Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

185results about How to "Extended Diffusion Path" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ndfeb permanent magnet material with high magnetic energy product and high coercivity and manufacturing method thereof

ActiveCN105957679ALow costSolve adhesionInorganic material magnetismSolid state diffusion coatingRare earthGraphite

The invention belongs to the technical field of permanent magnet materials, and claims a Ndfeb permanent magnet material with high magnetic energy product and high coercivity. Component of the Ndfeb permanent magnet material is RE1xRE2yFzBwMmHn, wherein RE1 is selected from one or more than two of Pr, Nd, Ho, Gd, La and Ce, RE2 is selected from one or two of Dy and Tb, B is selected from one or two of boron and carbon, M is selected from one or more than two of Al, Cu, Zr, Nb, Ga, Si, Mo and Ti, H is an oxygen element, the rest is F, and F is selected from one or more than two of transition elements Fe, Co and Ni; and a manufacturing method of the Ndfeb permanent magnet material is (1) sintering for preparing a blank, covering two sides of a base material with heavy rare earth plates, isolating the heavy rare earth plates from the base material with a molybdenum net, and placing the blank in a graphite material box after isolation; (2) performing deposition and diffusion under vacuum condition at high temperature; further performing solid-state atomic diffusion under vacuum condition at low temperature; (3) repeating the step (2) more than once.

