Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

190 results about "Creep rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Creep Rate. Time rate of deformation of a material subject to stress at a constant temperature. It is the slope of the creep vs. time diagram obtained in a creep test. Units usually are in/in/hr or % of elongation/hr. Minimum creep rate is the slope of the portion of the creep vs. time diagram corresponding to secondary creep.

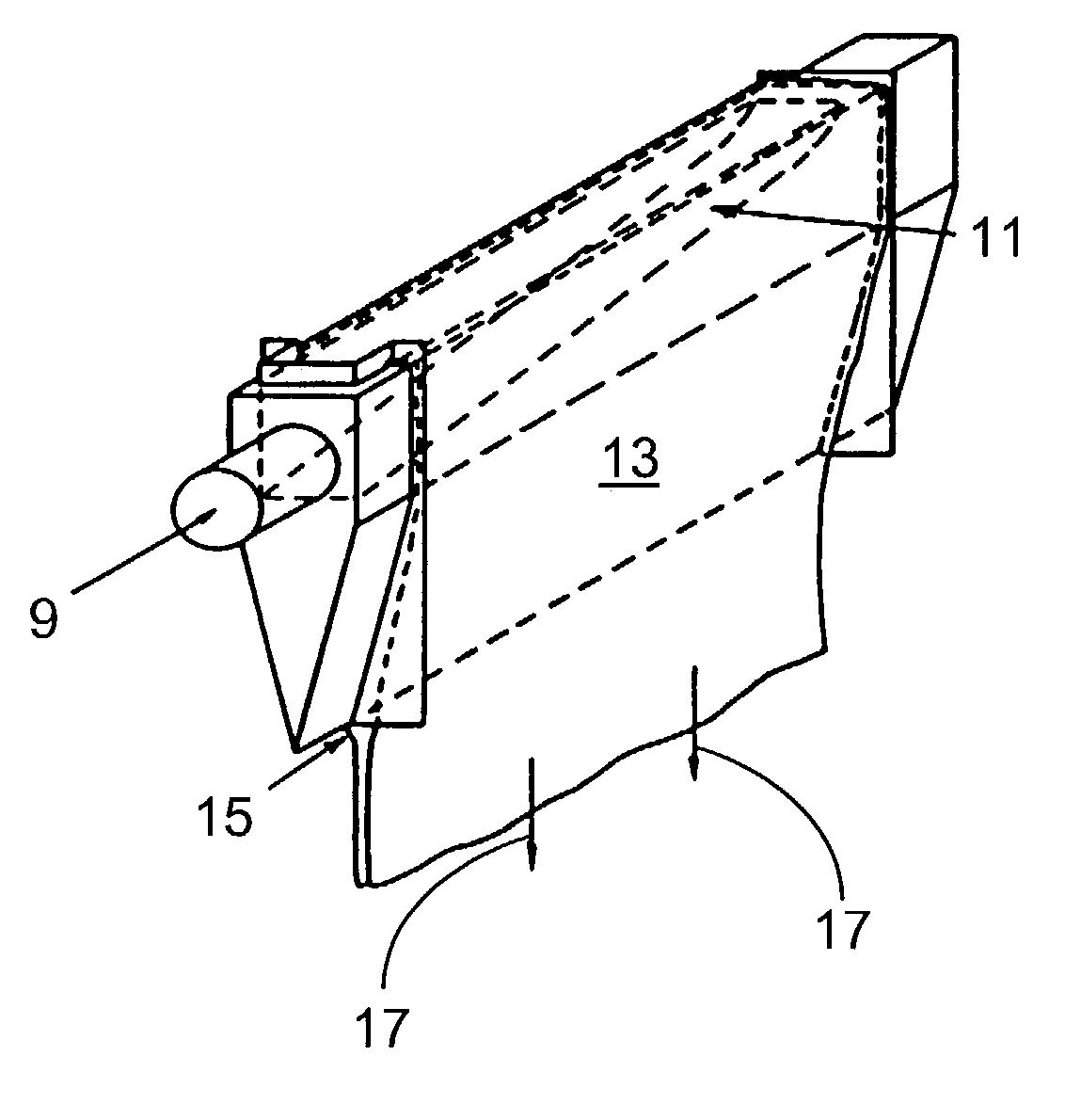

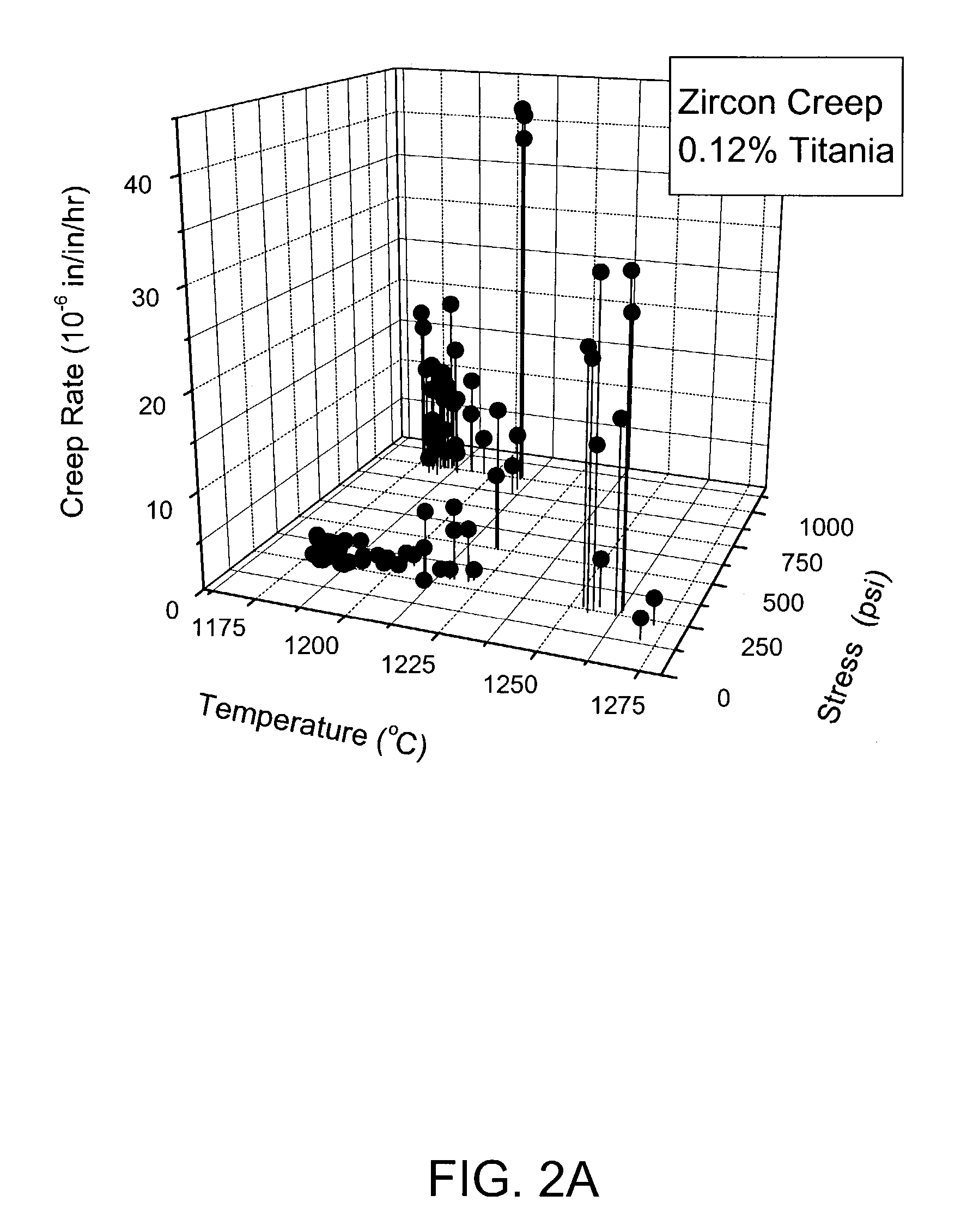

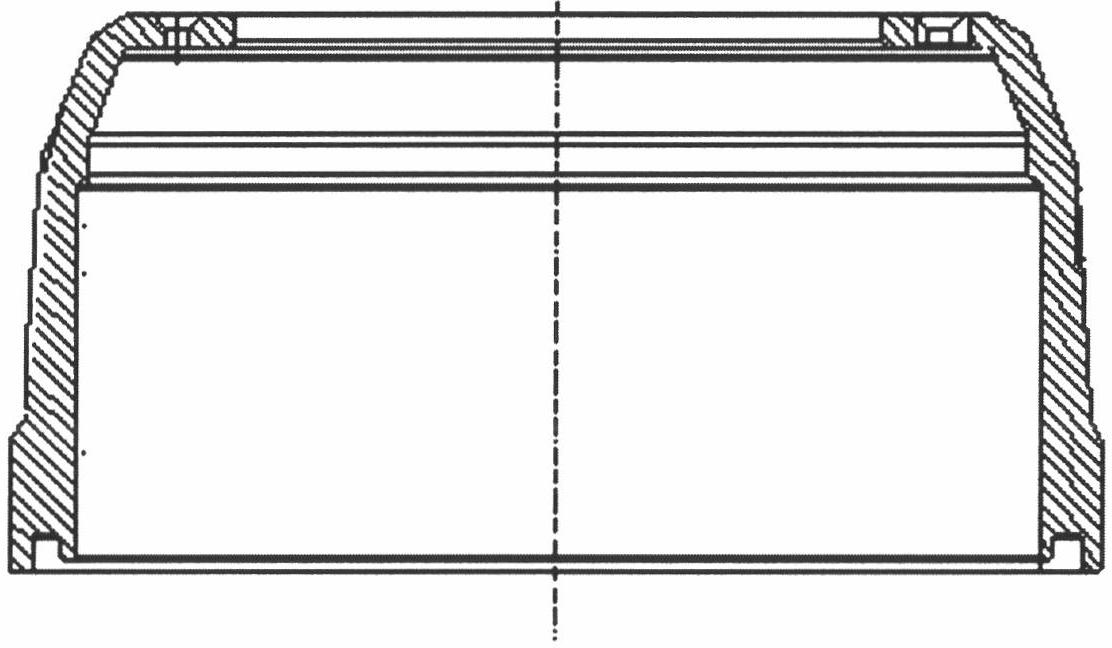

Sag control of isopipes used in making sheet glass by the fusion process

Isopipes for use in making sheet glass by a fusion process are provided which exhibit reduced sag. The isopipes are composed of a zircon refractory which has a mean creep rate (MCR) at 1180° C. and 250 psi and a 95 percent confidence band (CB) for said mean creep rate such that the CB to MCR ratio is less than 0.5, the MCR and the CB both being determined using a power law model. The zircon refractory can contain titania (TiO2) at a concentration greater than 0.2 wt. % and less than 0.4 wt. %. A concentration of titania in this range causes the zircon refractory to exhibit a lower mean creep rate than zircon refractories previously used to make isopipes. In addition, the variation in mean creep rate is also reduced which reduces the chances that the zircon refractory of a particular isopipe will have an abnormally high creep rate and thus exhibit unacceptable sag prematurely.

Owner:CORNING INC

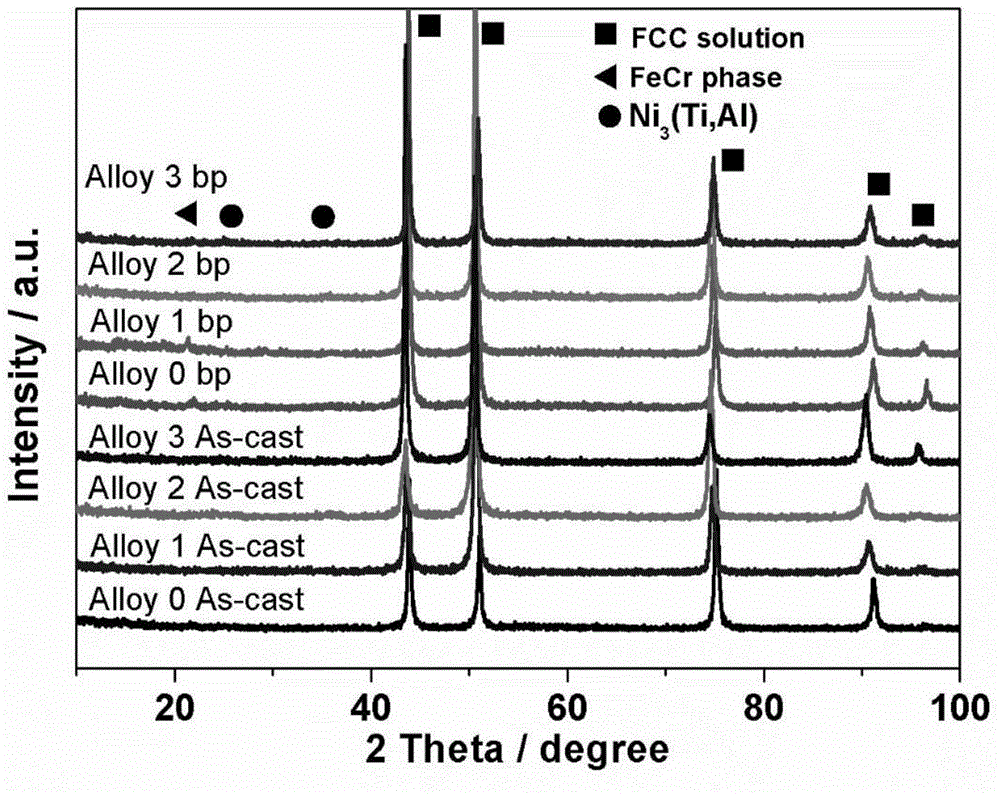

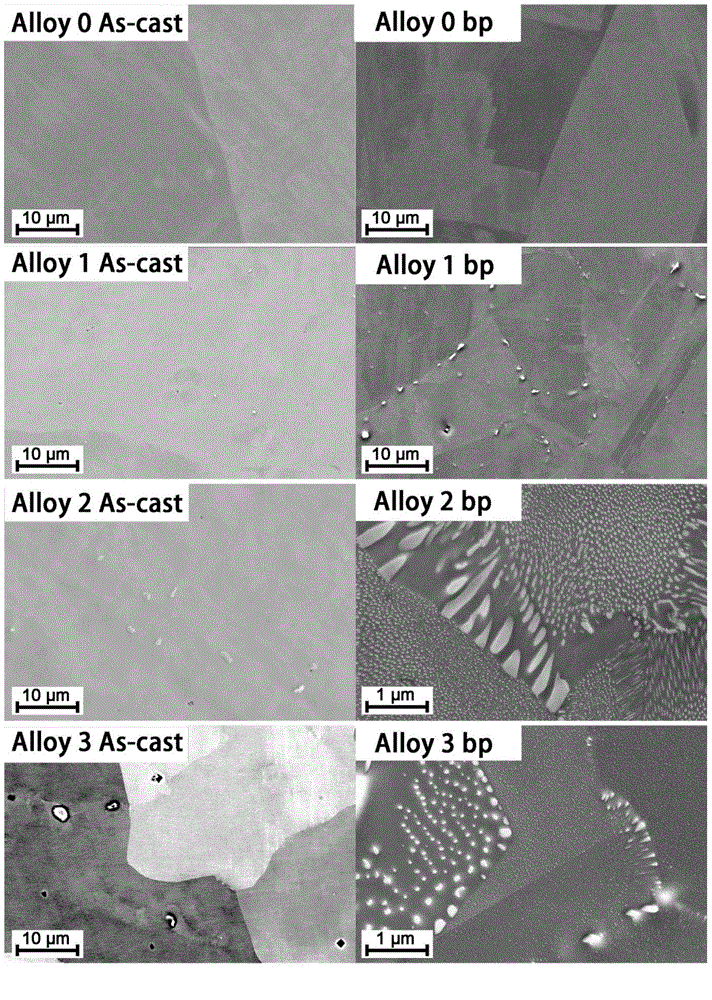

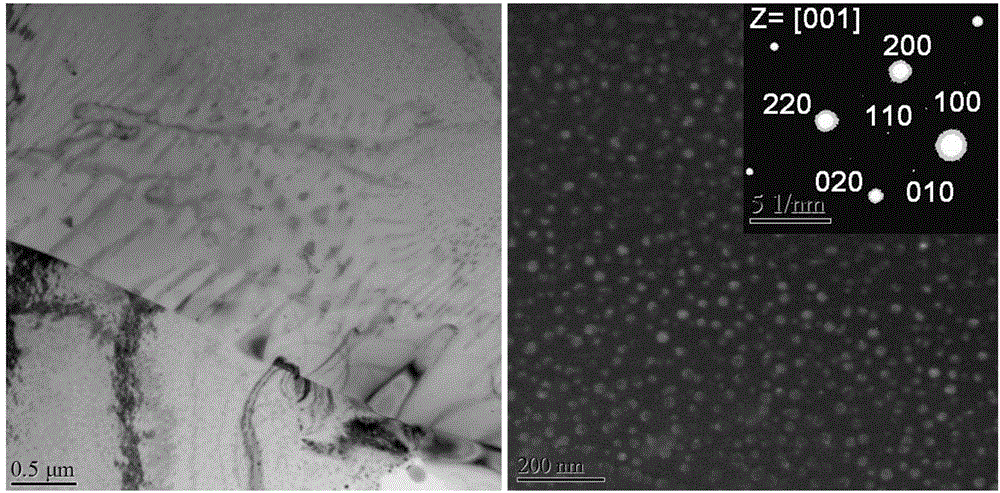

High-entropy alloy with dispersion nano-sized precipitate strengthening effect and preparing method thereof

ActiveCN104694808AWide range of ingredientsControl mechanical propertiesElectric arc furnaceHigh entropy alloys

The invention discloses high-entropy alloy with the dispersion nano-sized precipitate strengthening effect and a preparing method thereof. The method comprises the steps of removing oxidized skin of a metal material, and then conducting weighing and burdening accurately according to a ratio; conducing smelting in an electric-arc furnace in an argon shield atmosphere of titanium absorbed oxygen to obtain an initial high-entropy alloy ingot, and conducting cold rolling, wherein rolling reduction is 20-50%; placing the ingot in a heat treatment furnace with a temperature ranging from 900 DEG C to 1000 DEG C for heat preservation for 0.5-2 hours, and conducting quenching; placing the ingot in a heat treatment furnace with a temperature ranging from 700 DEG C to 800 DEG C for heat preservation for 2-18 hours, and conducting quenching. By means of precipitation strength, on the premise that high plasticity is kept, yield strength and tensile strength are improved greatly. The room-temperature tensile strength of (FeCoNiCr)94Ti2Al4 in the final state reaches 1094 MPa, plastic elongation is 35%, work hardening effect is remarkable, comprehensive room-temperature mechanical property is prominent, high-temperature tensile strength can reach 400 MPa at the temperature of 800 DEG C and strain rate of 10<-3>, steady creep rate is smaller than or equal to 10<-8> under the stress of 100 MPa and at the temperature of 750 DEG C, and high-temperature tensile strength and creep mechanical property are excellent.

