Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

93 results about "Creep strain" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In materials testing: Creep test …a period of time (creep strain) under constant load is measured, usually with an extensometer or strain gauge. In the same test, time to failure is also measured against level of stress; the resulting curve is called stress rupture or creep rupture.

Material high-temperature creep life-span accelerated test method

InactiveCN101308127AAccelerated Creep DesignMethod scienceSpecial data processing applicationsStrength propertiesRelaxation equationCreep rate

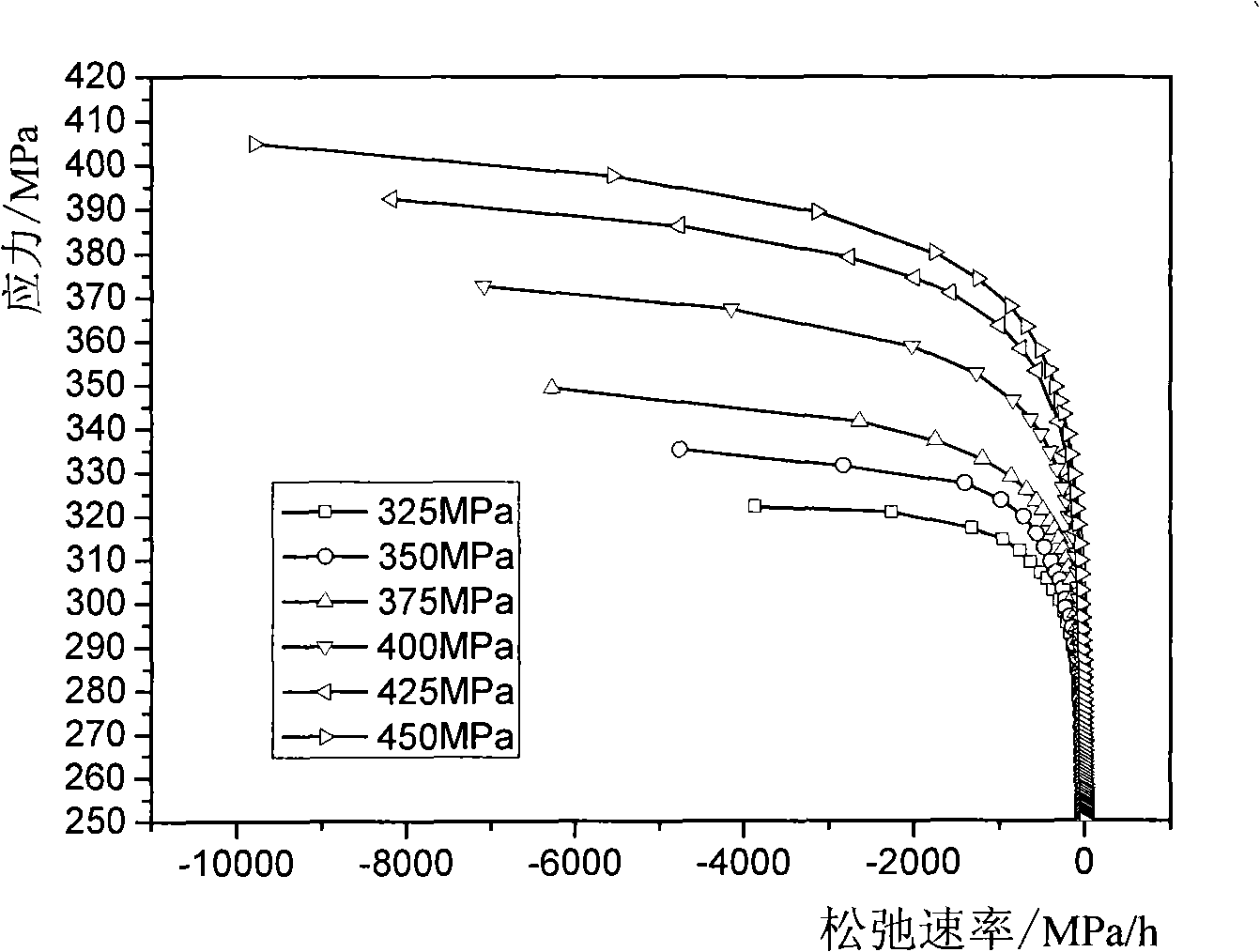

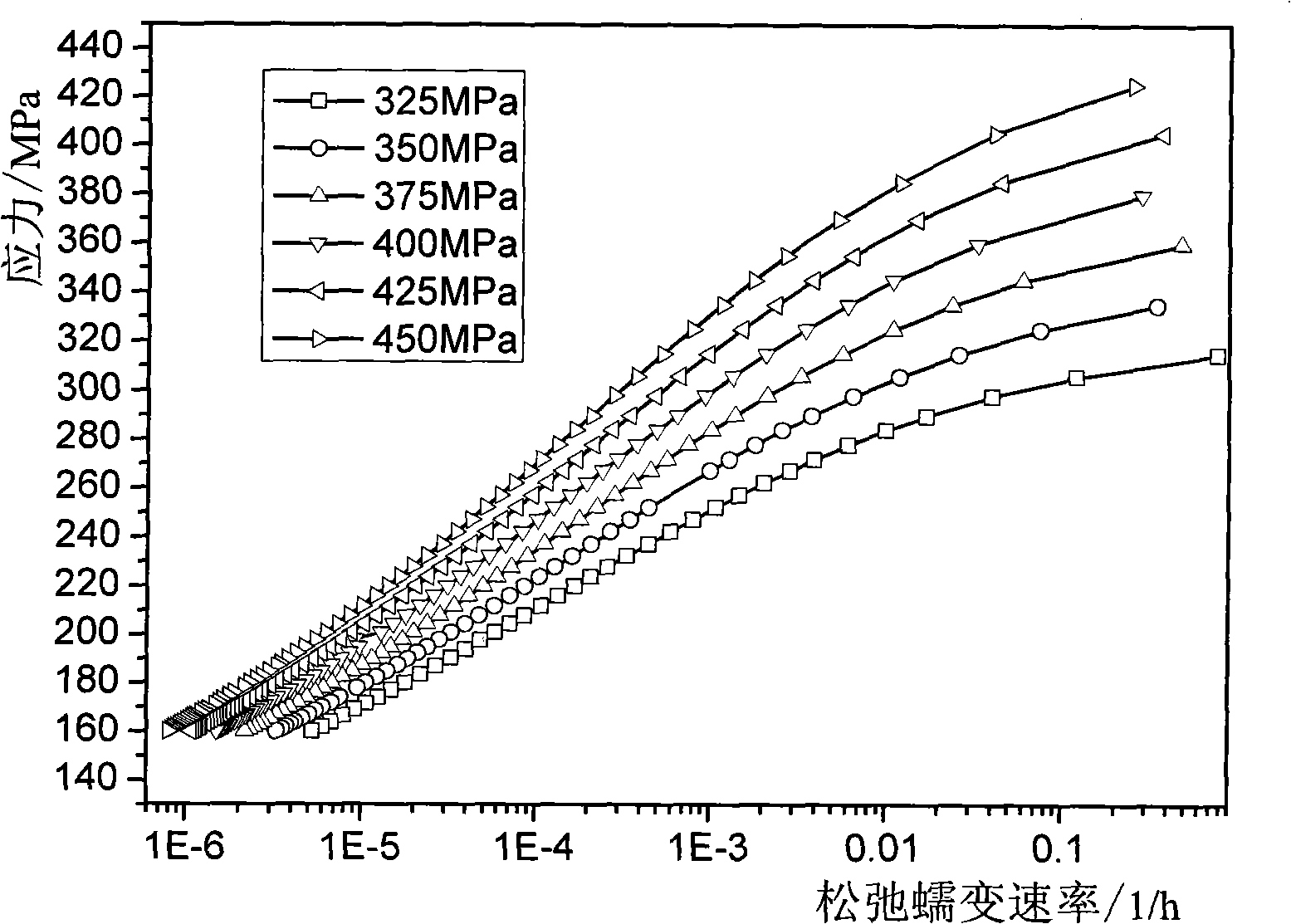

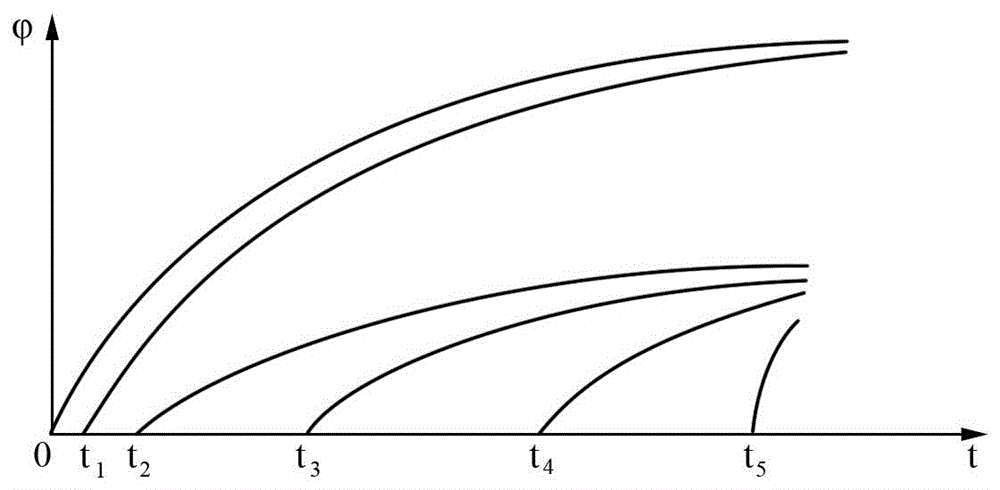

The invention relates to a high temperature creep life accelerated test method of a material, which comprises: a plurality of groups of short time stress relaxation tests of the material at the same temperature, acquiring a relaxation rate-stress curve based on the numerical differentiation principle, forming a relaxation creep rate-stress curve by utilizing a relaxation equation, calculating creep data to build a creep curve, and building a steady state creep rate curve and a Norton creep equation. The method starts from the physical relation between relaxation and creep, covers rather broad properties of creep strain rate by utilizing the short time relaxation process, and educes broader creep data than that educed from general creep tests by above ten times, thereby effectively reducing the amount of high temperature creep tests and time of tests and providing basic data for development of new material and engineering application.

Owner:EAST CHINA UNIV OF SCI & TECH

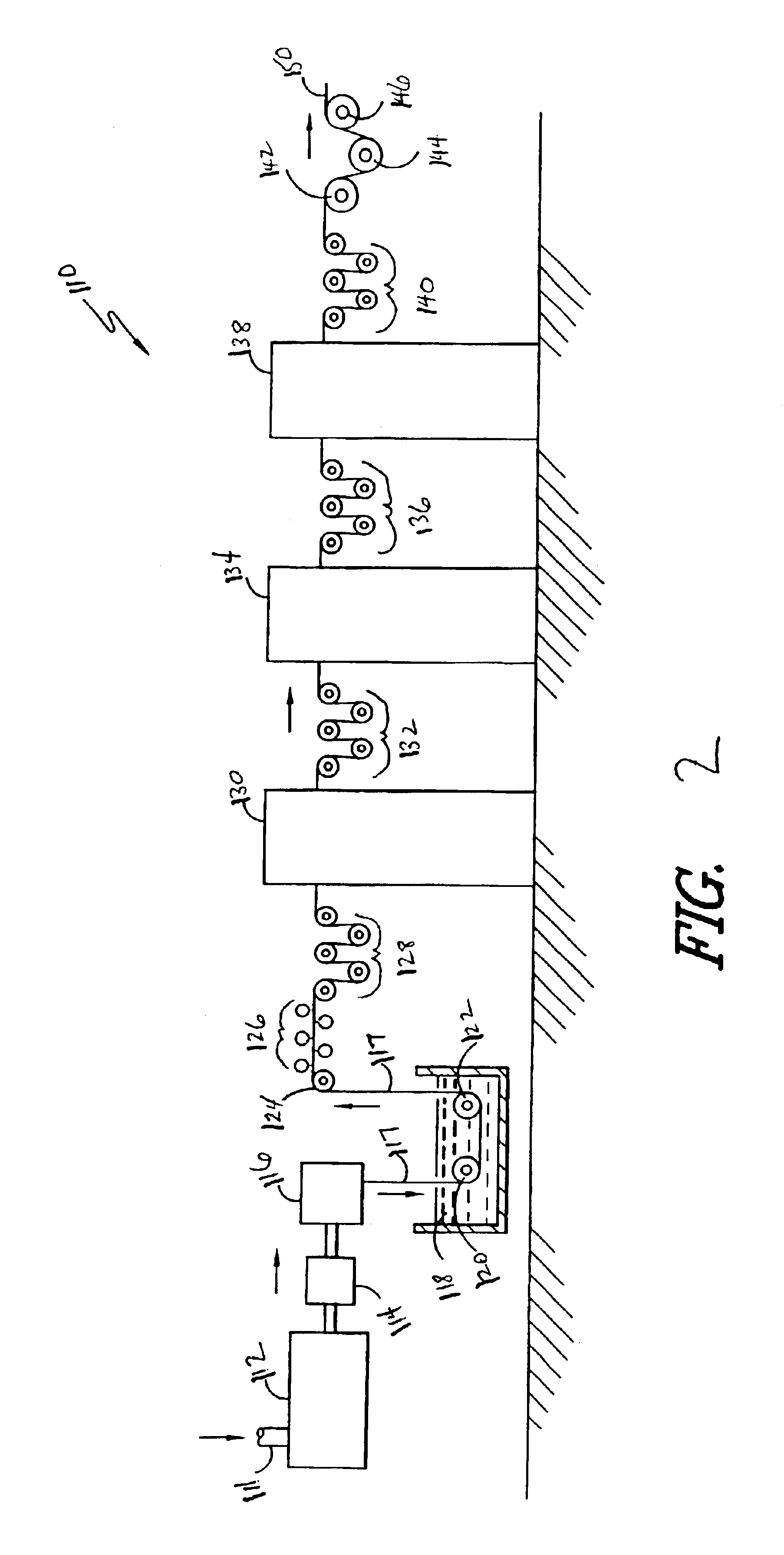

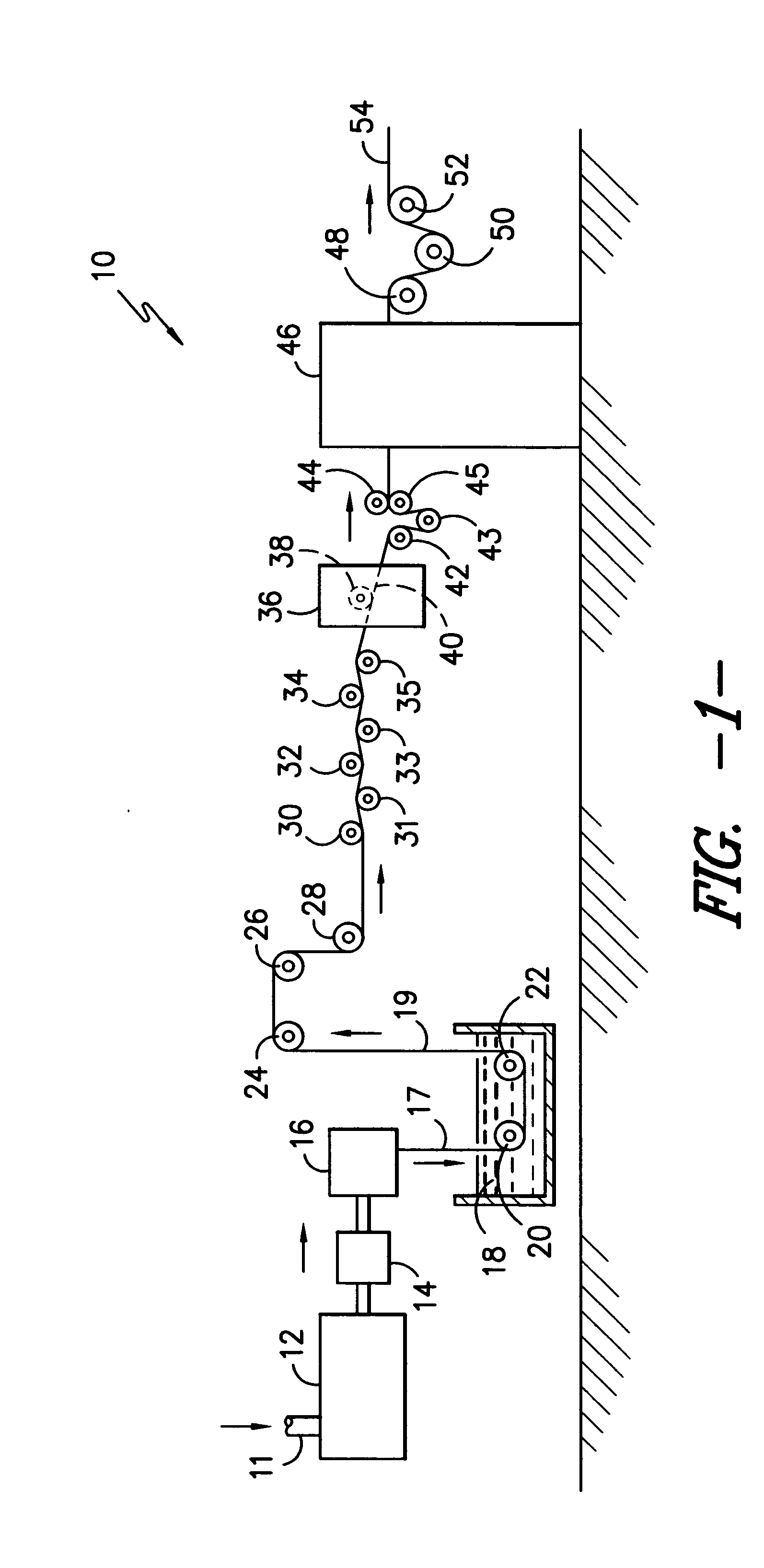

Polypropylene monofilament and tape fibers exhibiting certain creep-strain characteristics and corresponding crystalline configurations

InactiveUS6863976B2High tensile strengthLow shrinkageSynthetic resin layered productsFilament/thread formingYarnThermoplastic

