alloy can be improved by adding an Fe element; the high temperature creep resistance also can be obviously improved by Fe; the anti-fatigue performance of the alloy is improved; the strength and the high-temperature creep properties of the alloy can be improved by adding Cu and Mg; the anti-fatigue performance can be improved; the yield limit of the alloy can be improved by adding Sb; meanwhile, the alloy has superplasticity, so as to be drawn into a very thin alloy wire.

Owner:ANHUI JOY SENSE CABLE

A kind of al-fe-cu-mg-sb aluminum alloy for automobile wire and its wire harness

ActiveCN103725929BHigh mechanical strengthImprove tensile propertiesManufacturing wire harnessesMetal/alloy conductorsAdditive ingredientUltimate tensile strength

The invention discloses an Al-Fe-Cu-Mg-Sb aluminum alloy for an automotive wire, a manufacturing method of the aluminum alloy, and a wiring harness made of the aluminum alloy. The Al-Fe-Cu-Mg-Sb aluminum alloy for the automotive wire comprises the following ingredients in percentage by weight: 0.2-1.4wt% of Fe, 0.01-0.5wt% of Cu and Mg, 0.001-0.2wt% of Sb, and the balance of Al and inevitable impurities. The mechanical strength and the tensile properties of the alloy can be improved by adding an Fe element; the high temperature creep resistance also can be obviously improved by Fe; the anti-fatigue performance of the alloy is improved; the strength and the high-temperature creep properties of the alloy can be improved by adding Cu and Mg; the anti-fatigue performance can be improved; the yield limit of the alloy can be improved by adding Sb; meanwhile, the alloy has superplasticity, so as to be drawn into a very thin alloy wire.