Owner:ORIENT MAGNET TECH OMT

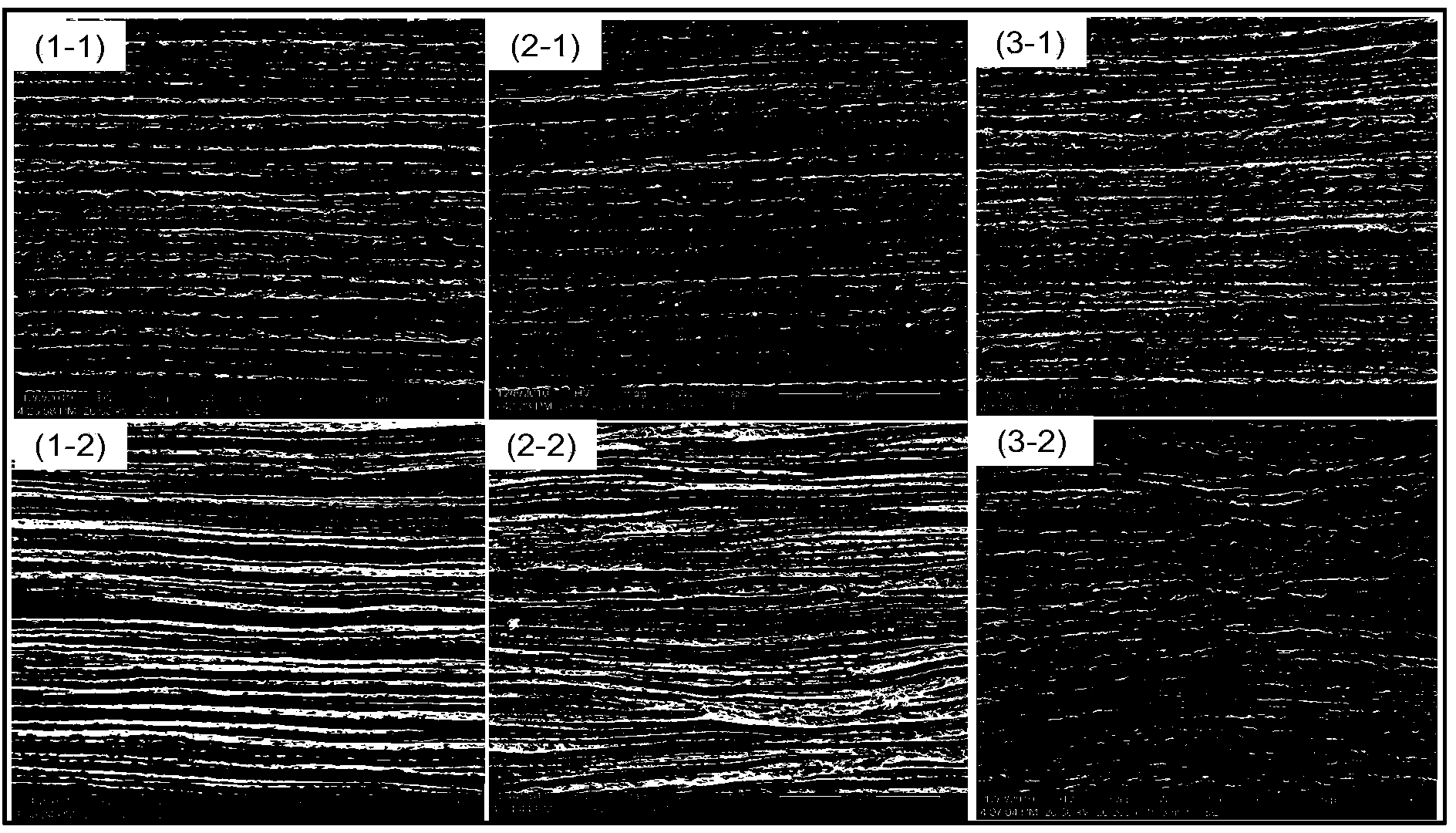

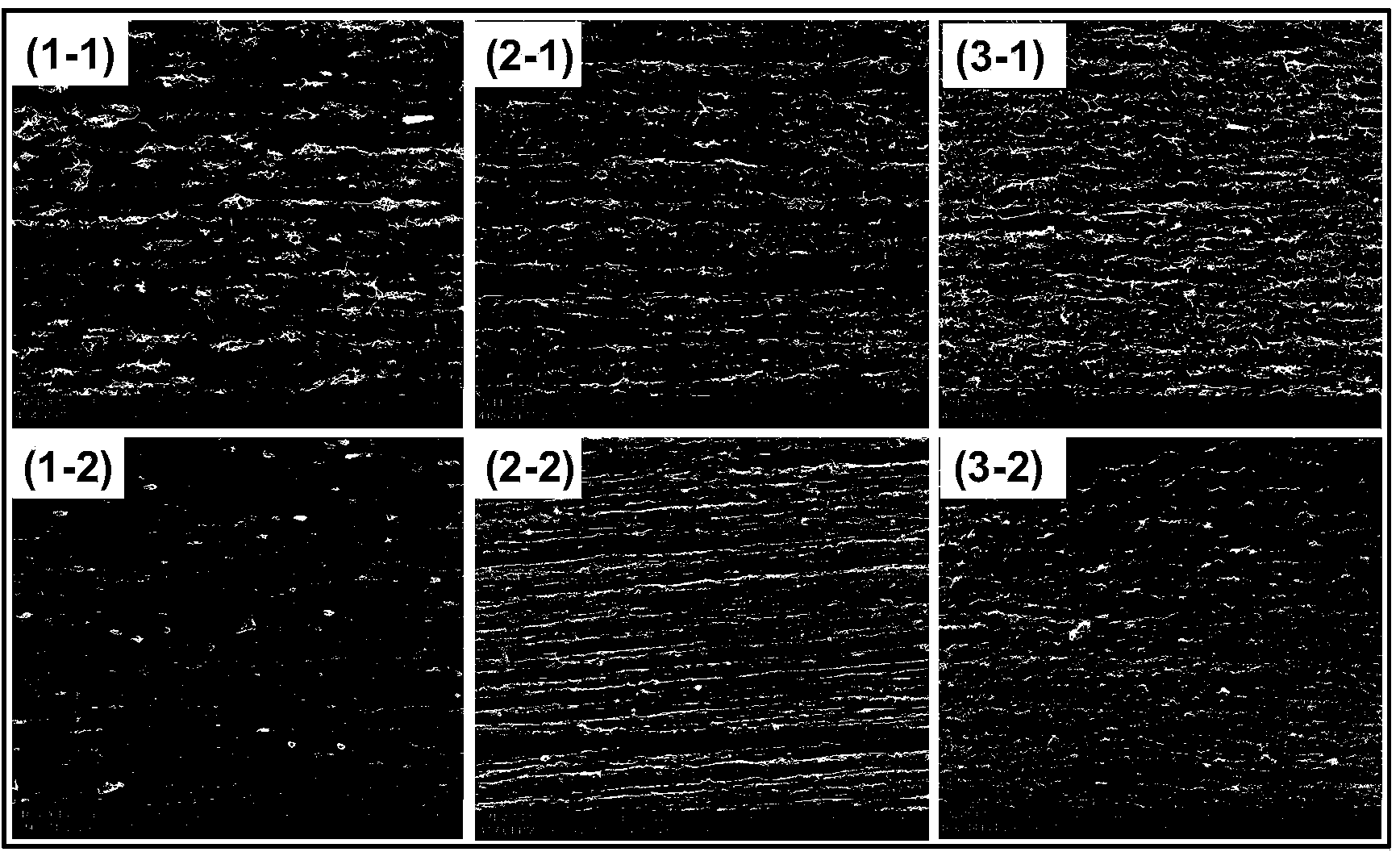

Polymer material with continuously-alternating layer structure and preparation method for same

ActiveCN103481393ASimple operation processReduce manufacturing costPolymer scienceInjection moulding

The invention discloses a preparation method for a polymer material with a continuously-alternating layer structure. The preparation method comprises the following steps of step 1, premixing 30-70 parts of first resin or a first resin compound and 70-30 parts of second resin or a second resin compound, adding the premix in a double-screw extruder, performing melt blending and extrusion at a temperature of 100-300 DEG C, cooling, and slicing to obtain blend grains; and step 2, performing high-speed thin-wall injection forming on the obtained blend grains at an injection temperature of 100-300 DEG C and an injection speed of 50-1200 mm / s, so as to obtain the polymer material with a continuously-alternating layer structure. The preparation method disclosed by the invention is simple in the whole operation process, low in production cost, suitable for large-scale industrialized production, capable of regulating and controlling the thickness of the continuously-alternating layer structure by adjusting the component proportioning ratio of the blend, and suitable for various blend systems.