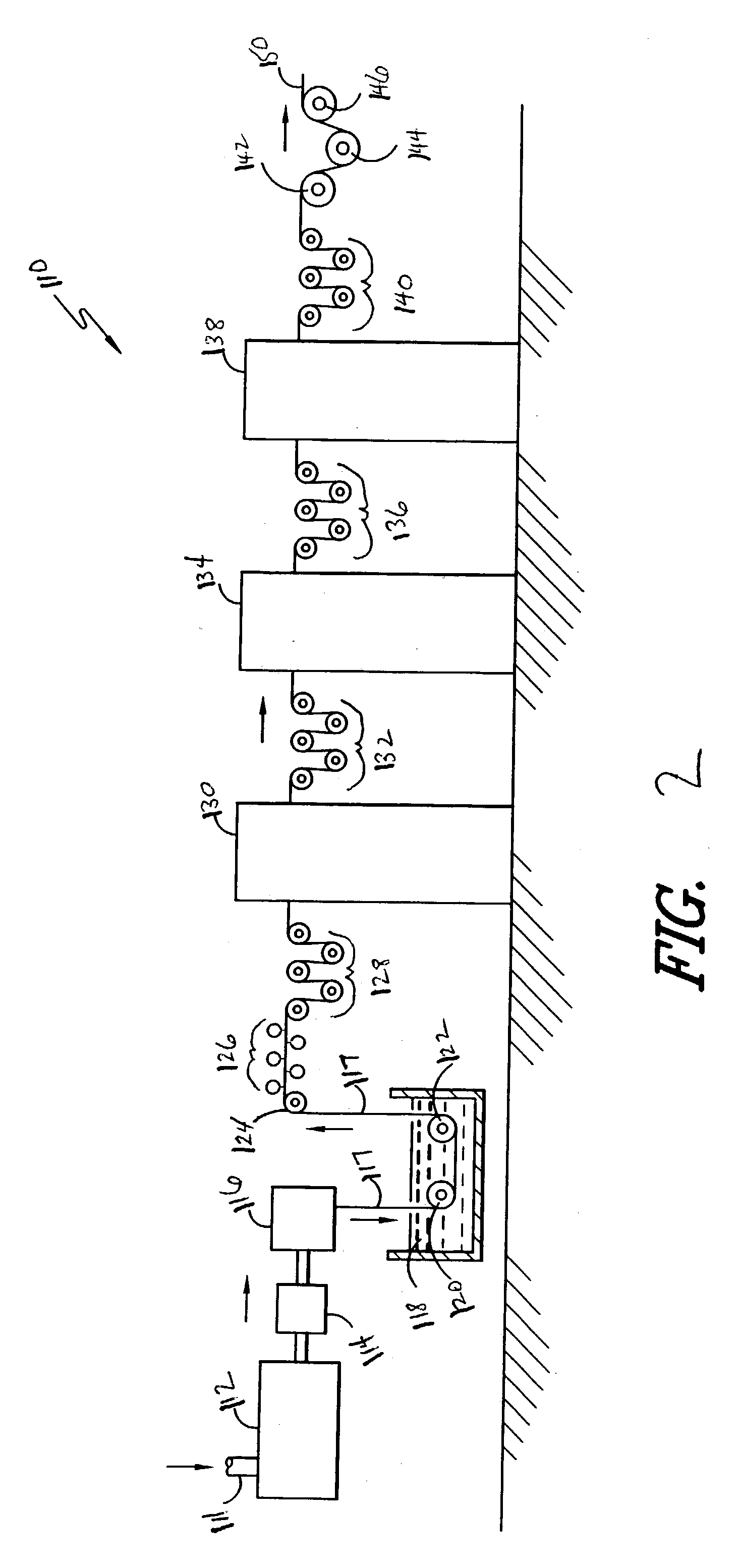

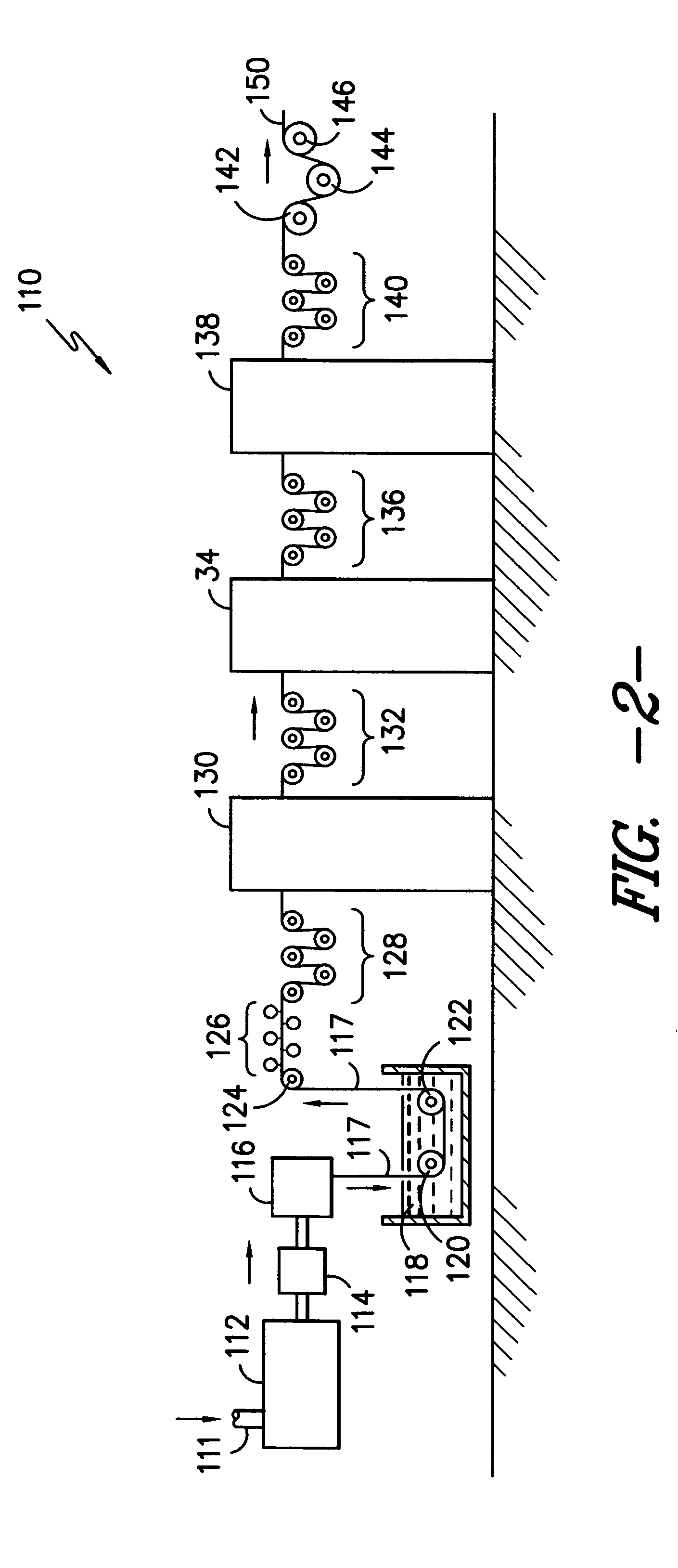

Unique thermoplastic (polypropylene, specifically) monofilament and / or tape fibers and yarns that exhibit heretofore unattained physical properties are provided. Such fibers are basically manufactured through the extrusion of thermoplastic resins that include a certain class of nucleating agent therein, and are able to be drawn at high ratios with such nucleating agents present, that the tenacity and modulus strength are much higher than other previously produced thermoplastic fibers (particularly those produced under commercial conditions), particularly those that also simultaneously exhibit extremely low shrinkage rates. Thus, such fibers require the presence of certain compounds that quickly and effectively provide rigidity to the target thermoplastic (for example, polypropylene), particularly after heat-setting. Generally, these compounds include any structure that nucleates polymer crystals within the target thermoplastic after exposure to sufficient heat to melt the initial pelletized polymer and allowing such an oriented polymer to cool. The compounds must nucleate polymer crystals at a higher temperature than the target thermoplastic without the nucleating agent during cooling. In such a manner, the “rigidifying” nucleator compounds provide nucleation sites for thermoplastic crystal growth. The preferred “rigidifying” compounds include dibenzylidene sorbitol based compounds, as well as less preferred compounds, such as [2.2.1]heptane-bicyclodicarboxylic acid, otherwise known as HPN-68, sodium benzoate, talc, certain sodium and lithium phosphate salts [such as sodium 2,2′-methylene-bis-(4,6-di-tert-butylphenyl)phosphate, otherwise known as NA-11]. Specific methods of manufacture of such inventive thermoplastic fibers, as well as fabric articles made therefrom, are also encompassed within this invention.

Owner:MILLIKEN & CO

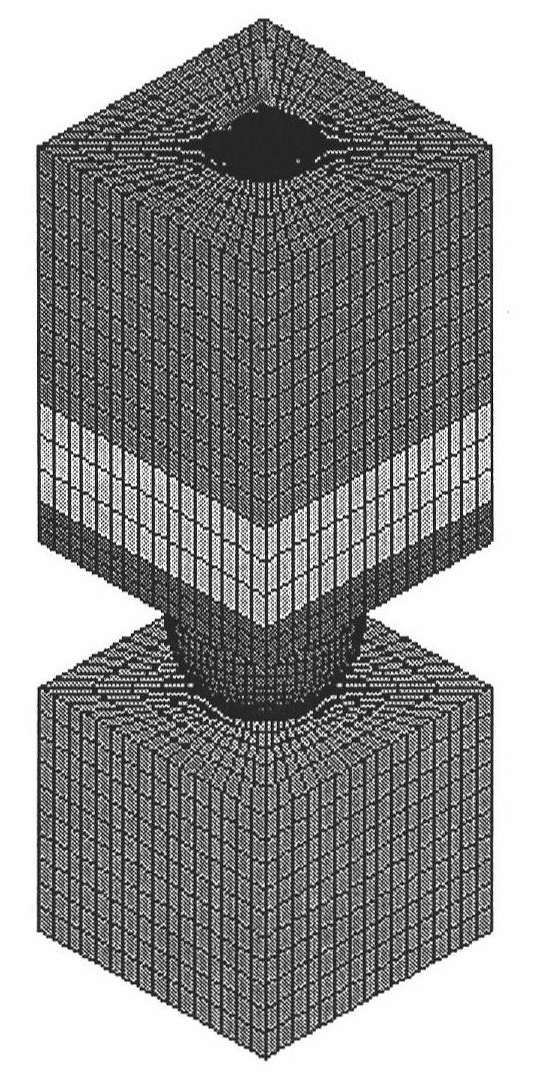

Method for predicting fatigue life of lead-free solder joint in electronic packaging

InactiveCN101984442AHigh precisionImprove reliabilitySpecial data processing applicationsElement modelPredictive methods

The invention discloses a method for predicting the fatigue life of a lead-free solder joint in electronic packaging, which belongs to the technology of materials science and engineering application. How to effectively predict the service life of the lead-free solder joints of an electronic packaging structure attracts great attention of enterprises. The method for predicting the fatigue life of the lead-free solder joint in electronic packaging comprises the following steps: (1) obtaining the performance parameter of the material of each part of an electronic packaging device, and determining a constitutive model of the solder joint; (2) establishing a three-dimensional finite element model according to the researched structure of the electronic packaging device, and adding boundary conditions and corresponding loads according to the actual service conditions to perform value analogue analysis; and (3) analyzing the solder joint reliability and predicting the service life. The invention has the advantages of reasonably considering the coupling effect of plastic strain and creep strain generated by the same mechanism, thus greatly improving the precision and reliability of the service life prediction result, while ensuring simple prediction method and shortening the product development period.

Owner:BEIJING UNIV OF TECH

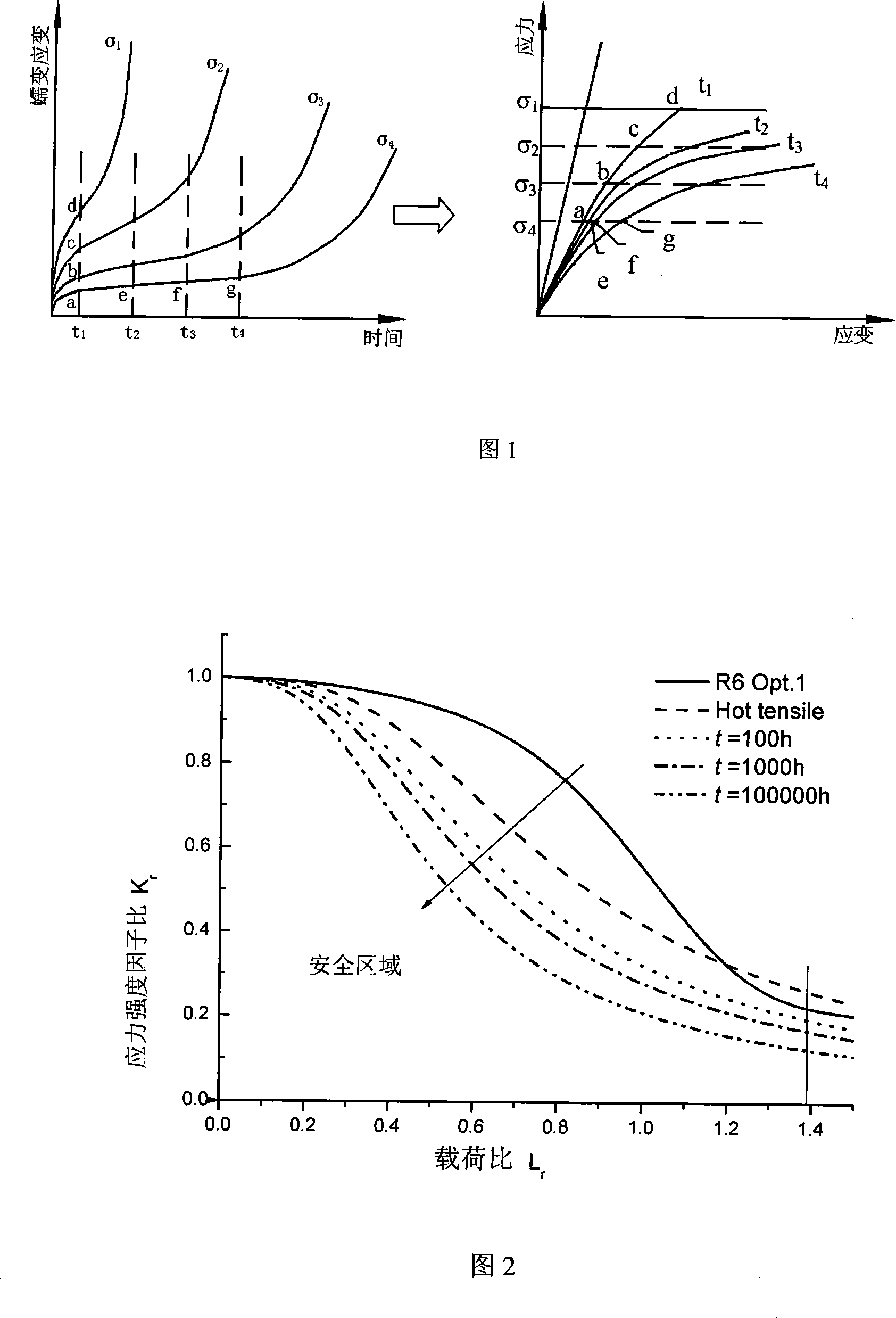

Safety evaluation method of high-temperature production facility or component defect

InactiveCN101178590AReasonable reflectionLow professional knowledge requirementProgramme controlComputer controlFailure assessmentCreep strain

The invention discloses a safety evaluation method for the shortcomings of a high temperature production device or part, comprising the steps as follows: a creep strain-time curve of the material of the high temperature production device or part at a particular temperature is obtained, and an isochronous stress-strain curve corresponding to the particular time is established based on the creep strain-time curve; a failure assessment curve chart related to time is established; and a parameter Kr which can determine and reflect the cracking failure degree of the part and a parameter Lr which can determine and reflect the ultimate load failure degree of the part are counted; and finally the parameters(Kr and Lr) are put into the failure assessment chart as state points for comparing so as to determine the failure assessment point and judge the safety of the failure assessment point. The method can be used for analyzing the safety of the shortcomings during the production process and the use process of the high temperature production device or part, thereby avoiding unnecessary maintenance and premium, and further increasing the rationality of making maintenance plans for high temperature production devices.

Owner:EAST CHINA UNIV OF SCI & TECH

Polypropylene monofilament and tape fibers exhibiting certain creep-strain characteristics and corresponding crystalline configurations

Unique thermoplastic (polypropylene, specifically) monofilament and / or tape fibers and yarns that exhibit heretofore unattained physical properties are provided. Such fibers are basically manufactured through the extrusion of thermoplastic resins that include a certain class of nucleating agent therein, and are able to be drawn at high ratios with such nucleating agents present, that the tenacity and modulus strength are much higher than other previously produced thermoplastic fibers (particularly those produced under commercial conditions), particularly those that also simultaneously exhibit extremely low shrinkage rates. Thus, such fibers require the presence of certain compounds that quickly and effectively provide rigidity to the target thermoplastic (for example, polypropylene), particularly after heat-setting. Generally, these compounds include any structure that nucleates polymer crystals within the target thermoplastic after exposure to sufficient heat to melt the initial pelletized polymer and allowing such an oriented polymer to cool. The compounds must nucleate polymer crystals at a higher temperature than the target thermoplastic without the nucleating agent during cooling. In such a manner, the "rigidifying" nucleator compounds provide nucleation sites for thermoplastic crystal growth. The preferred "rigidifying" compounds include dibenzylidene sorbitol based compounds, as well as less preferred compounds, such as [2.2.1]heptane-bicyclodicarboxylic acid, otherwise known as HPN-68, sodium benzoate, talc, certain sodium and lithium phosphate salts [such as sodium 2,2'-methylene-bis-(4,6-di-tert-butylphenyl)phosphate, otherwise known as NA-11]. Specific methods of manufacture of such inventive thermoplastic fibers, as well as fabric articles made therefrom, are also encompassed within this invention.