Owner:ANHUI JOY SENSE CABLE

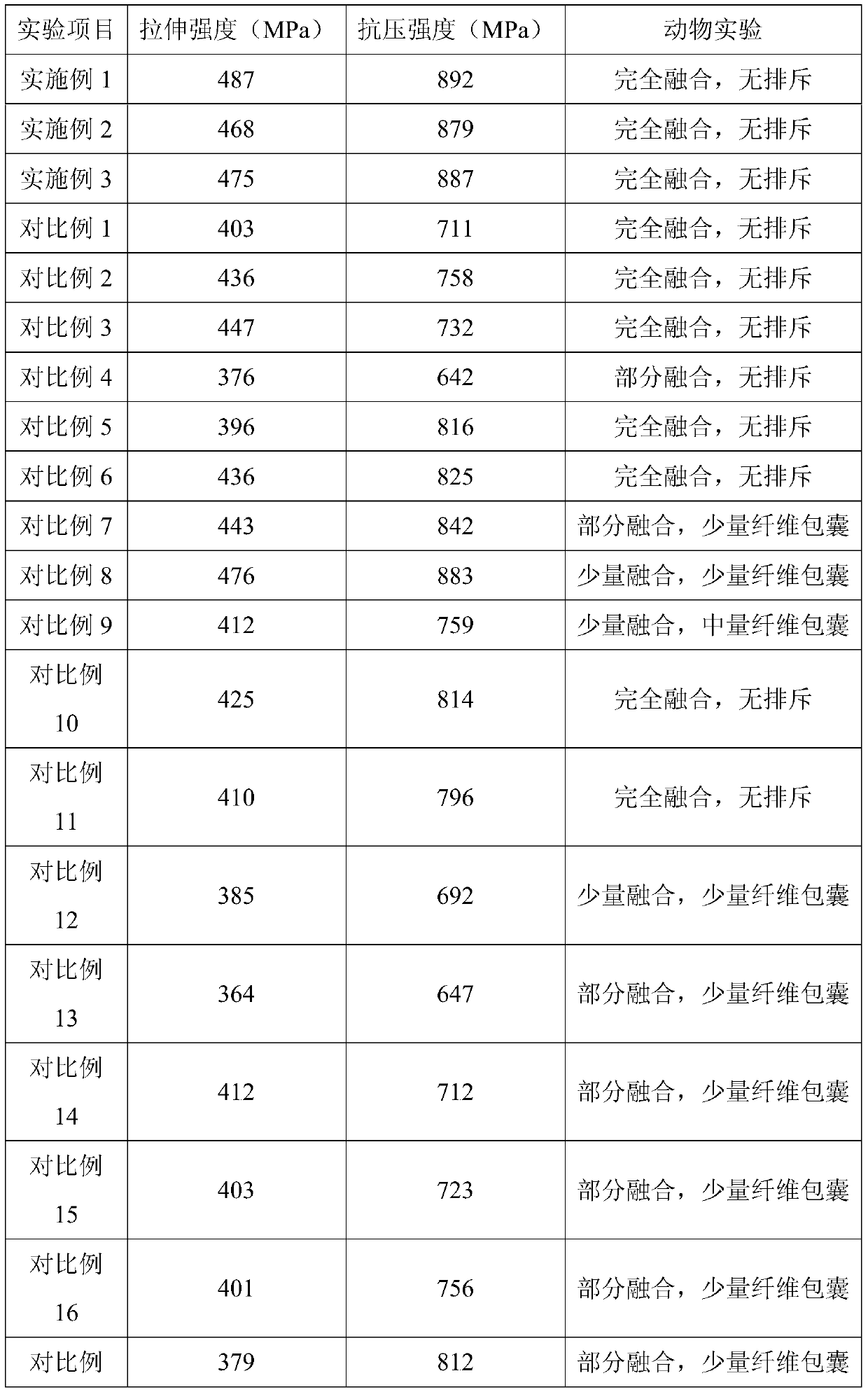

Medical magnesium-based alloy material and preparation method thereof

InactiveCN110639057AAvoid surface crackingHigh affinityTissue regenerationCoatingsFiberHydroxylapatite

The invention discloses a medical magnesium-based alloy material and a preparation method thereof. The medical magnesium-based alloy material comprises an alloy matrix and a biological coating. The alloy matrix comprises the following components in percentage by weight: 2.2-3.2% of Cu, 0.6-1.2% of Fe, 1.2-1.6% of Sb, 0.4-0.8% of Ta, 1.2-3.2% of Ca, 0.6-1.2% of V, 0.2-0.4% of Mo, 1.2-1.4% of Ag, 2.2-3.2% of P, 0.3-0.7% of Si, 0.02-0.04% of F, 0.1-0.3% of S, 5.2-6.4% of nano-hydroxyapatite, and the balance of Mg. The surface of the alloy matrix is polished to smooth the unsmooth surface caused by the nano-hydroxyapatite floating on the surface layer of the alloy matrix, and the polishing thickness is 1-3 [mu]m. The main materials of the biological coating are collagenous fibers and chitin. According to the invention, metal elements Cu, Fe and Sb are added, inorganic elements P, Si, F and S are jointly added, the nano-hydroxyapatite is added, the surface is polished, and then the surfaceis coated with the biological coating, so that the strength and biocompatibility of the alloy material are improved.

Owner:长沙凯泽工程设计有限公司

Al-Fe-Cu-Zn aluminum alloy for automobile wire and wire harness thereof

PendingCN103757490AOvercoming processabilityOvercoming creep resistanceMetal/alloy conductorsElectrical conductorCreep rate

The invention discloses an Al-Fe-Cu-Zn aluminum alloy for an automobile wire, a preparation method thereof and an automobile wire harness prepared by using the Al-Fe-Cu-Zn aluminum alloy. The Al-Fe-Cu-Zn aluminum alloy for the automobile wire comprises the following components: 0.2-1.4wt% of Fe, 0.01-0.5wt% of Cu, 0.001-0.2wt% of Zn and the balance of Al and inevitable impurities. According to the Al-Fe-Cu-Zn aluminum alloy disclosed by the invention, by adding Fe, the mechanical strength and tensile properties of the alloy can be improved, and Fe can also obviously improve the high-temperature creep resistance and improve the anti-fatigue performance of the alloy; by adding Cu, the strength and high-temperature creep property of the alloy can be improved, and the anti-fatigue performance can be improved; by adding Zn, the electrical conductivity of the aluminum alloy can be slightly reduced, the strength can be effectively improved to a certain extent, and the creep rate of a conductor is simultaneously improved.

