Corrosion-resistant and high-temperature creep-resistant die-cast magnesium alloy and prep ration method thereof

A high-temperature and corrosion-resistant technology, applied in the field of lightweight metal materials, can solve the problems of poor corrosion resistance and high temperature creep resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

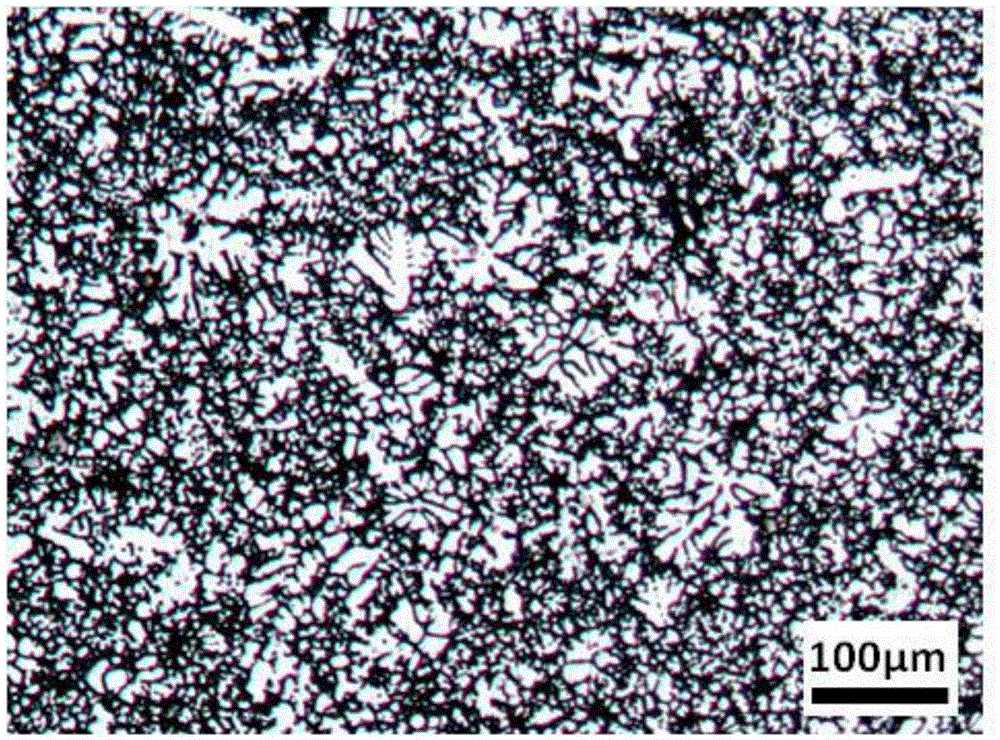

Image

Examples

preparation example Construction

[0044] The present invention also provides a method for preparing a corrosion-resistant and high-temperature creep-resistant die-cast magnesium alloy, comprising the following steps:

[0045] Step 1, smelting magnesium source, aluminum source, zinc source, manganese source, mixed rare earth source, ytterbium source, samarium source and strontium source to obtain a uniform alloy liquid;

[0046] Step 2: Pour the alloy liquid obtained in Step 1 into a cold chamber die-casting machine for die-casting to obtain a corrosion-resistant, high-temperature creep-resistant die-cast magnesium alloy

[0047] According to the present invention, the magnesium source, the zinc source, the manganese source, the mixed rare earth source, the ytterbium source, the samarium source and the strontium source are first smelted, the smelting temperature is preferably 730-760°C, and the smelting time is preferably 10-15min, A uniform alloy liquid is obtained; preferably, when the melt temperature is 750...

