Clamped straight rod small sample creep testing method and apparatus thereof

A creep test and small sample technology, which is applied to the device for the creep test of the small sample of the clamped straight rod, and the test field that uses the small sample of the clamped straight rod to test the creep performance of the material, which can solve the limitation of promotion Application, complex manufacturing process, difficult analysis of test data, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] Embodiment 1, creep test of fixed straight bar small sample

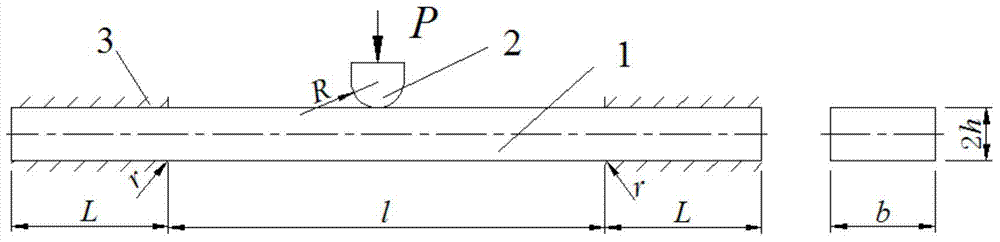

[0078] (1) The test material is aluminum alloy A7N01, and the sample size is: length (2L+l)=19.8mm, width b=1.9mm, thickness 2h=1.0mm.

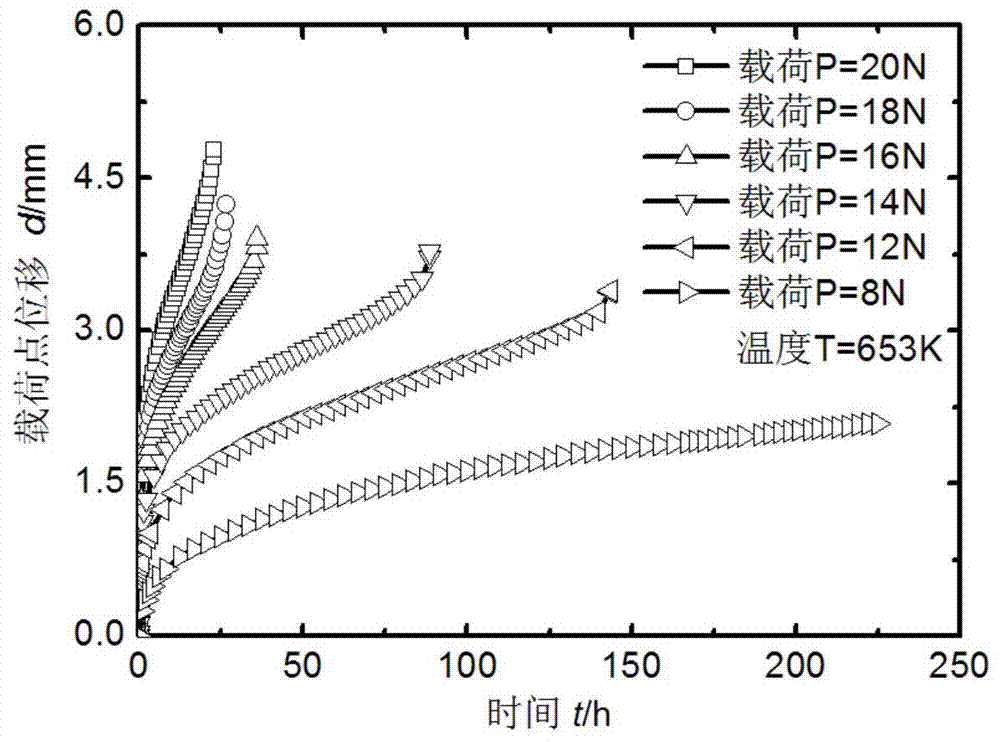

[0079] (2) Refer to the attached figure 1 , during the test, the two ends of the two ends of the straight rod sample 1 are fixed with the upper mold 3 of the fixture, and the fixed distance L is 3.9mm. The lower end of the semi-cylindrical indenter 2 compresses the middle area of the straight rod small sample 1 . Creep tests with 6 sets of loads were carried out at a temperature of 653K. The test time is shown in Table 1. The obtained displacement-time curve results are as follows figure 2 shown.

[0080] Table 1 A7N01 aluminum alloy straight bar small sample creep test time

[0081]

[0082] (3) Creep displacement rate of construction materials - time t-curve.

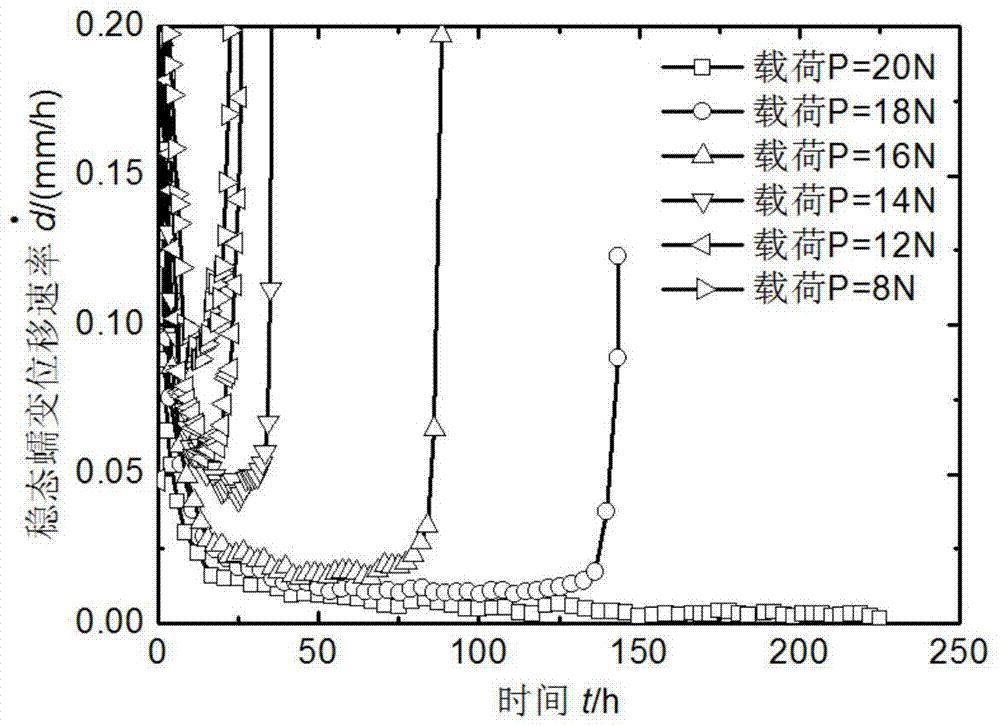

[0083] right figure 2 Doing differentiation, we get image 3 The material creep displacement rate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com