Owner:ANHUI JOY SENSE CABLE

Treatment process of corrosion-resistant and wear-resistant type water pump piston

InactiveCN106590077AHigh strengthImprove antioxidant capacityFireproof paintsAnti-corrosive paintsMetal coatingWear resistant

The invention discloses a treatment process of a corrosion-resistant and wear-resistant type water pump piston. From inside to outside, the surface of the piston is sequentially coated with a corrosion-resistant metal coating and a strippable anticorrosive coating, and the corrosion-resistant metal coating comprises the following components in percentage by mass: 0.02-0.05% of C, 0.33-0.37% of Zn, 0.32-0.35% of Cu, 0.25-0.28% of W, 0.75-0.78% of Nb, 8.32-8.35% of Cr, 0.27-0.29% of Si, 0.52-0.55% of Mo, 0.13-0.15% of Co, 3.4-3.6% of Al, 2.65-2.68% of rare earth, and the balance of Fe and trace impurities, wherein the rare earth comprises the following components in percentage by weight: 3.2-3.5% of La, 2.6-2.8% of Tm, 5.2-5.6% of Ho, 5.5-5.8% of Tb, 4.1-4.3% of Eu, 12.5-12.8% of Sm, and the balance of Gd.

Owner:苏州富艾姆工业设备有限公司

High-yield die casting alloy material suitable for use in mobile phone medium plate and preparation method of high-yield die casting alloy material

The present invention relates to a high-yield die casting alloy material suitable for use in a mobile phone medium plate and a preparation method of the high-yield die casting alloy material. The alloy comprises the following components of, 11.0 wt%-15.0 wt% of Si, 1.0 wt%-2.0 wt% of Mg, 0.1%-0.5% of Fe, 0.2 wt%-0.8 wt% of Mn, less than 0.5 wt% of Ce, 0.01 wt%-0.5 wt% of Zr, less than 0.15 wt% ofCu, less than 0.01 wt% of rest of impurities, and the balance of Al. compared to the prior art, the preparation method significantly improves the yield strength and elongation of the material by adding Mn, Si, Mg and Ce to the aluminum alloy and introducing three strengthening phases Mg2Si, MnAl6 and Al11Ce3 binary precipitated phase.