Owner:SICHUAN UNIV

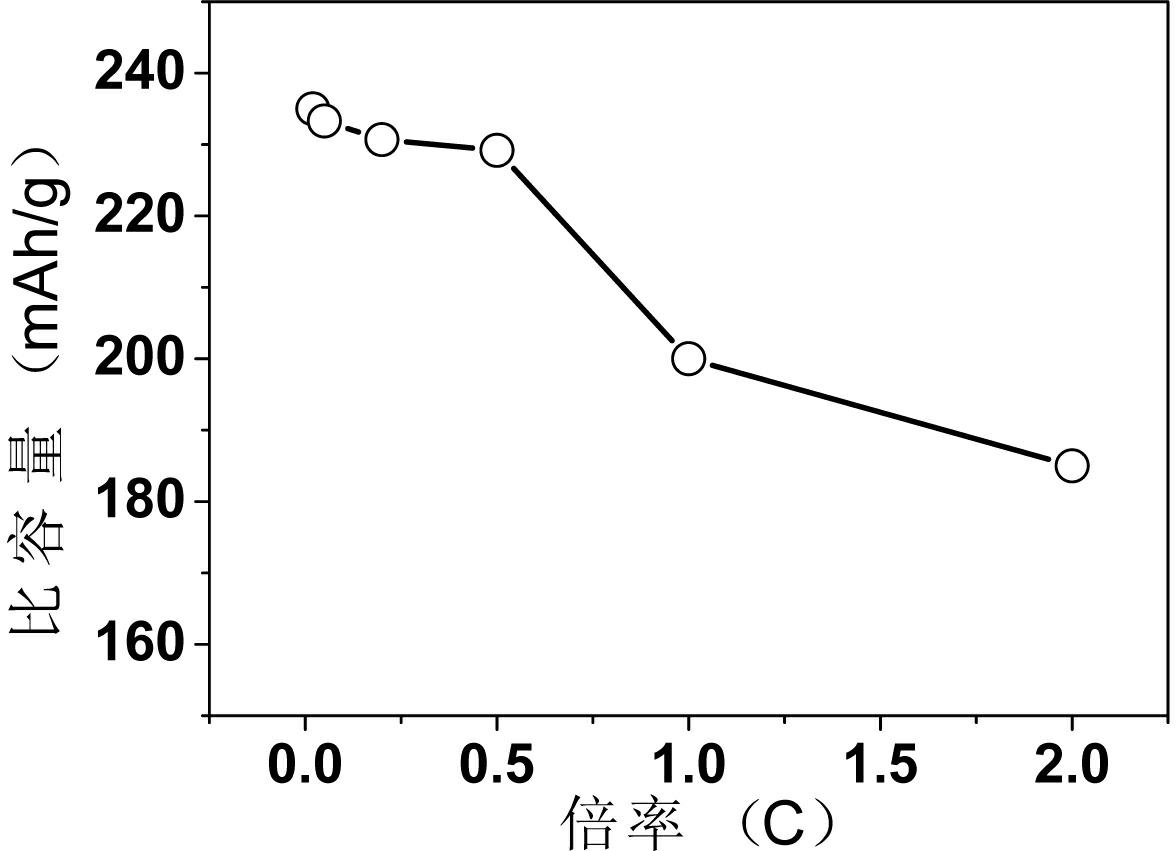

Cathode active material and preparation method thereof, cathode material and lithium ion battery

ActiveCN102569774AExtended Diffusion PathImprove stabilityCell electrodesSecondary cellsManganeseSodium-ion battery

The invention provides a cathode active material and a preparation method thereof, a cathode material and a lithium ion battery. The cathode active material is provided with a kernel and a shell wrapped on the surface of the kernel, wherein the kernel is made of a lithium-enriched manganese-based material; the composition of the lithium-enriched manganese-based material is Li1+xMnaMbOz, wherein x is more than or equal to 0 and less than or equal to 1, a is more than 0 and less than or equal to 2, b is more than or equal to 0 and less than or equal to 2, z is more than or equal to 2 and less than or equal to 5, and M is selected from one or more of Co, Ni, Fe, Mg, Ca, Sn, Ti, Zr, Zn and Cr; and the shell is made of boron oxide. The rate capability and the circulation performance of the lithium ion battery prepared by adopting the cathode active material are high.