Owner:MILLIKEN & CO

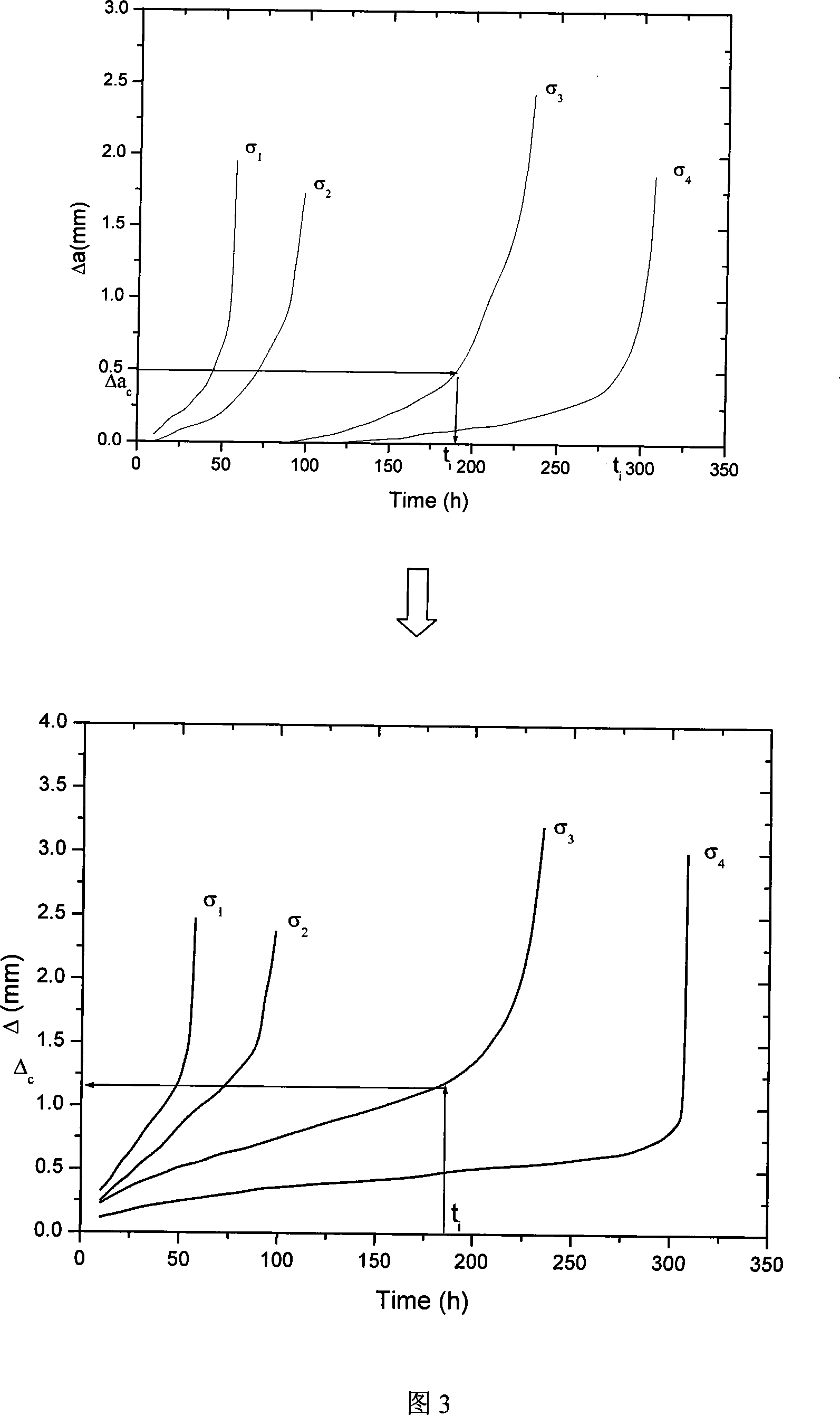

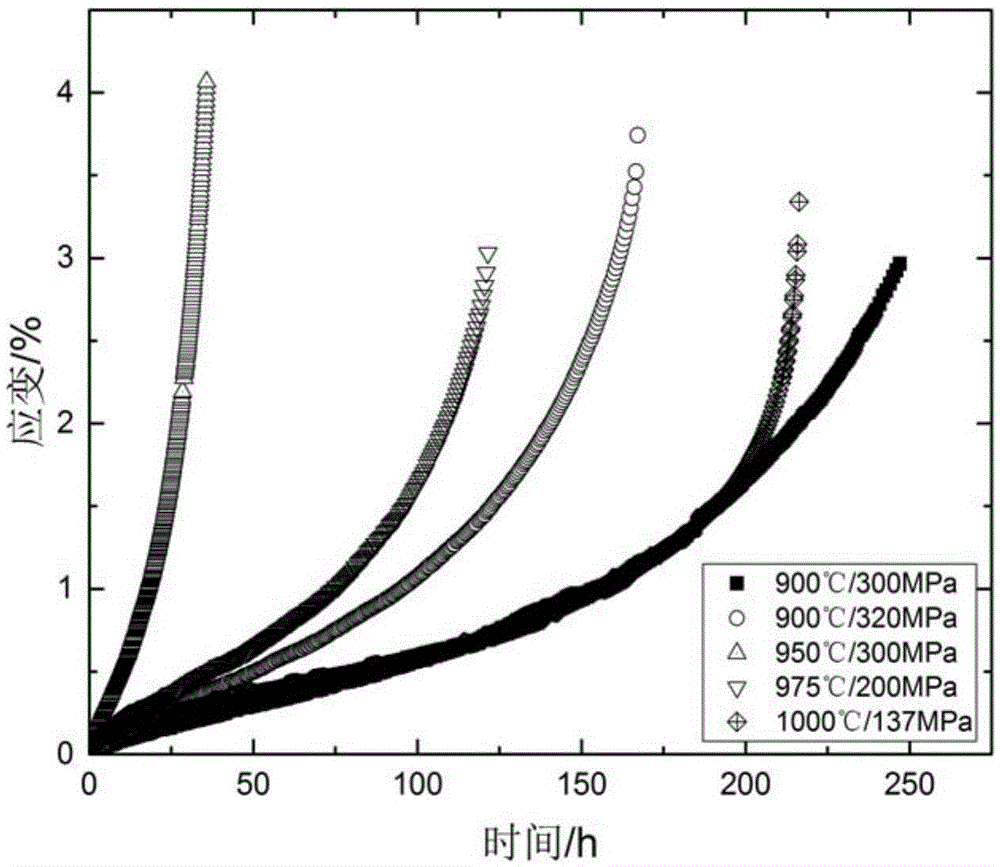

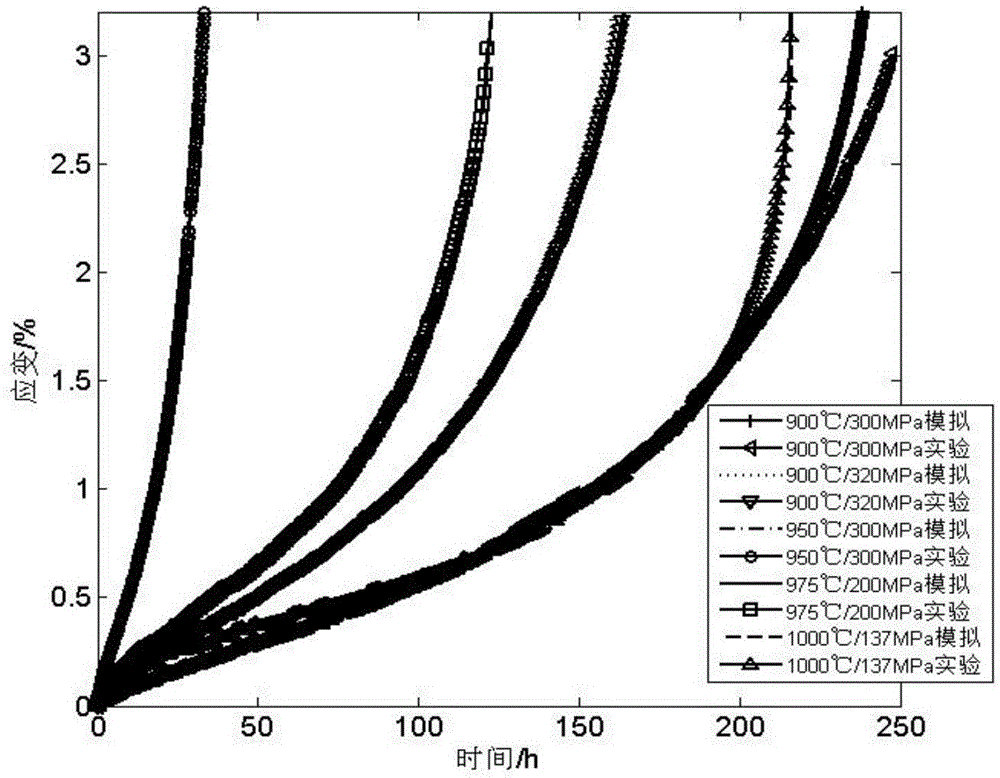

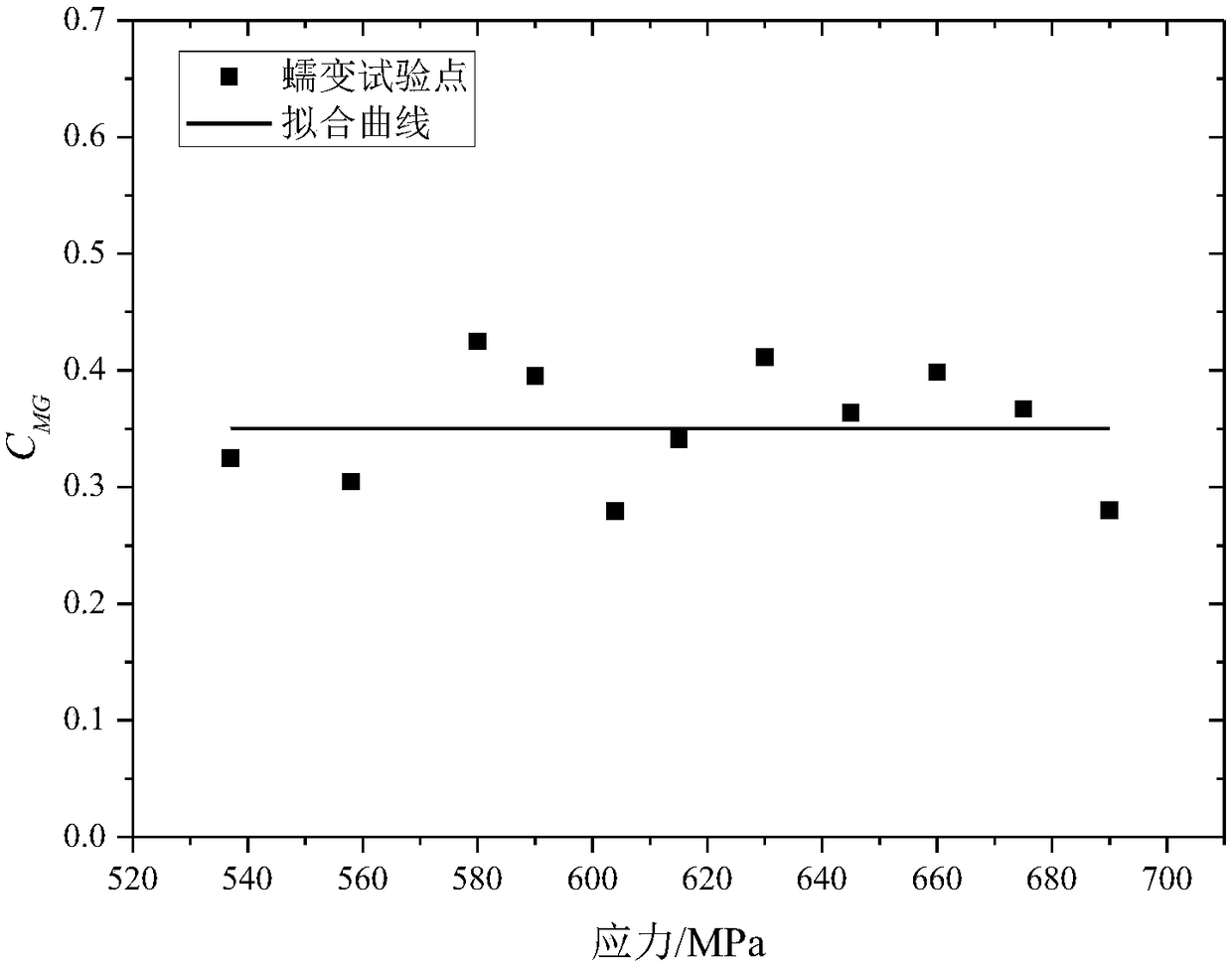

Method for forecasting high-temperature-alloy creep life

ActiveCN105628511AImprove forecast accuracyEstimated time of serviceMaterial strength using tensile/compressive forcesCreep strainPredictive methods

The invention provides a method for forecasting the high-temperature-alloy creep life. The method includes the steps that on the basis of the theta projection method, the factor that changes of true stress are caused by changes of the material shape in the creep process is introduced, the correction theta projection method is obtained, and the concrete form is epsilon= theta1*(1-exp(theta2*(1+theta5*epsilon)*t))+theta3*(exp(theta4*(1+theta5*epsilon)*t)-1). The method can be used for forecasting a creep curve at the whole homogeneous deformation stage through initial data from the first stage to the third stage of the creep curve, and the obtaining time of creep data can be shortened. Meanwhile, the method can be used for forecasting creep curves under other creep conditions, and the forecasting process comprises forecasting of the creep rupture time under the some creep condition and the creep interruption time corresponding to some creep strain. The method is simple, reliable and suitable for different-type high temperature alloy and engineering application, and has broad prospects in the aspect of high-temperature-alloy creep life management.

Owner:UNIV OF SCI & TECH BEIJING

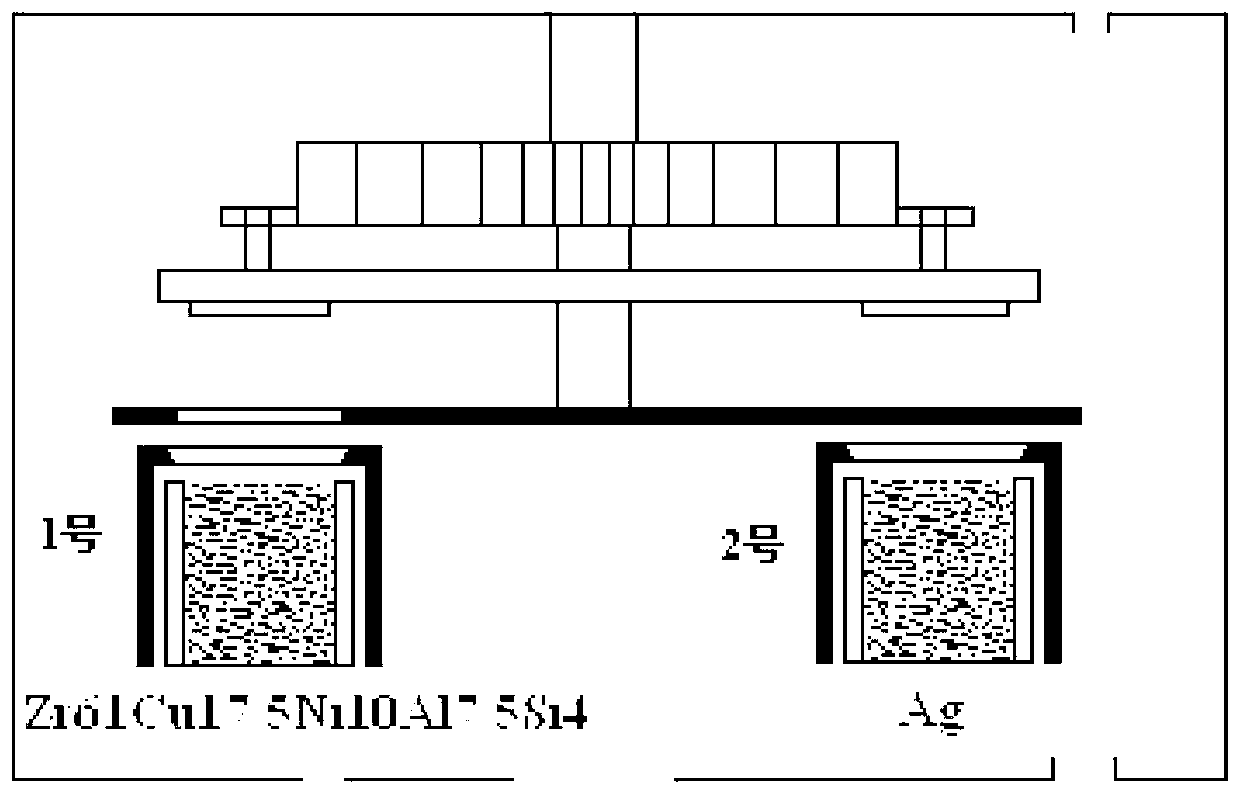

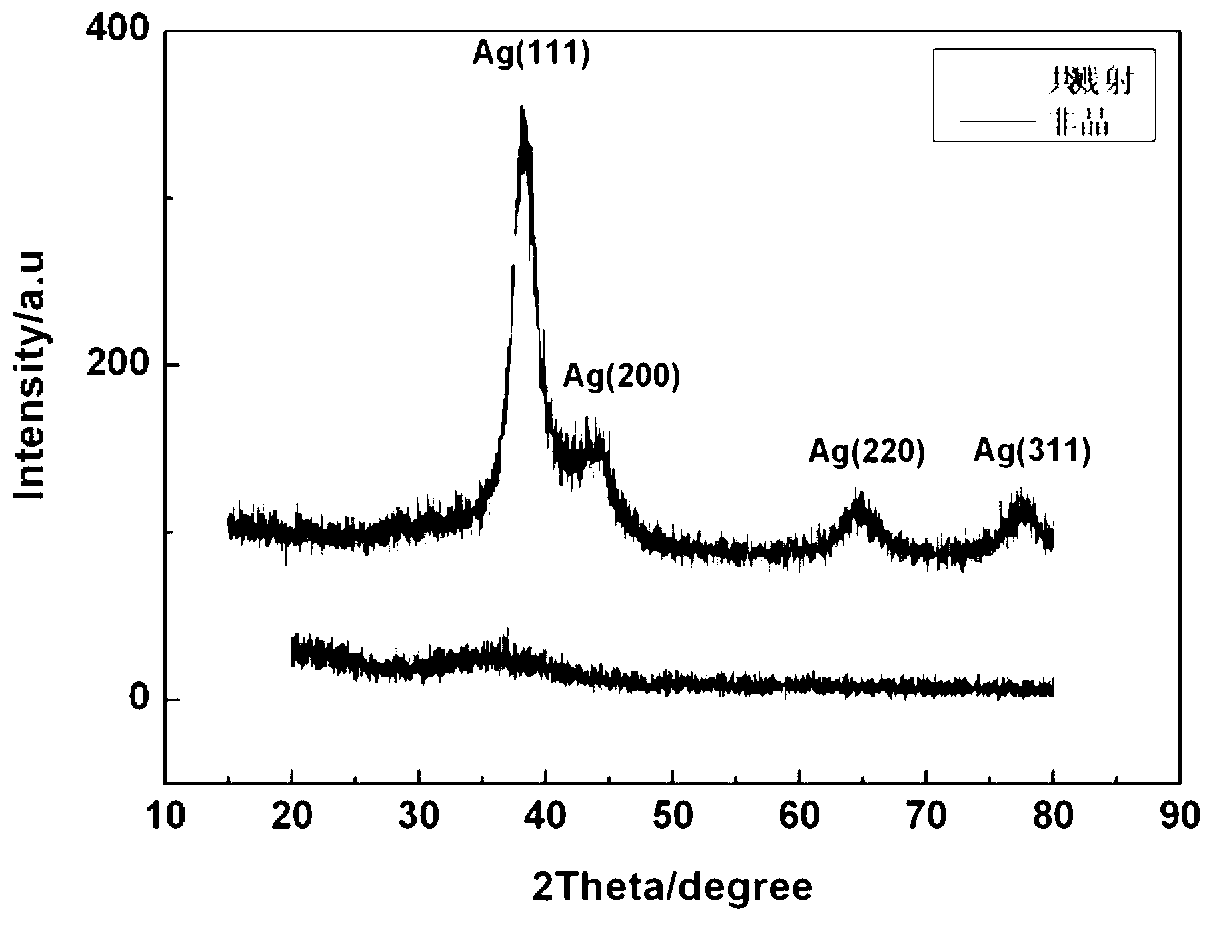

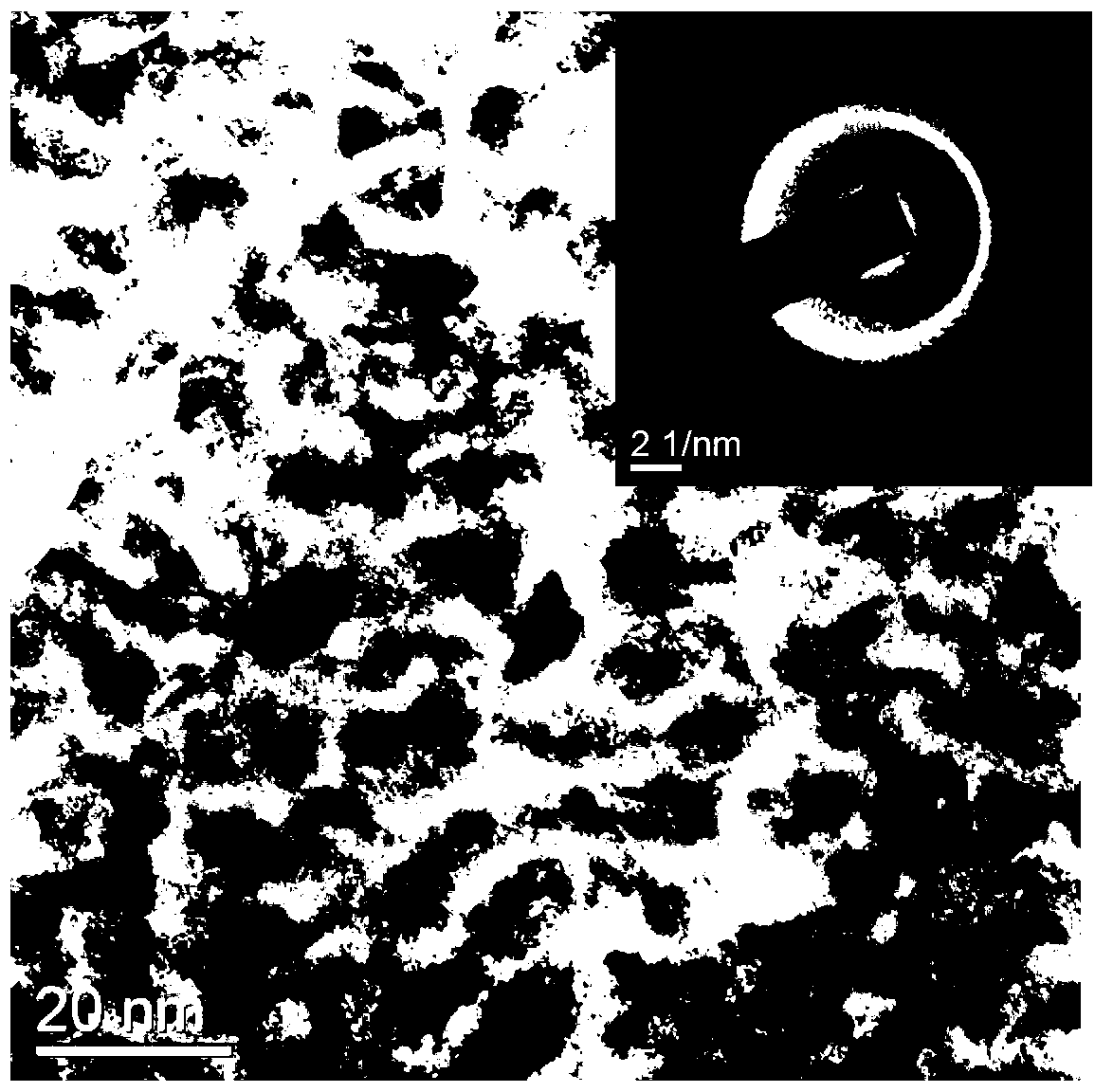

Method for preparing noncrystalline-nanocrystalline composite membrane by adopting co-sputtering method

InactiveCN103215555AAvoid secondary processingEasy to controlVacuum evaporation coatingSputtering coatingSputteringCreep strain

The invention discloses a method for preparing a noncrystalline-nanocrystalline composite membrane by adopting a co-sputtering method, wherein a mixture thin membrane with a noncrystalline phase and a crystalline phase coexisting is prepared by means of implementing double-target magnetron sputtering on a matrix and simultaneously depositing the noncrystalline phase and a nanocrystalline phase. The noncrystalline co-sputtered membrane prepared by the method has a high creep strain rate sensitive value, an excellent mechanical property and uniform plastic deformation. By virtue of the method which is simple and feasible, the noncrystalline mixture thin membrane with the noncrystalline phase and the crystalline phase coexisting is prepared. The thin membrane can be widely applied to the fields of protective coating, functional coating and the like of various precise instruments such as micro electro mechanical systems (MEMS) and nanometer electro mechanical systems (NEMS).

Owner:昆山昊盛泰纳米科技有限公司

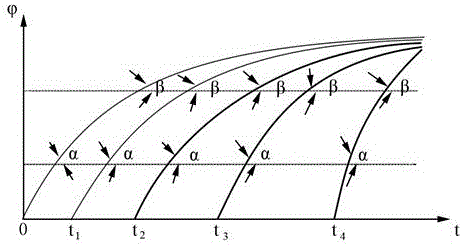

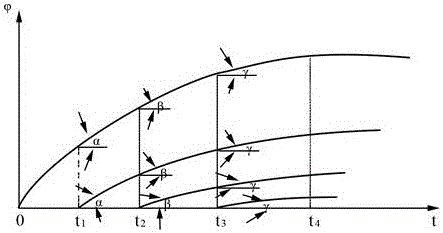

Concrete creep strain calculation method

InactiveCN106650098ASimple calculationGuaranteed accuracyGeometric CADDesign optimisation/simulationBridge engineeringCreep strain

The invention relates to the technical field of bridge engineering, in particular to a concrete creep strain calculation method. The method comprises the following steps that 1, a creep coefficient phi(t, tau0) of concrete from the moment tau 0 loaded to the moment t and an elasticity modulus E(t, tau 0) are calculated; 2, an elasticity modulus E(t, tau 0) of concrete from the moment tau 0 loaded to the moment t is calculated; 3, according to the steps 1 and 2, a concrete creep strain calculation equation is obtained, and the equation is applied for calculating concrete creep strain, the calculation equation is shown in the description, the elasticity modulus E(t, tau 0) is obtained according to an aging coefficient, the elasticity modulus E(t, tau 0) is an effective modulus adjusted according to ages, and the expression is shown in the description. According to the method, the modulus is reduced, deformation modulus caused by concrete creep is achieved, strain changing along with time can be applied to concrete in one step, and therefore the problem that an effective modulus method overstates creep strain caused by stress increment obtained after loading is performed for the first time is solved.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

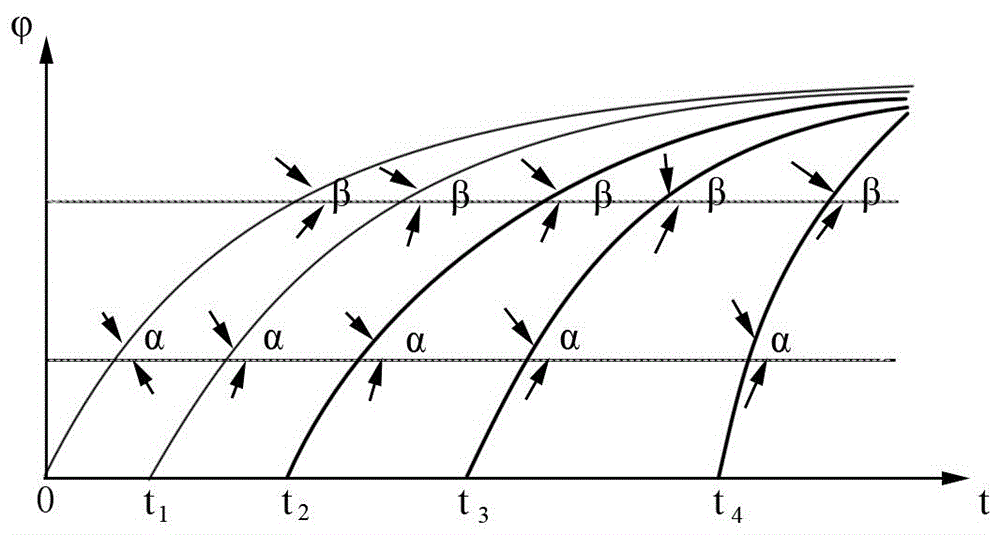

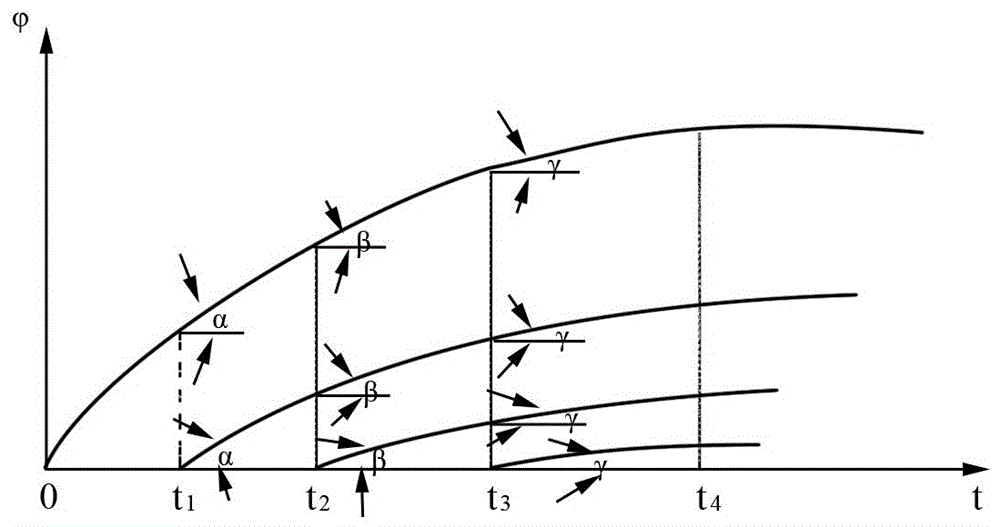

Creep damage calculation method and model under variable load history

ActiveCN109142083AMaterial strength using tensile/compressive forcesSpecial data processing applicationsCreep strainComputational model