Owner:UNIV OF SCI & TECH BEIJING

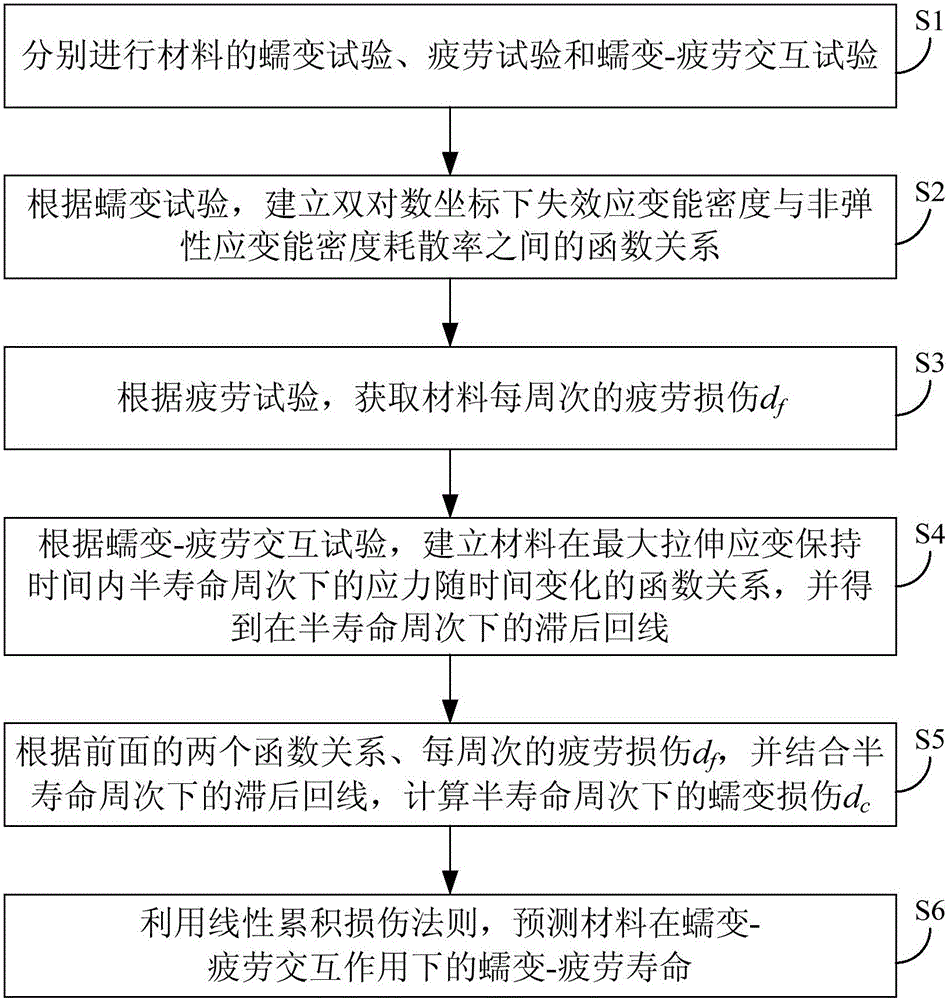

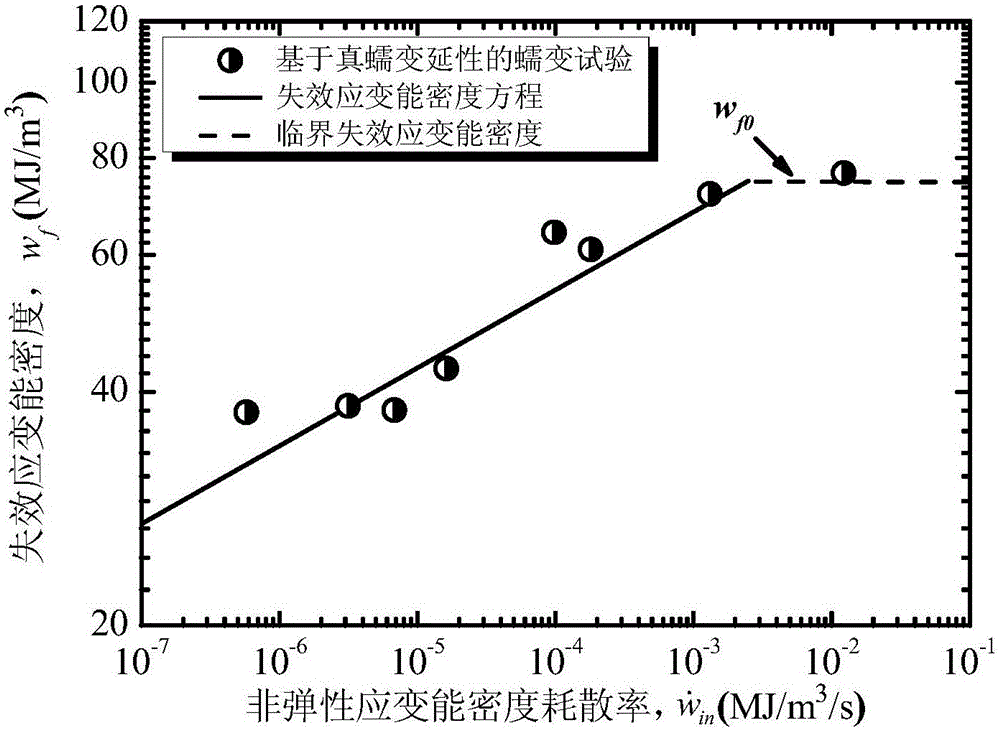

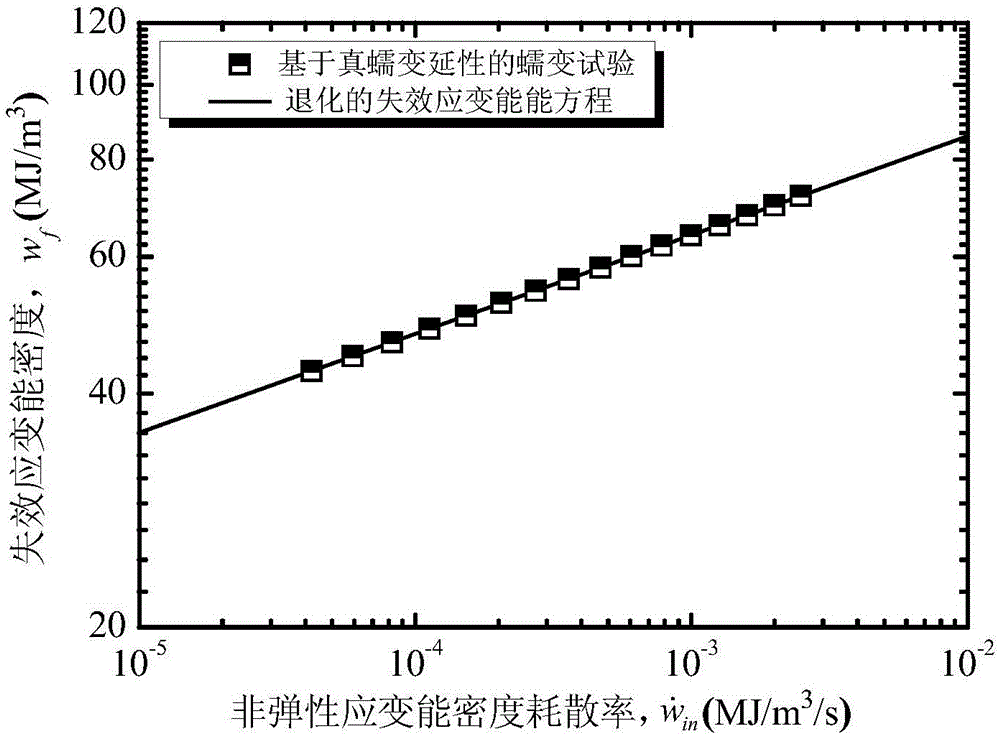

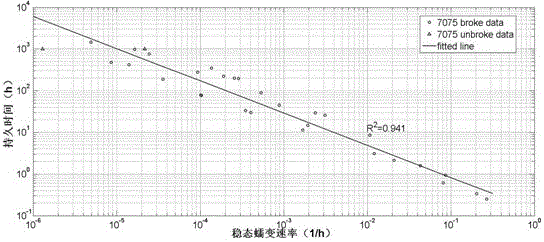

Forecasting method for creep-fatigue life of material

ActiveCN105158084ALife expectancyReal-time Damage DetectionMaterial strength using tensile/compressive forcesFatigue damageHysteresis

The invention provides a forecasting method for creep-fatigue life of a material. The method comprises the following steps: respectively performing a creep test, a fatigue test and a creep-fatigue interaction test for the material at a same test temperature; establishing a relation between the failure strain energy density wf and a non-elastic strain energy density dissipation rate of the material under a log-log coordinate according to the creep test; acquiring the fatigue damage df of the material per period according to the fatigue test; acquiring a hysteresis loop under a half-life period according to the creep-fatigue interaction test and establishing a function relation of the change of the stress Sigma (t) of the material under the half-life period within the maximum tensile strain maintaining time along with the change of time t; calculating the creep damage dc under the half-life period by combining with the hysteresis loop and based on the relation between wf and the function as shown in the specification and the relation of change of the fatigue damage df and the stress Sigma (t) along with the change of time t; and utilizing a linear accumulating damage rule to forecast the creep-fatigue life of the material under a creep-fatigue interaction. According to the method provided by the invention, the life of the material under the creep-fatigue interaction can be accurately forecasted.

Owner:EAST CHINA UNIV OF SCI & TECH

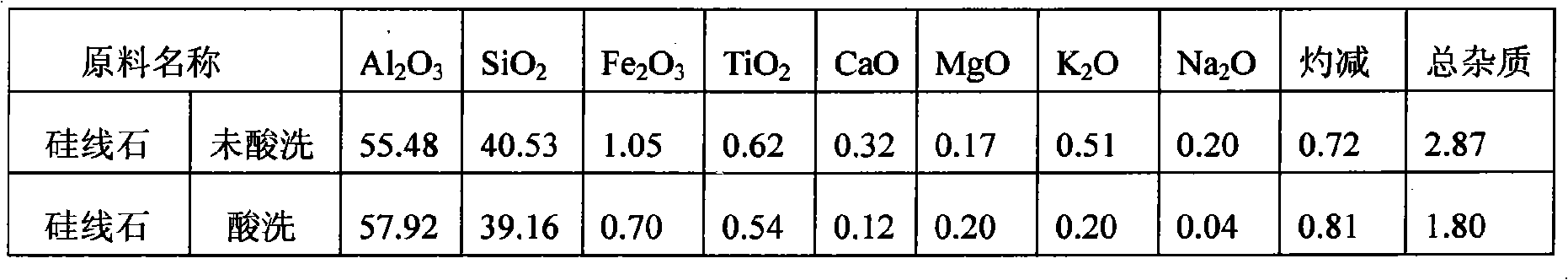

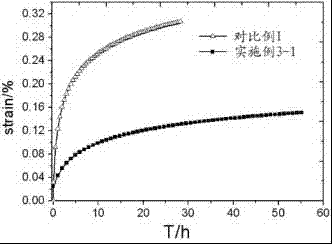

Sillimanite brick for large-scale blast furnace hot blast stove and method of manufacturing the same

InactiveCN101343190AImproved and enhanced high temperature performanceImprove and improve qualityBrickMullite

The invention discloses a sillimanite brick used in the large blast furnace stove and a production method thereof. The raw material of the sillimanite brick contains 30 to 60 percent of mullite, 30 to 60 percent of sillimanite or / and andalusite and 10 to 40 percent of common milling powder, and additionally, a binder, whose weight accounts for 2 to 5 percent of the total weight of the above raw materials, is added into the above raw materials. The production method of the brick comprises mulling, aging, molding, drying and firing processes; and green bricks are heat preserved for 8 to 12 hours under 1480 to 1520 DEG C to be fired, and are taken out of the kiln after being cooled naturally. The creep rate of the sillimanite brick is only 0.179 percent in the conditions of 1450 DEG C and 50 hours, the compressive strength reaches 76.2 Mpa, and the service life of the product is long. Thus, the product can completely meet the performance requirements of the sillimanite brick used in the blast furnace stove, and the product surpasses the performances of the same kind products at home and abroad and ends the history that the product has been imported from foreign countries all the time.

Owner:巩义市第五耐火材料总厂 +1

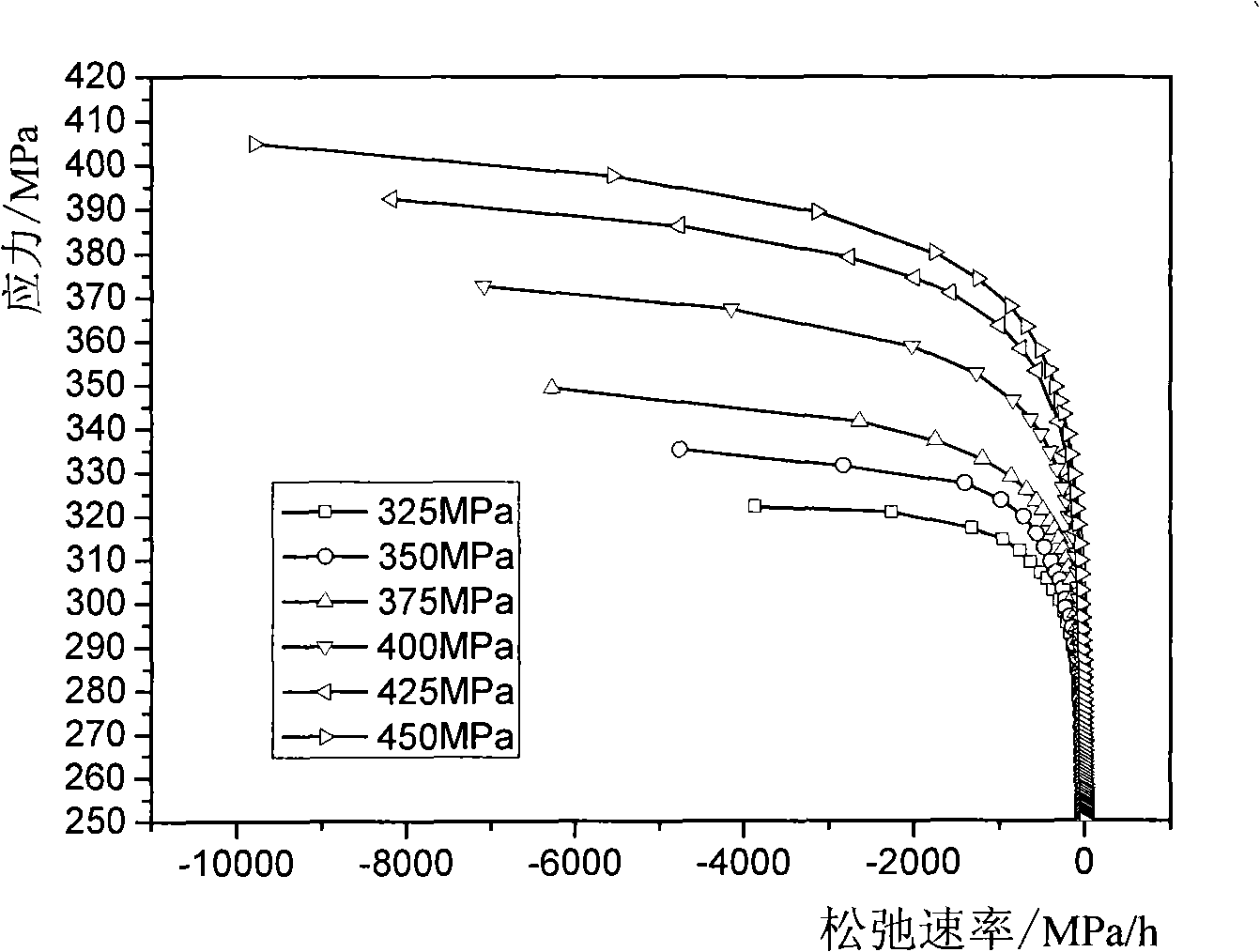

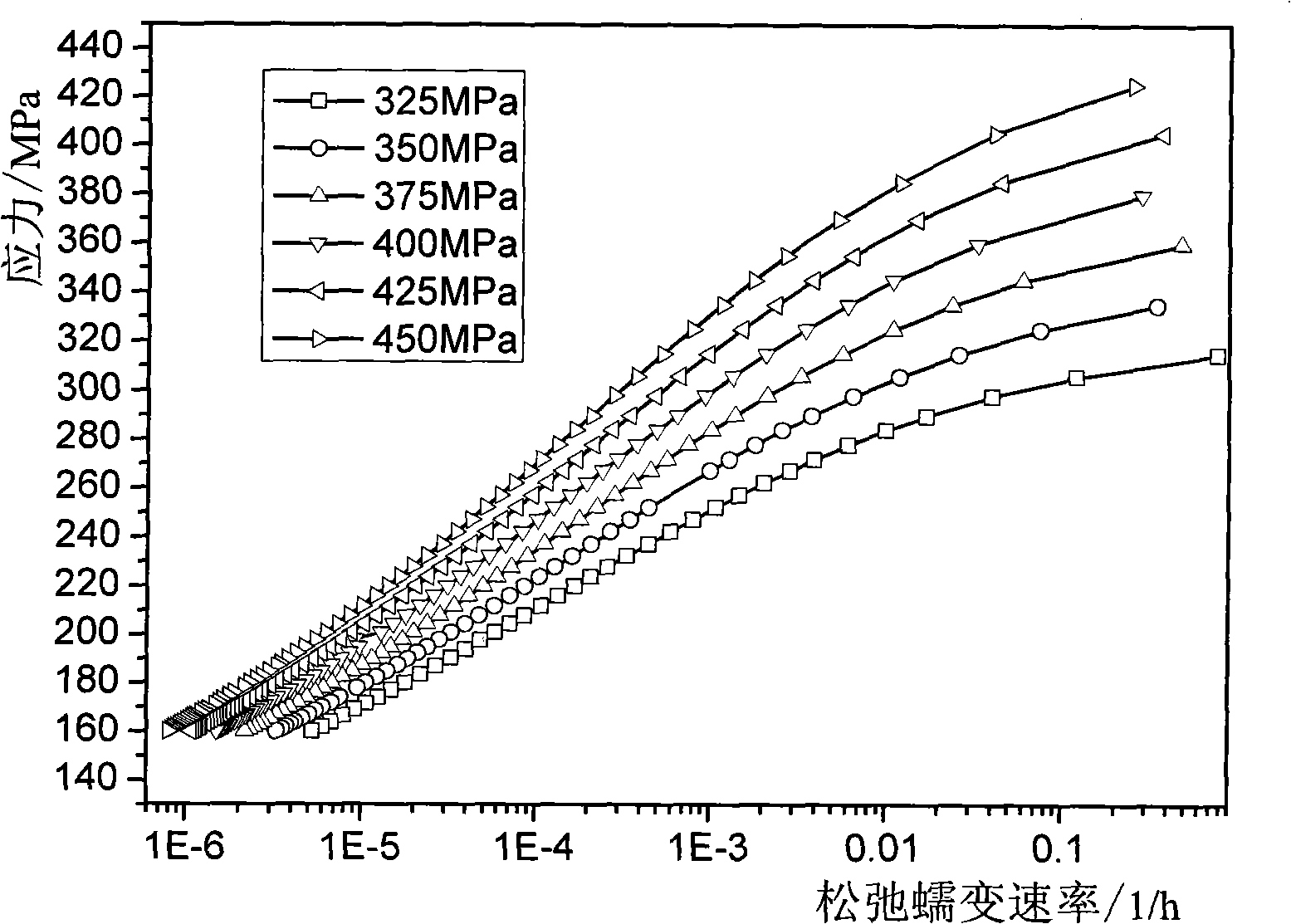

Material high-temperature creep life-span accelerated test method

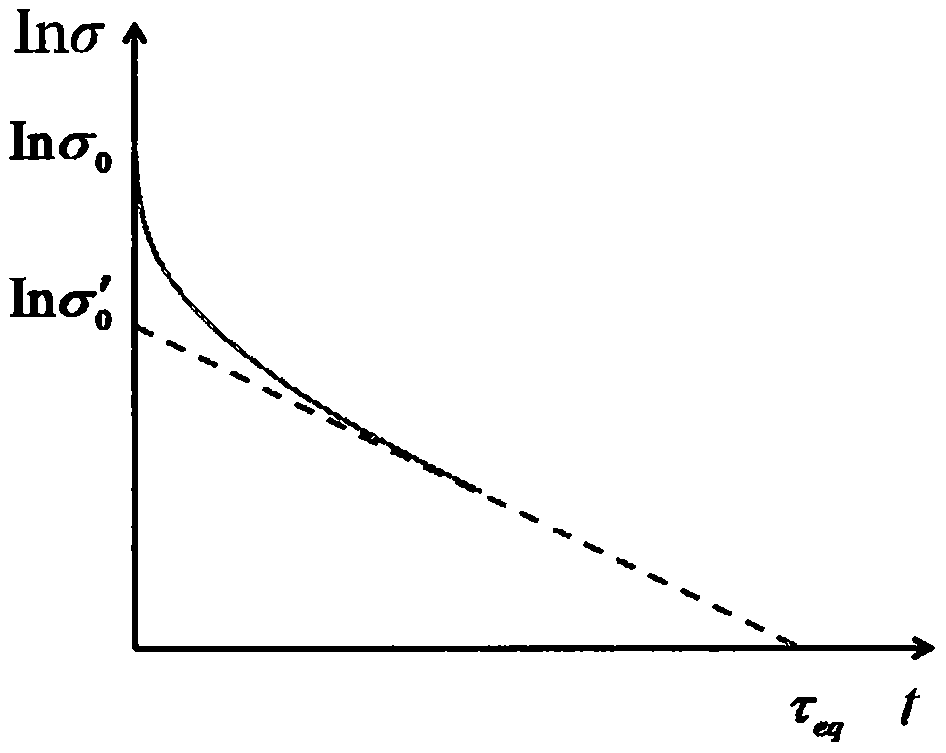

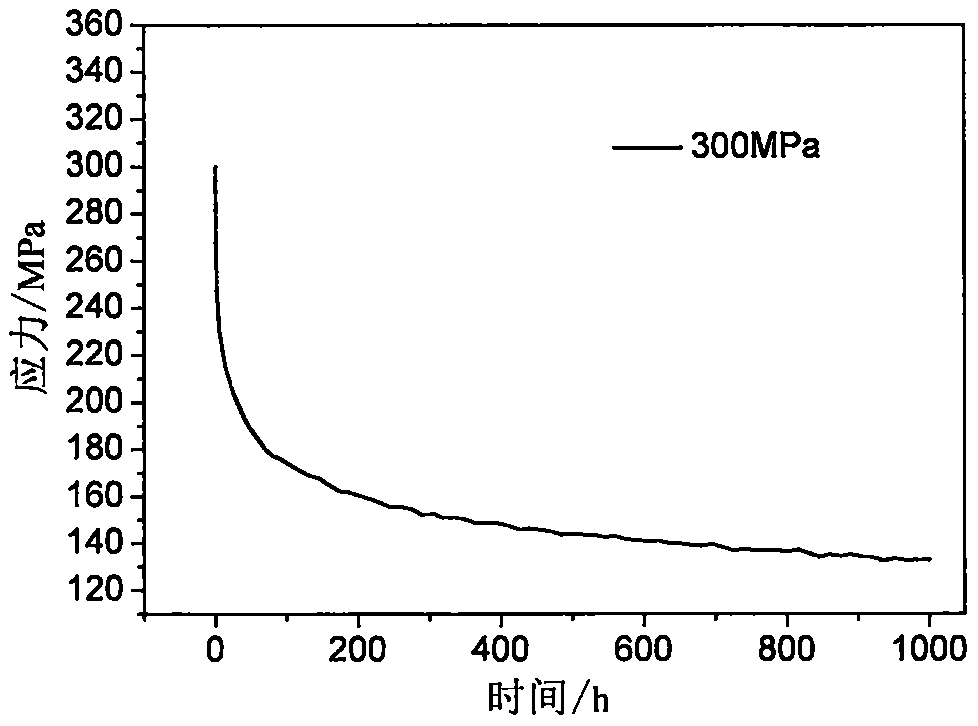

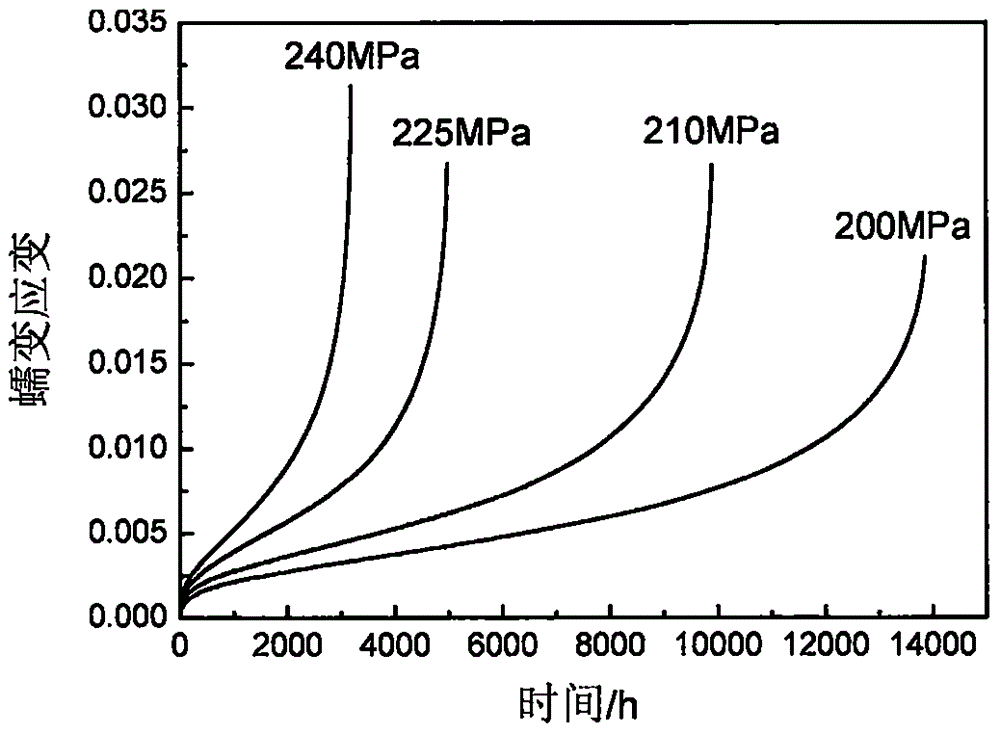

InactiveCN101308127AAccelerated Creep DesignMethod scienceSpecial data processing applicationsStrength propertiesRelaxation equationCreep rate

The invention relates to a high temperature creep life accelerated test method of a material, which comprises: a plurality of groups of short time stress relaxation tests of the material at the same temperature, acquiring a relaxation rate-stress curve based on the numerical differentiation principle, forming a relaxation creep rate-stress curve by utilizing a relaxation equation, calculating creep data to build a creep curve, and building a steady state creep rate curve and a Norton creep equation. The method starts from the physical relation between relaxation and creep, covers rather broad properties of creep strain rate by utilizing the short time relaxation process, and educes broader creep data than that educed from general creep tests by above ten times, thereby effectively reducing the amount of high temperature creep tests and time of tests and providing basic data for development of new material and engineering application.