Owner:BYD CO LTD

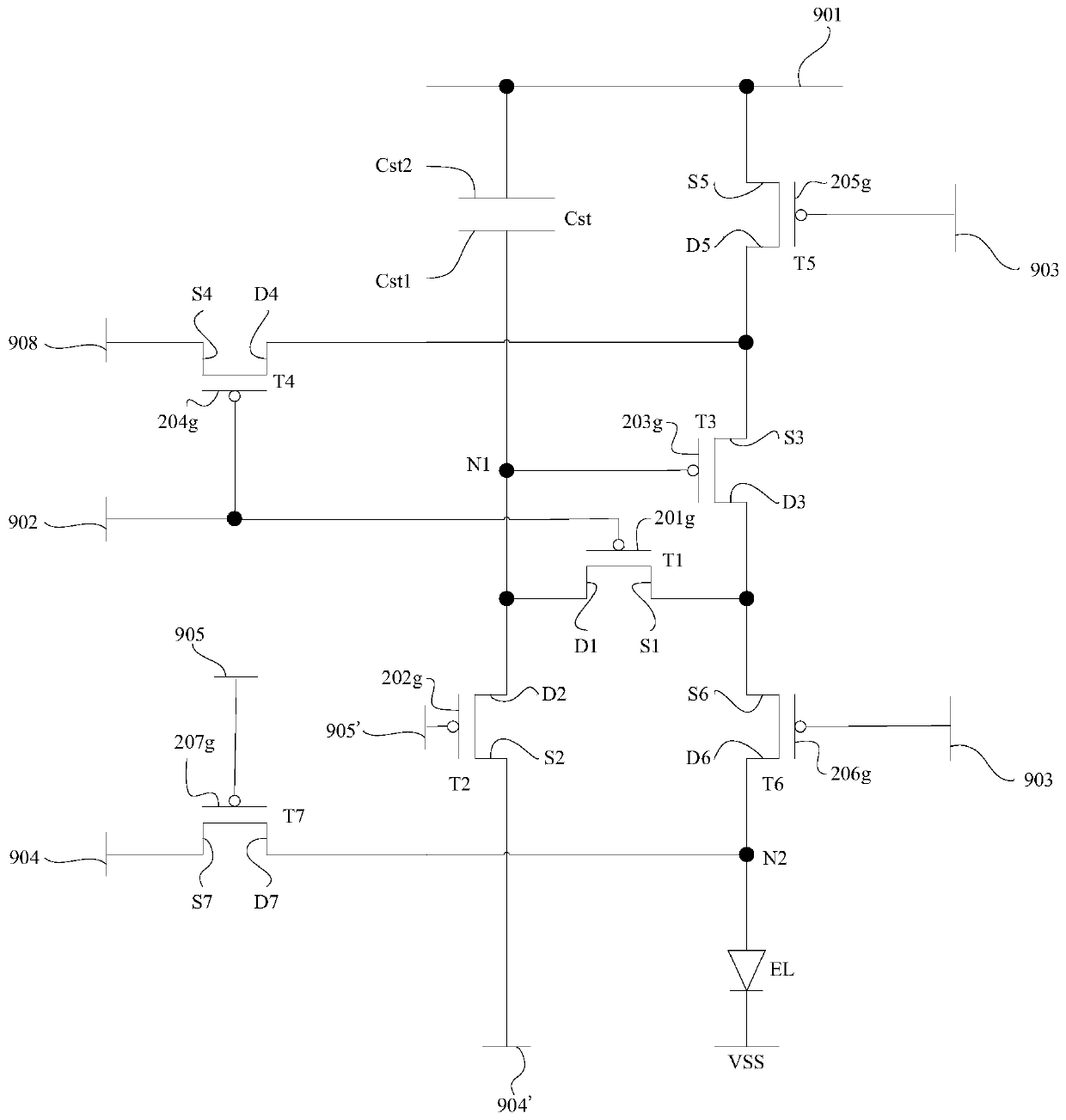

Display panel, manufacturing method thereof and display device

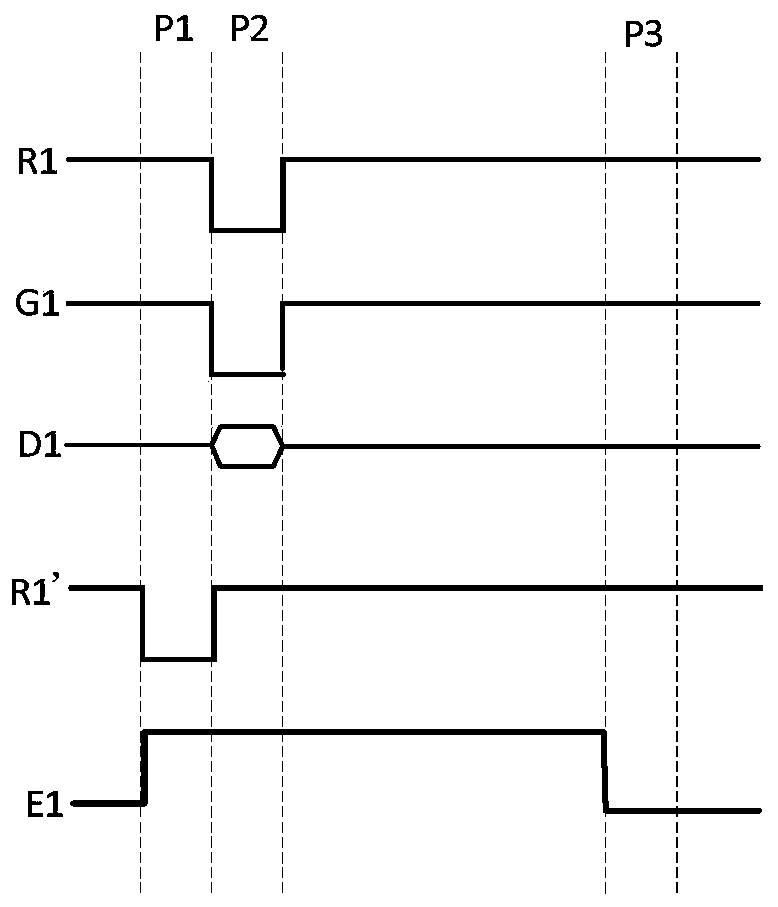

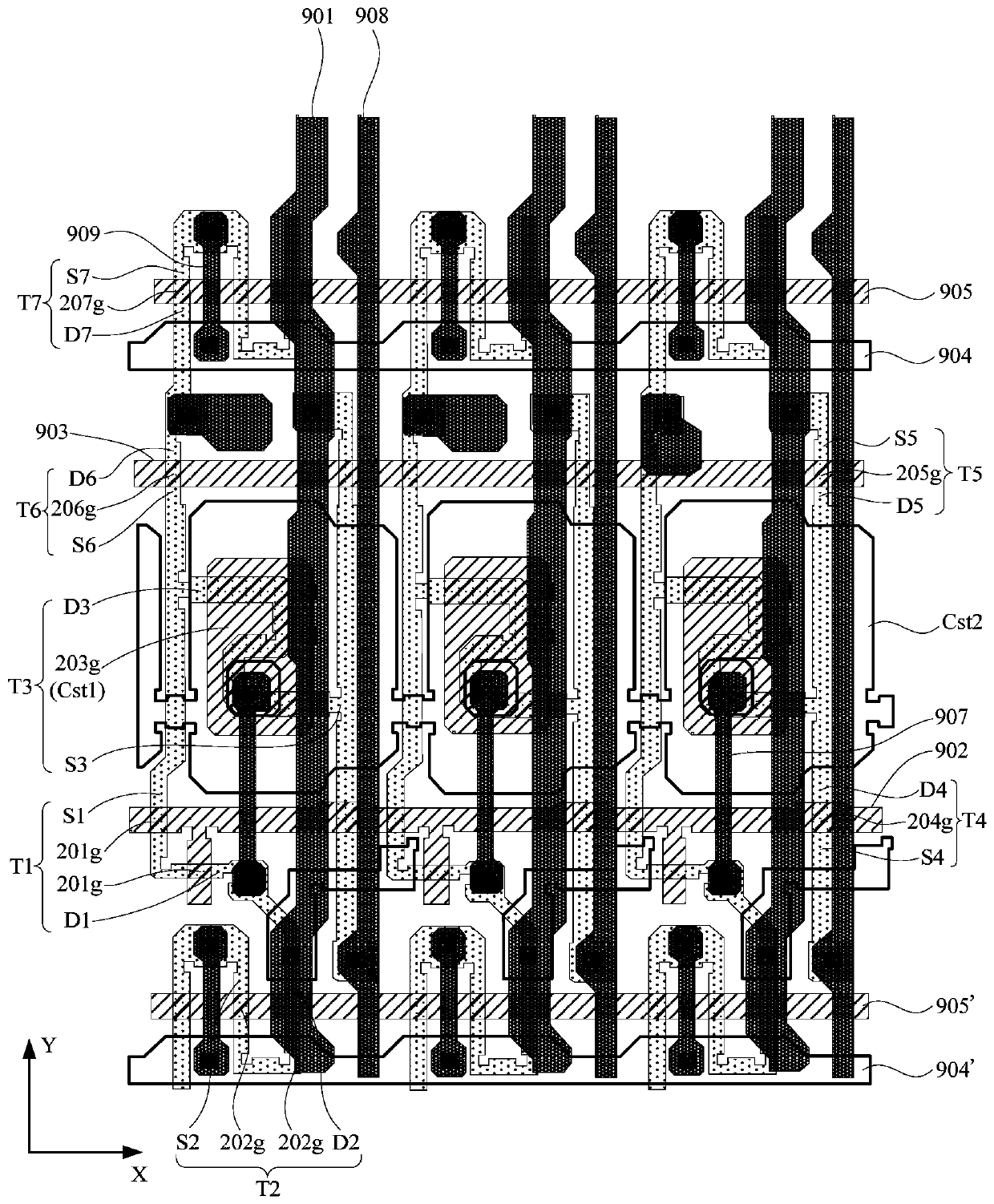

ActiveCN111584599AExtended Diffusion PathSlow release rateStatic indicating devicesSolid-state devicesGraphicsDisplay device

The invention provides a display panel, a manufacturing method thereof and a display device, relates to the technical field of the display, and aims to solve the problem that in the use process of a display product, water molecules in a flat layer escape and erode a light-emitting functional layer, so that the service life of the display product is shortened. The display panel comprises a substrate and a plurality of pixel units arranged on the substrate, the plurality of pixel units are distributed in an array, and each pixel unit comprises a plurality of sub-pixels; each sub-pixel comprisesa sub-pixel driving circuit, a flat layer and an anode pattern which are sequentially stacked; the anode patterns in at least part of the sub-pixels comprise middle parts and edge parts surrounding the middle parts; the surfaces, back to the substrate, of the flat layers are provided with grooves, the orthographic projections of the grooves on the substrate surrounds the orthographic projections of the middle parts on the substrate, and the orthographic projections of at least parts of the edge parts on the substrate are located in the orthographic projections of the grooves on the substrate.The display panel provided by the invention is used for displaying pictures.

Owner:BOE TECH GRP CO LTD +1

Method for preparing polyolefin-based barrier material product

The invention discloses a novel method for preparing a polyolefin-based barrier material product, which is characterized in that: a micro-layered coextrusion method is combined with the methods such as mold pressing, injection molding, blow molding or extrusion molding and the like to prepare the polyolefin-based barrier material products with different shapes. The micro-layered coextrusion can effectively control a lamellar morphological structure and a length-diameter ratio of a barrier phase, and the mold pressing, the injection molding, the blow molding or the extrusion molding has diversity, so the method not only can compensate the single type of the product which is prepared through the micro-layered coextrusion method, but also overcomes the defect that in the traditional mold pressing, the injection molding, the blow molding or the extrusion molding, a lamella blend of the product cannot be molded on an original position. The prepared polyolefin-based barrier material product has a parallel lamella structure, the lamella structure of the high aspect ratio of the barrier phase can greatly lengthen a diffusion path of small molecules, so the barrier property of the material can be greatly improved, or the consumption of the barrier polymer can be remarkably reduced on the premise of reaching the same barrier effect, and the cost can be saved. At the same time, the mechanical property of the material can be remarkably improved.