The invention discloses a creep damage calculation method and model under variable load history. The method includes: acquiring the creep strain-time curve, minimum creep rate epsilon<c>m, fracture creep strain epsilon<c>f and fracture life tf of a material under different temperature and stress according to a uniaxial creep test; selecting a creep constitutive equation, and using uniaxial creep test fitting to obtain the creep constitutive parameters of the material; acquiring parameters A and B according to two simple two-stage variable load creep test data fitting; recording deformation increment generated by each stage of load according to the multi-stage variable load creep test of the material; calculating creep damaged generated of the n-1 stage before the multi-stage variable loadcreep test of the material; according to the variable load creep damage calculation model, if the acting time of the nth-stage load is known, predicting the deformation of the material under the nth-stage load, and if the nth-stage load is loaded until fracture occurs, predicting the acting time of the nth-stage load. The method can precisely consider the loading history.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

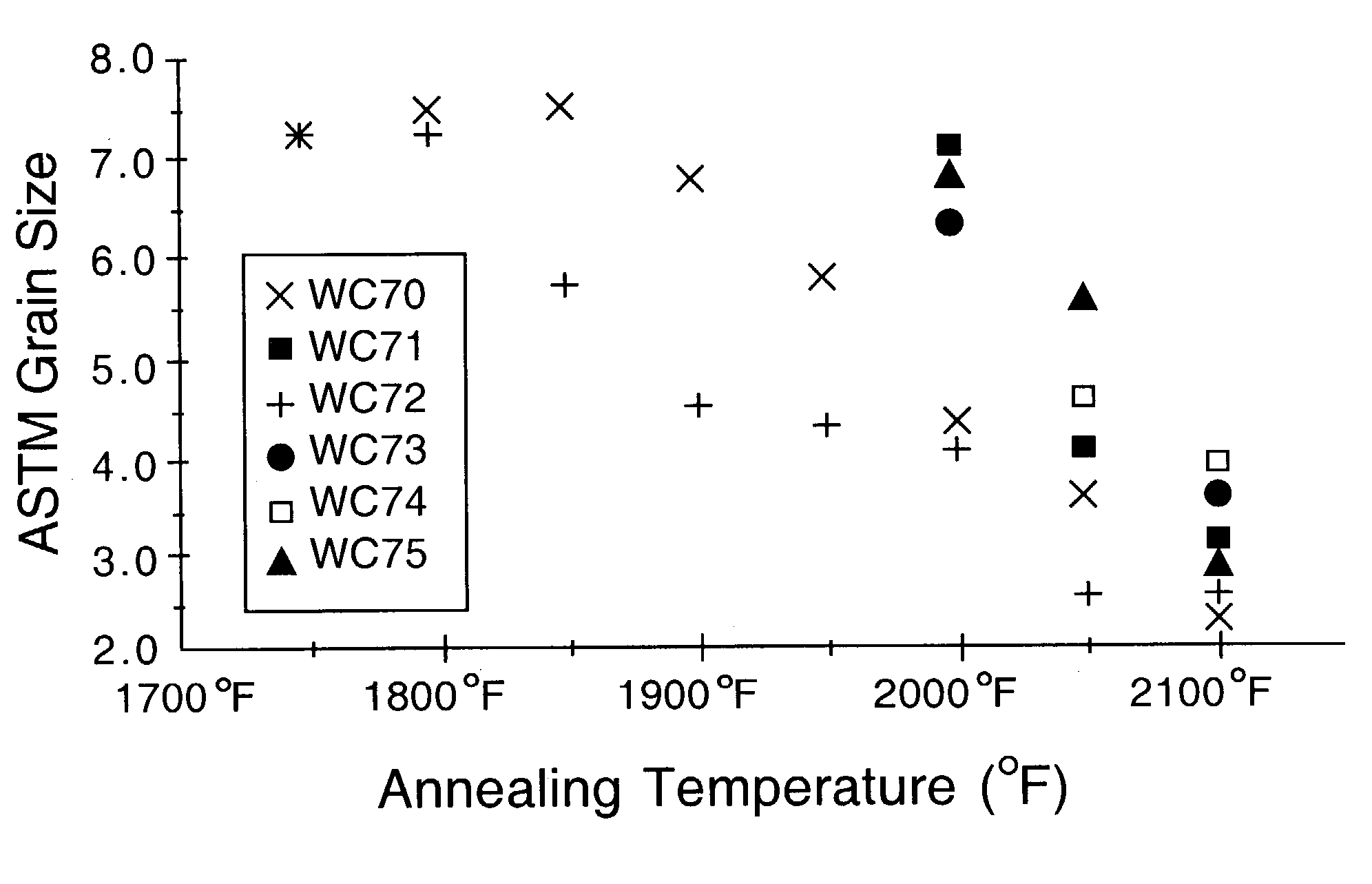

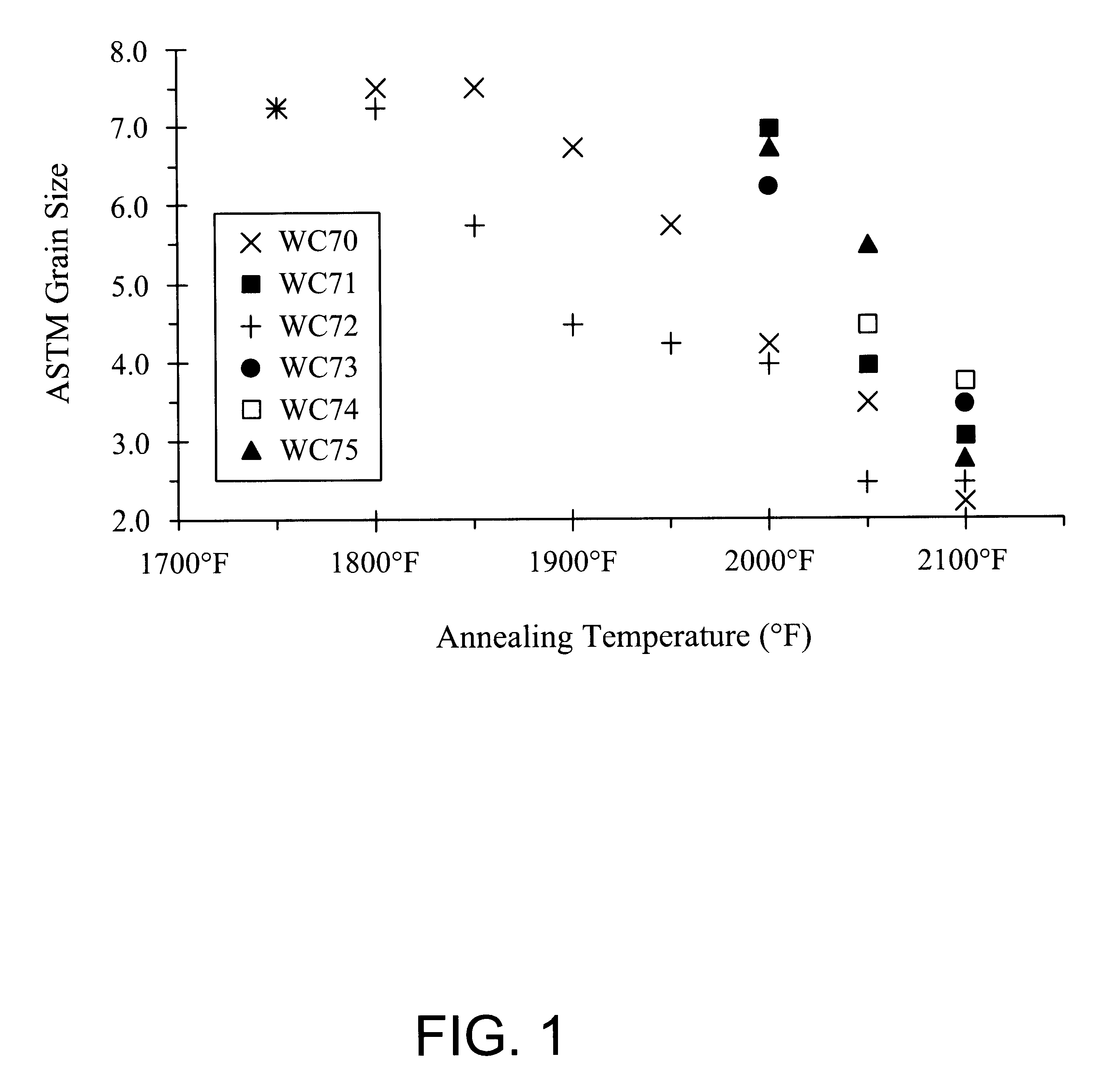

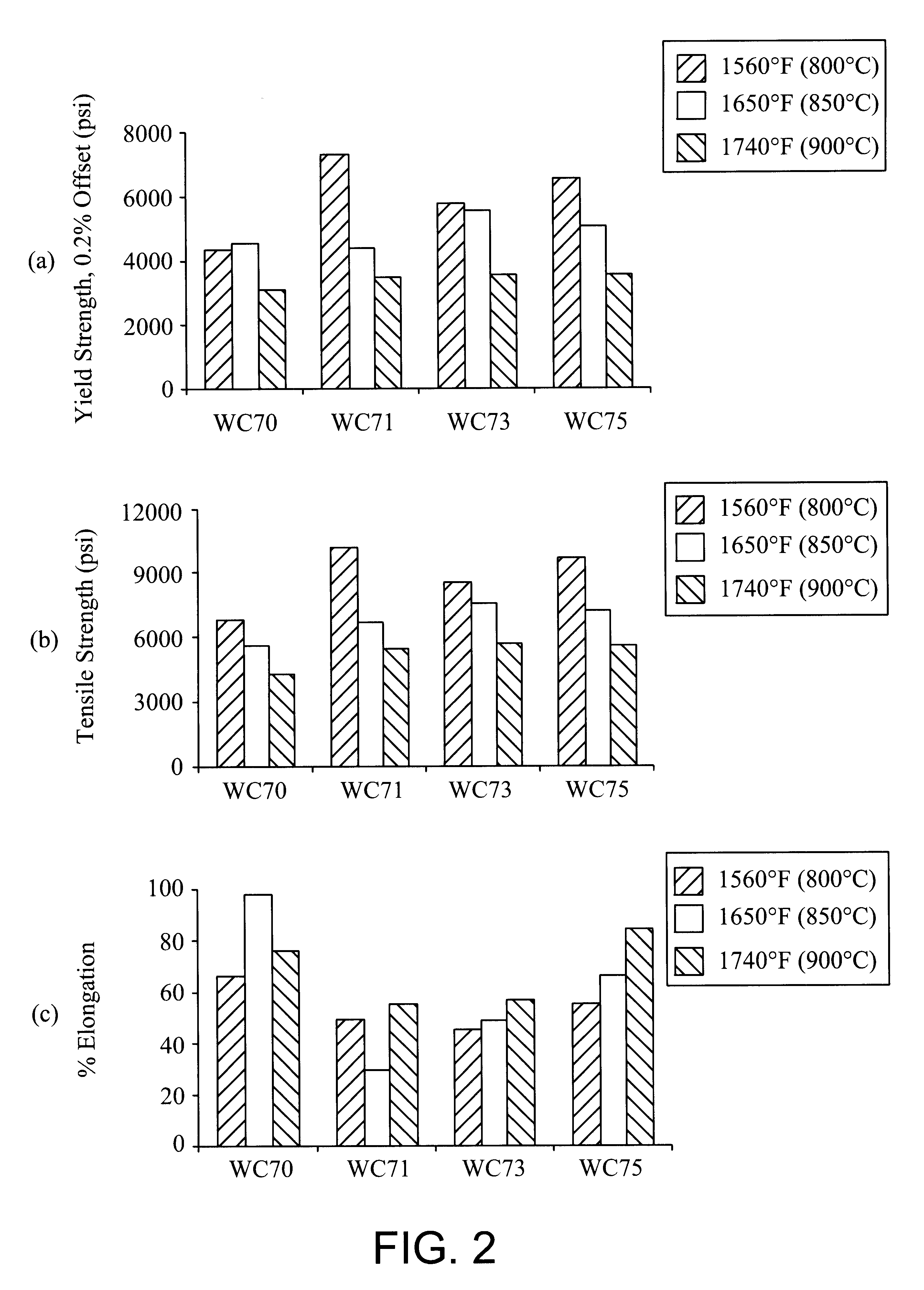

Ferritic stainless steel having high temperature creep resistance

InactiveUS20040050462A1Improve efficiencyEasy to operateFinal product manufactureFurnace typesNiobiumThermal expansion

A ferritic stainless steel having improved high temperature mechanical properties includes greater than 25 weight percent chromium, 0.75 up to 1.5 weight percent molybdenum, up to 0.05 weight percent carbon, and at least one of niobium, titanium, and tantalum, wherein the sum of the weight percentages of niobium, titanium, and tantalum satisfies the following equation: 0.4<=(% Nb+% Ti+½(% Ta))<=1. The coefficient of thermal expansion of the ferritic stainless steel is within 25 percent of the CTE of stabilized zirconia between 20° C. (68° F.) and 1000° C. (1832° F.), and the steel exhibits at least one creep property selected from creep rupture strength of at least 1000 psi at 900° C. (1652° F.), time to 1% creep strain of at least 100 hours at 900° C. (1652° F.) under load of 1000 psi, and time to 2% creep strain of at least 200 hours at 900° C. (1652° F.) under load of 1000 psi. The steel is particularly suited for high temperature applications including, but not limited to, current collecting interconnects in solid oxide fuel cells, furnace hardware, equipment for the chemical process, petrochemical, electrical power generation, and pollution control industries, and equipment for handling molten copper and other molten metals.

Owner:GRUBB JOHN F

Epoxy resin structural adhesive and preparation method thereof

InactiveCN101906282AHigh strengthImprove toughnessNon-macromolecular adhesive additivesCarboxyl rubber adhesivesEpoxyAdhesive

The invention discloses an epoxy resin structural adhesive and a preparation method thereof, belonging to the technical filed of chemical adhesive preparation. The used raw material consists of a resin system, an adhesive component A and a curing agent system component B, and the component A and component B are completely mixed and then cured at room temperature. The structural adhesive in the invention has the advantages of high strength and toughness, good creep resistance, little creep strain, good fatigue resistance and shock resistance, good heat resistance, medium resistance and corrosion resistance, particularly good muggy and aging resistance, excellent creep rupture strength, enough safety and reliability, good flame retardant property, low stress, high strength, high adhesive force, high reliability and the like, and complies with environmental requirements. The epoxy resin structural adhesive is mainly used for adhering composite materials, such as manufacturing yachts, building houses with composite boards, adhering and manufacturing containers made of large-scale composite materials, and the like.

Owner:强军锋

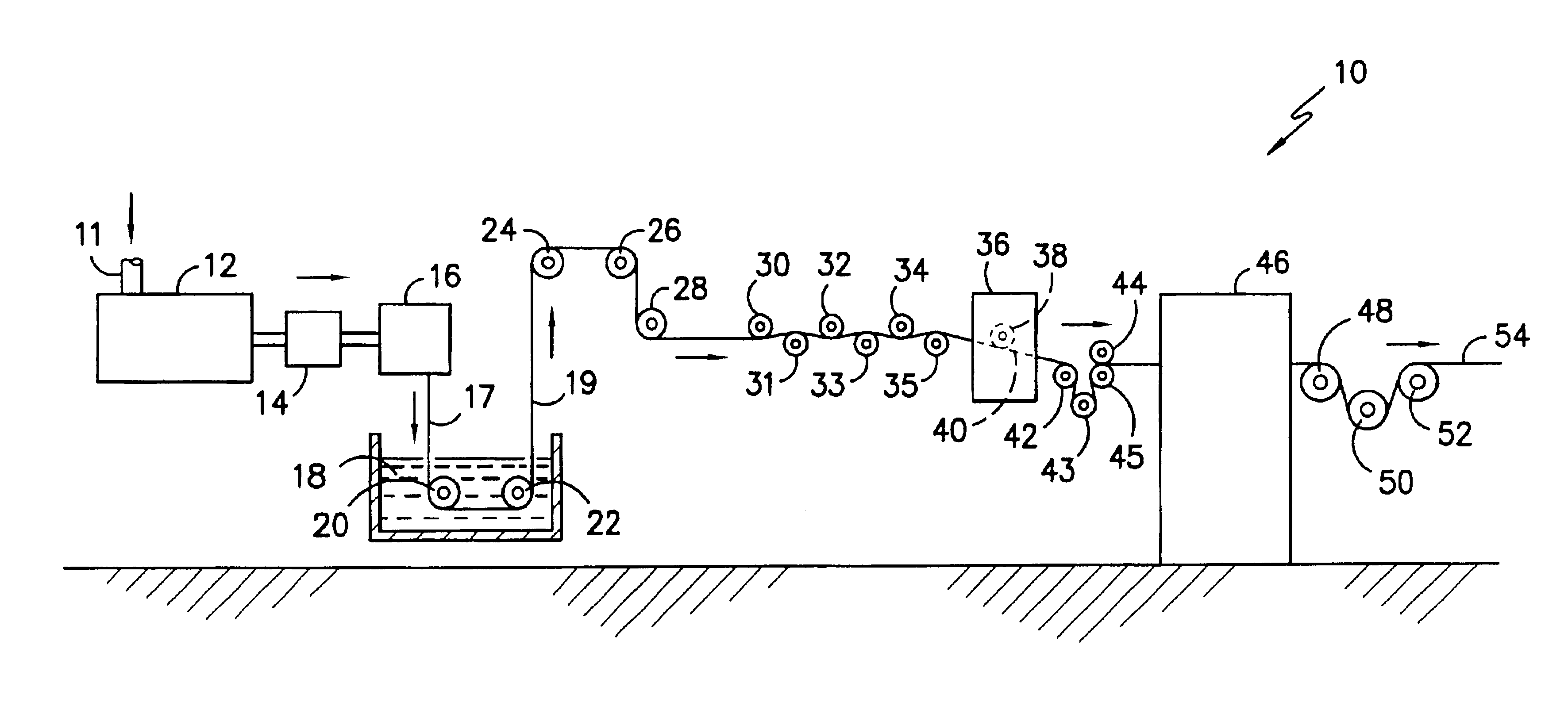

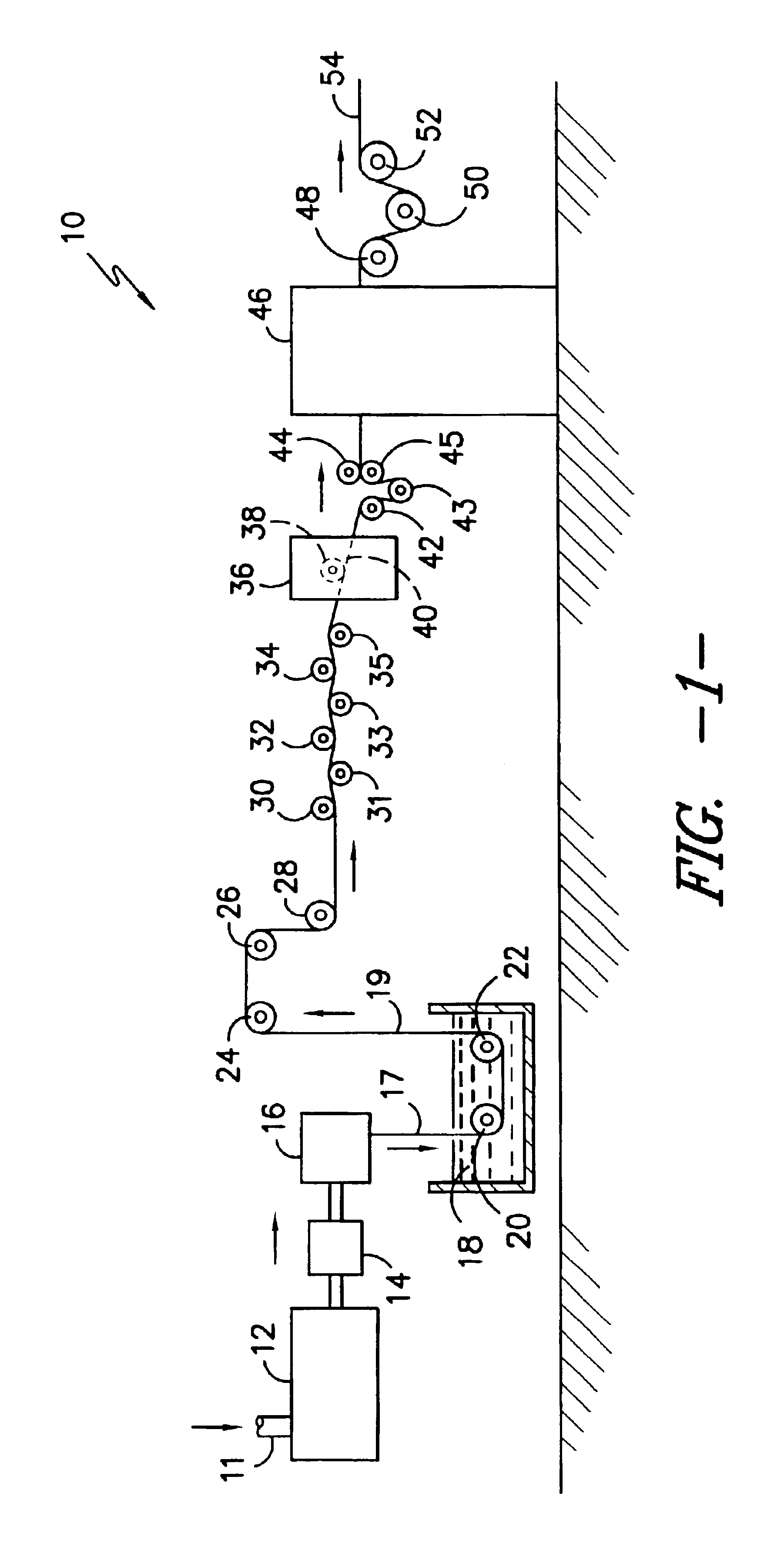

Polypropylene monofilament and tape fibers exhibiting certain creep-strain characteristics and corresponding crystalline configurations

InactiveUS20050019565A1High tensile strengthLow shrinkageSynthetic resin layered productsFilament/thread formingYarnThermoplastic

Unique thermoplastic (polypropylene, specifically) monofilament and / or tape fibers and yarns that exhibit heretofore unattained physical properties are provided. Such fibers are basically manufactured through the extrusion of thermoplastic resins that include a certain class of nucleating agent therein, and are able to be drawn at high ratios with such nucleating agents present, that the tenacity and modulus strength are much higher than other previously produced thermoplastic fibers (particularly those produced under commercial conditions), particularly those that also simultaneously exhibit extremely low shrinkage rates. Thus, such fibers require the presence of certain compounds that quickly and effectively provide rigidity to the target thermoplastic (for example, polypropylene), particularly after heat-setting. Generally, these compounds include any structure that nucleates polymer crystals within the target thermoplastic after exposure to sufficient heat to melt the initial pelletized polymer and allowing such an oriented polymer to cool. The compounds must nucleate polymer crystals at a higher temperature than the target thermoplastic without the nucleating agent during cooling. In such a manner, the “rigidifying” nucleator compounds provide nucleation sites for thermoplastic crystal growth. The preferred “rigidifying” compounds include dibenzylidene sorbitol based compounds, as well as less preferred compounds, such as [2.2.1]heptane-bicyclodicarboxylic acid, otherwise known as HPN-68, sodium benzoate, talc, certain sodium and lithium phosphate salts [such as sodium 2,2′-methylene-bis-(4,6-di-tert-butylphenyl)phosphate, otherwise known as NA-11]. Specific methods of manufacture of such inventive thermoplastic fibers, as well as fabric articles made therefrom, are also encompassed within this invention.