Owner:苏州慧驰轻合金精密成型科技有限公司

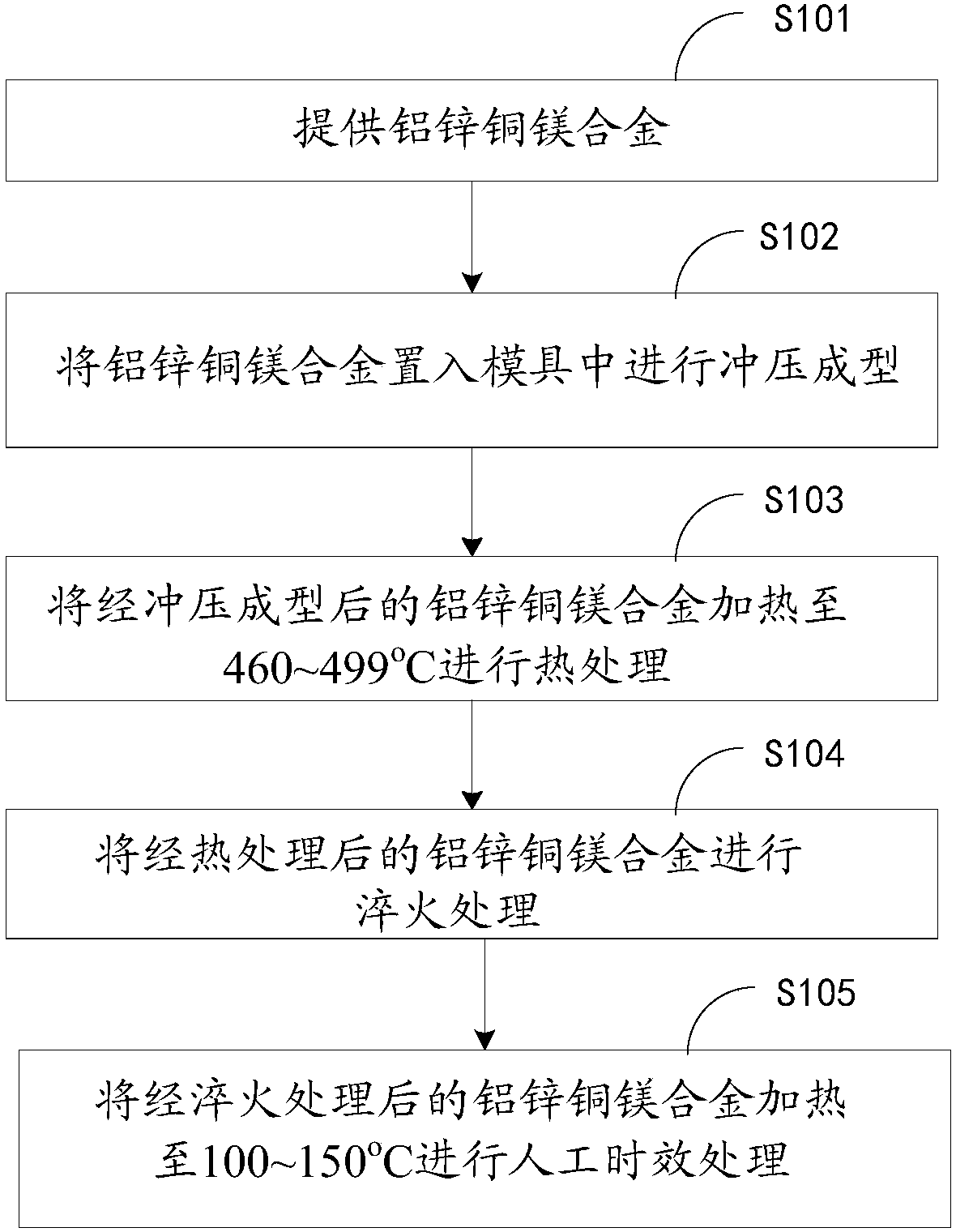

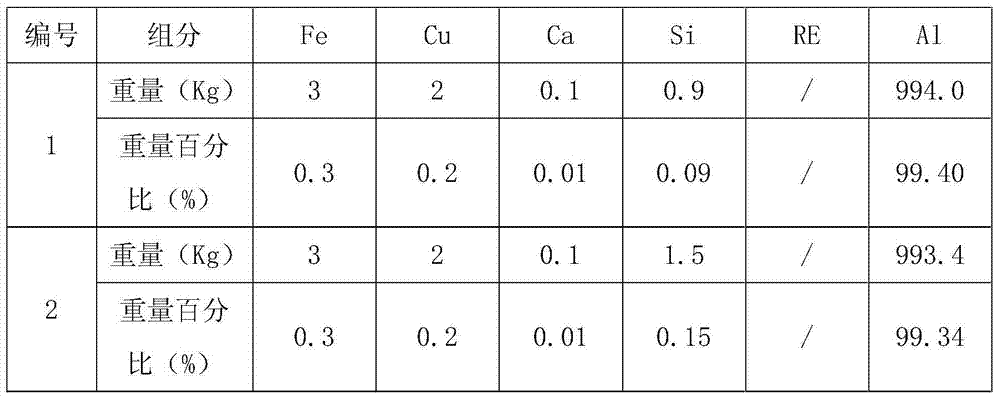

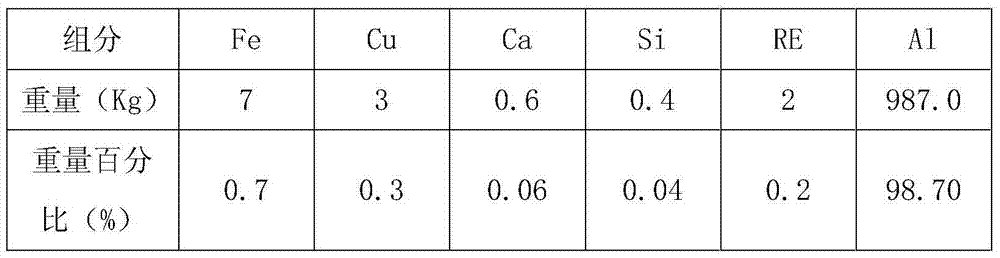

Aluminum, zinc, copper and magnesium alloy and machining process thereof

The invention discloses an aluminum, zinc, copper and magnesium alloy and a machining process thereof. The aluminum, zinc, copper and magnesium alloy comprises, by weight, 0.1%-0.15% of metallic zirconium and 0.03%-0.08% of metallic nickel. The process comprises the steps that the aluminum, zinc, copper and magnesium alloy is provided; the aluminum, zinc, copper and magnesium alloy is placed intoa die to be stamped and molded; the stamped and molded aluminum, zinc, copper and magnesium alloy is heated to 460 DEG C to 499 DEG C to be subject to heat treatment; the aluminum, zinc, copper and magnesium alloy subject to heat treatment is subject to quenching treatment; and the aluminum, zinc, copper and magnesium alloy subject to quenching treatment is heated to 100 DEG C to 150 DEG C to be subject to artificial aging treatment. By means of the above manner, the stamping and molding performance of the artificial aging treatment can be improved.

Owner:缪彬彬

Corrosion-resistant coating for high-precision instrument probe

InactiveCN107936747AHigh strengthImprove antioxidant capacityAnti-corrosive paintsEpoxy resin coatingsWear resistantMetal powder