Owner:SICHUAN UNIV

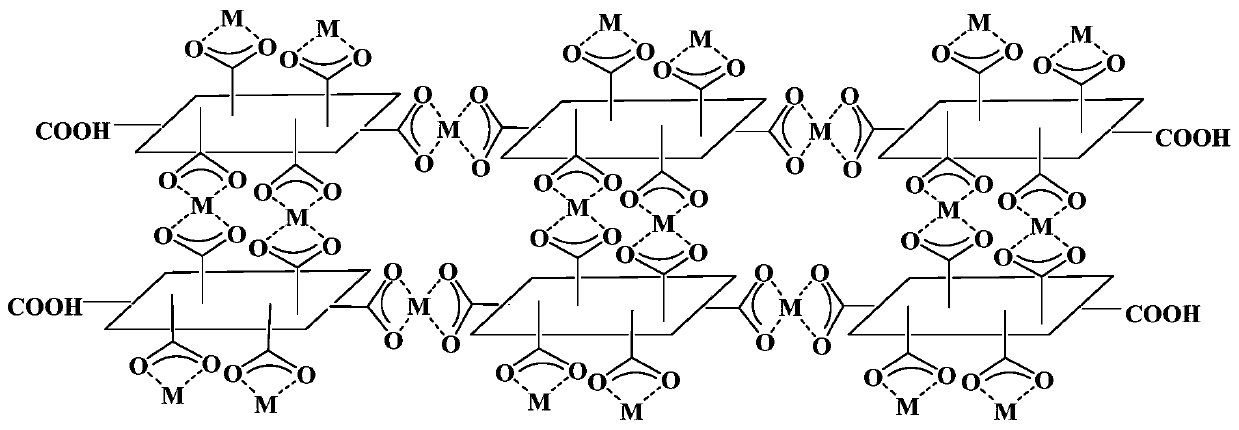

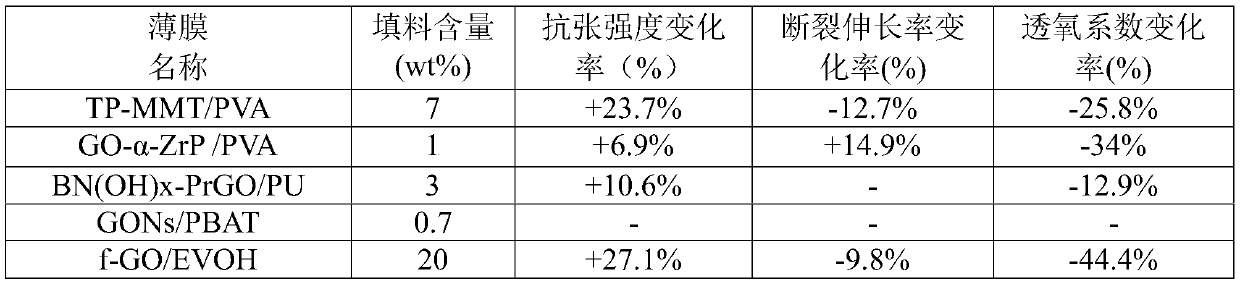

High-oxygen-resistance polymer nano-composite film and preparation method thereof

InactiveCN109880267AExcellent gas barrier propertiesHigh gas barrierMetal chlorideMechanical property

The invention discloses a high-oxygen-resistance nano-composite membrane and a preparation method thereof. The preparation method comprises the following steps: adding a filler dispersion liquid intoa first solution, conducting uniform stirring, dropwise adding a second solution, conducting uniform mixing under stirring, carrying out ultrasonic degassing treatment and standing, conducting tape-casting on the mixed liquid to enable the mixed liquid to enter a mold, and conducting drying and curing to obtain the high-oxygen-resistance nano-composite film. The lamellar nano-filler is controlledto account for 0.2-2 wt% of the total mass of the raw materials. The first solution is obtained by adding a hydrophilic polymer into deionized water and conducting heating and stirring to completely dissolve the hydrophilic polymer; the second solution is obtained by dissolving a metal chloride in deionized water to prepare a metal ion solution; and the uniform filler dispersion liquid is obtainedby adding a lamellar nano-filler into deionized water and conducting uniform stirring and mixing and ultrasonic treatment. The high-oxygen-resistance nano-composite membrane has the advantages of being excellent in oxygen barrier property, small in filler consumption, simple and convenient to operate, easy to process, biodegradable and excellent in comprehensive mechanical property.

Owner:SOUTH CHINA UNIV OF TECH

Positive pole material with nuclear shell structure for lithium battery, and preparation method and application thereof

InactiveCN102169991AExtended Diffusion PathEasy to spreadCell electrodesLi-accumulatorsNiobiumDry mixing

The invention discloses a positive pole material with a nuclear shell structure for a lithium battery, and a preparation method thereof. The positive pole material with a nuclear shell structure for a lithium battery has the general formula of LixFeyPO4.z(LiaMbPO4), wherein the nuclear material has the general formula of LixFeyPO4, wherein x is not less than 0.9 and less than 1.0, and y is not less than 0.9 and less than 1.0; the shell material has the general formula of LiaMbPO4, wherein a is not less than 1.15 and not larger than 1.25, and b is not less than 1.15 and not larger than 1.25; M is selected from one of ferrum, cobalt, nickel, manganese, vanadium, niobium, zirconium and titanium; and z is larger than 0 and not larger than 0.3. The invention further discloses a preparation method of the positive pole material with the nuclear shell structure for the lithium battery, which adopts the production technology of dry mixing without the process of drying; therefore, the energy in industrial production can be effectively saved compared with the prior art.

Owner:SICHUAN SIMEI TECH

Aqueous polyanion metal composite anti-corrosion material and method for preparing the same

InactiveCN1803951AInhibition of Adsorption and GrowthImprove anti-corrosion performanceAnti-corrosive paintsEpoxy resin coatingsAmmonium sulfateIon

Disclosed is a water-based polyaniline composite metal corrosion-proof material and method for preparation, wherein the material is prepared from the following raw materials (by weight portions): sodium-based montmorillonite 3-8 parts, polystyrolsulfon acid 3-9 parts, deionized water 64-110 parts, phenylamine 1-4 parts, ammonium persulphate 3-9 parts, water-based epoxy resin emulsion 50-60 parts, and water-based epoxy resin curing agent emulsion 20-35 parts.

Owner:NORTHWEST NORMAL UNIVERSITY

Waterborne epoxy graphene zinc anticorrosive coating and preparation method and application thereof

InactiveCN109762446AIncrease the conductive pathIncrease profitAnti-corrosive paintsEpoxy resin coatingsEpoxyEmulsion

The invention discloses a waterborne epoxy graphene zinc anticorrosive coating. The waterborne epoxy graphene zinc anticorrosive coating comprises a first component and a second component, wherein thefirst component is prepared from the following components in parts by weight: 5-10 parts of a waterborne epoxy resin curing agent, 0.5-1 part of a dispersant, 1-3 parts of an anti-settling agent, 1-3parts of a coalescing agent, 10-15 parts of body pigment, 42-65 parts of zinc powder and 4.5-5 parts of graphene dispersion slurry. The second component is prepared from the following components in parts by weight: 30-40 parts of aqueous epoxy emulsion, 1-2 parts of an anti-flash rust agent, 5-15 parts of water and 0.2-0.8 part of a defoaming agent. The waterborne epoxy graphene zinc anticorrosive coating has high utilization rate of zinc powder and is easy to prepare, and the formed coating has excellent comprehensive properties, such as good compactness, excellent cathodic protection performance and shielding performance, anticorrosive performance is remarkably improved, and the waterborne epoxy graphene zinc anticorrosive coating has wide application prospects in the field of marine equipment anticorrosion.