Owner:EAST CHINA UNIV OF SCI & TECH

Designing and prediction method for converting high-temperature stress relaxation data into creep data

InactiveCN105842087ALow conversion accuracyReasonable technical pathInvestigating material ductilityComplex mathematical operationsTemperature stressConstant stress

The invention discloses a designing and prediction method for converting high-temperature stress relaxation data into creep data. The method mainly comprises the following steps: establishing a stress relaxation two-stage superposition model; creating the concepts of equivalent full relaxation time and equivalent relaxation creep rates, carrying out simulation of an equivalent relaxation creep rate in two integrated relaxation stages to obtain a steady-state creep rate under constant stress and establishing a stress relaxation-creep conversion model; acquiring stress relaxation performance data of a high-temperature component material; subjecting the data and the stress relaxation two-stage superposition model to fitting so as to obtain a corresponding material constant; and carrying out calculating according to a numerical analysis program, solving the stress relaxation-creep conversion model and eventually converting stress relaxation data into creep data so as to obtain a steady-state creep rate curve and a steady-state creep curve. According to the invention, accurate association between stress relaxation data and creep data behaviors is established; a prediction method for converting single relaxation data into creep data under any stress is constructed; so a novel approach is provided for designing of creep strength of a high-temperature member and for evaluation of the service life of the high-temperature member.

Owner:ANYANG INST OF TECH

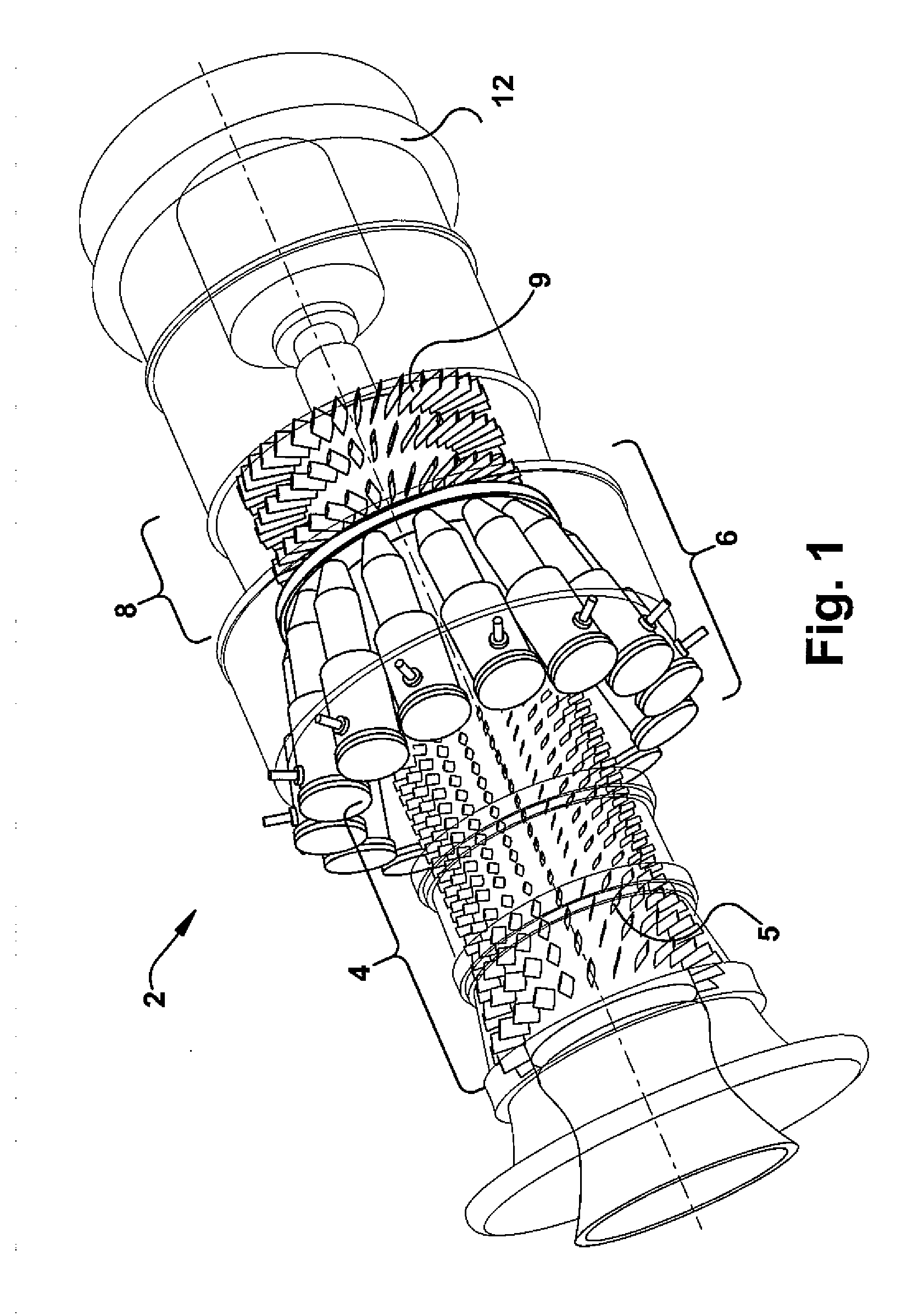

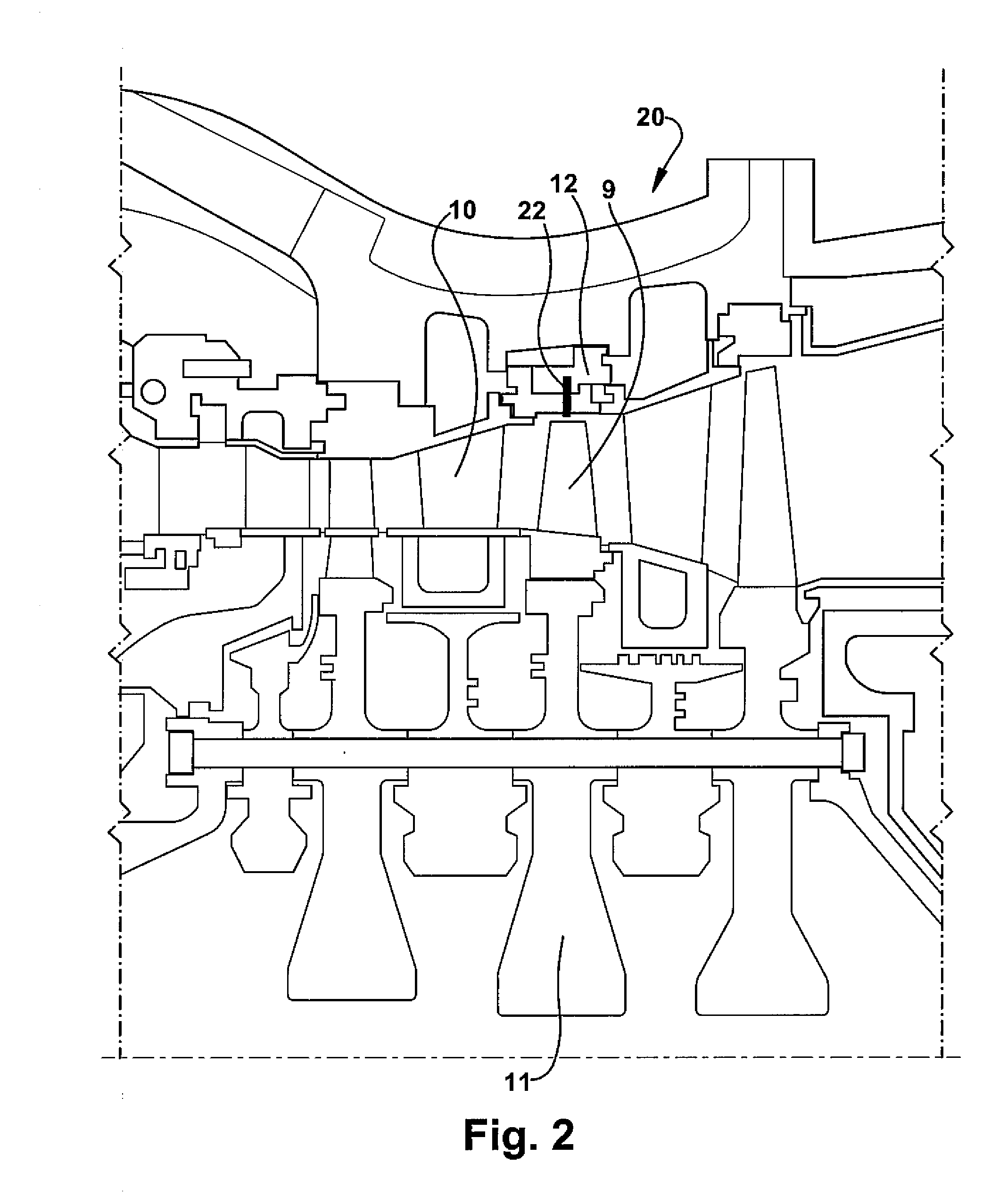

Method and systems for operating turbine engines

A method of operating a turbine, the method including the steps of: 1) gathering measured creep data for a blade while the turbine operates at different operating temperatures, the measured creep data comprising at least a measured creep rate for the blade (wherein the different operating temperatures include at least a first operating temperature and a second operating temperature); and 2) given the measured creep data for the blade while the turbine operated at the first operating temperature and the measured creep data for the blade while the turbine operated at the second operating temperature, determining whether operating the turbine at the first operating temperature or the second operating temperature is more economically efficient.

Owner:GENERAL ELECTRIC CO

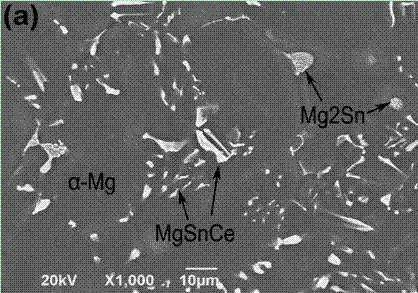

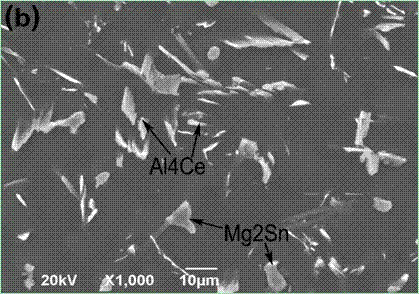

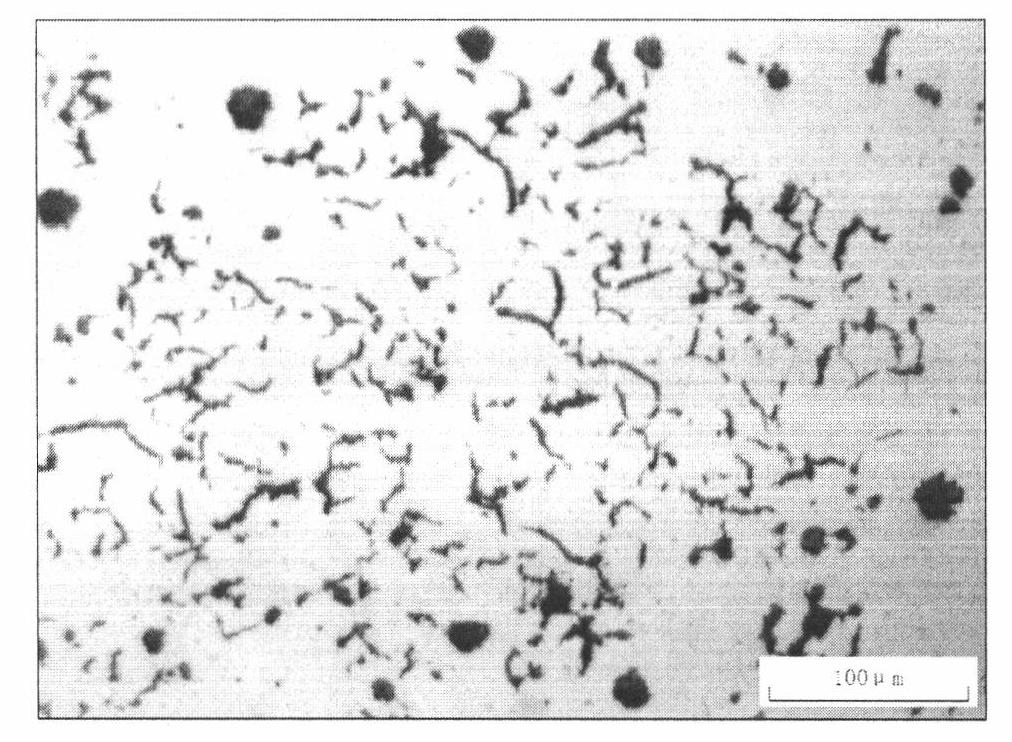

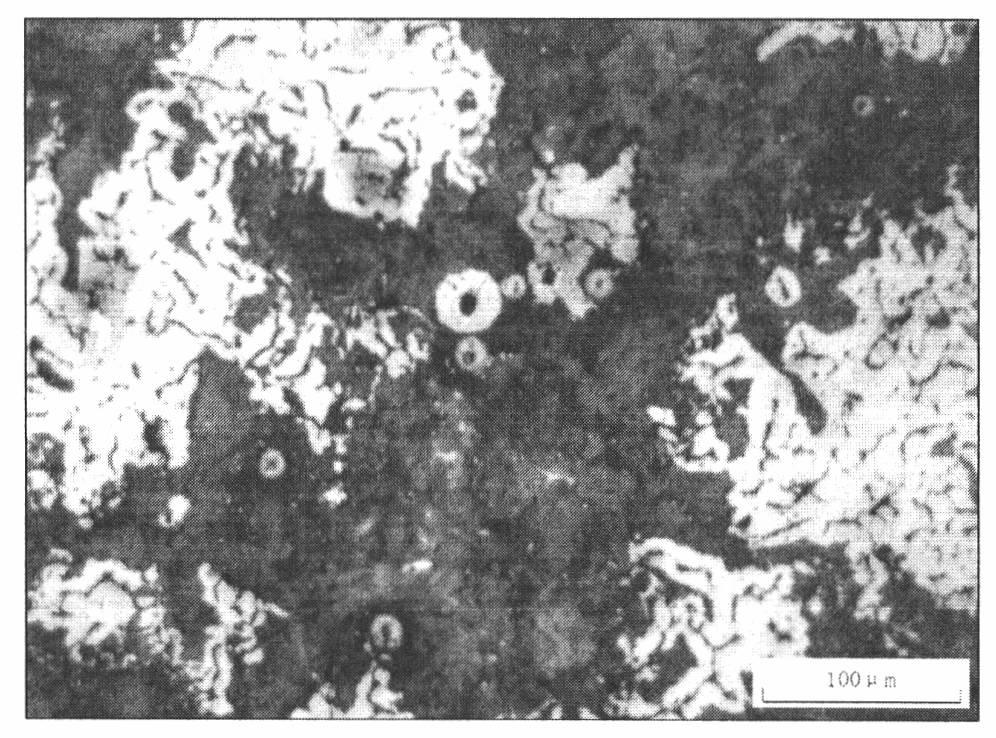

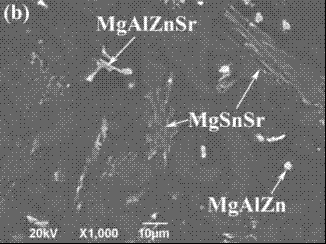

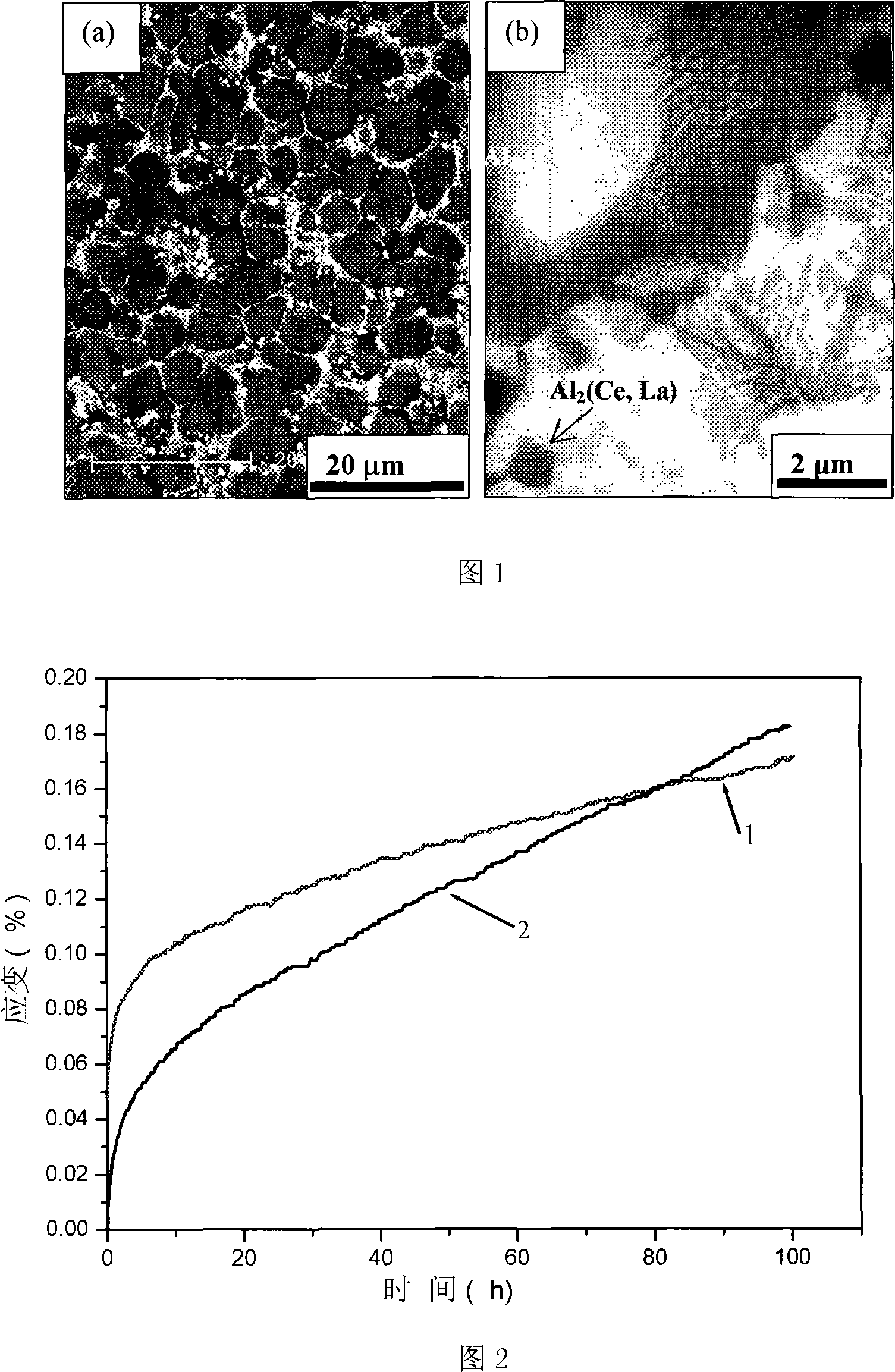

Al and Zn strengthened Mg-Sn-RE-based high-toughness heat-resistant magnesium alloy

The invention provides a cheap-light-rare-earth-containing Mg-Sn-RE-based high-toughness heat-resistant magnesium alloy. The chemical formula of the alloy is Mg-xSn-yRE-zM, wherein x is more than or equal to 2 weight percent and less than or equal to 8 weight percent, y is more than or equal to 0.5weight percent and less than or equal to 3 weight percent, z is more than or equal to 1 weight percent and less than or equal to 6 weight percent, RE represents La and Ce, M is one or two elements of Al and Zn, and the balance is Mg, a small amount of other elements and unavoidable impurities. The Al and the Zn have an obvious strengthening effect on the Mg-Sn-RE-based alloy, the alloy has the tensile strength of 270MPa and the elongation of about 15 percent in an as-cast state, and the steady-state creep rate of the alloy at the temperature of 175 DEG C under the pressure of 55MPa can be reduced to about 1.0*10<-7> / percent.s, which is far lower than that of an alloy junction (AJ) series heat-resistant magnesium alloy AJ52x; meanwhile, compared with the conventional rare-earth-containing heat-resistant magnesium alloy, the magnesium alloy has higher economy.