Owner:MILLIKEN & CO

Electronic isolation shield and a method of determining the minimum number of securing points required on the shield to sufficiently secure the shield to a circuit board

An electronic isolation shield mounts on a circuit board, around an electronic component to provide a minimum amount of shielding over a set period of time. The shield has a body made from a shielding material that is sized and shaped to fit around and cover the electronic component. The body has a sealing edge that is adapted to contact an upper surface of the circuit board and surround the electronic component. Resilient downwardly projecting tabs are attached to the body and each includes a securing end that extends past the sealing edge. The tab is securable to the circuit board along a securing axis. The sealing edge of the body is forced into sealing engagement with the upper surface of circuit board. The tab is laterally displaced with respect to the securing axis continuously over the set period of time so that the sealing edge is forced into the circuit board sufficiently to provide the minimum amount of shielding to the electronic component over the set period of time. A method of determining the minimum number of tabs that are required includes ascertaining the creep strain for the tab material, determining the mathematical ratio between pressure applied by the tabs at the beginning of the shield's service life to the pressure applied at the end of the service life, determining the minimum amount of pressure that is required to be applied by the tabs throughout the service life, and determining the minimum number of tabs that are required to apply the determined minimum pressure throughout the entire set period of time based on the determined mathematical ratio.

Owner:LUCENT TECH INC

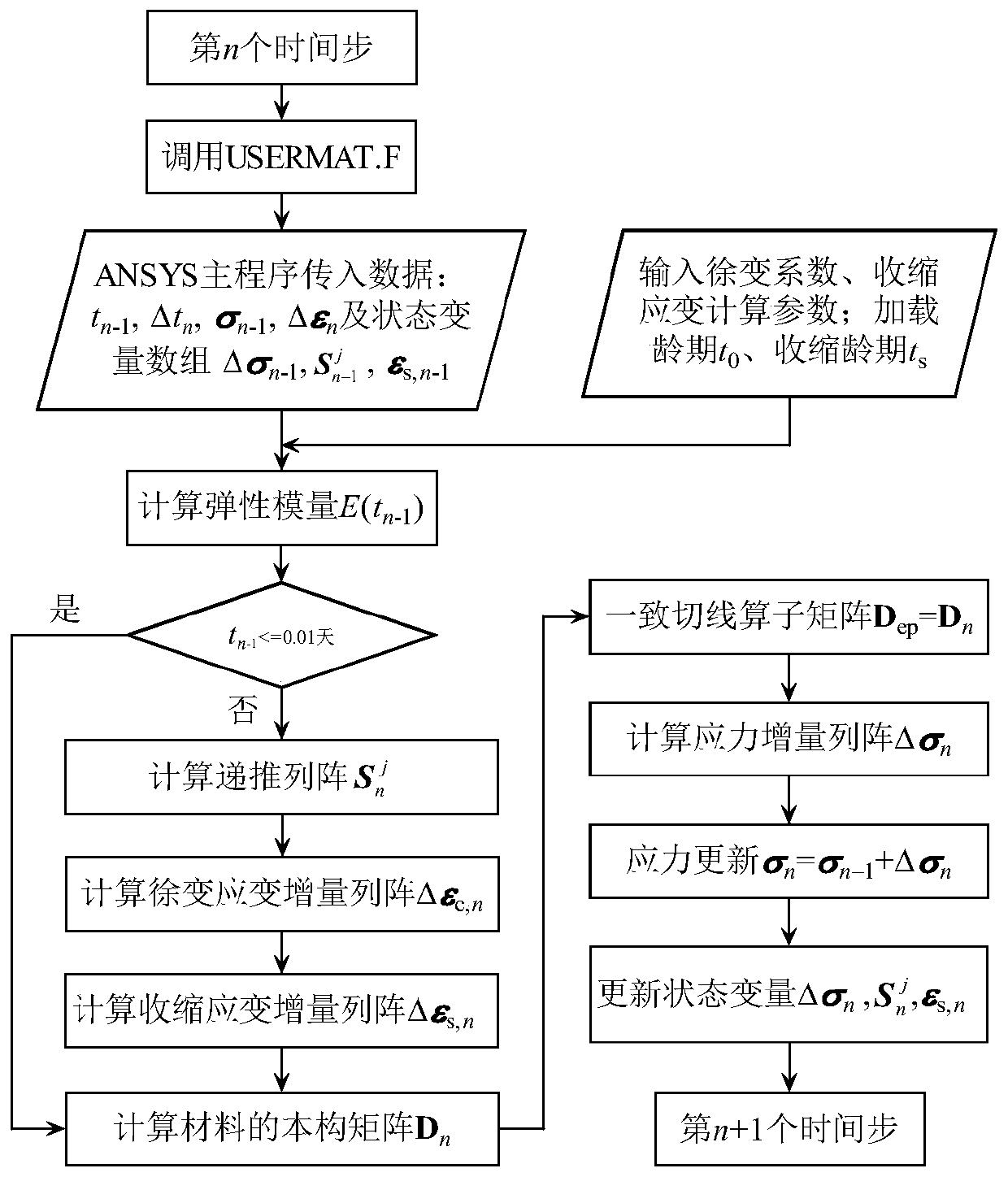

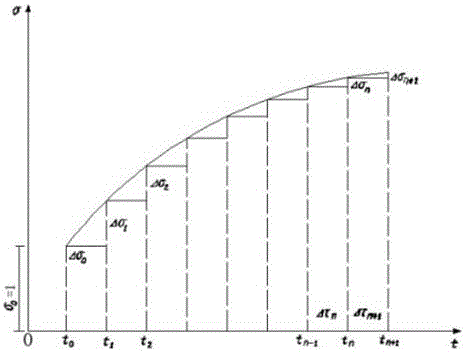

Entity finite element calculation method for time-varying effect of concrete structure

ActiveCN110162827AFine calculation of time-varying effectsOvercoming the disadvantage of difficulty in variable effectDesign optimisation/simulationSpecial data processing applicationsStress processStressed state

The invention relates to an entity finite element calculation method for a time-varying effect of a concrete structure, which comprises the following steps of: 1) discretizing the stress process of concrete according to a stepwise method, and deducing creep strain increment in an nth time period; 2) fitting the creep coefficient expression into an exponential series form by using Matlab software;3) substituting the creep coefficient fitting expression into a creep strain increment calculation formula, and establishing a concrete uniaxial creep strain increment recurrence calculation formula;4) considering the creep Poisson effect, and establishing a concrete time-varying constitutive equation in the constitutive structure of the entity unit material; and 5) developing the time-varying constitutive structure of the concrete in the USERMAT subprogram of the ANSYS software by using the Fortran language. Compared with the prior art, time-varying effect value prediction of the concrete structure in a complex stress process under a spatial stress state can be realized, and the joint with a creep and shrinkage model of a common design specification is good.

Owner:HOHAI UNIV

Linear object composed of magnesium alloy, bolt, nut, and washer

InactiveUS20130209195A1Improve plastic processing performanceImprove heat resistanceWashersNutsCreep strainHeat resistance

A linear object is composed of a magnesium alloy including, in percent by mass, 0.1% to 6% of Zn, 0.4% to 4% of Ca, and the balance being Mg and incidental impurities, in which, when a creep test is performed on the linear object under conditions of a temperature of 150° C., a stress of 75 MPa, and a holding time of 100 hours, the linear object has a creep strain of 1.0% or less. Zn and Ca interact with each other to improve heat resistance, and thus it is possible to obtain the linear object having an excellent creep property. By incorporating Zn and Ca, in amounts in specific ranges, into the magnesium alloy, it is also possible to obtain the linear object having excellent plastic workability.

Owner:SUMITOMO ELECTRIC IND LTD

Ferritic stainless steel having high temperature creep resistance

InactiveUS6641780B2Improve efficiencyEasy to operateFinal product manufactureFurnace typesNiobiumThermal expansion

A ferritic stainless steel having improved high temperature mechanical properties includes greater than 25 weight percent chromium, 0.75 up to 1.5 weight percent molybdenum, up to 0.05 weight percent carbon, and at least one of niobium, titanium, and tantalum, wherein the sum of the weight percentages of niobium, titanium, and tantalum satisfies the following equation:The coefficient: of thermal expansion of the ferritic stainless steel is within 25 percent of the CTE of stabilized zirconia between 20° C. (68° F.) and 1000° C. (1832° F.), and the steel exhibits at least one creep property selected from creep rupture strength of at least 1000 psi at 900° C. (1,652° F.), time to 1% creep strain of at least 100 hours at 900° C. (1652° F.) under load of 1000 psi, and time to 2% creep strain of at least 200 hours at 900° C. (1652° F.) Under load of 1000 psi. The steel is particularly suited for high temperature applications including, but not limited to, current collecting interconnects in solid oxide fuel cells, furnace hardware, equipment for the chemical process, petrochemical, electrical power generation, and pollution control industries, and equipment for handling molten copper and other molten metals.

Owner:ATI PROPERTIES +1

Linear object, bolt, nut and washer each comprising magnesium alloy

InactiveUS20120070248A1Improve plastic formabilitySpecific compositionWashersNutsHeat resistanceCreep strain

There is provided a linear object comprising magnesium-alloy having not only excellent heat resistance but also excellent plastic formability. The linear object comprising magnesium-alloy contains, on a mass percent basis, 0.1% to 6% Y, one or more elements selected from the group consisting of 0.1% to 6% Al, 0.01% to 2% Zn, 0.01% to 2% Mn, 0.1% to 6% Sn, 0.01% to 2% Ca, 0.01% to 2% Si, 0.01% to 2% Zr, and 0.01% to 2% Nd, and the balance being Mg and incidental impurities, in which the linear object comprising magnesium-alloy has a creep strain of 1.0% or less, the creep strain being determined by a creep test at a temperature of 150° C. and a stress of 75 MPa for 100 hours.

Owner:SUMITOMO ELECTRIC IND LTD

Concrete creep effect analysis method

InactiveCN106777716ASimple calculationConducive to programming calculation analysisGeometric CADDesign optimisation/simulationBridge engineeringCreep strain

The invention relates to the technical field of bridge engineering, in particular to a concrete creep effect analysis method. The method comprises the following steps that 1, a time-dependent concrete stress value sigma (t) is measured; 2, according to the time-dependent concrete stress value sigma (t) measured in the step 1, a time(t)-dependent variation curve graph is obtained; 3, a recurrence method is adopted for obtaining a creep strain increment; 4, according to a stress relaxation coefficient R(t, tau)=sigma(t) / sigma0, the curve graph obtained in the step 2 and the step 3, a stress value sigma 0 of the moment tau 0 of concrete is set to be equal to 1, and a computational formula of a stress relaxation coefficient R(t, tau) at the time t is obtained, wherein the equation of the computational formula is shown in the description; 5, according to the stress relaxation coefficient R(t, tau), a concrete time-dependent elasticity modulus E(t, t0) is obtained; 6, according to the computational formula of the stress relaxation coefficient R(t, tau) and the elasticity modulus E(t, t0), concrete creep effect analysis is completed. According to the analysis method, the stress-strain algebraic equation is adopted, computation is greatly simplified, and programming computational analysis is promoted.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

Aging life evaluation method for carbon-fiber composite core wire

InactiveCN105784501AMaterial strength using tensile/compressive forcesTemperature stressCreep strain

The invention provides an aging life evaluation method for a carbon-fiber composite core wire.The method comprises the following steps that 1, shift processing is conducted on creep test data of the composite core wire on the basis of a time-temperature equivalence principle, and a corresponding time-temperature shift factor is obtained; 2, shift processing is conducted on a test result obtained in the first step on the basis of a time-stress equivalence principle, and a corresponding time-stress shift factor is obtained; 3, the carbon-fiber composite core wire is evaluated by means of a time-temperature-stress equivalence principle; 4, fitting is conducted on an obtained creep strain master curve by means of an improved Findley model.According to the aging life evaluation method for the carbon-fiber composite core wire, influences of temperature and stress on wire creep behaviors in the practical use process of the novel carbon-fiber composite core wire are considered overall, and the aging life evaluation method can be well applied to service life prediction of the novel carbon-fiber composite core wire.

Owner:河南中煌节能电器有限公司

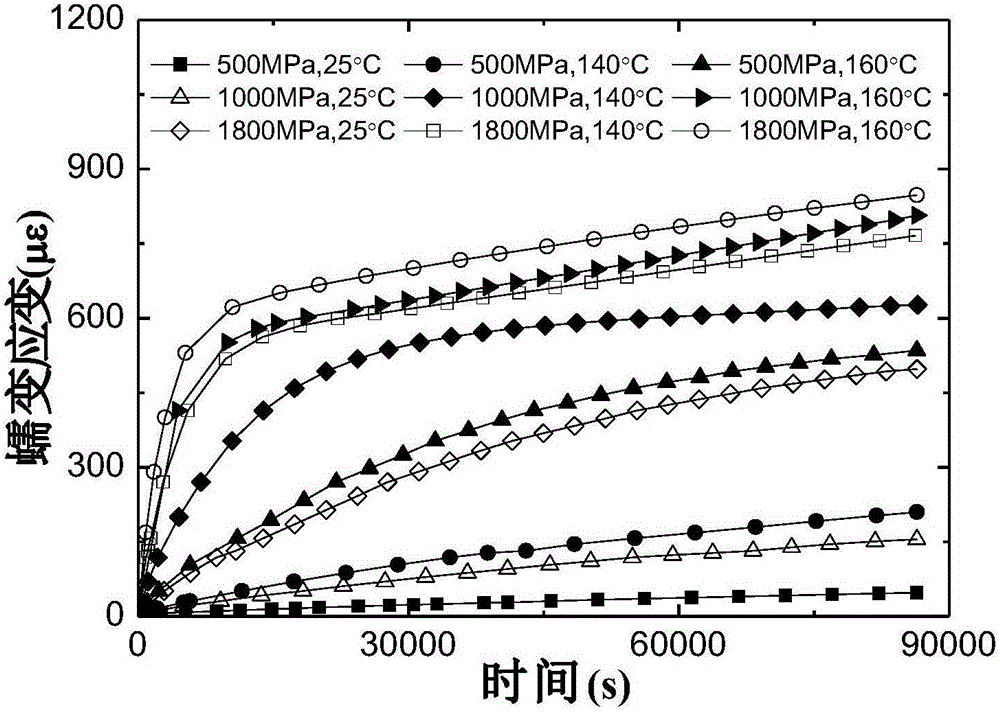

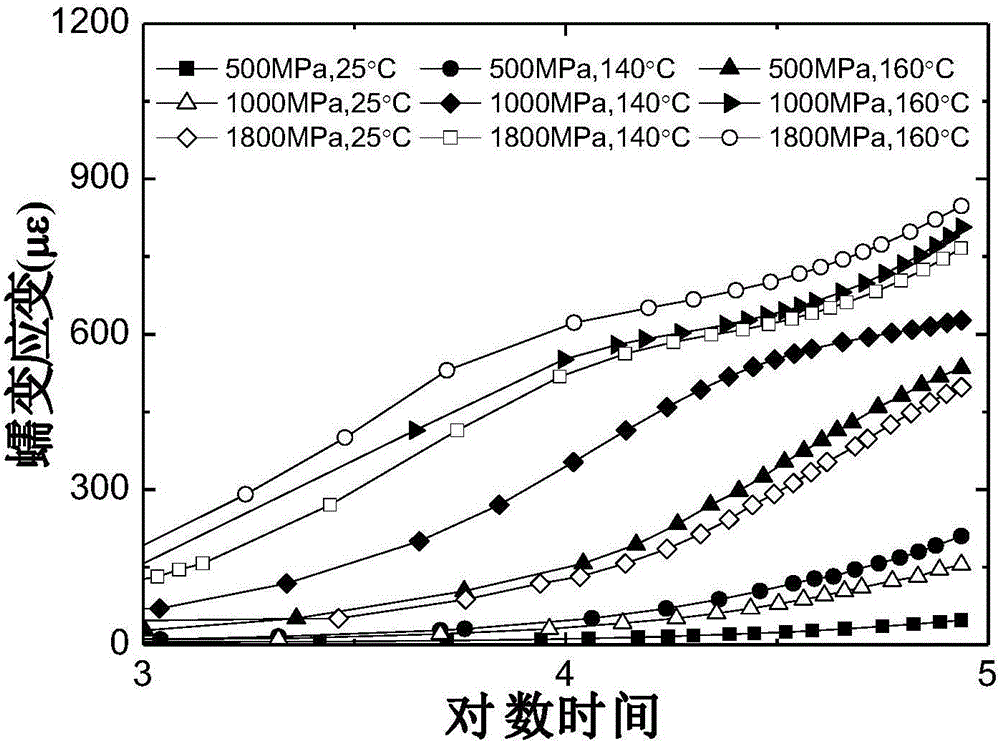

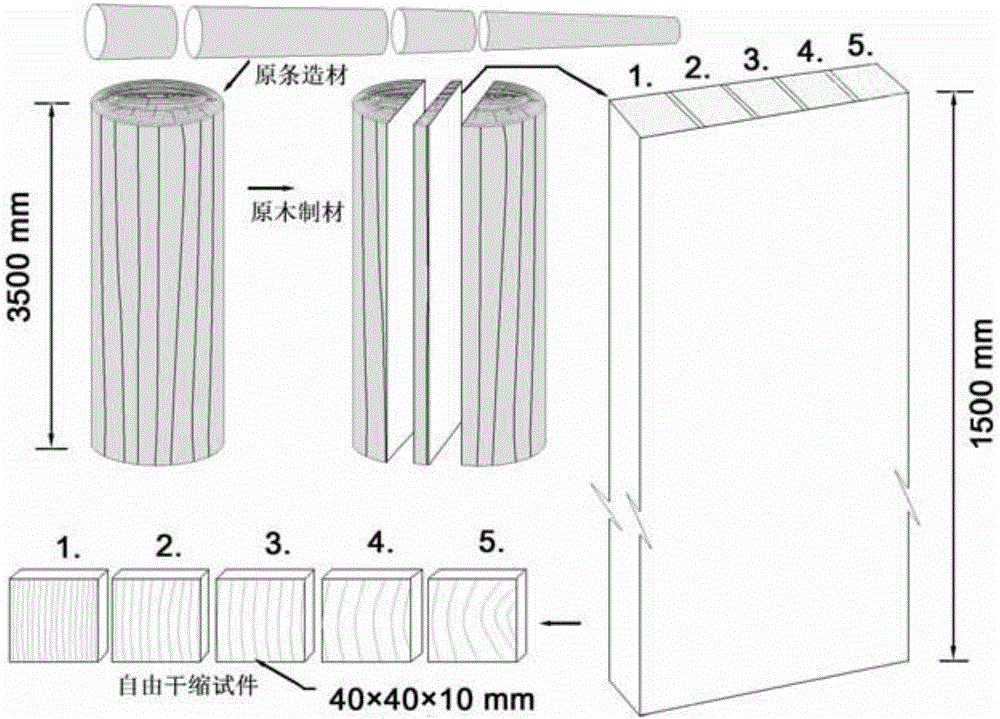

Sawn timber drying stress evaluating method for timber quality control

ActiveCN106225969AAchieve scientific evaluationOvercoming "Technical Ambiguity"Wood testingApparatus for force/torque/work measurementCreep strainAmbiguity

A sawn timber drying stress evaluating method for timber quality control is disclosed. The invention relates to a sawn timber drying stress evaluating method, and solves the problem that the drying stress and residual stress detection and analysis technology in a timber drying process in the prior art are low in precision, and that the purposes of controlling drying quality and shortening drying period can not be achieved. In order to test visco elastic creep along a sheet material width direction and free drying shrinkage strain of small dimension test pieces of same tree species under drying conditions, the mechano-sorptive creep strain along the sheet material width direction is calculated based on timber drying rheology principles. Timber drying mechano-sorptive creep gradient is defined, and affecting mechanism of timber mechano-sorptive creep gradient, timber water content gradient and other parameters on sheet material drying stress releasing process is determined. Technical ambiguity of describing timber drying stress by using conventional fork-tooth microtomy can be eliminated. The method is applicable to quantified description of coniferous wood drying stress, and scientific evaluation of timber drying quality is realized. The method is applied in the timber processing technical field.