The invention discloses a corrosion-resistant coating for a high-precision instrument probe. The corrosion-resistant coating consists of a component I, a component II and wearing-resistant metal powder, wherein the component I consists of a component A and a component B in a ratio of 0.5:1.5 through mixing. The corrosion-resistant coating is convenient to process and is of a buffer structure, theservice life of elements can be prolonged, materials are saved, and the cost is reduced.

Owner:苏州威斯道智能科技有限公司

Al-Fe-Cu-Ca aluminum alloy for automobile wire and wire harness thereof

PendingCN103757497AOvercoming processabilityAchieving Lightweight IssuesNon-insulated conductorsMetal/alloy conductorsAluminium alloyUltimate tensile strength

The invention discloses an Al-Fe-Cu-Ca aluminum alloy for an automobile wire, a preparation method thereof and an automobile wire harness prepared by using the Al-Fe-Cu-Ca aluminum alloy. The Al-Fe-Cu-Ca aluminum alloy for the automobile wire comprises the following components: 0.2-1.4wt% of Fe, 0.01-0.5wt% of Cu, 0.001-0.2wt% of Ca and the balance of Al and inevitable impurities. According to the Al-Fe-Cu-Ca aluminum alloy disclosed by the invention, by adding Fe, the mechanical strength and tensile properties of the alloy can be improved, and Fe can also obviously improve the high-temperature creep resistance and improve the anti-fatigue performance of the alloy; by adding Cu, the strength and high-temperature creep property of the alloy can be improved, and the anti-fatigue performance can be improved; by adding Ca, the electrical conductivity of the aluminum alloy can be improved, and the cutting performance of the aluminum alloy can be simultaneously improved so as to be favorable for removing hydrogen in an aluminum solution.

Owner:ANHUI JOY SENSE CABLE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com