Owner:SICHUAN UNIV

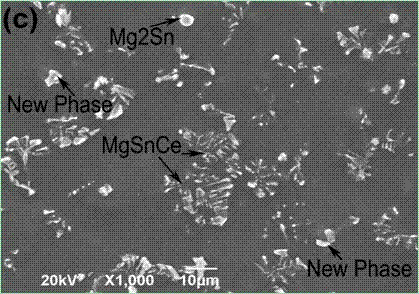

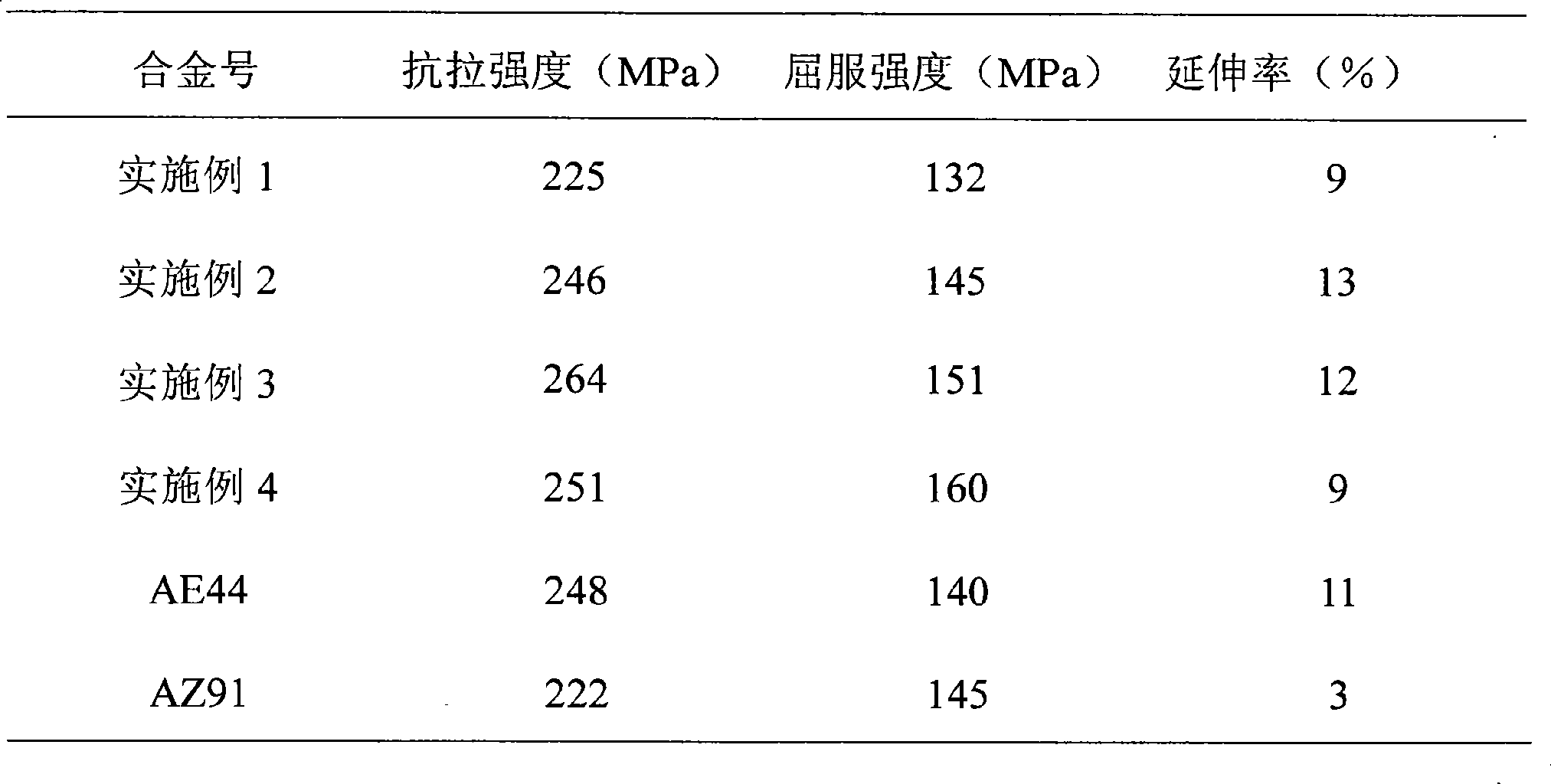

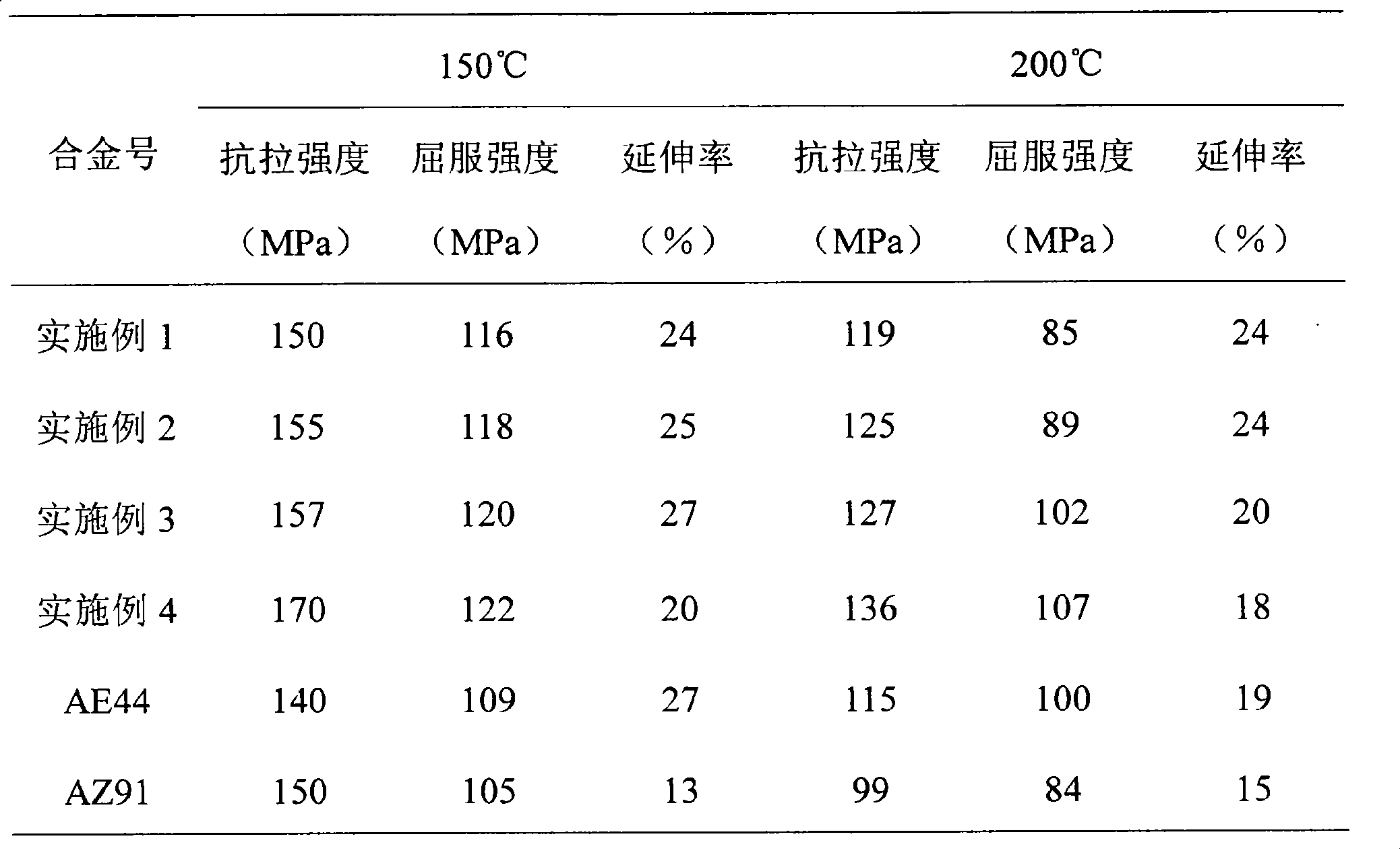

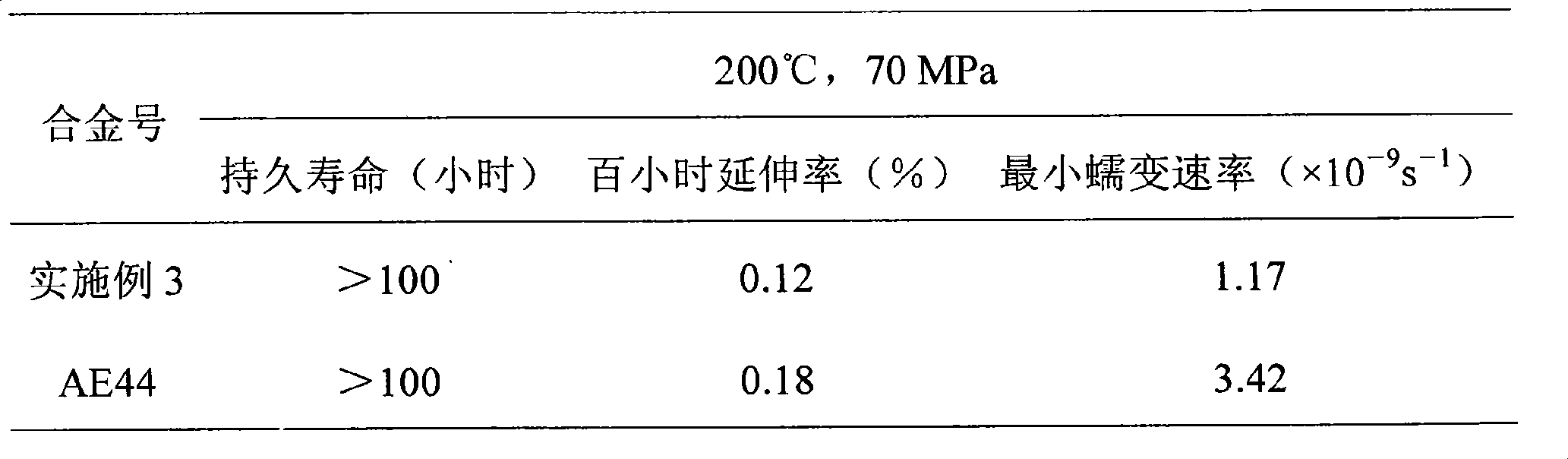

Preparation of lanthanum-containing AE heat resisting die-casting magnesium alloy

The invention relates to a lanthanum contained AE series heat-resistant die-casting magnesium alloy and a preparation method thereof. The alloy consists of the following compositions by mass percentage: 3.5 to 4.5 percent of Al, 1 to 6 percent of La, 0.2 to 0.6 percent of Mn, and less than 0.03 percent of gross of impurity elements Fe, Cu and Ni, and the balance being magnesium. The method comprises the following steps: preheating pure magnesium, aluminum, aluminum-manganese interalloy and magnesium-lanthanum interalloy to the temperature of 200 DEG C according to a proportion; then, putting the mixture into a crucible which is preheated to the temperature of 300 DEG C, and introducing shield gas with a volume ratio of SF6 to CO2 being 1:100; adding the magnesium-lanthanum interalloy into the crucible after melt reaching a temperature of between 720 and 740 DEG C; continuously introducing the shield gas to stir the melt for 5 to 10 minutes; introducing argon gas to refine the melt for 5 to 10 minutes; and keeping the mixture stand for 28 to 32 minutes to obtain the lanthanum contained AE series heat-resistant die-casting magnesium alloy. The alloy has tensile strength at 200 DEG C of between 119 and 136MPa, yield strength of between 85 and 107MPa, elongation percentage of between 18 and 24 percent, and creep rate under 70MPa at 200 DEG C of 1.17*10<-9>s<-1>.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

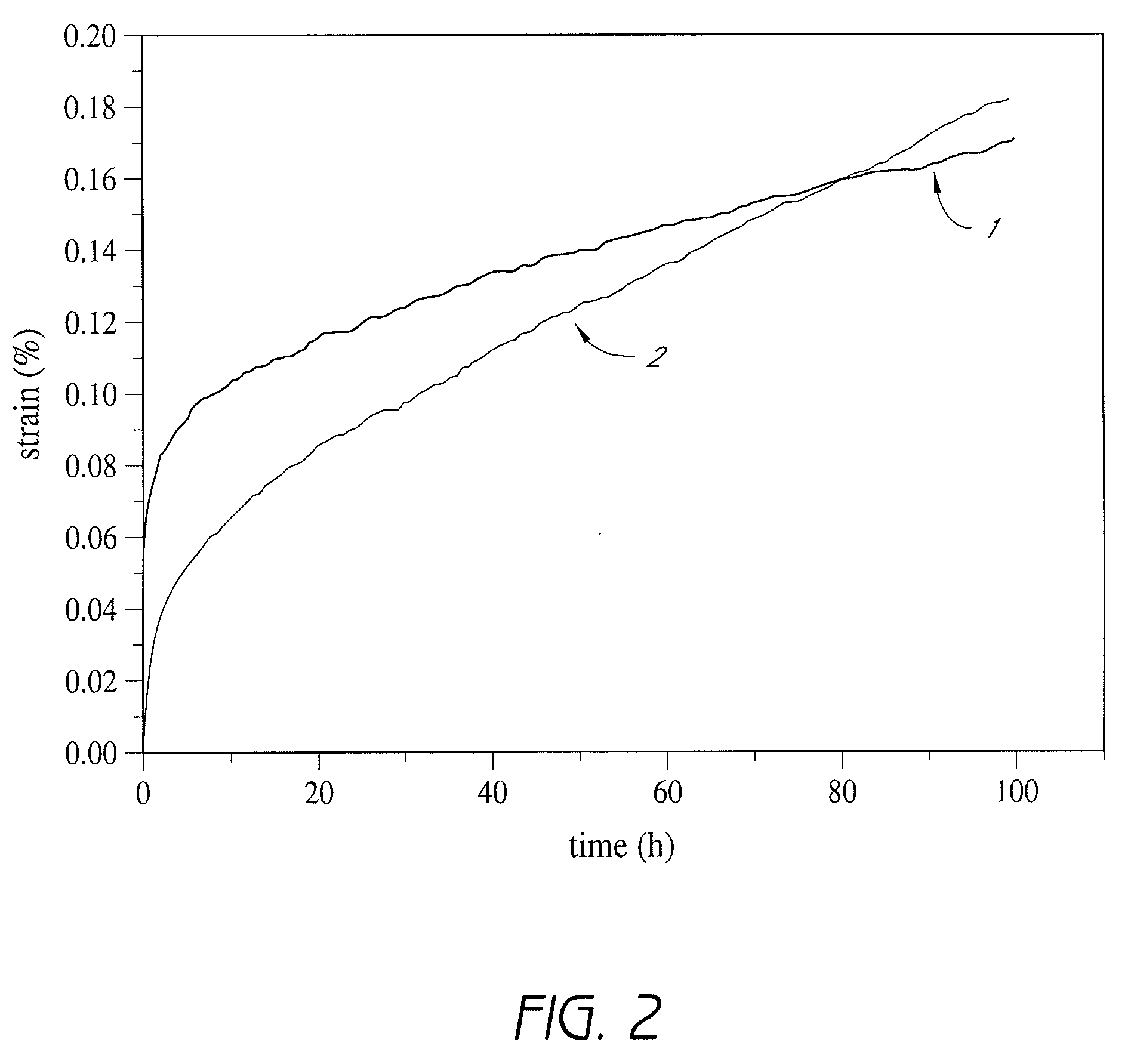

Rare earth-containing heat-resisting magnesium alloy

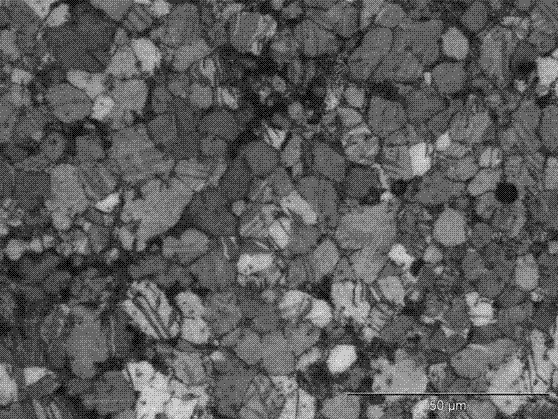

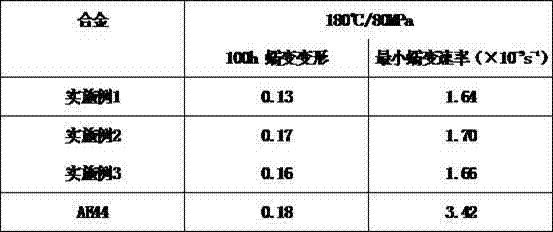

The invention relates to a rare earth-containing heat-resisting magnesium alloy which is characterized by comprising the chemical components in the terms of weight percent: 3.5-4.4 percent of Al, 5.5-6.4 percent of RE and 0.17-0.25 percent of Mn, wherein RE is cerium, lanthanum and neodymium with the weight proportion of (35-40):(60-55):5. Room temperature and high temperature mechanical properties of the rare earth-containing heat-resisting magnesium alloy are superior to those of an AE44 alloy; and the rare earth-containing heat-resisting magnesium alloy can work for a long time under the condition of 180 DEG C / 80MPa, has the minimum creep rate of not more than 1.7*10<-9> / s under the condition of 180 DEG C / 80MPa and the maximum creep elongation of not more than 0.17 percent within 100h, and can be used for manufacturing parts such as an automatic gearbox housing and the like with higher high-temperature creep property requirements for materials.