Owner:宁波中科银亿新材料有限公司 +1

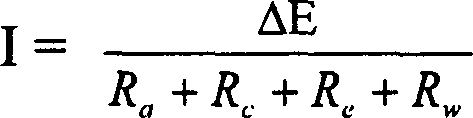

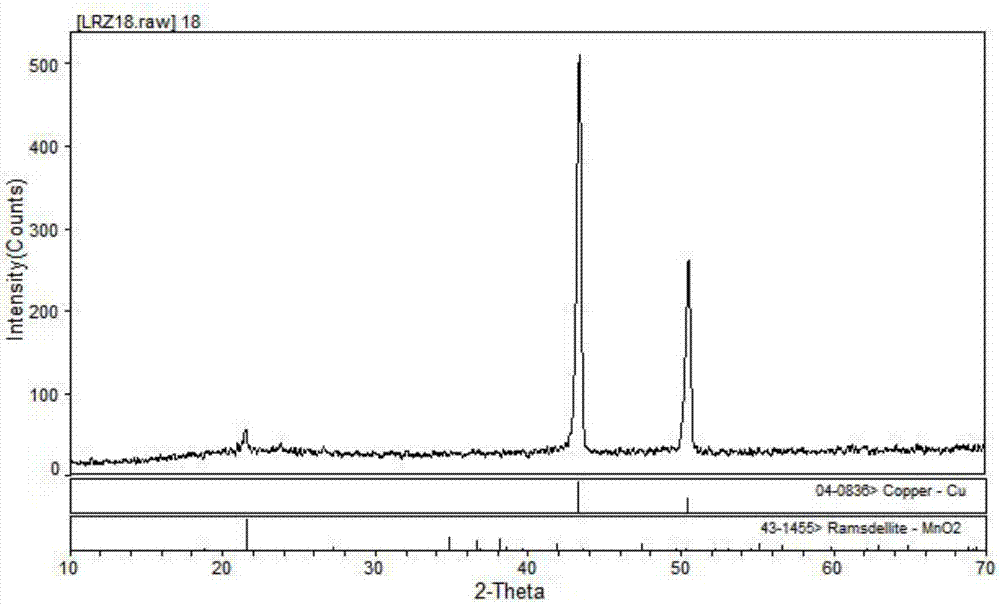

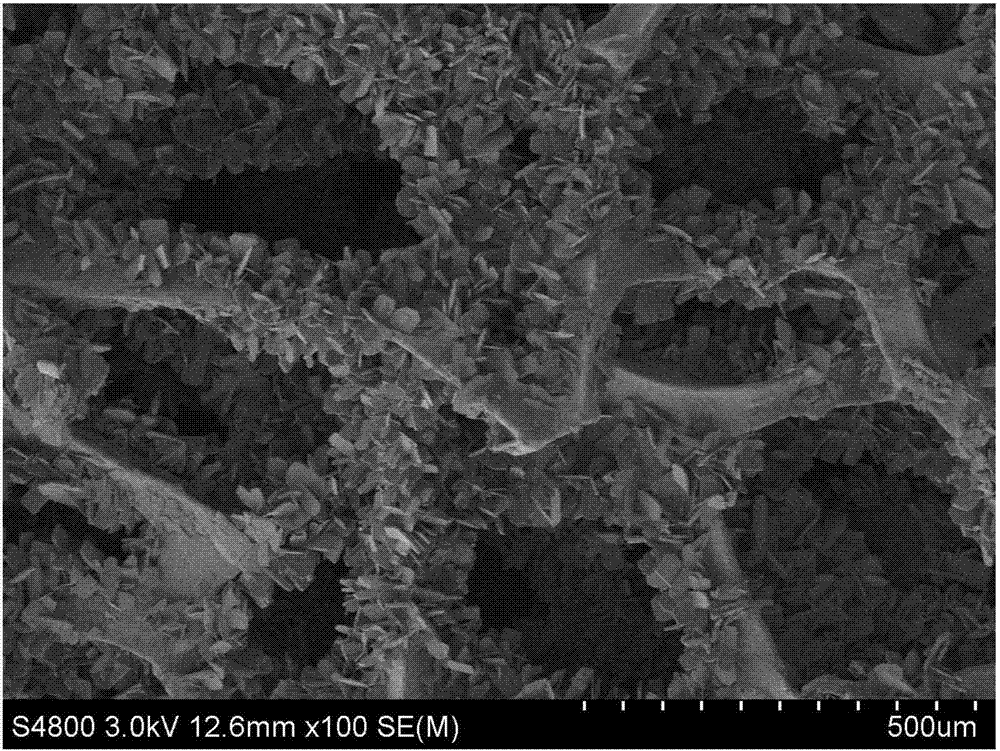

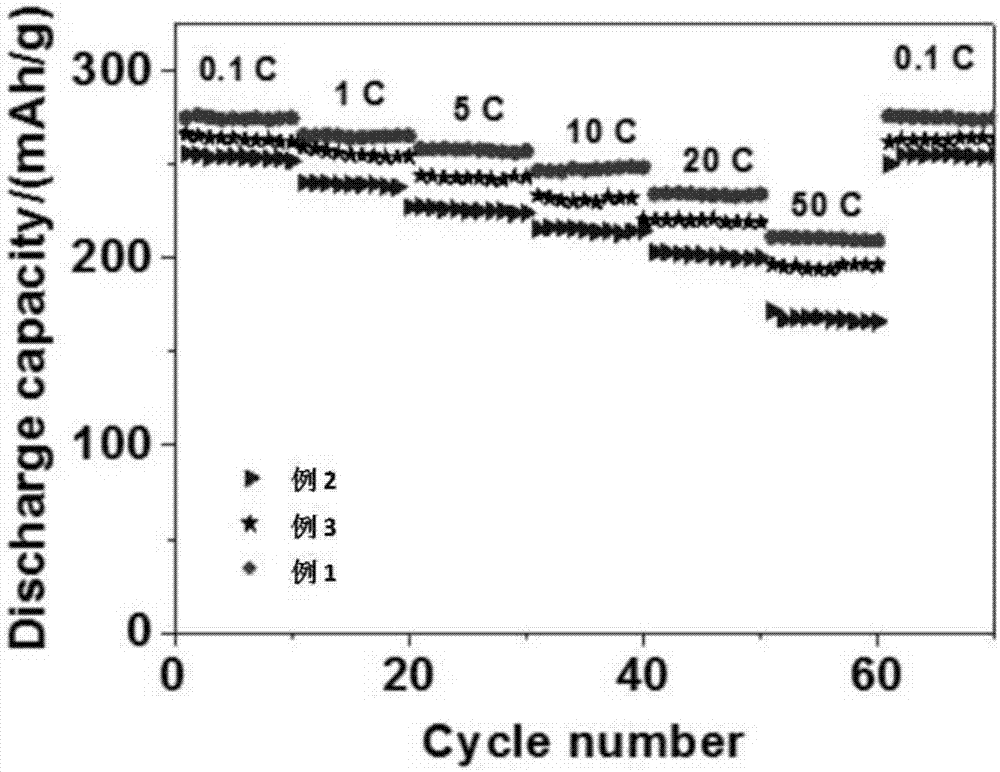

Manganese dioxide/copper foam sodium ion battery self-supporting negative pole preparation method

ActiveCN107093703ACapacity does not affectExcellent rate performanceElectrode carriers/collectorsSecondary cellsAlcoholSulfate

The invention discloses a manganese dioxide / copper foam sodium ion battery self-supporting negative pole preparation method. The method comprises the steps that flake copper foam is treated with absolute ethyl alcohol, washed to be clean and dried, and an electrode substrate is obtained; a manganese sulfate solution of a certain concentration is prepared; the obtained solution and a copper foam sheet are put into a hydrothermal reaction kettle, heating and heat preservation are conducted for a certain time through hydrothermal induction heating equipment, and then the manganese dioxide / copper foam sodium ion battery self-supporting negative pole with a three-dimensional porous communicating frame-shaped structure is obtained.

Owner:SHAANXI UNIV OF SCI & TECH

High-entropy alloy diffusion barrier layer for Cu interconnect integrated circuit and preparation method of high-entropy alloy diffusion barrier layer for Cu interconnect integrated circuit

ActiveCN108336062AThin diffusion barrierUniform compositionSemiconductor/solid-state device detailsVacuum evaporation coatingHigh entropy alloysIntegrated circuit

The invention relates to the technical field of semiconductor integrated circuits, in particular to a high-entropy alloy diffusion barrier layer for a Cu interconnect integrated circuit and a preparation method of the high-entropy alloy diffusion barrier layer for the Cu interconnect integrated circuit. The high-entropy alloy diffusion barrier layer for the Cu interconnect integrated circuit sequentially comprises a Si substrate layer, a high-entropy alloy intermediate coating and a Cu film from bottom to top, wherein the high-entropy alloy intermediate coating sequentially comprises a third coating, a second coating and a first coating from bottom to top; the first coating is an AlCrTaTiZrMo high-entropy alloy coating; the second coating is a pure Ti coating; and the third coating is an AlCrTaTiZrMoNx high-entropy alloy coating. According to the high-entropy alloy diffusion barrier layer for the Cu interconnect integrated circuit, improvement of the atomic bulk density is facilitated,generation of defects, such as vacancies is reduced, a diffusion channel for atoms is reduced, and the diffusion barrier performance and the heat stability of the high-entropy alloy coatings are improved.