Owner:NORTHEAST FORESTRY UNIVERSITY

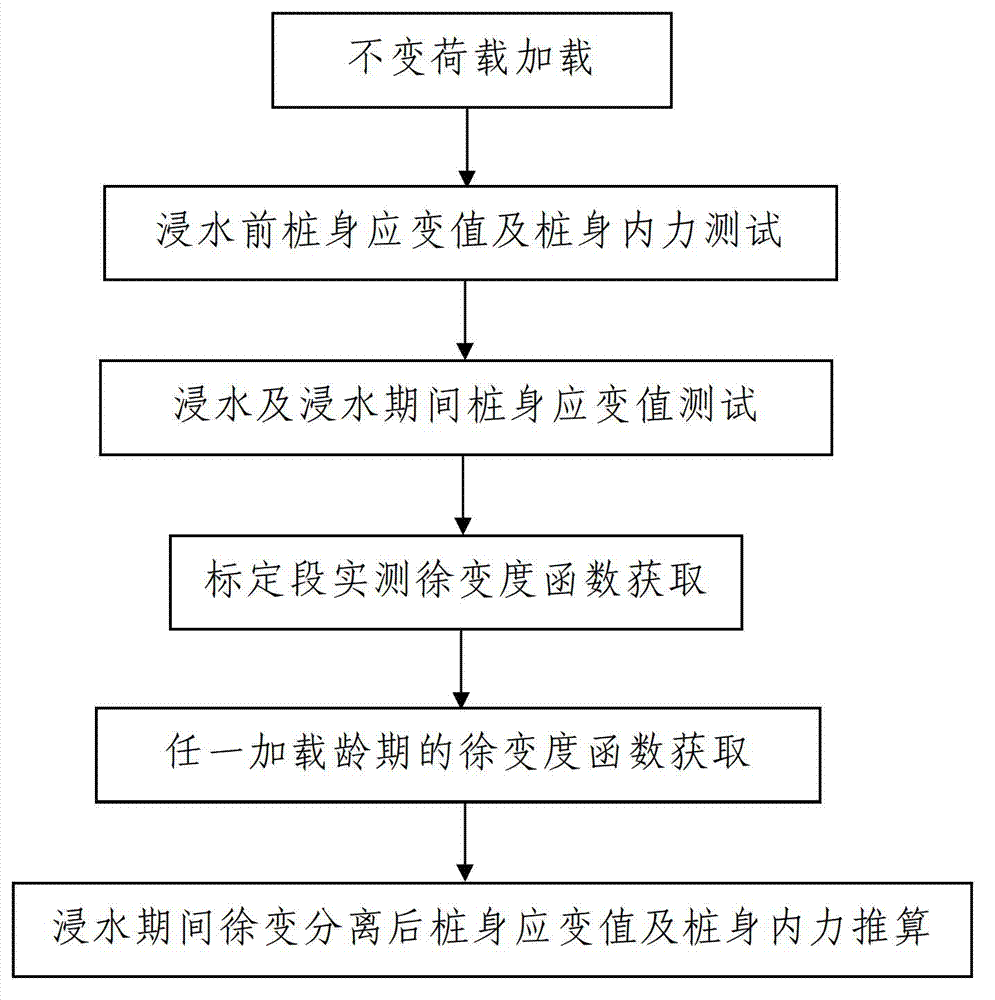

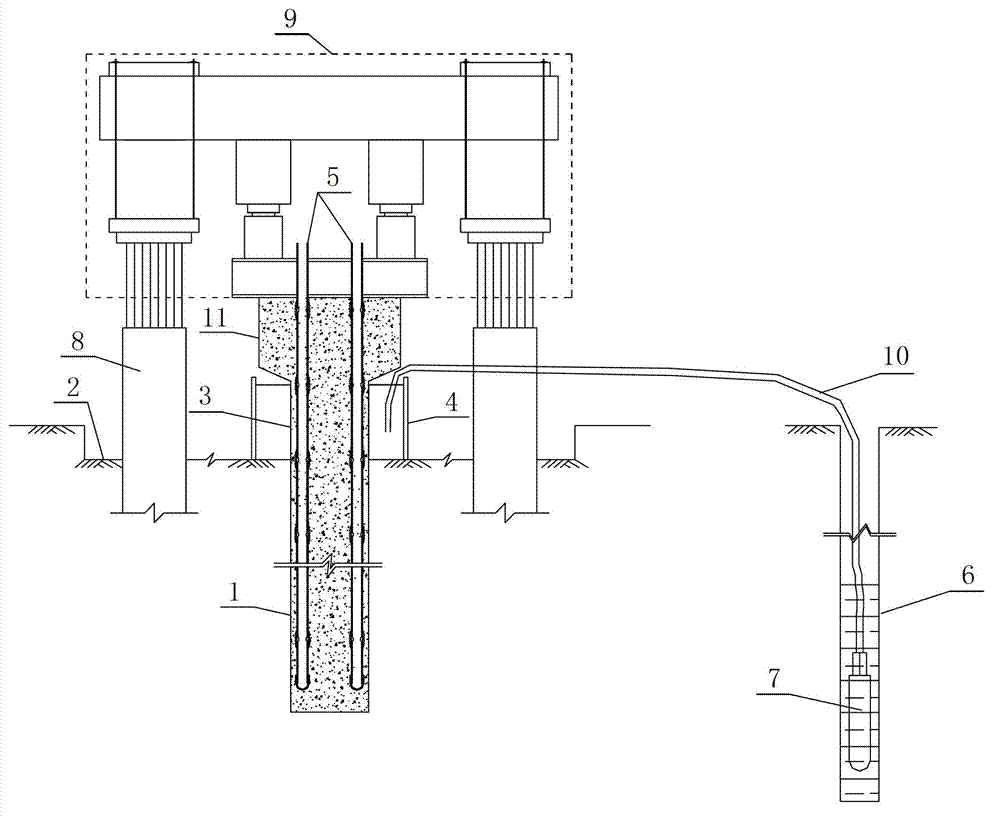

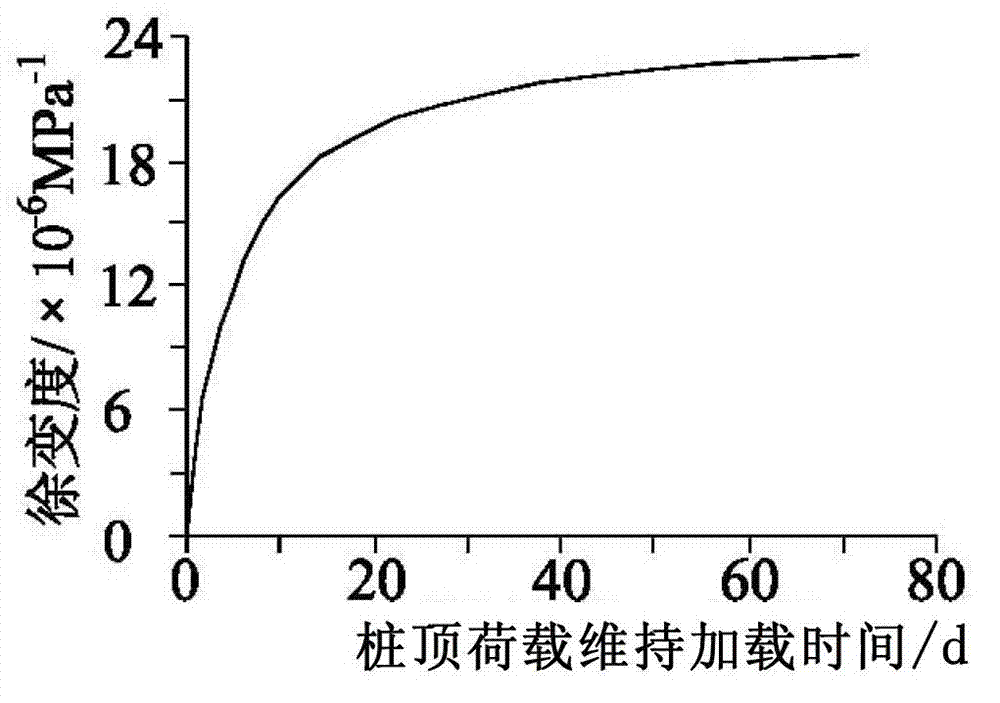

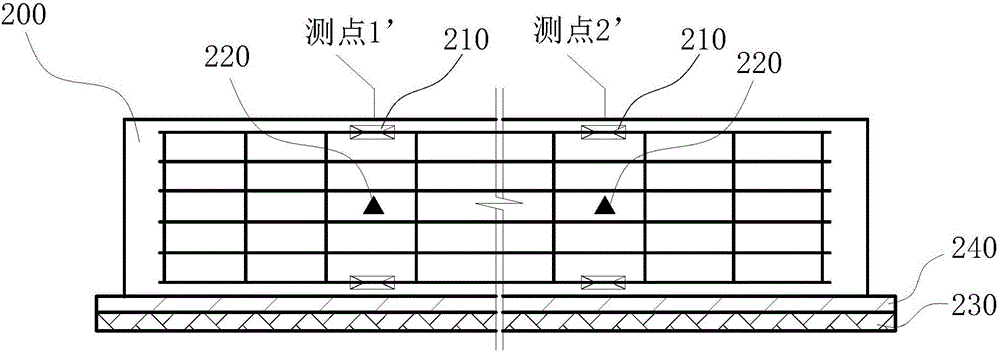

Pile foundation soaking load test method based on creep-strain separation

ActiveCN102808429AThe method steps are simpleReasonable designFoundation testingConstant loadCreep strain

The invention discloses a pile foundation soaking load test method based on creep-strain separation, which comprises the steps as follows: firstly, a constant load is loaded; secondly, strain values of a pile body and internal force of the pile body before the soaking are tested, that is, when the settlement of a test pile is stabilized, the strain values in different depth positions of the pile body of the test pile are tested and the internal force in different depth positions of the pile body of the test pile before the soaking are analyzed; thirdly, the soaking is conducted and the strain values of the pile body during the soaking are tested, that is, when the settlement of the test pile is stabilized, the test pile is soaked, and after the test pile is soaked, the strain values in different depth positions of the pile body of the test pile are tested at regular intervals of Delta t; fourthly, an actually measured creep degree function of a calibration section is obtained; fifthly, the creep degree function during each loading age is obtained; and sixthly, the strain values of the pile body and the internal force of the pile body are calculated after creep separation during the soaking. The method disclosed by the invention has the advantages that the steps are simple, the testing is convenient, creep and strain can be separated from a pile body strain test result simply, conveniently, rapidly and accurately, so that the test result approximates to the practical stress state of the pile body as much as possible.

Owner:CHINA JK INST OF ENG INVESTIGATION & DESIGN

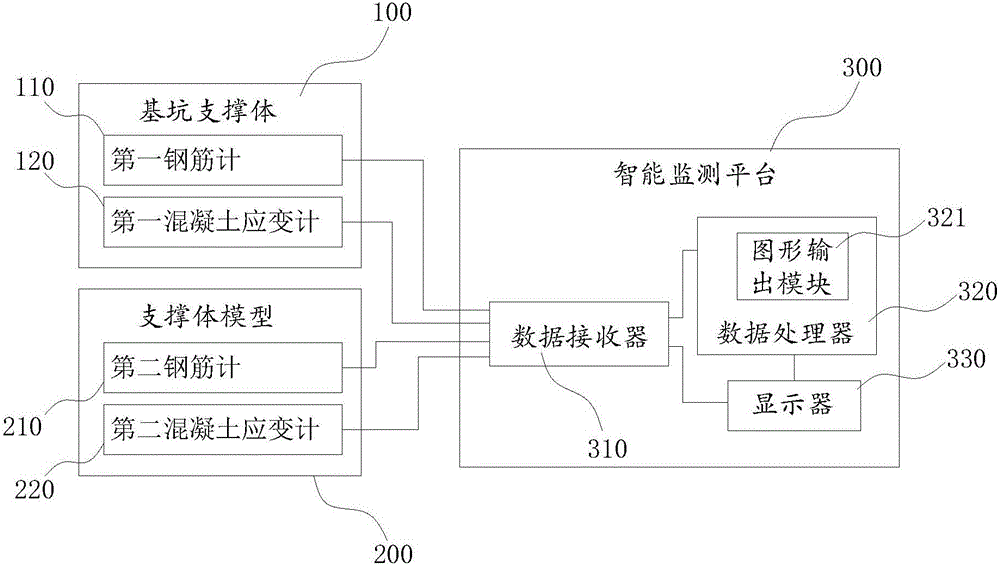

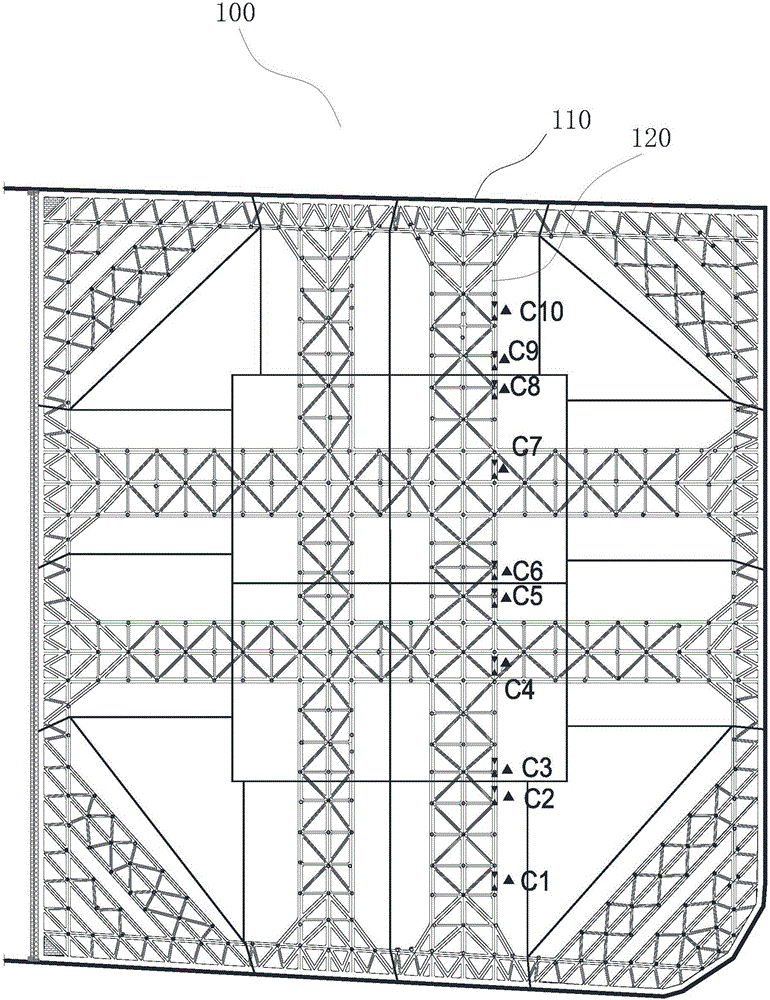

Large-scale foundation pit support body deformation automation analysis system and data analysis method thereof

ActiveCN106524989AAccurately reflect the actual stress situationReal-time monitoring of deformation dataMeasurement devicesTemperature stressStress conditions

The invention discloses a large-scale foundation pit support body deformation automation analysis system and a data analysis method thereof and belongs to the foundation pit engineering field. A foundation pit support body is a reinforced concrete beam. A support body model, which has a same cross section, same reinforcement and a same concrete proportion with the foundation pit support body and is simultaneously poured, is arranged in a construction site. A data monitoring analysis system comprises a first reinforcement meter, a first concrete strain meter, a second reinforcement meter, a second concrete strain meter and an intelligent monitoring platform. The intelligent monitoring platform can correspondingly decompose a stress and strain of the monitored foundation pit support body into data of a load stress, a temperature stress, a contraction stress, load strain, temperature strain, contraction strain, creep strain and the like through using each monitored data. In the technical scheme of the invention, a stress condition of the foundation pit support body can be accurately grasped so that safety guarantee is provided for foundation pit construction.

Owner:SHANGHAI CONSTR NO 1 GRP

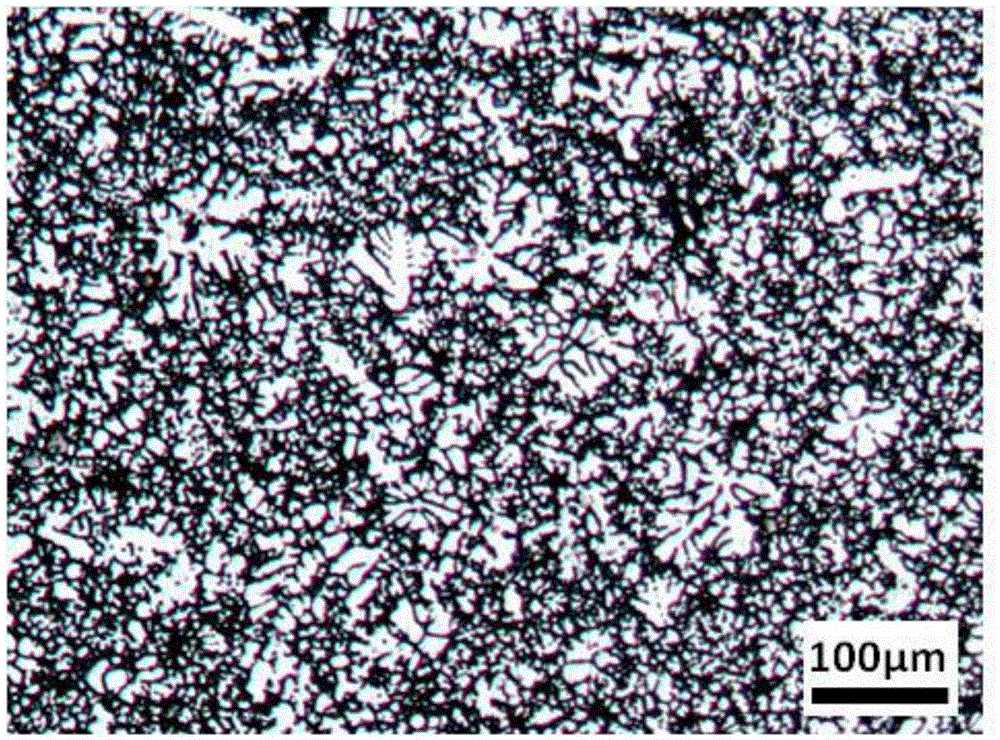

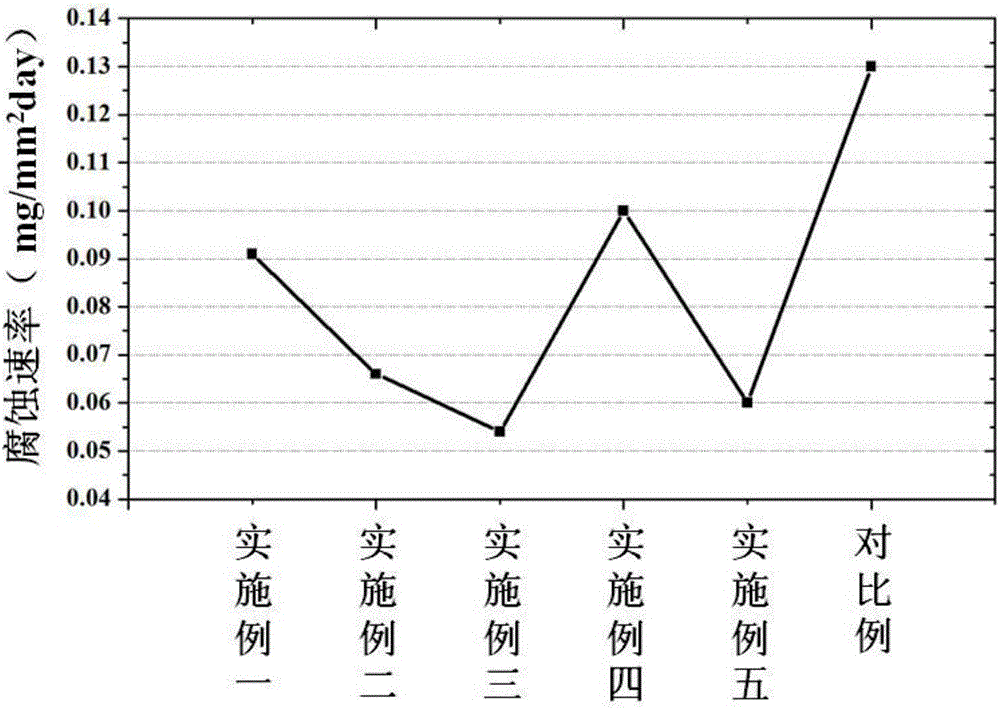

Corrosion-resistant and high-temperature creep-resistant die-cast magnesium alloy and prep ration method thereof

The invention provides a corrosion-resistant and high-temperature creep-resistant die-cast magnesium alloy and a prep ration method thereof and belongs to the technical field of light metal materials. The die-cast magnesium alloy comprises the following components in percentages by mass: 7.0-11.5wt.% of Al, 0.5-2.0wt.% of Zn, 0.3-0.4wt.% of Mn, 0.2-2.5wt.% of RE, 0.1-3.3wt.% of Yb, 0.1-5.8wt.% of Sm, 0.1-2.0wt.% of Sr and the balance of Mg and inevitable impure elements, wherein RE is mixed rare earth. The invention also provides a preparation method of the corrosion-resistant and high-temperature creep-resistant die-cast magnesium alloy. A test verifies that in a condition of the applied stress is 50MPa and the testing temperature is 150 DEG C, the 100h steady state creep rate of the magnesium alloy is 1.81*10<9> / s and 100h creep strain is 0.18%; through a neutral salt spray test by 5% NaCl for 100h at 35 DEG C, the corrosion rate is 0.055mg / cm<2>day.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