Owner:LINJIANG DONGFENG NON FERROUS METALS

Method for describing creep curve of metal material

ActiveCN105004617ASimple structureHigher than precisionMaterial strength using tensile/compressive forcesConstant stressMetallic materials

Owner:SHENYANG POLYTECHNIC UNIV

Creep damage calculation method and model under variable load history

ActiveCN109142083AMaterial strength using tensile/compressive forcesSpecial data processing applicationsCreep strainComputational model

The invention discloses a creep damage calculation method and model under variable load history. The method includes: acquiring the creep strain-time curve, minimum creep rate epsilon<c>m, fracture creep strain epsilon<c>f and fracture life tf of a material under different temperature and stress according to a uniaxial creep test; selecting a creep constitutive equation, and using uniaxial creep test fitting to obtain the creep constitutive parameters of the material; acquiring parameters A and B according to two simple two-stage variable load creep test data fitting; recording deformation increment generated by each stage of load according to the multi-stage variable load creep test of the material; calculating creep damaged generated of the n-1 stage before the multi-stage variable loadcreep test of the material; according to the variable load creep damage calculation model, if the acting time of the nth-stage load is known, predicting the deformation of the material under the nth-stage load, and if the nth-stage load is loaded until fracture occurs, predicting the acting time of the nth-stage load. The method can precisely consider the loading history.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

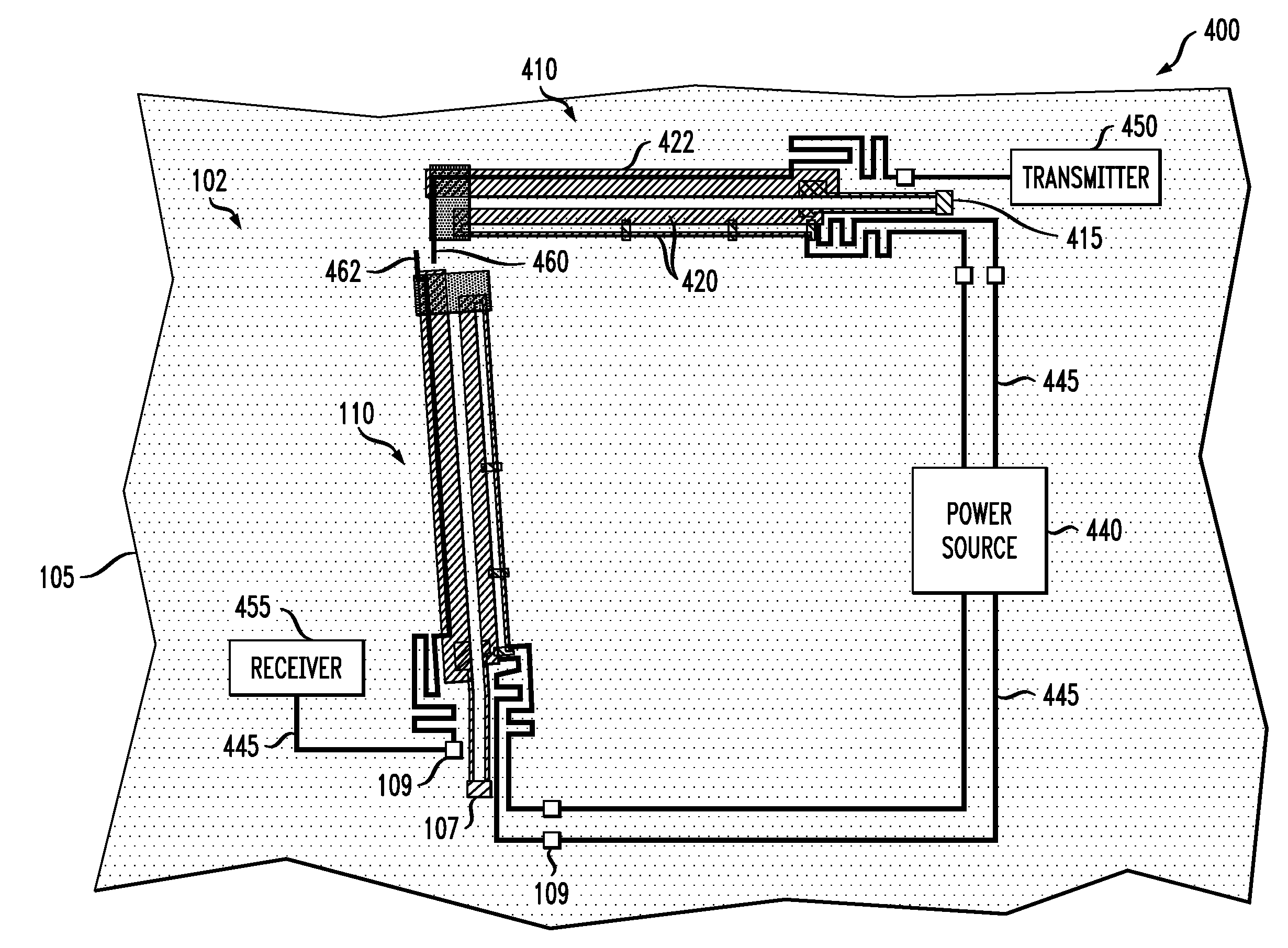

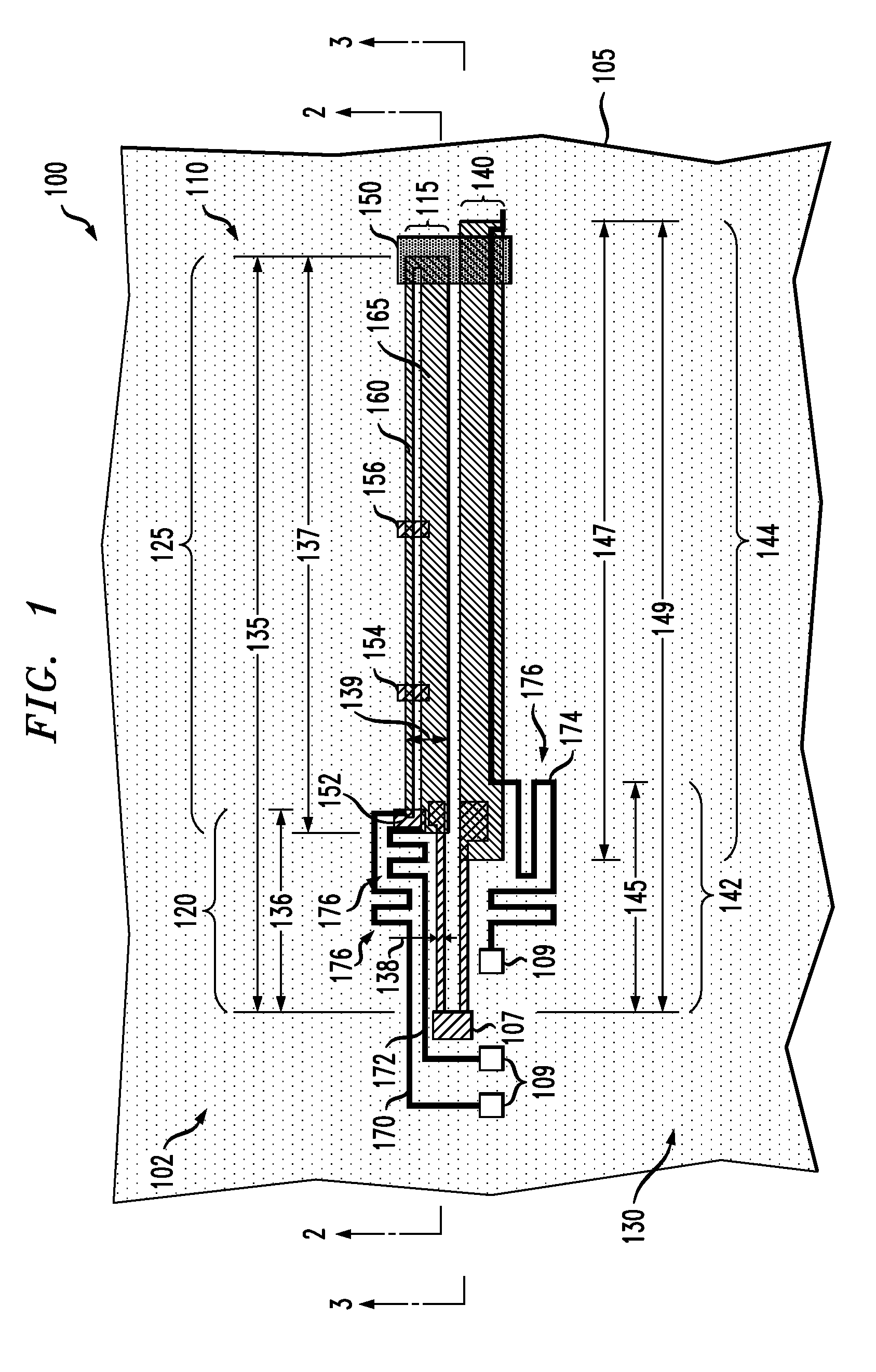

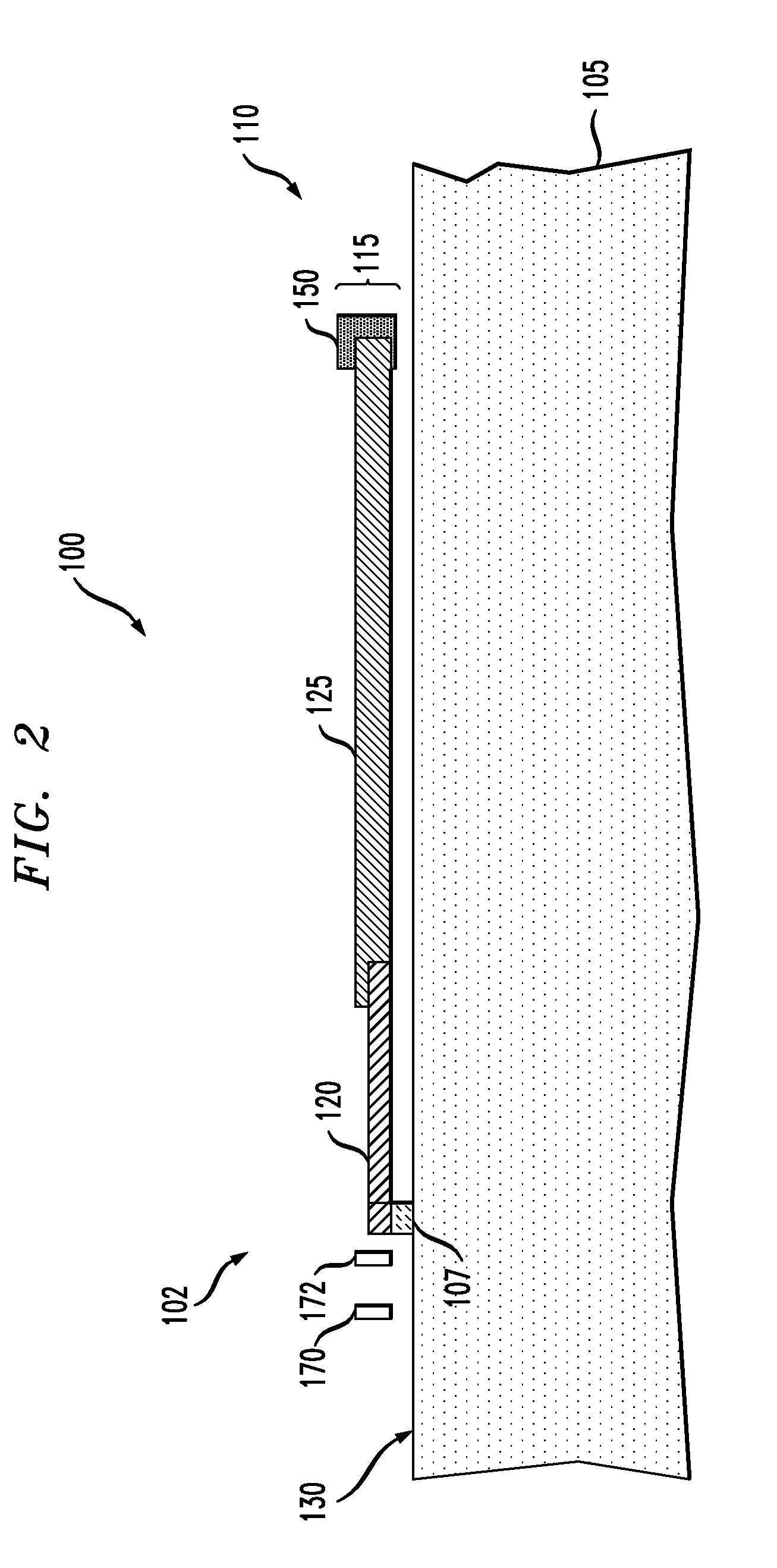

Robust MEMS actuator for relays

InactiveUS7471184B1Electrothermal relaysSemiconductor/solid-state device detailsMicroelectromechanical systemsEngineering

An apparatus comprising a microelectromechanical system (MEMS) device. The MEMS device includes a substrate having an anchoring pad thereon and a structural element. The structural element has a beam that includes a first part and a second part. The first part is attached to both the anchoring pad and to the second part. The second part is movable with respect to the substrate and made of an electrically conductive material. Additionally, at least one of the following conditions hold: the first part is made of a material having: a first yield stress that is greater than a second yield stress of the electrically conductive material of the second part; a fatigue resistance that is greater than a second fatigue resistance of the electrically conductive material of the second part; or, a creep rate that is less than a second creep rate of the electrically conductive material of the second part.

Owner:LUCENT TECH INC

Vanadium-titanium vermicular cast iron brake drum and preparation method thereof

The invention discloses a vanadium-titanium vermicular cast iron brake drum and a preparation method thereof. The vanadium-titanium vermicular cast iron brake drum comprises the following components in percentage by weight: 3.4 to 3.9 percent of carbon, 2.1 to 2.8 percent of silicon, 0.5 to 0.9 percent of manganese, less than or equal to 0.10 percent of phosphorus, less than or equal to 0.07 percent of sulfur, 0.10 to 0.35 percent of vanadium, 0.1 to 0.25 percent of titanium, and the balance of ferrum and unavoidable impurities. The tensile strength of the vanadium-titanium vermicular cast iron brake drum is 354 to 421MPa and the Brinell hardness is 234 to 273HBW; the creep rate in a metallographic structure is 70 to 95 percent, and the pearlite content in a matrix is 60 to 90 percent. The performance indexes of the vanadium-titanium vermicular cast iron brake drum are higher than the performance indexes of the existing gray cast iron, vanadium-titanium cast iron and alloy cast iron; and the vanadium-titanium vermicular cast iron brake drum has good market prospect.

Owner:CHONGQING UNIV +1

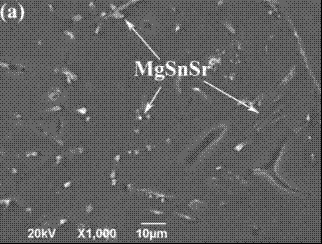

A mg-sn-sr-based high-strength and tough heat-resistant magnesium alloy

The invention relates to a casting magnesium alloy material, and provides a Mg-Sn-Sr based high-strength, toughness and heat-resistant magnesium alloy with good comprehensive mechanical properties. The composition of the alloy is: Mg-xSn-ySr-zM, wherein 2wt%≤x≤7wt%, 0.5wt%≤y≤5wt%, 1wt%≤z≤7wt%, and M is at least one of Al and Zn elements, and the rest are Mg and unavoidable impurities. The tensile strength of the magnesium alloy of the present invention in the as-cast state can reach 240MPa, the yield strength is about 120MPa, the elongation can reach 12%, and the steady-state creep rate at 175°C and 55MPa is lower than that of the commercially available AJ52X alloy.