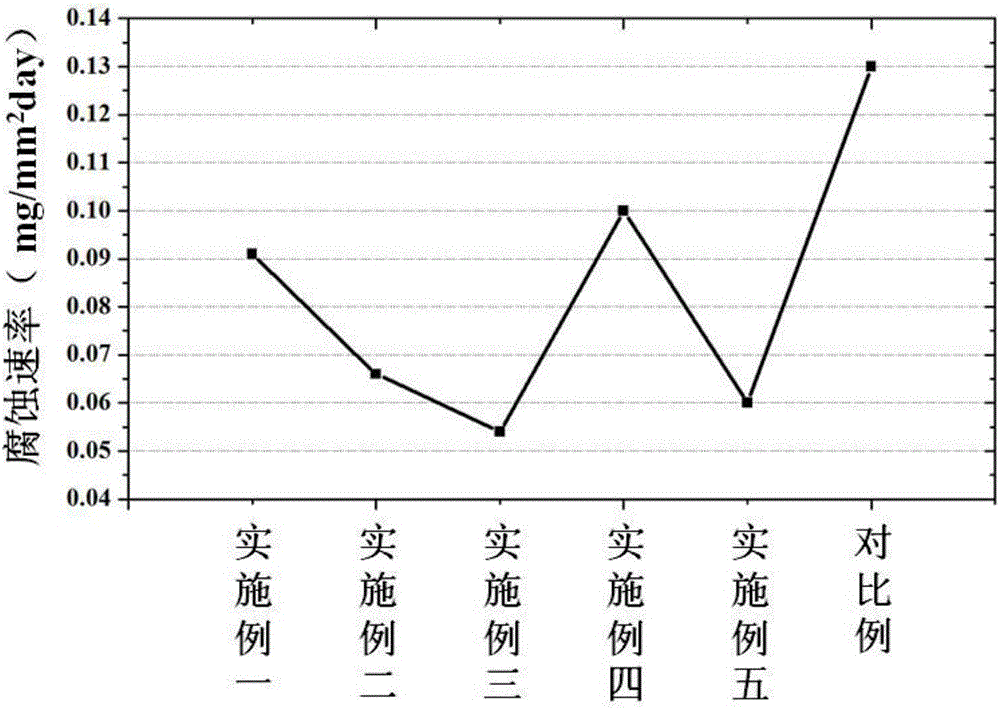

Embodiment 1

[0054] A corrosion-resistant, high-temperature creep-resistant die-casting magnesium alloy is made of the following components by mass percentage: Al: 8.5wt.%; Zn: 0.5wt.%; Mn: 0.35wt.%; RE: 0.4wt% %; Yb: 1.0 wt.%; Sm: 2.0 wt.%; Sr: 0.2 wt.%; the balance is pure magnesium and inevitable impurities.

[0055] A preparation process of corrosion-resistant and high-temperature creep-resistant magnesium alloy die-casting, the steps are as follows:

[0056] 1) Combine pure magnesium ingot, pure aluminum ingot, pure zinc ingot, magnesium-manganese master alloy containing 2% manganese, magnesium rare earth master alloy containing 20% mixed rare earth, magnesium-ytterbium master alloy containing 15% ytterbium, and 20% samarium The magnesium-samarium master alloy and the magnesium-strontium master alloy containing 15% strontium were smelted at 730°C, and stirred for 10 minutes to obtain a uniform alloy liquid;

[0057] 2) The furnace temperature was raised to 750°C, and argon was intr...

Embodiment 2

[0062] A corrosion-resistant, high-temperature creep-resistant die-cast magnesium alloy is made of the following components by mass percentage: Al: 9.0wt.%; Zn: 0.8wt.%; Mn: 0.35wt.%; RE: 0.8wt% %; Yb: 1.5 wt. %; Sm: 3.0 wt. %; Sr: 0.8 wt. %; the balance is pure magnesium and inevitable impurities.

[0063] A preparation process of corrosion-resistant and high-temperature creep-resistant magnesium alloy die-casting, the steps are as follows:

[0064] 1) Combine pure magnesium ingot, pure aluminum ingot, pure zinc ingot, magnesium-manganese master alloy containing 2% manganese, magnesium rare earth master alloy containing 20% mixed rare earth, magnesium-ytterbium master alloy containing 15% ytterbium, and 20% samarium The magnesium-samarium master alloy and the magnesium-strontium master alloy containing 15% strontium were smelted at 740 ° C, and stirred for 15 minutes to obtain a uniform alloy liquid;

[0065] 2) The furnace temperature was raised to 750°C, and argon was in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com