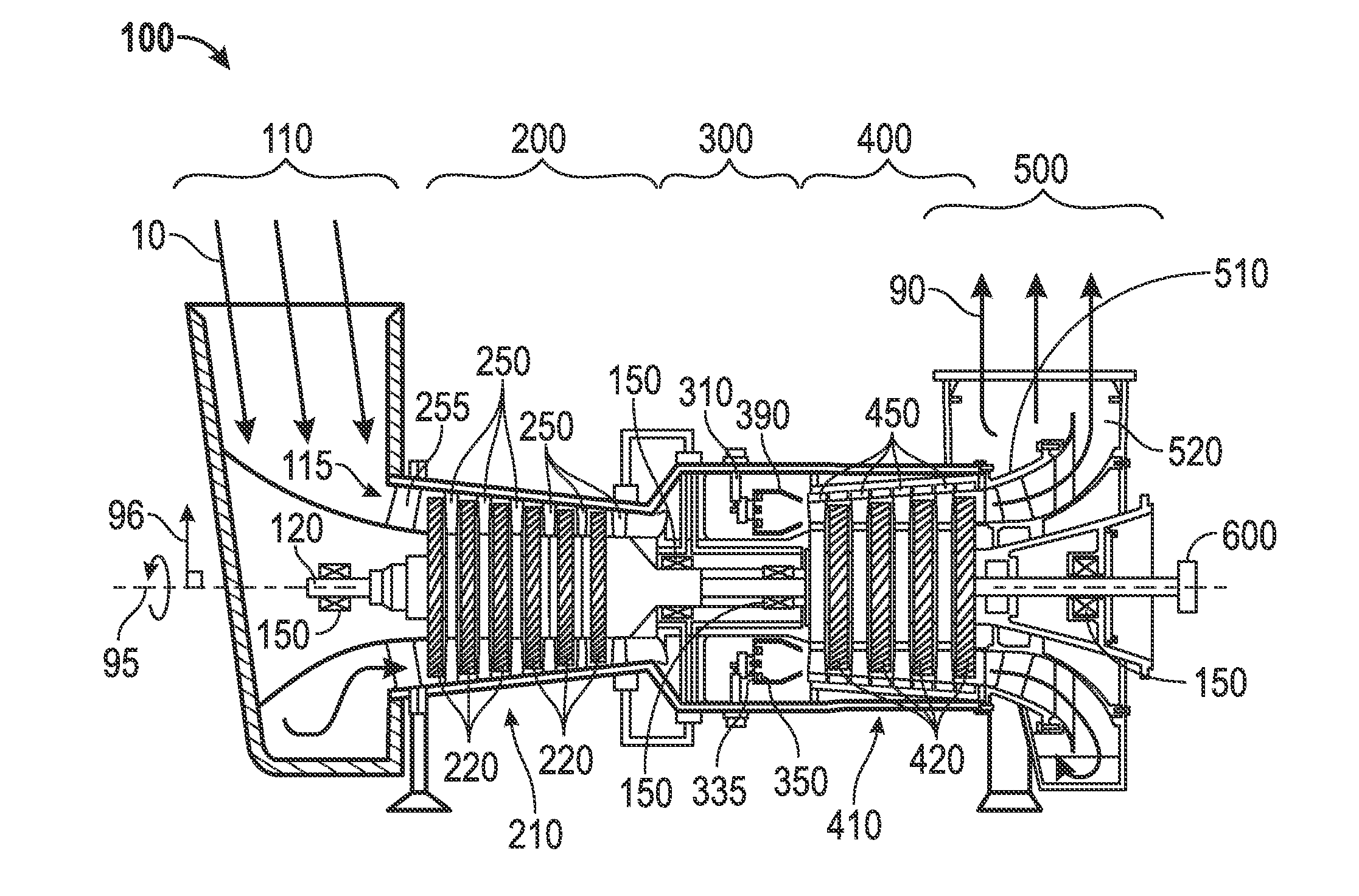

Single crystal turbine blade lifing process and system

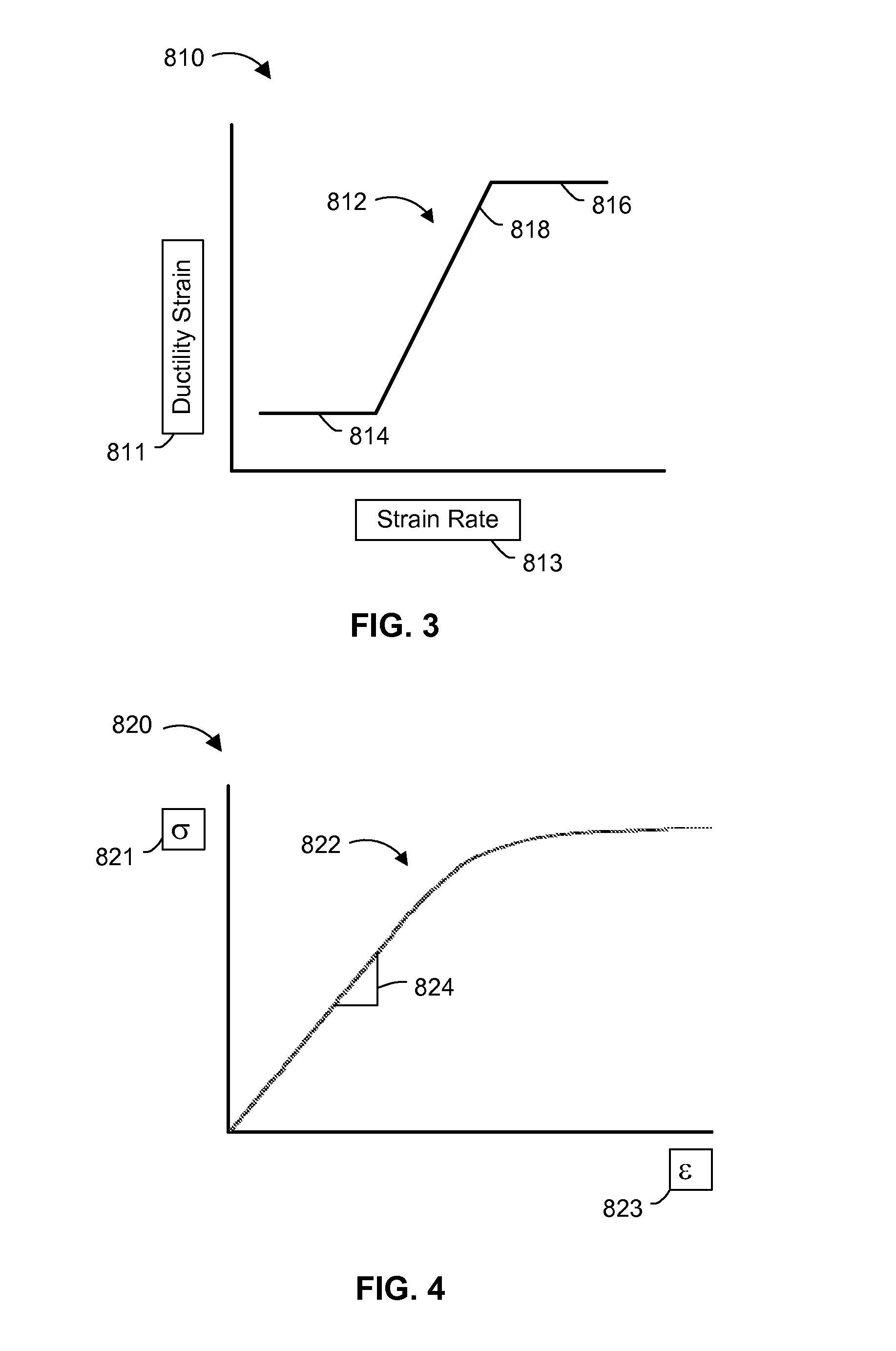

A system and methods for lifing a single crystal turbine blade of a gas turbine engine is disclosed. The system and methods determine the anisotropic strain of the single crystal turbine blade caused by fatigue and creep by resolving the shear stresses on each of the primary slip systems of the single crystal turbine blade. The system and methods use a ductility exhaustion method to combine the anisotropic fatigue and creep strains to determine the operating life of the single crystal turbine blade.

Owner:SOLAR TURBINES

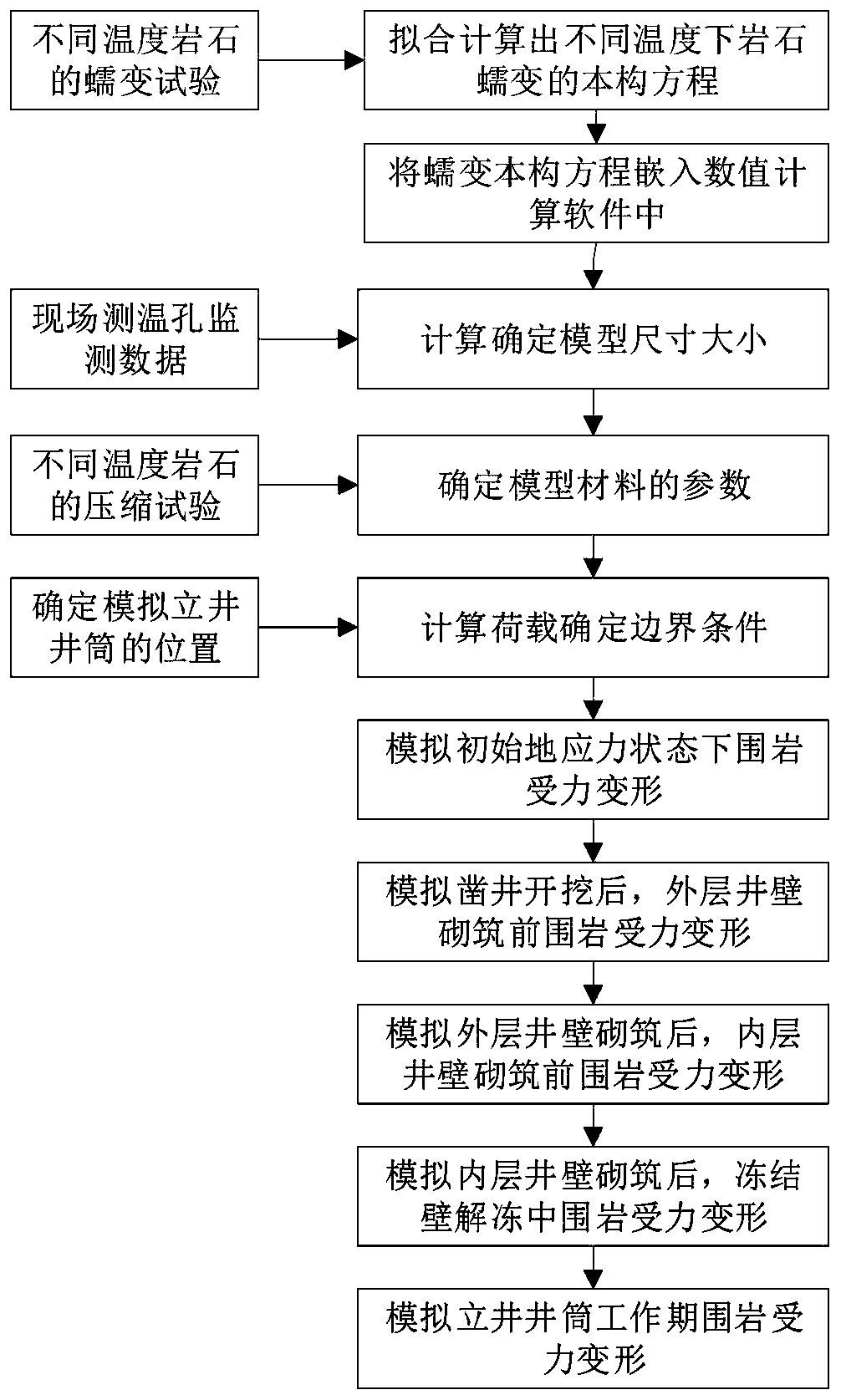

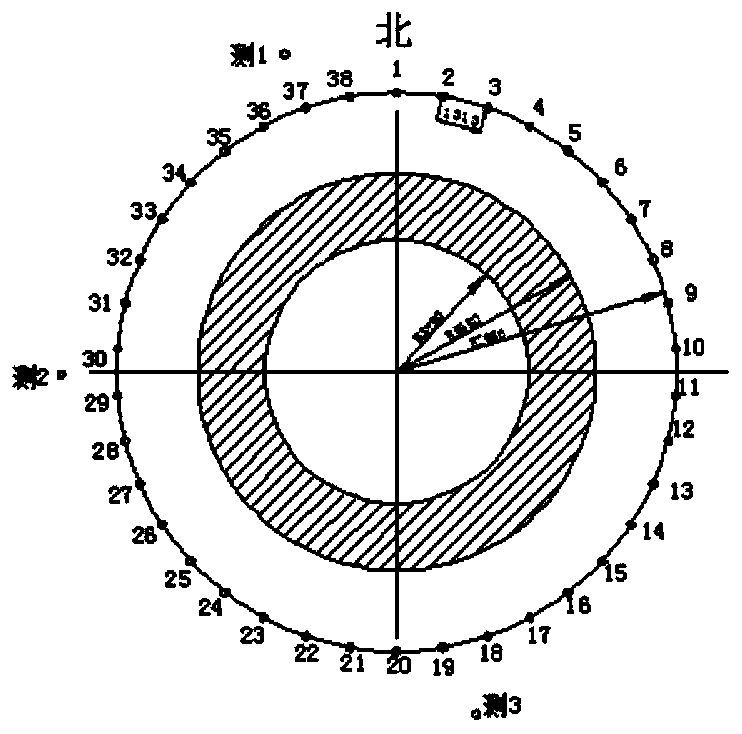

Coal mine vertical shaft freezing sinking process simulation calculation method

ActiveCN111460703AReliable data supportGeothermal energy generationDesign optimisation/simulationCreep strainClassical mechanics

The invention belongs to the technical field of coal mine freezing method vertical shaft sinking simulation, particularly relates to a coal mine vertical shaft freezing sinking process simulation calculation method. The method comprises the following two steps of 1, carrying out rock creep test, coring a frozen wall of a vertical shaft to be simulated, processing the frozen wall into a cylindricalrock sample with the diameter of 50mm and the height of 100mm, carrying out rock uniaxial creep tests at different temperatures to obtain a change rule of creep strain of the rock sample along with time in different temperature states, and calculating a rock creep constitutive equation at different temperatures according to the change rule; and 2, establishing a vertical shaft sinking model, embedding the creep constitutive equation obtained in the step 1 in finite element simulation software under different temperature states, setting temperature change and control time, and simulating the whole vertical shaft sinking process through the established model. According to the method, the stress deformation condition of the stratum confining pressure in each construction stage of freezing method sinking is simulated and calculated according to the actual influence of the creep deformation of the frozen wall, and the calculation result can guide the actual construction guidance.

Owner:XIAN UNIV OF SCI & TECH

Design method for reinforcing railway karst roadbed with high-strength geotextiles

A design method for reinforcing railway karst roadbed with high-strength geotextiles is provided, in order to solve the problem of lack of the theoretical basis and the design method when using high-strength geotextiles to reinforce the railway karst roadbed in actual design. The method is performed as the following steps: determining the size of the cavern and the upper load of the high-strengthgeotextile; determining the permissible value of the road surface deformation and the long-term strain and the creep strain tolerance of the high-strength geotextile; determining the ultimate strength, the short-term tension-strain relationship, and the long-term used tension-strain relationship of the high-strength geotextile; calculating the tension and the corresponding strain when the high-strength geotextile reaches the equilibrium position; calculating the deformation of the roadbed surface caused by deformation of the high-strength geotextile; calculating the long-term strain and the creep strain of the high-strength geotextile; and calculating the anchorage segment length to complete the design process.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

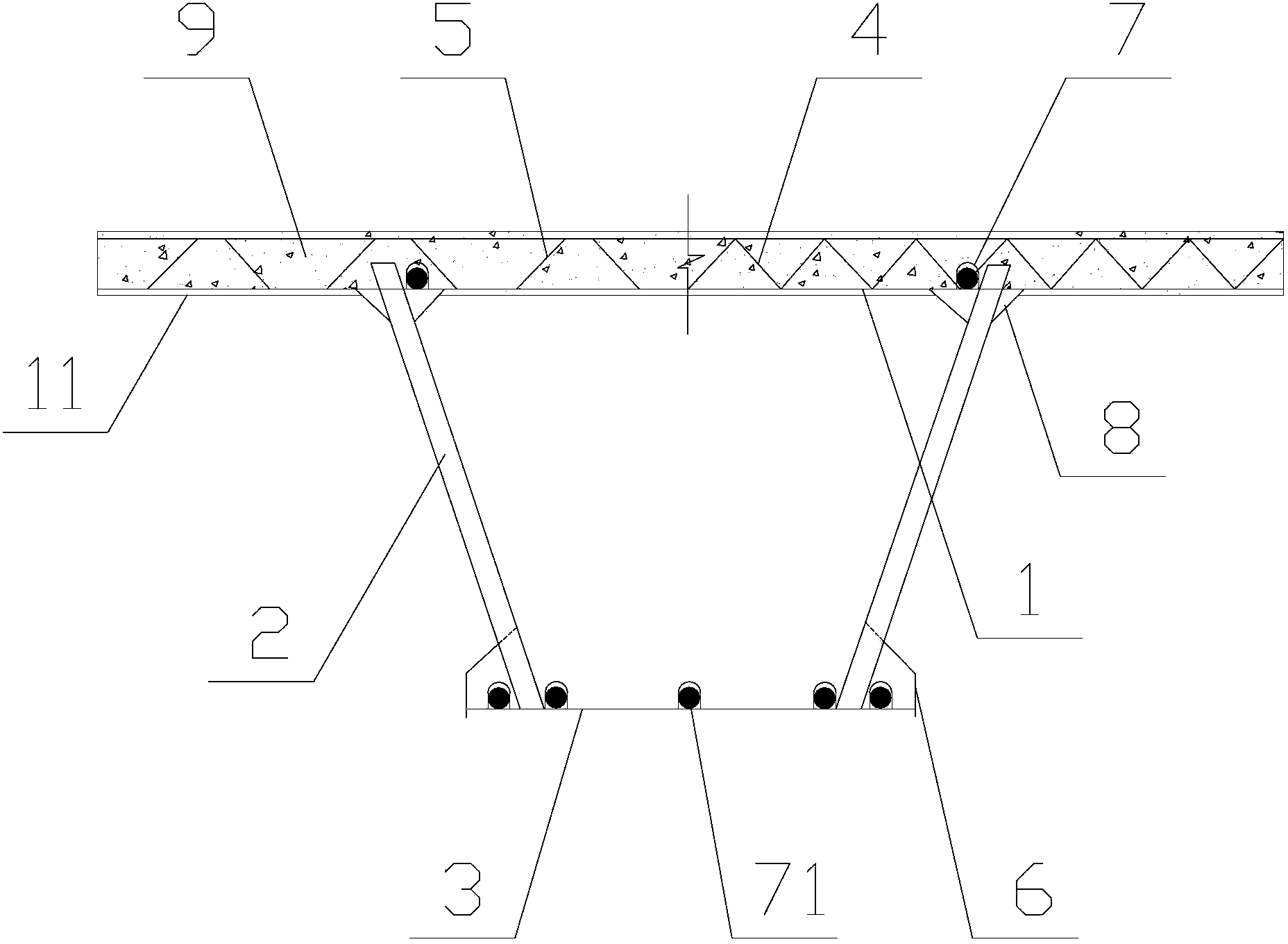

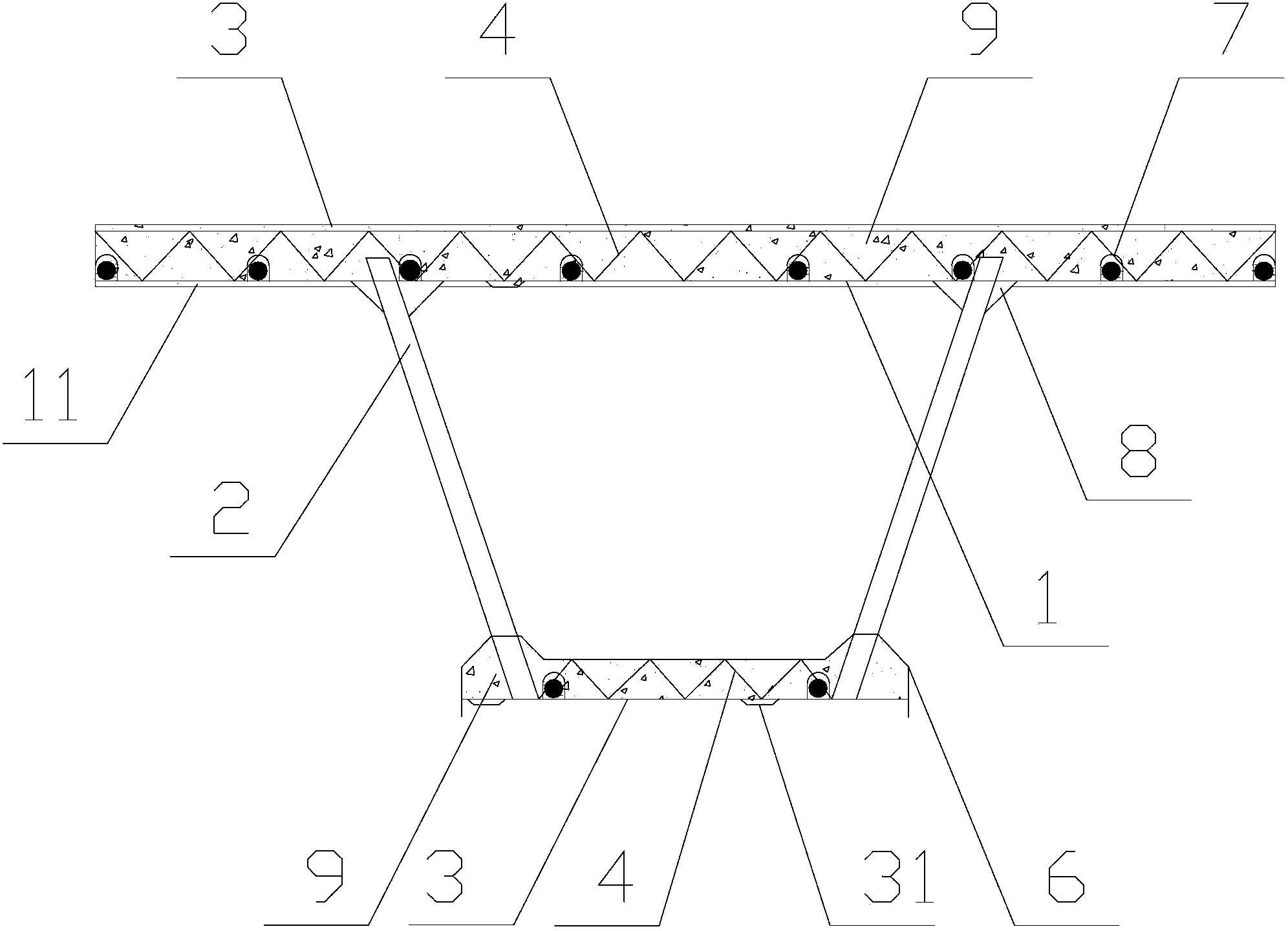

Steel die and reinforced concrete integrated combination beam structure

ActiveCN103437496AFast constructionLow costLoad-supporting elementsBridge structural detailsTransverse forceReinforced concrete

The invention relates to a combination beam structure, and discloses a steel die and reinforced concrete integrated combination beam structure. The steel die and reinforced concrete integrated combination beam structure comprises a steel top board (1), steel baseboards (3) and corrugated steel sheets (2), the corrugated steel sheets (2) are connected with the steel top board (1) and the steel baseboards (3), reinforced concrete (9) is poured on the steel top board (1), the steel top board (1) is arranged at two sides of the corrugated steel sheets (2), and the corrugated steel sheets (2) traverse through the steel top board (1) and then are inserted into the reinforced concrete (9). The lightweight steel die and reinforced concrete integrated structure adopting the corrugated steel sheet as an anti-shear structure, the support type steel sheet as a steel die and combination structure duplicate member, a steel bar skeleton or corrugated porous sheet as an anti-blend member, micro-stress waves as a concrete shrink creeping strain measure and a prestress external or internal steel rope or high-strength steel bar as a tensile member avoid traditional wet joints, and has the advantages of good transverse force transmission, light weight, fast construction and low cost.