Owner:SICHUAN UNIV

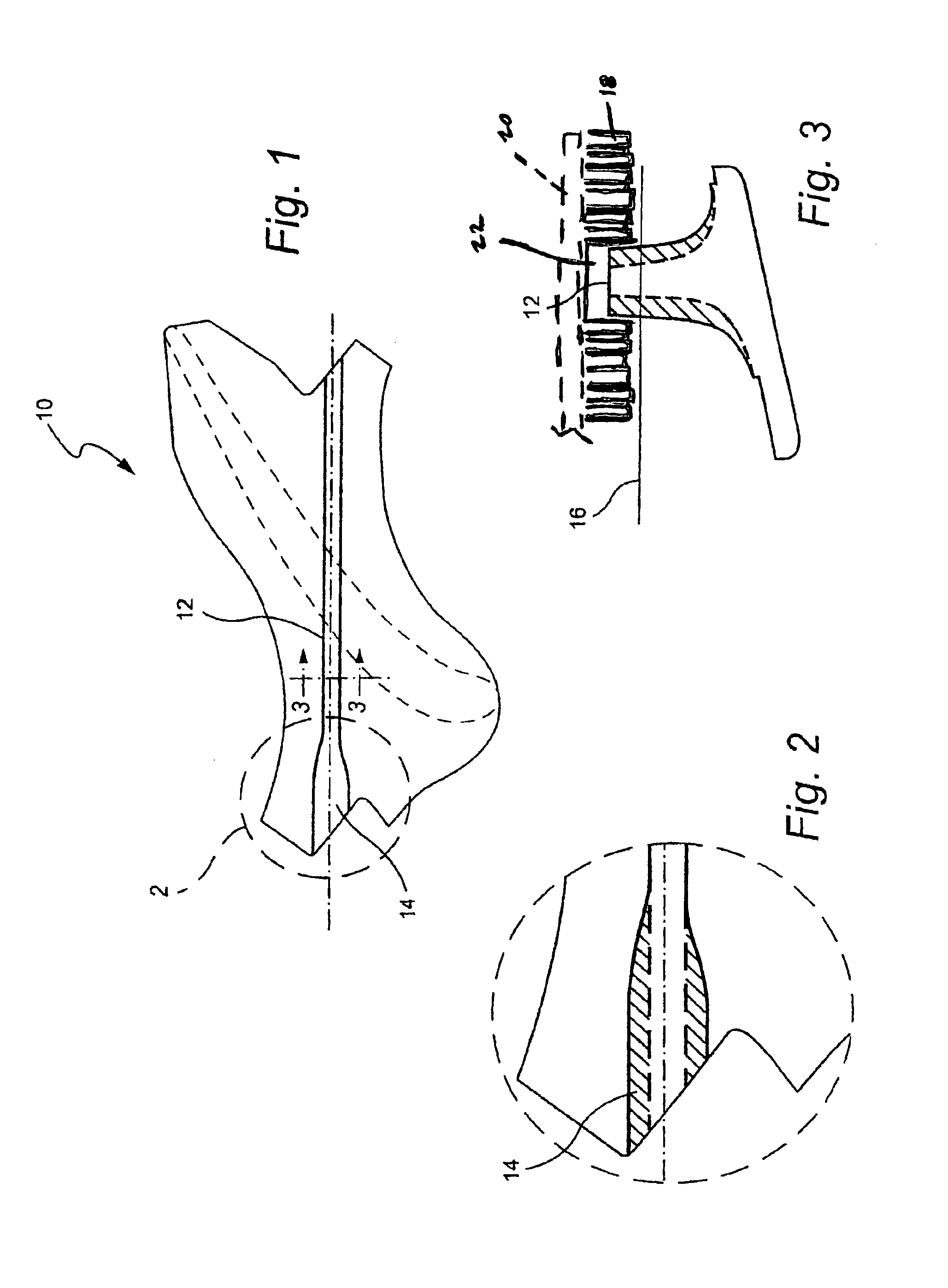

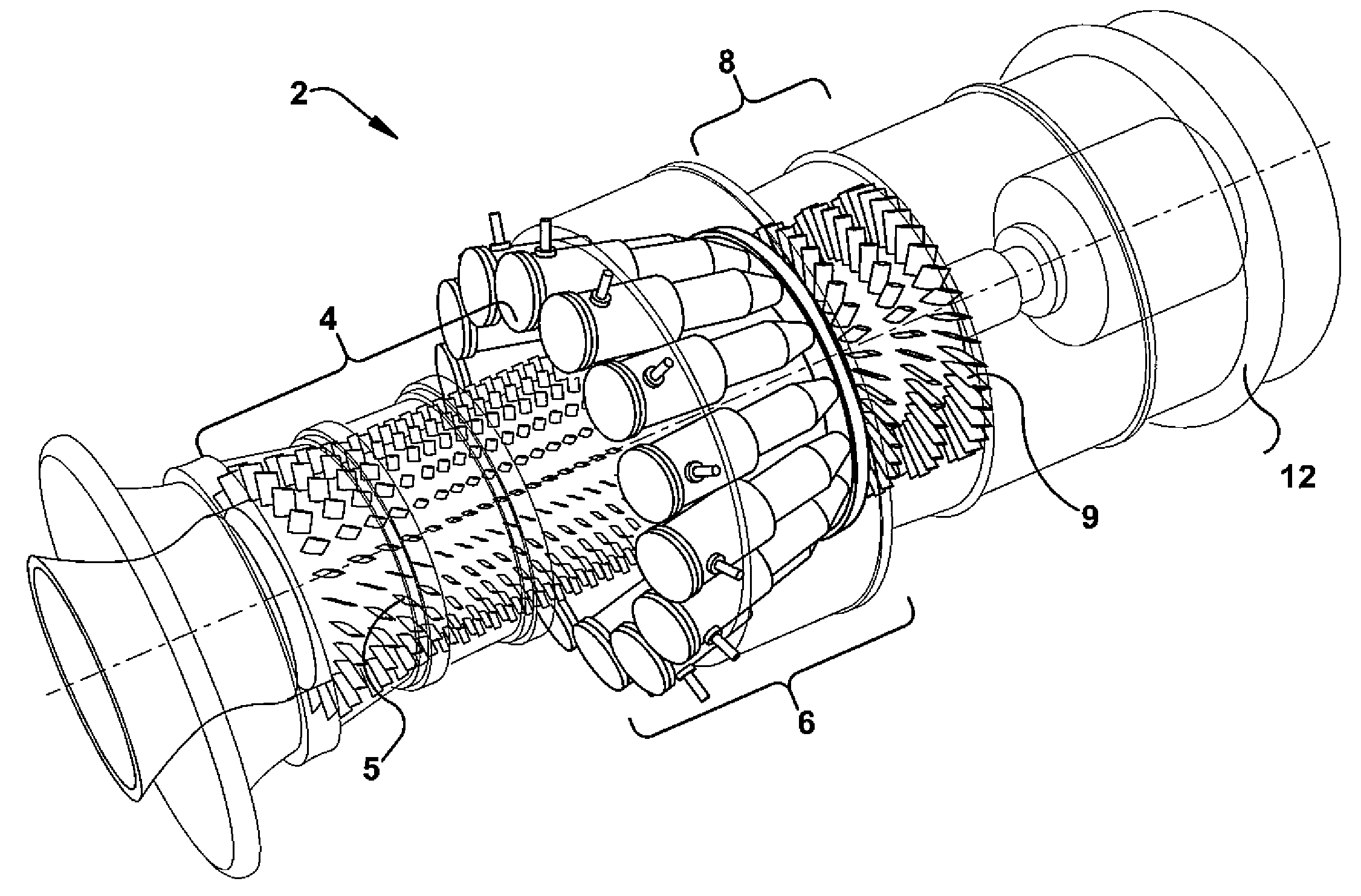

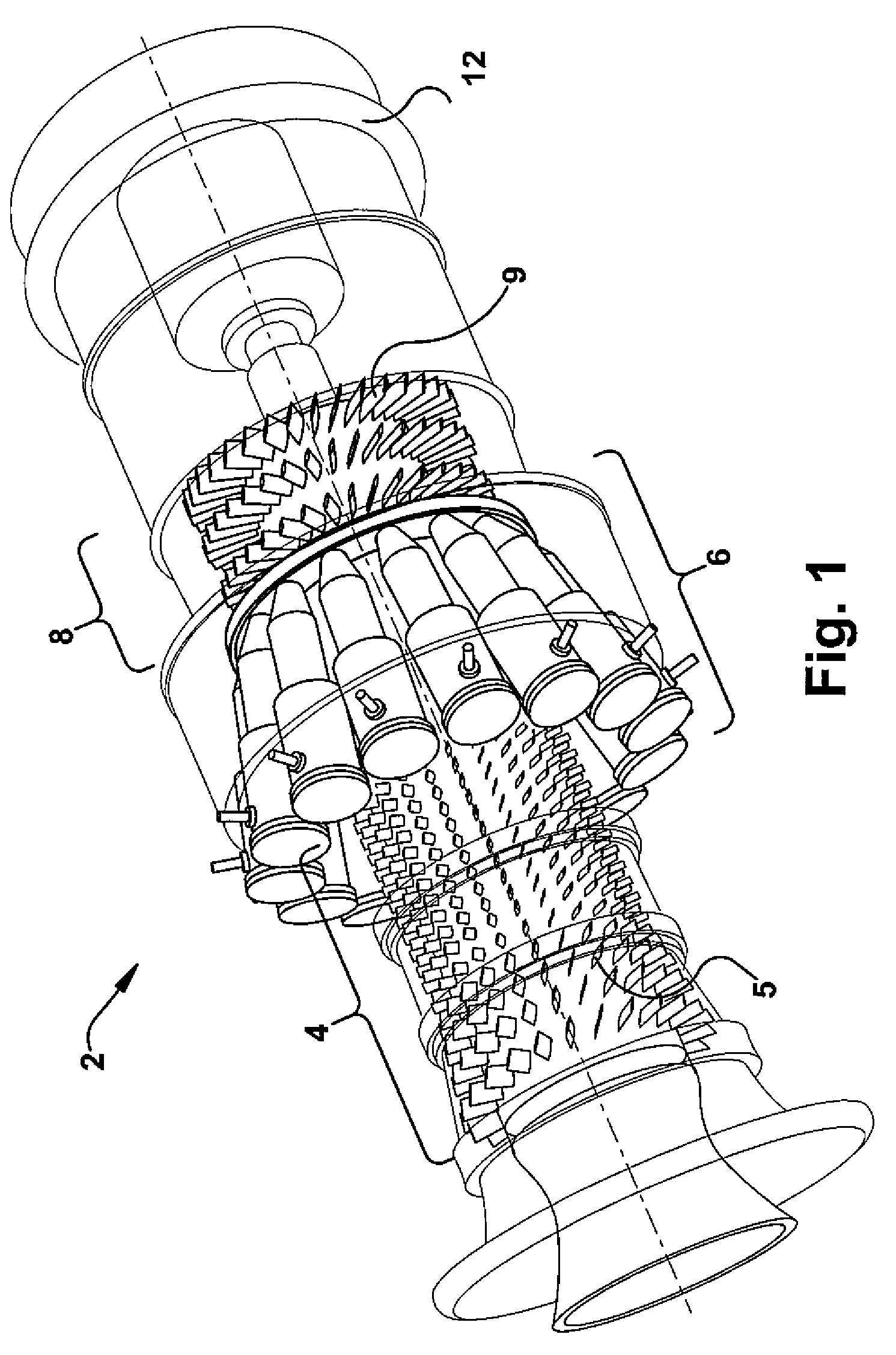

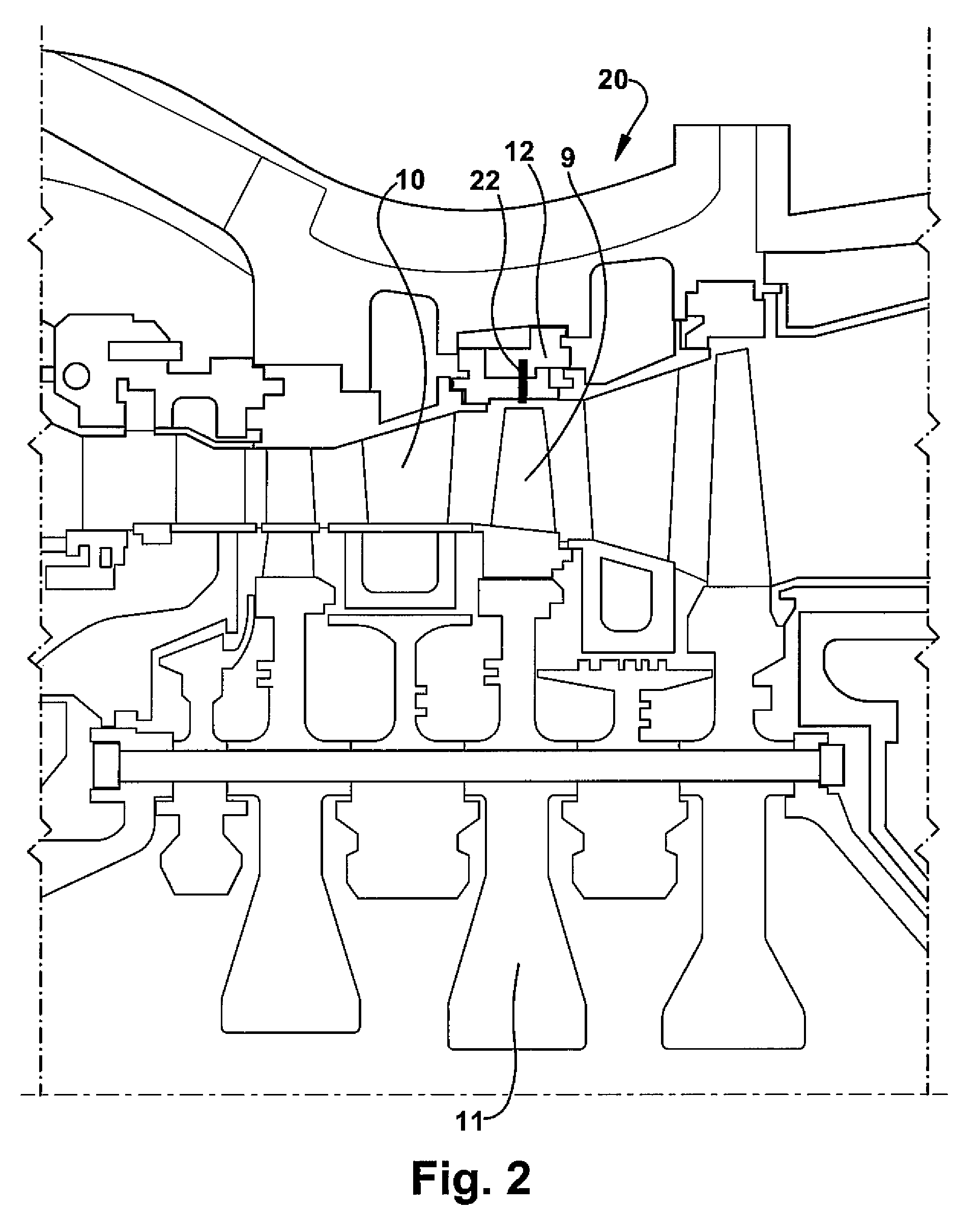

Gas turbine and method for reducing bucket tip shroud creep rate

A bucket tip shroud in a gas turbine includes a seal rail having a cutter tooth at one end. Bucket tip shroud creep rate can be reduced by removing the cutter tooth from the bucket tip shroud seal rail after use or with a pre-groove honeycomb shroud. Preferably, the remaining geometry matches a geometry of the seal rail within a predetermined tolerance.

Owner:GENERAL ELECTRIC CO

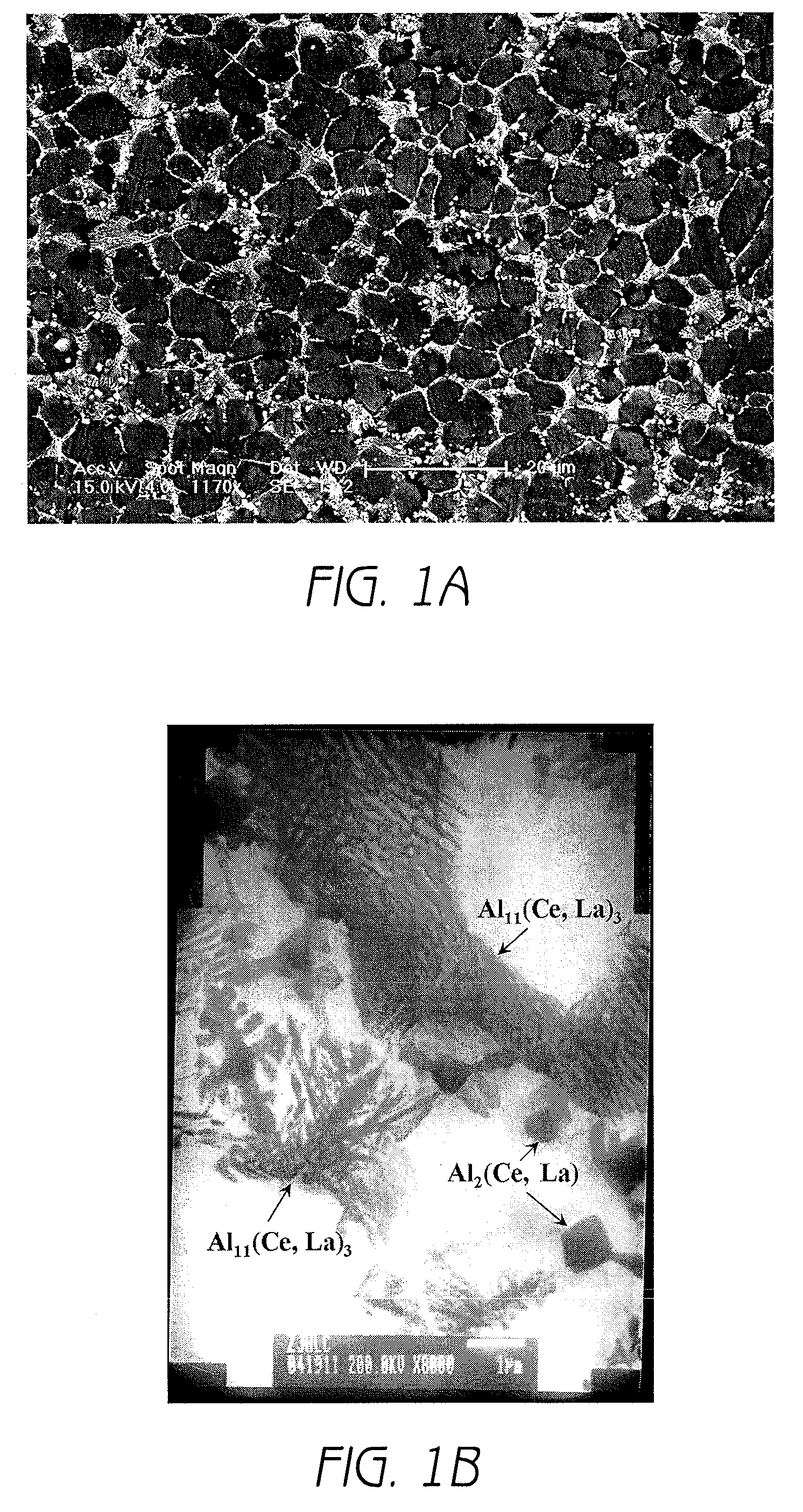

Ae series heat resistant compression casting magnesium alloy containing cerium and lanthanum

This invention relates to an AE series heat resistant compression casting magnesium alloy containing cerium and lanthanum and the composition ingredients and the weight percentage thereof are as follows: Al: 3%˜5%, Ce: 0.4%˜2.6%, La: 0.4%˜2.6%, Mn: 0.2%˜0.6%, and the remainder is magnesium. The raw material of cerium lanthanum mixture of rare earth used is the residual, cheap and overstocked cerium lanthanum mixture of rare earth obtained from common cerium rich mixture of rare earth after the Nd, Rr with high value and good market have been separated. The mechanical performance of this invention at room temperature and high temperature excels that of AE 44 and AZ 91 alloys, and the minimum creep rate of 1.82×10-9 S-1 and the creep percentage elongation in 100 h of 0.17% at the condition of 200° C. and 70 MPa excel these of AE 44 alloy.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

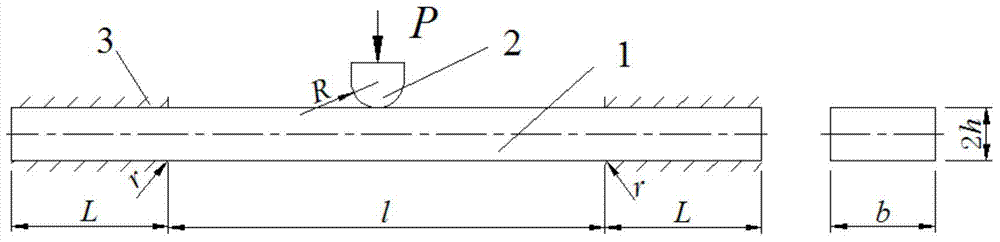

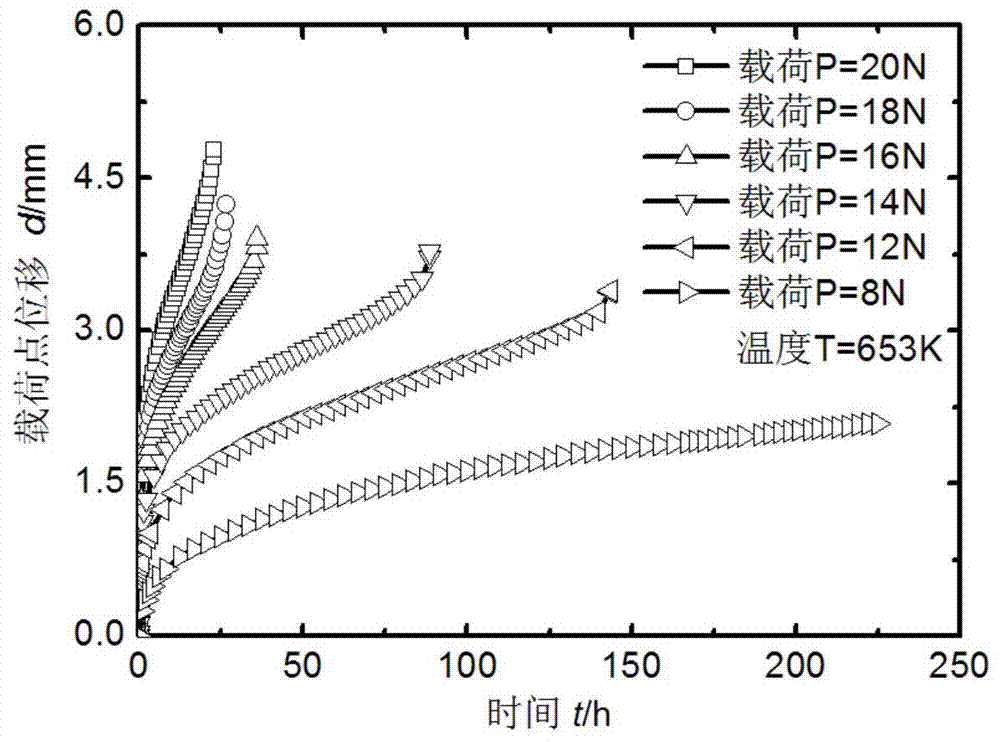

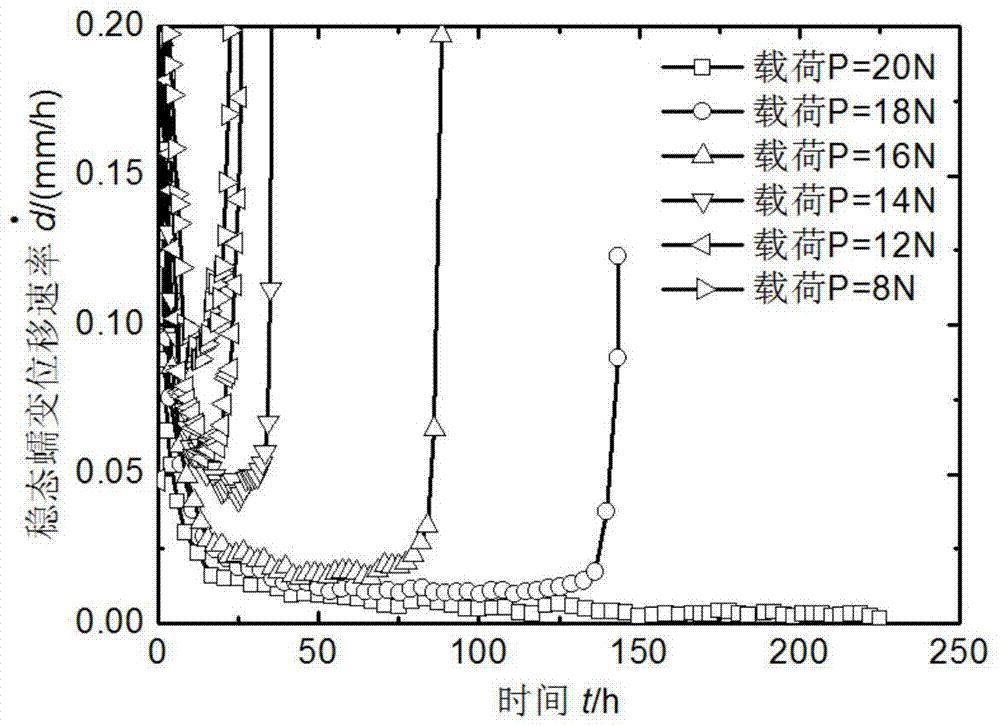

Clamped straight rod small sample creep testing method and apparatus thereof

InactiveCN103487336ASimple and fast operationImprove test accuracyInvestigating material ductilitySmall sampleComputer module

The invention provides a clamped straight rod small sample creep testing method and an apparatus thereof. The testing apparatus comprises a heating module, a loading module, a clamping module, a displacement measuring module and an external support; and the testing method comprises the following steps: designing and making a clamped straight rod small sample, carrying out multiple creep tests of a material at a same temperature under different loads, establishing a steady state creep rate curve, obtaining a Kachanov-Rabotnov creep damage constitutive equation, and adopting a finite element to carry out parameter optimization. The small sample creep testing method provided by the invention solves the problems of difficult data parse and many testing influence factors of present small sample technologies, has the advantages of simple operation, high testing precision and low cost, and provides basic data for the exploitation of a new material, the high-temperature integrity evaluation of a service member and the performance evaluation of an irradiated material.

Owner:EAST CHINA UNIV OF SCI & TECH

AE series thermo-stable die-casting magnesium alloy containing cerium and lanthanide

The invention relates to an AE series heat resistant casting magnesium alloy containing cerium and lanthanum, which comprises and has the weight percentage of each element of: Al:3%-5%, Ce:0.4%-2.6%, La:0.4%-2.6%, Mn:0.2%-0.6%, the rest being magnesium. The lanthanum cerium mischmetal used is produced by separating the Nd, Pr which is more valuable and selling from ordinary cerium rich mischmetal which leaves the cheap and abundant cerium lanthanum mischmetal. The invention has better mechanical performance in both normal and high temperature than AE44 and AZ91alloy, and the minimum creep rate under 200 DEG C, 70MPa is 1.82 multiplied by10-9s-1, 100 hour creeping elongation rate is 0.17%, all being better than an AE44 alloy.