Owner:ZHEJIANG CTB WAVEFORM STEEL WEB

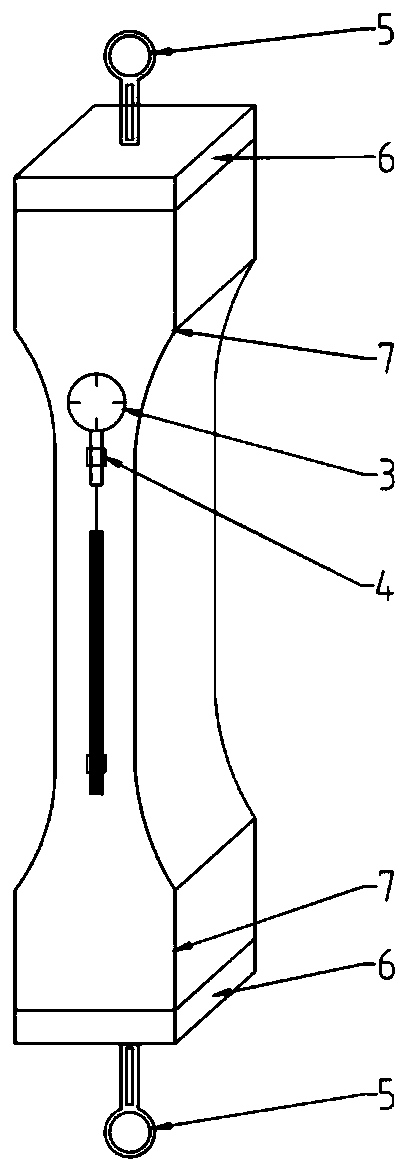

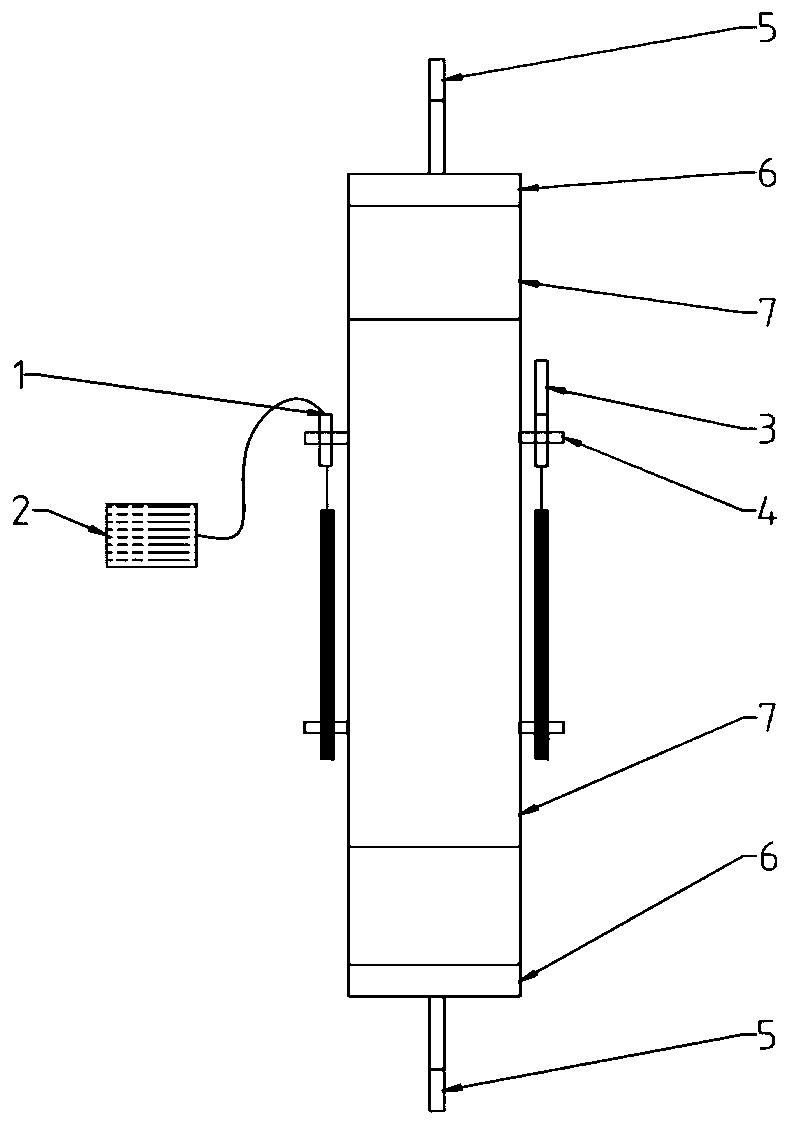

Tensile creep test device and method for high-strength concrete

PendingCN110926945AAccurate measurement of elastic deformation processGuaranteed integrityMaterial strength using tensile/compressive forcesCreep strainStructural engineering

The invention relates to a tensile creep test device and method for high-strength concrete. A double-spring tensile creep device and a concrete test piece creep strain acquisition method are included.The double-layer spring tension creep device ensures the stability of the loading process and the later-stage load holding by utilizing double springs; a linear differential displacement sensor is arranged on one side of the concrete detection test piece, and a dial indicator detector is arranged on the other side of the concrete detection test piece; on the premise of ensuring that the difference between the two acquisition modes is within an error range, data points of sensors are used in the earlier stage, and the reading point of the dial indicator is used in the later period, and a logarithmic mapping method is used for mapping, so that the instantaneous deformation including elastic deformation in the initial loading stage can be displayed, the deformation in several years cannot beclose to the level, and the limitations that the value of the traditional strain acquisition method cannot be distinguished in a short time and the value of the traditional strain acquisition methodis positioned outside the graph are overcome; the test device and method have the characteristics of simple operation, low cost, reliable data and the like, and are suitable for carrying out tensile creep test for a long time.

Owner:SOUTHEAST UNIV

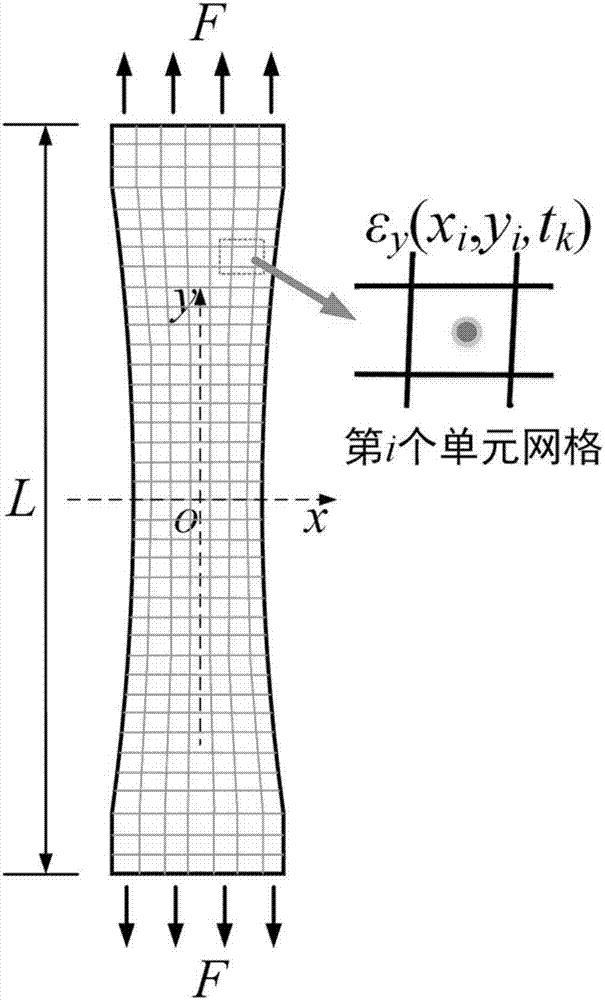

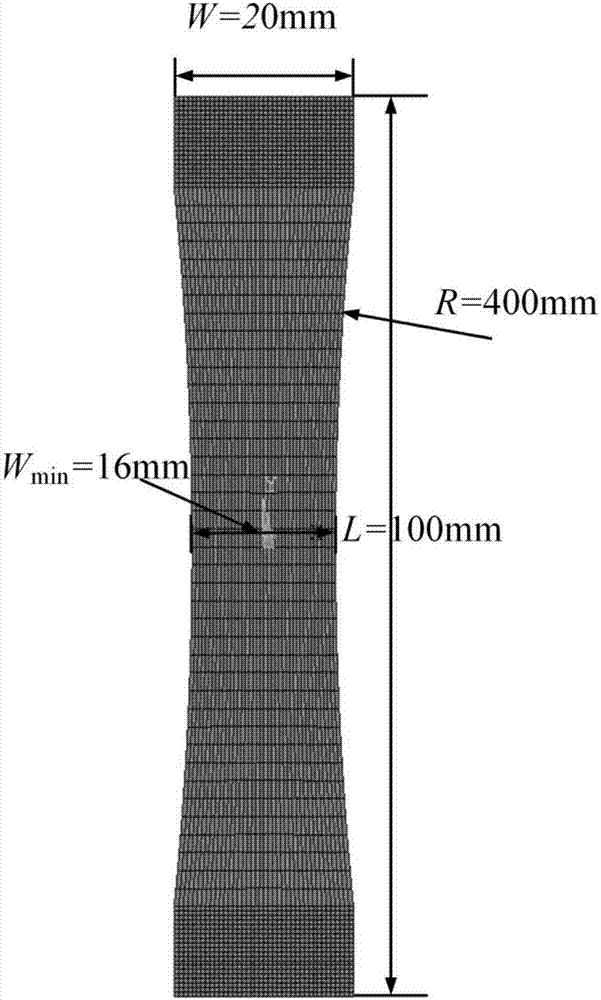

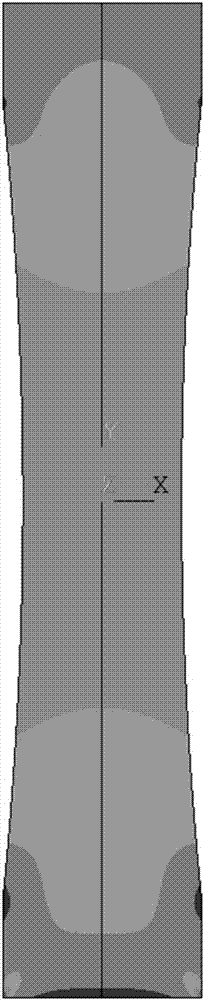

Creep constitutive model parameter identification method for creep test

ActiveCN108009311APredicting Creep Deformation BehaviorSatisfied with the optimal solutionDesign optimisation/simulationSpecial data processing applicationsStress conditionsMeasurement point

The invention discloses a creep constitutive model parameter identification method for creep test. The method includes the steps: extracting a strained measuring value epsilon y (xi, yi and tk) of ani measuring point of a sample analysis surface at a k strained measuring moment tk by a creep load F in a y direction to obtain a creep strain of the i measuring point of the sample analysis surface at the moment tk as shown in the specification; determining a grid area Ai taking the i measuring point as a center; selecting a creep constitutive model, and enabling the creep strainepsilon <cr> to express a function of stress level sigma and creep time t; acquiring virtual work under the action of the creep load F; acquiring an objective function phi (p) for identifying creep constitutive model parameters, and solving a value popt and a parameter popt of a corresponding p of a minimal value of the objective function. The corresponding parameter popt is an identified creep constitutive model parameter. The method has the advantages that sample material creep deformation behaviors can be forecasted according to stress conditions without change of materials and environmental conditions.

Owner:HEFEI GENERAL MACHINERY RES INST +1

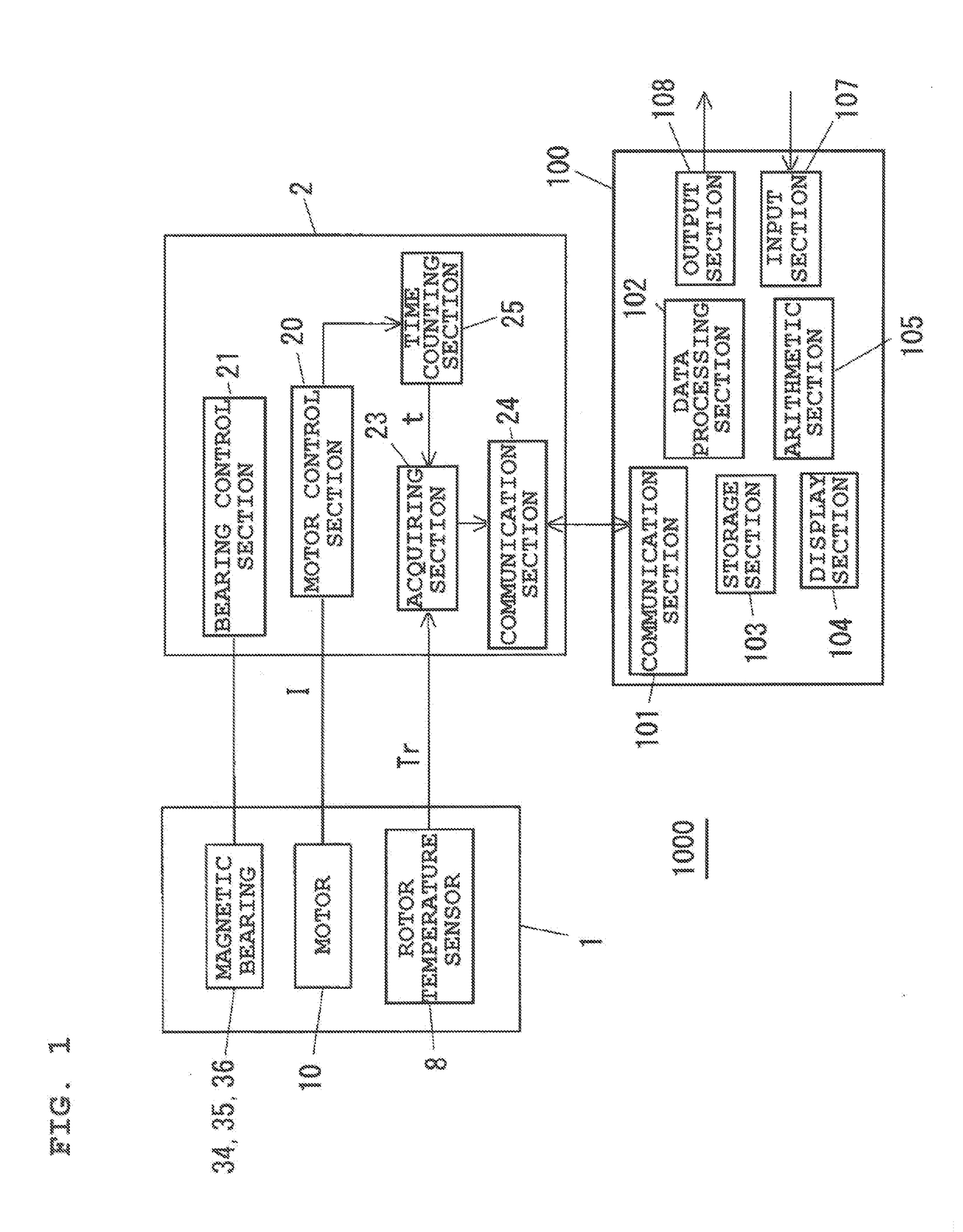

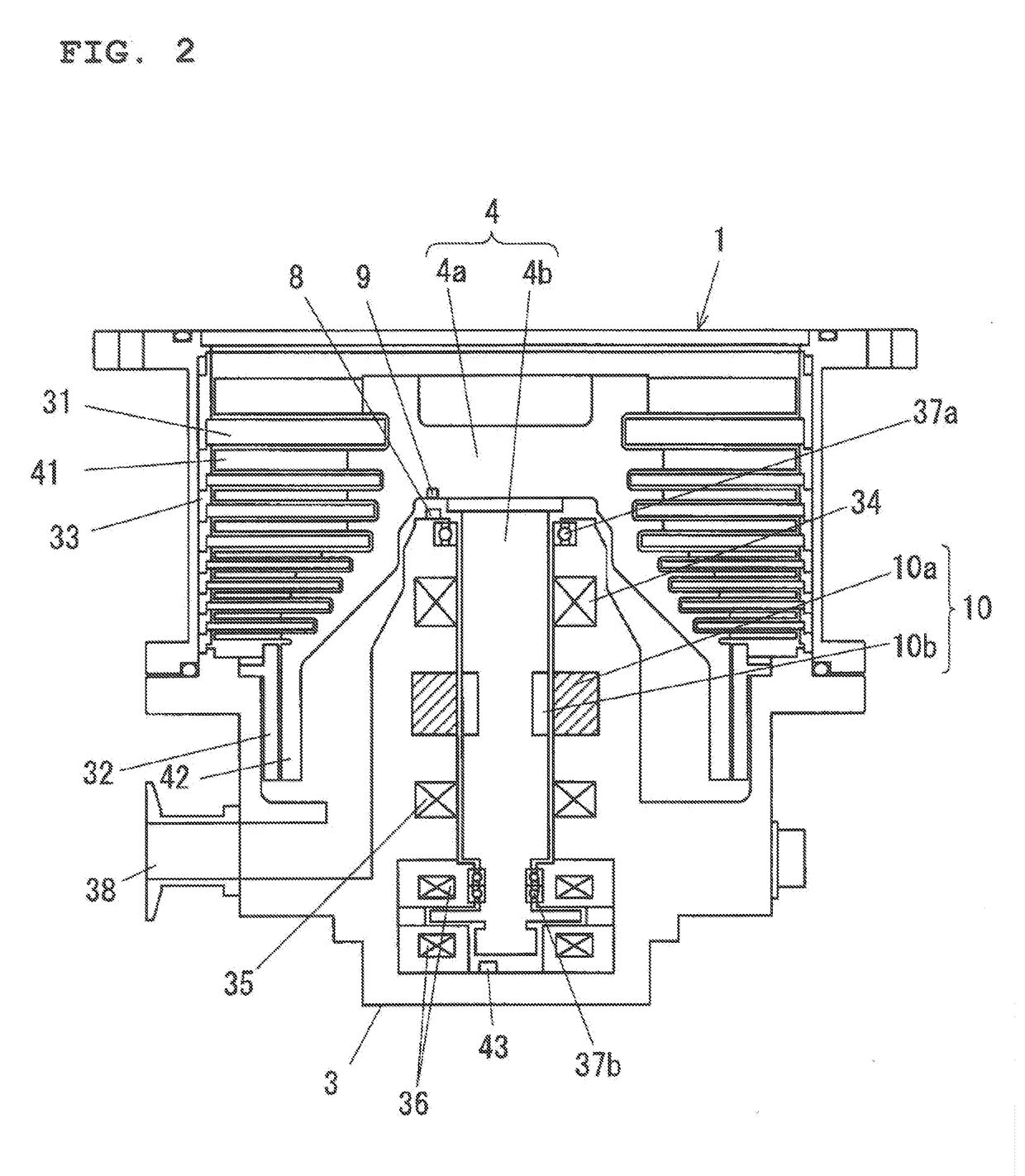

Rotor life estimation device and vacuum pump

ActiveUS20170371330A1Reduce in quantityPump componentsElectric testing/monitoringCreep strainEngineering

A rotor life estimation device of a vacuum pump including a rotor rotatably driven by a motor and a rotor temperature detection section configured to detect a temperature of the rotor, comprises: an arithmetic section configured to calculate a strain equivalent corresponding to creep strain of the rotor based on a correlation between a creep strain speed equivalent and the temperature of the rotor and the temperature detected by the rotor temperature detection section; an estimation section configured to estimate a rotor life based on the calculated strain equivalent; and a providing section configured to provide information on the estimated rotor life.

Owner:SHIMADZU CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com