Owner:白山市天安金属镁矿业有限公司

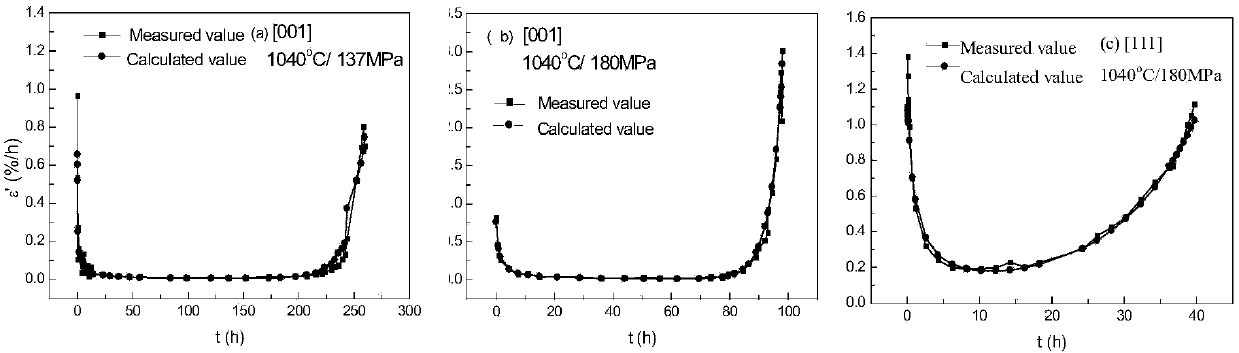

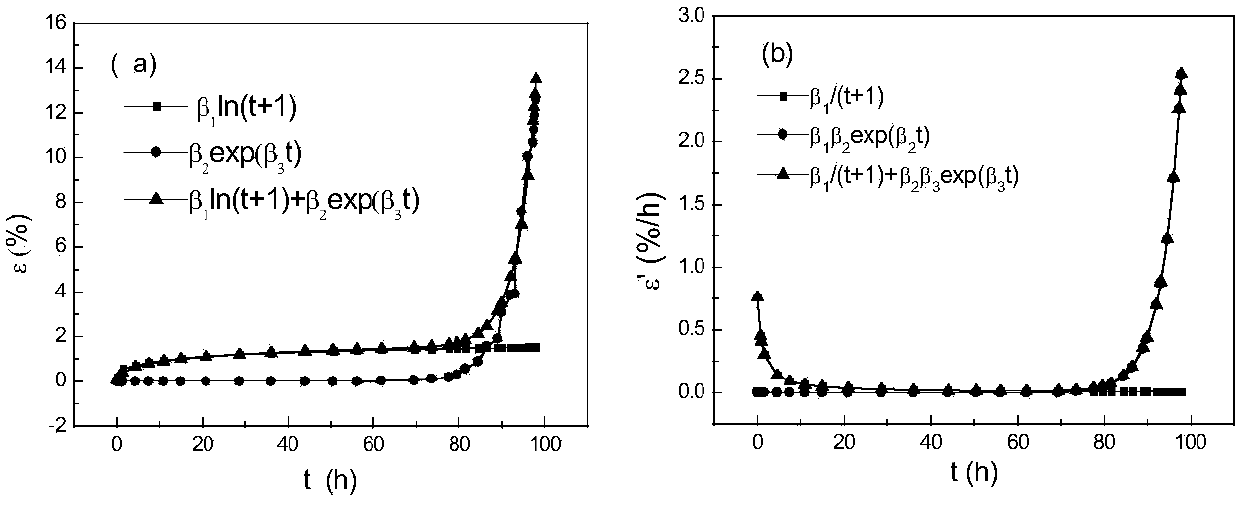

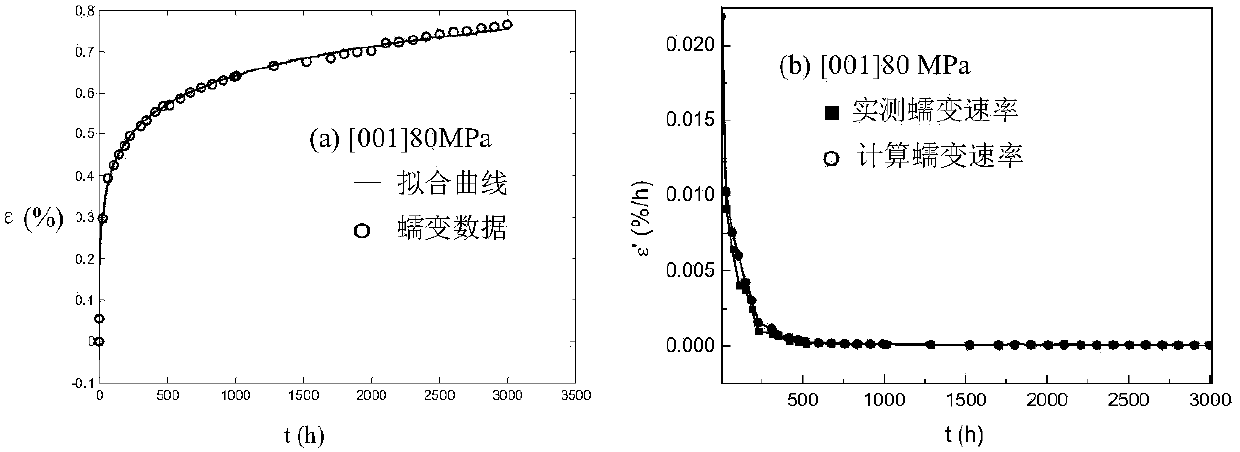

Method for representing single-crystal Ni-base alloy creep resistance

InactiveCN105784508ASimple structureMethod is feasibleInvestigating material ductilityConstant stressSingle crystal

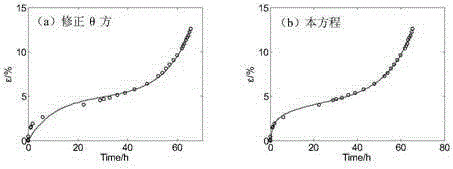

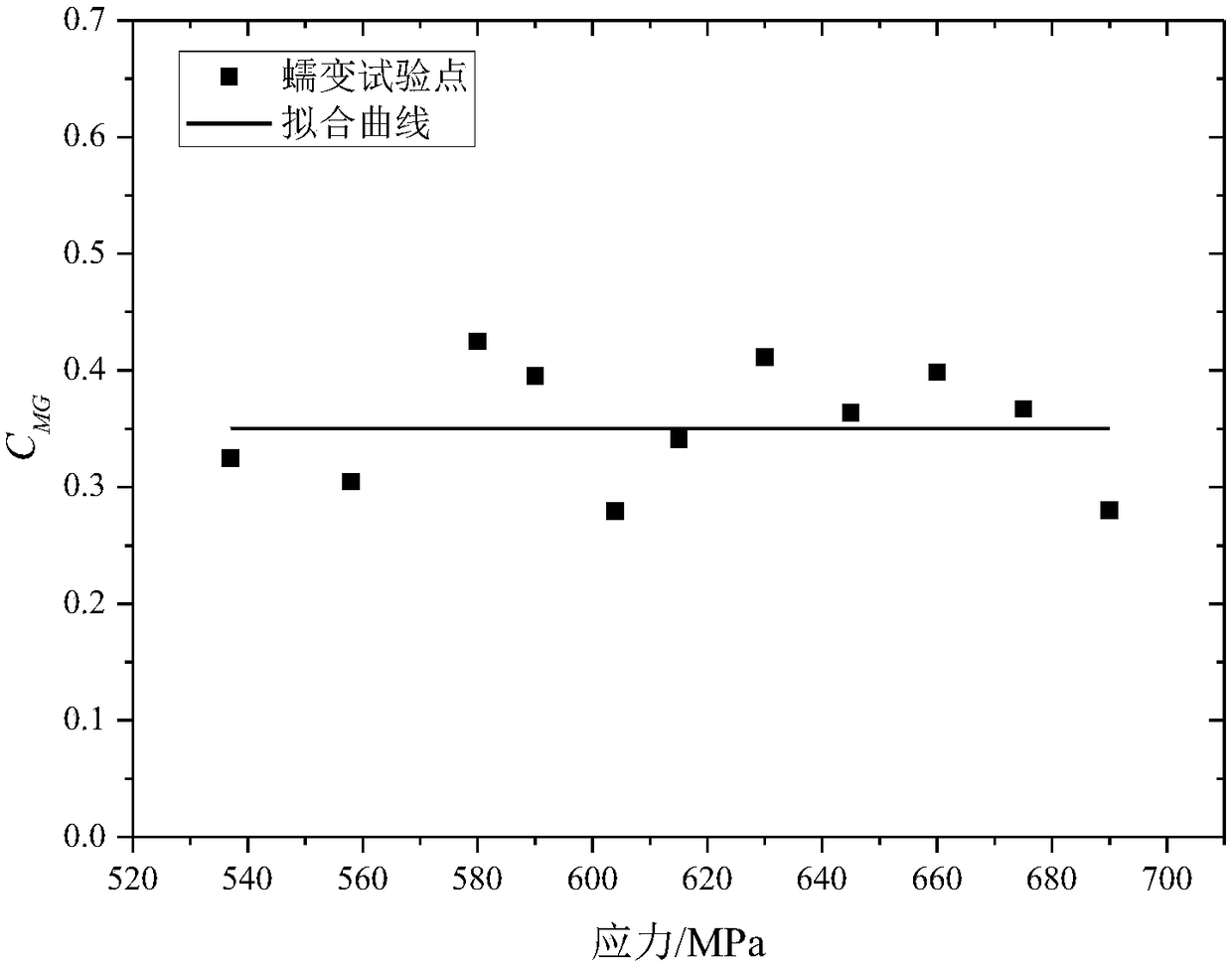

A method for representing single-crystal Ni-base alloy creep resistance comprises the steps of building a creep curve model suitable for single-crystal Ni-base alloy creep characteristics; determining model parameters to obtain a creep curve equation; performing creep data regression to obtain a fitting creep curve for describing a creep process; obtaining a creep rate equation, obtaining the minimum calculation creep rate and calculating a creep rate curve; combining specific requirements for representing the single-crystal Ni-base alloy creep resistance.Various single-crystal Ni-base alloy creep curves under constant temperature and constant stress except the extremely-high temperature or extremely-high stress and creep rate distribution can be accurately expressed; the corresponding relations of various creep curve equation items and creep parameters and alloy creep curves is revealed; the problem that some alloy cannot represent creep characteristics easily through the creep activated energy and stress indexes is solved; and the method is of great importance in further knowing the creep characteristics and rules of single-crystal Ni-base alloy.

Owner:SHENYANG POLYTECHNIC UNIV

High-temperature-resistant and creep-resistant polyethylene heat shrinkage film and film-blowing process thereof

InactiveCN104890334AImprove high temperature creep resistanceLow viscositySynthetic resin layered productsLaminationLow-density polyethyleneLinear low-density polyethylene

The invention discloses a high-temperature-resistant and creep-resistant polyethylene heat shrinkage film and a film-blowing process thereof, and belongs to the field of plastic films. The film is prepared by co-extruding an inner layer, a middle layer and an outer layer, wherein the raw materials of both the inner layer and the outer layer comprise bimodal linear low-density polyethylene, metallocene polyethylene and low-pressure high-density polyethylene, and the raw materials of the middle layer comprise metallocene polyethylene and high-pressure low-density polyethylene. The polyethylene heat shrinkage film provided by the invention is excellent in high-temperature resistance and creep resistance; under the environment of 40 DEG C or above, when 50 MPa tensile stress is applied to the film for 120 hours, the creep rate of the film is 0.2% or below, the lateral shrinkage of the film is 15-30%, the longitudinal shrinkage of the film is 55-80%, the lateral tensile strength is 50 mpa or above and the longitudinal tensile strength is 52 mpa or above. In addition, the raw materials are mixed according to appropriate proportion; in the preparation process, the melt viscosity is greatly reduced when being compared with the prior art that only linear low-density polyethylene is adopted, and the energy consumption is reduced by 35% or above when being compared with the prior art that only linear low-density polyethylene is adopted.

Owner:成都市益诚包装有限公司

High-intensity creep-resistant and low-copper alloy material and application thereof

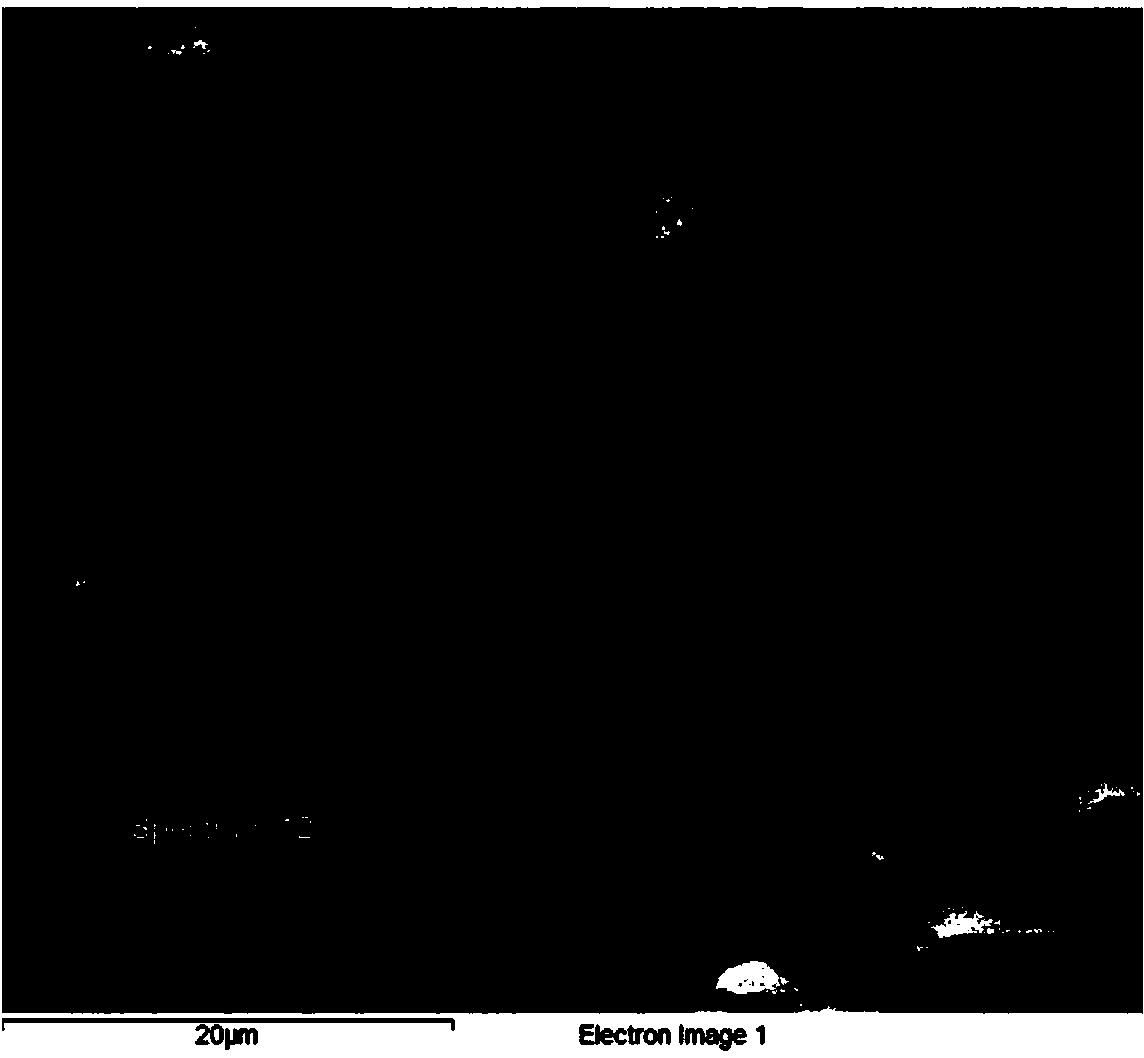

ActiveCN104073685AImprove plasticityImprove creep resistanceCoupling contact membersMetal/alloy conductorsBand shapeCreep rate

The invention discloses a high-intensity creep-resistant and low-copper alloy material. The material comprises the following components in percentage by weight: 4 to 10wt% of Cu, 0.01 to 0.5wt% of Mg, 0.01 to 2.0wt% of Mg, 0.01 to 1.0wt% of Ti, and the balance of Zn and inevitable impurities; and the phase composition of an as-cast structure of the low-copper alloy material includes a substrate Zn, an equiaxial chrysanthemum shaped CuZn5 phase and a belt-shaped network type Zn-Cu-Ti-Mg-Mn compound. The alloy is outstanding in creep resisting performance, the creeping rate reaches (1.18-8.87)*10<-6>s<-1>, the elongation is 10 to 20%, the tensile strength is 400-550MPa, and the hardness HV5 is 100 to 150 under the conditions that the temperature is 100 DEG C and the creeping loading stress is 100MPa. The alloy can be used as a substitute of lead brass in the communication connector industry, and can also be applied to other industries to replace some copper alloy parts.

Owner:NINGBO POWERWAY ALLOY MATERIAL

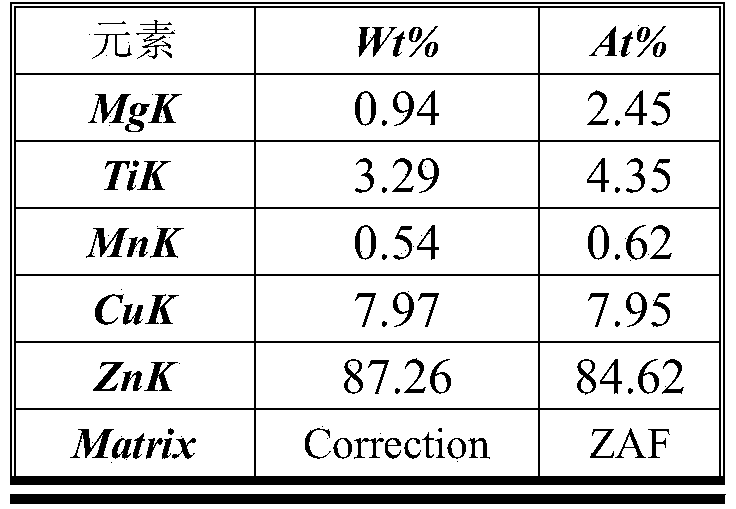

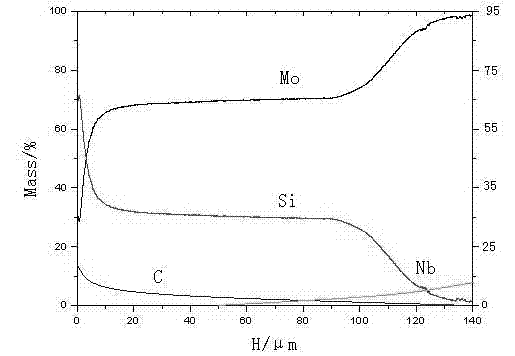

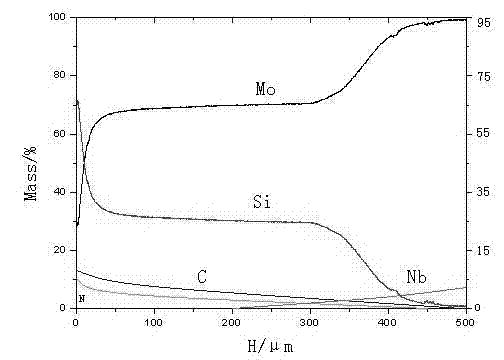

Mo-C-N-Si-Nb gradient coating material and preparation method thereof

InactiveCN102851635AIncrease the speed of diffusionHigh temperature strengthSolid state diffusion coatingCoated surfaceSurface layer

The invention discloses Mo-C-N-Si-Nb gradient coating material and a preparation method thereof. One side or two sides of Mo-Nb alloy are provided with composite coatings. The composite coatings are gradient coatings with Si, C and N content gradually increasing and Mo and Nb content gradually decreasing from inside to outside along the Mo-Nb alloy direction. The gradient coatings are tightly combined with a base. The gradient coatings are high in bending strength. Steady-state creep rate of base material is 3 levels lower than that of pure Mo monocrystal. The surface of the coatings has high silicon content. The surface layers of the coatings are mainly made from, MoSi2, SiC, Si3N4 and Si, the middle layers of the coatings are mainly made from MoSi2, SiC and Si3N4, and transition layers of the coatings are mainly made from Mo5Si3, MoSi3 and a trace of NbSi2. No cryogenic pulverization occurs in low-temperature oxidation experiment at 500 DEG C, and the coatings are high in high-temperature oxidation resistance. The preparation method has the advantages that the formation speed of gradient layers is high, the preparation time is short, and the thickness of the coatings is free to control. The Mo-C-N-Si-Nb gradient coating material has the advantages of compact surface structure, fine high-temperature creep resistance, fine high-temperature oxidation resistance and the like.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

As-cast high pearlite quantity and high vermicular rate vermicular graphite cast iron and preparation method thereof

ActiveCN108624807AEvenly distributedSimple preparation processProcess efficiency improvementCrack resistanceCreep rate

The invention discloses as-cast high pearlite quantity and high vermicular rate vermicular graphite cast iron and a preparation method thereof. The vermicular graphite cast iron is prepared from the following components by weight percent: 3.5-3.8% of C, 2.2-2.4% of Si, 0.8-1% of Mn, 0.2-0.4% of Cu, 0-0.4% of Mo, 0.08-0.1% of Sn, 0.2-0.4% of Cr, 0.2-0.5% of Ni, 0.05-0.1% of Nb, less than or equal to 0.06% of S, less than or equal to 0 .06% of P, and the balance of Fe and impurities introduced by raw materials. The vermicular graphite cast iron with a high creep rate (90-98%) is obtained by using an Mg-RE creeping method for controlling; furthermore, by means of micro-regulation of multiple alloy elements, the vermicular graphite cast iron with a high high pearlite quantity (90%-100%) can bestably obtained; the tensile strength of the vermicular graphite cast iron is greater than or equal to 500MPa, the elongation of the vermicular graphite cast iron is greater than or equal to 1.5%, Brinell hardness of the vermicular graphite cast iron is 230-260HBW, and the microhardness of pearlite is 300-320HV. The vermicular graphite cast iron provided by the invention has the characteristics of being good in mechanical properties, thermal fatigue resistance, thermal crack resistance and wear resistance under the extremely harsh working conditions; the preparation method is simple in control method and can stably produce castings with excellent comprehensive performance, thus being suitable for industrial mass production.

Owner:西安洪盛冶金科技有限公司

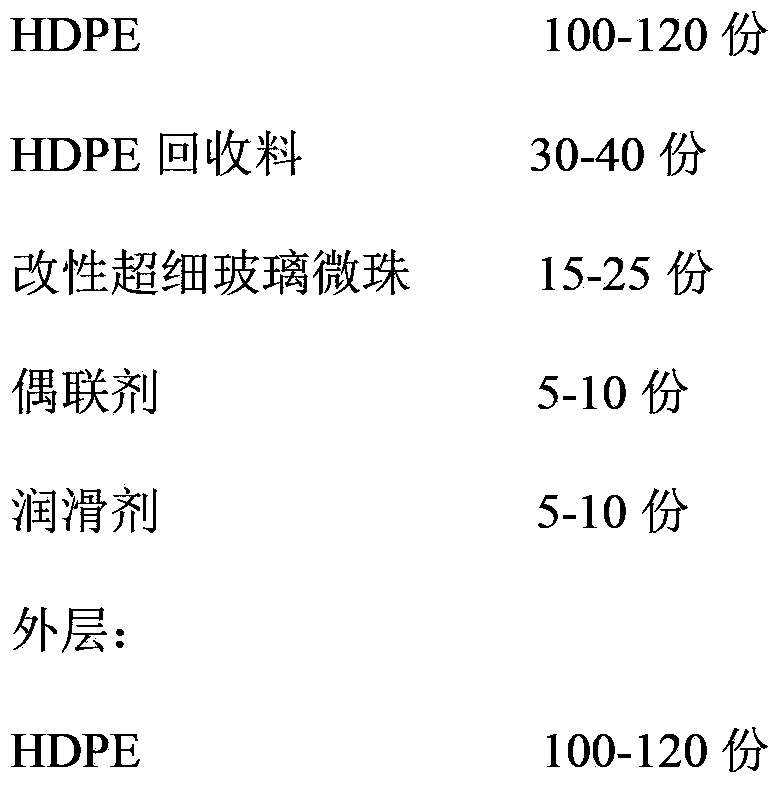

Modified HDPE (High-Density Polyethylene) double-wall corrugated pipe and manufacturing method thereof

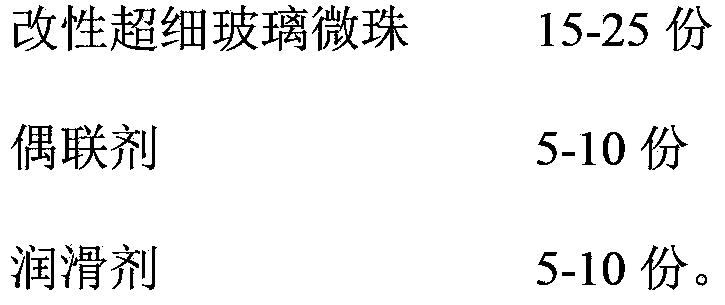

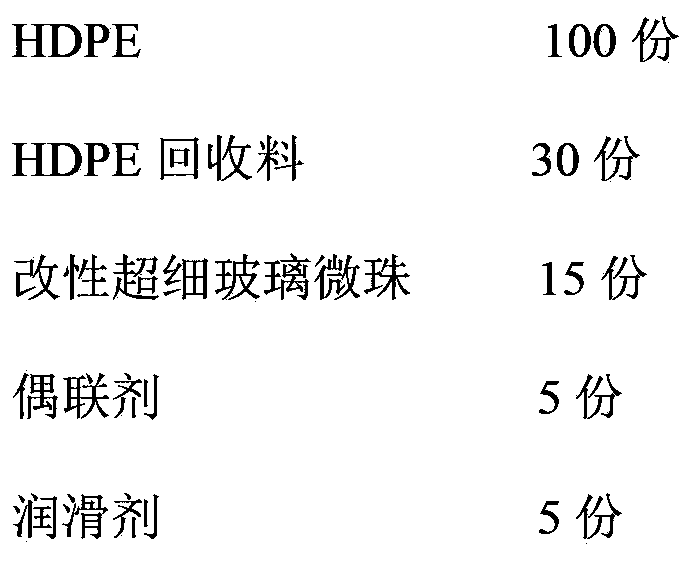

InactiveCN103470866ADoes not affect physical propertiesHigh strengthCable installations in underground tubesRigid pipesLow-density polyethyleneEngineering

The invention discloses a manufacturing material of a modified HDPE (High-Density Polyethylene) double-wall corrugated pipe. The manufacturing material comprises the following components in parts by weight: 100-120 parts of HDPE, 15-25 parts of modified ultrafine glass microbead, 5-10 parts of coupling agent and 5-10 parts of lubricating agent at the outer layer, 100-120 parts of HDPE, 30-40 parts of HDPE recovery material, 15-25 parts of modified ultrafine glass microbead, 5-10 parts of coupling agent and 5-10 parts of lubricating agent at the inner layer. The manufacturing material disclosed by the invention has the beneficial effects that organic modified ultrafine glass microbeads are used as a filler for manufacturing the double-wall corrugated pipe, so that the drop-hammer impact strength and the ring stiffness can be effectively improved, the creep rate of the organic modified ultrafine glass microbeads filled into the HDPE double-wall corrugated pipe is low, and the unit weight can be effectively reduced under the condition of not influencing the physical property of the double-wall corrugated pipe.

Owner:TIANJIN SHENGXIANG PLASTIC PIPE IND

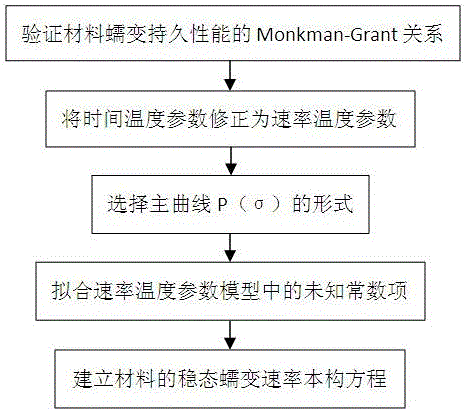

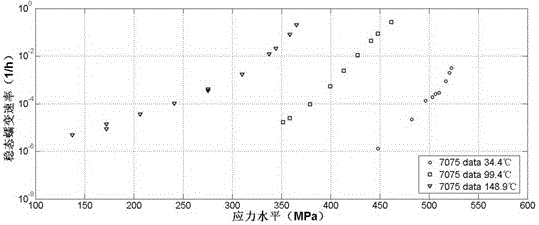

Calculation method for steady creep rate fitting equation of metal material

ActiveCN106446390AImprove applicabilityImprove accuracyDesign optimisation/simulationSpecial data processing applicationsMetallic materialsCreep rate

The invention discloses a calculation method for a steady creep rate fitting equation of a metal material. The method comprises the following steps that 1, a Monkman-Grant relation for the creep durability of the material is verified; 2, a time-temperature parameter is corrected into a rate-temperature parameter; 3, the form of a main curve P(sigma) is selected; 4, fitting is conducted on unknown constant terms in a rate-temperature parameter model; 5, the steady creep rate fitting equation of the material is established. According to the method, the problem that the steady creep rate cannot be calculated through a traditional time-temperature parameter is solved, and application in reliability design and optimization of equipment components is wider; the steady creep rate in the wide experimental condition range can be fitted, influences of creep mechanism changes on the creep rate are reduced, the applicability and the accuracy of the steady creep rate fitting equation of the material are improved, and a universal study and application value is achieved.

Owner:RES INST OF PHYSICAL & CHEM ENG OF NUCLEAR IND

Preparation method of flame-retardant carbon nanotube enhanced ultra-high molecular weight polyethylene fiber

InactiveCN105568421AImprove creep resistanceHigh strengthFlame-proof filament manufactureArtificial filament washing/dryingPentaerythritolCarbon nanotube

The invention discloses a preparation method of a flame-retardant carbon nanotube enhanced ultra-high molecular weight polyethylene fiber. Carbon nanotubes are purified and functionalized firstly, and thus good interface performance between the carbon nanotubes and a polyethylene fiber matrix can be achieved; the carbon nanotubes and a fire retardant are subjected to ultrasonic dispersion so that all additives can be uniformly dispersed into the matrix of the ultra-high molecular weight polyethylene fiber. As the carbon nanotubes are added, the creep resistance, strength and modulus of the ultra-high molecular weight polyethylene fiber are improved; besides, as the compound intumescent flame retardant prepared from ammonium polyphosphate, pentaerythritol, melamine and aluminum hydroxide can achieve a synergism effect together with the carbon nanotubes, the flame-retarding effect of the intumescent flame retardant is further improved. The prepared flame-retardant carbon nanotube enhanced ultra-high molecular weight polyethylene fiber can be applied the fields of protective articles and the like with high flame retardancy requirements and is low in creep rate and suitable for long-term use.

Owner:西安艾菲尔德复合材料科技有限公司

Determining optimal turbine operating temperature based on creep rate data and predicted revenue data

A method of operating a turbine, the method including the steps of: 1) gathering measured creep data for a blade while the turbine operates at different operating temperatures, the measured creep data comprising at least a measured creep rate for the blade (wherein the different operating temperatures include at least a first operating temperature and a second operating temperature); and 2) given the measured creep data for the blade while the turbine operated at the first operating temperature and the measured creep data for the blade while the turbine operated at the second operating temperature, determining whether operating the turbine at the first operating temperature or the second operating temperature is more economically efficient.

Owner:GE INFRASTRUCTURE TECH INT LLC

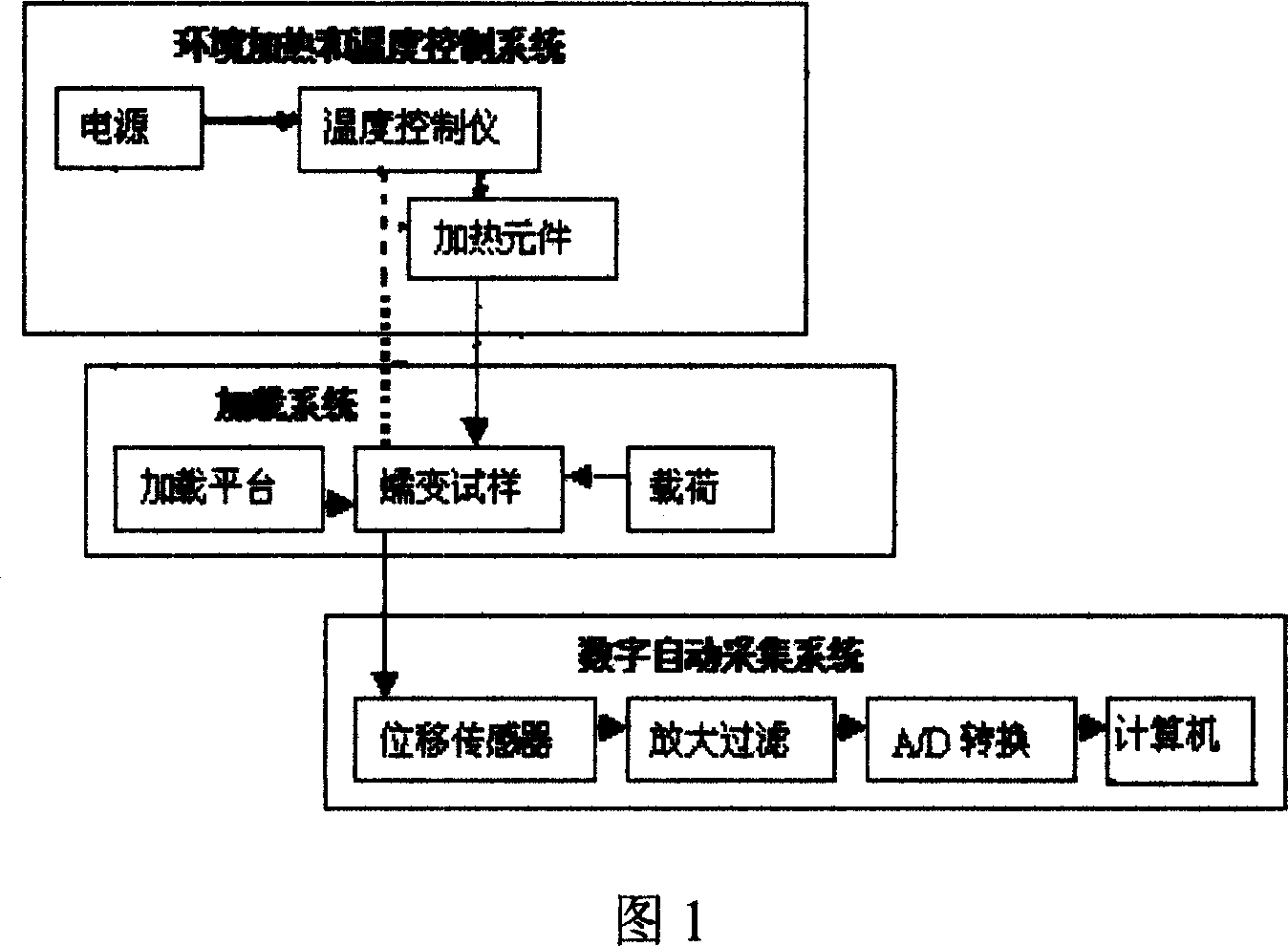

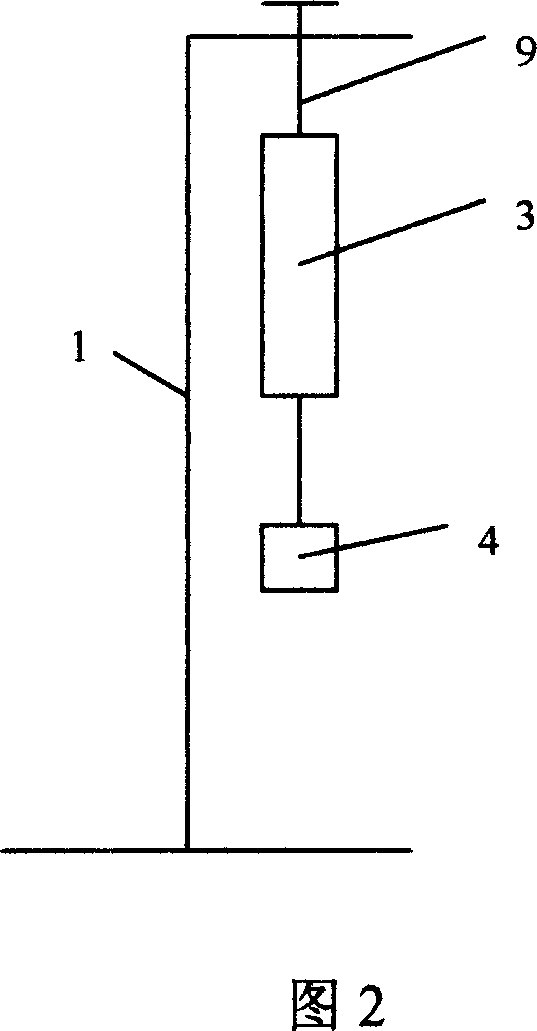

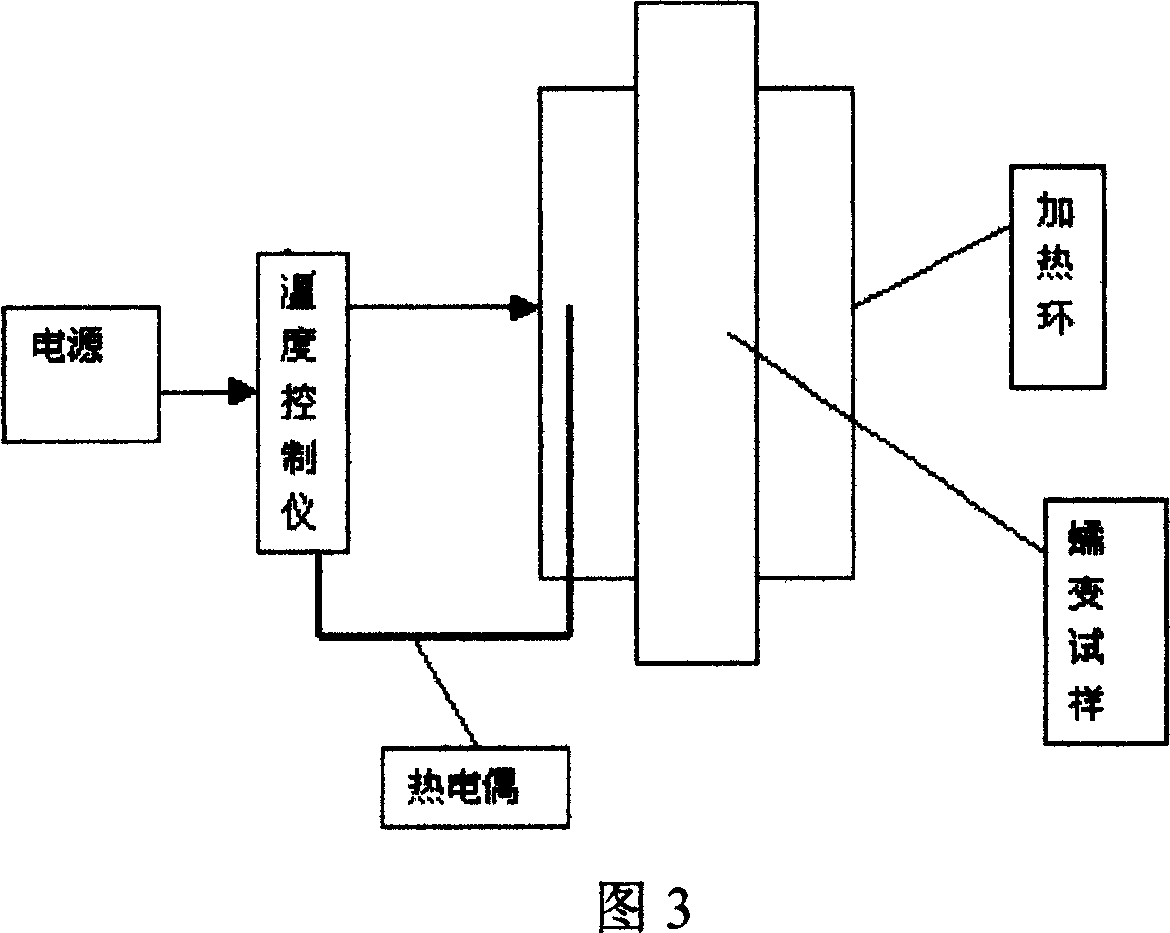

Testing apparatus and method of data auto-acquiring stretching creep deformation

The invention supplies data auto collecting drawing creep measuring device and method. The device includes loading system, environment heating and temperature control system, data auto collecting system. The invention can realize the measuring for various materials high temperature creep performance with different temperature and drawing loading, process auto collecting for the tested material creep performance with litter collecting data error, follows material creep process, connects with computer to directly protract the creep process, and detects the material steady state creep rate in the given experimental condition.

Owner:HENAN UNIV OF SCI & TECH

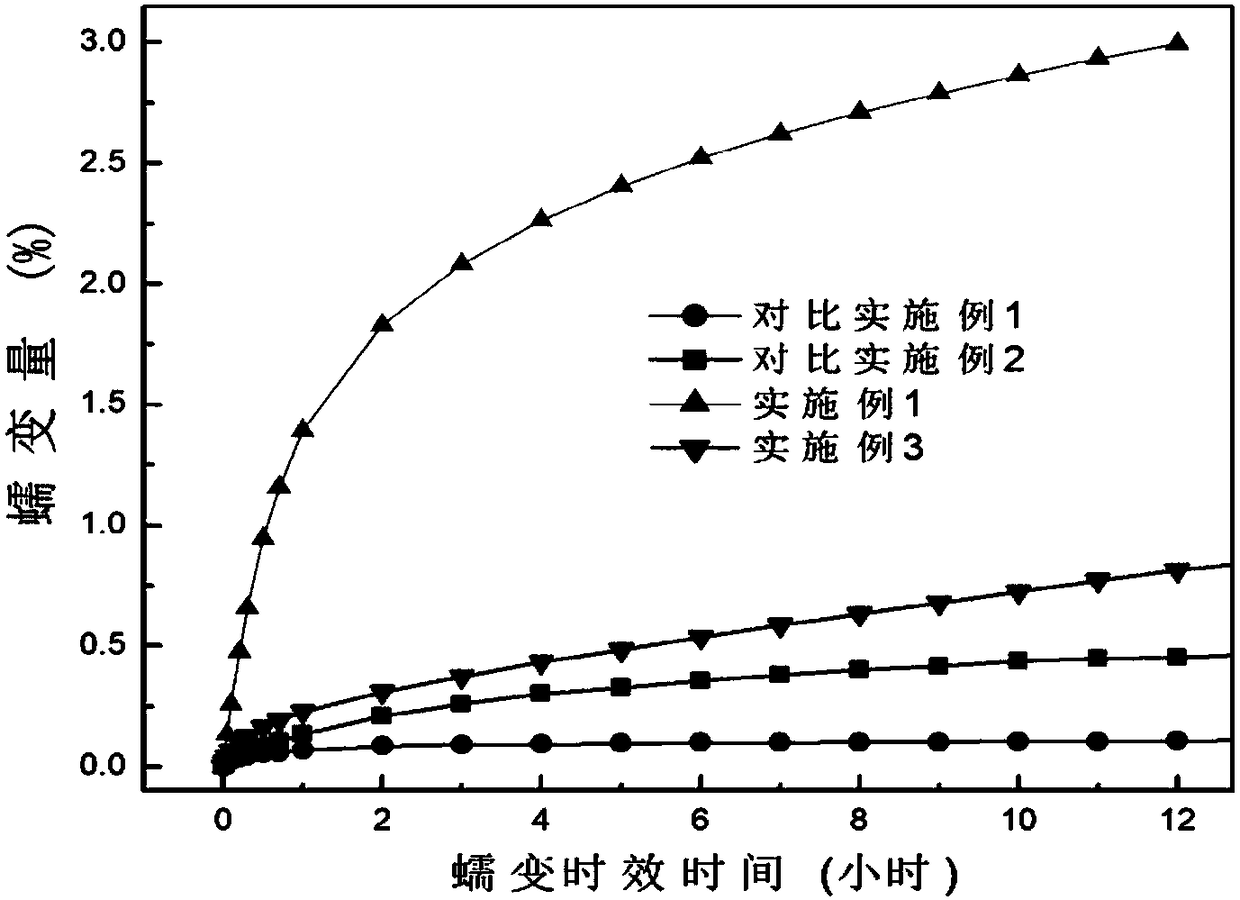

High-efficient creep age forming method for aluminum alloy

The invention relates to a high-efficient creep age forming method for an aluminum alloy. A hot-rolled aluminum alloy panel is subjected to solid solution and is then water-quenched, the quenched panel is placed in the middle and is subjected to cold deformation with the deformation being 20 to 90 percent at the room temperature until the required thickness is obtained, and then creep age formingis carried out. According to the high-efficient creep age forming method for the aluminum alloy provided by the invention, through cold deformation after alloy solid solution-quenching and before creep aging, a large number of dislocation, dislocation configuration and natural aging atom clusters are introduced into the alloy, and a part of dislocation and natural aging atom clusters can be used as a heterogeneous nucleation area of a precipitated phase, so that the precipitation of a main strengthening phase is promoted, the density of the precipitated phase is increased, the dimension is remarkably refined, and the creep rate and a mechanical property of creep aging are finally improve greatly. Through 20 to 90 percent of cold deformation, a large number of movable dislocation is introduced into the alloy, and the alloy creep quantity can be remarkably improved at lower temperature and stress through a creep age forming process, so that the age forming efficiency of the alloy is greatly improved.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com