Owner:SHANGHAI DIANJI UNIV

Graphite phase like carbonitride/epoxy resin anti-corrosive coating, and preparation method and applications thereof

ActiveCN110157296AEasy to prepareFast preparation methodAnti-corrosive paintsEpoxy resin coatingsResin coatingGraphite

The invention discloses a graphite phase like carbonitride / epoxy resin anti-corrosive coating, and a preparation method and applications thereof. The graphite phase like carbonitride / epoxy resin anti-corrosive coating comprises following components: graphite phase like carbonitride, an epoxy resin, a solvent, and a curing agent; wherein the weight ratio of the graphite phase like carbonitride to epoxy resin is controlled to be 0.5-5:100; the epoxy resin is a glycidyl ether epoxy resin. The preparation method is capable of avoiding defects of pure epoxy resin coating at sea environment such aspoor corrosion resistance and poor durability; graphite phase like carbonitride is large in specific surface area, and is capable of blocking corrosion mediums from penetration into coating, so that coating penetration path is more deflective; compared with pure epoxy resin coating, the corrosion rate of the composite coating is reduced by 2 to 3 orders of magnitudes; the clunging force between coating and substrate is increased obviously from 3B grade to 5B grade; and epoxy resin and metal substrate surface clunging force is enlarged effectively with greatly improved metal substrate corrosionresistance.

Owner:TAIYUAN UNIV OF TECH

High-temperature thin film sensor with self-healing composite protective layer and preparation method thereof

InactiveCN107201502AImprove antioxidant capacityExtended service lifeEngine testingVacuum evaporation coatingSelf-healingMultilayer membrane

The invention belongs to the technical field of a sensor, and provides a high-temperature thin film sensor with a self-healing composite protective layer and a preparation method thereof, and aims to realize miniaturization and thin-film application of the sensor. The thin film sensor is composed of a substrate, a thin film sensor sensitive functional layer and the self-healing composite protective layer, which are arranged from bottom to top in order, wherein the structure of the self-healing composite protective layer comprises YSiO / HfSiBCN periodic multilayer membrane structures from bottom to top in order, and the lowest layer and the topmost layer of the protective layer are both YSiO low-oxygen diffusion coefficient layers. The high-temperature thin film sensor adopts the self-healing composite protective layer with the self-healing composite protective layer, the YSiO low-oxygen diffusion coefficient layers and HfSiBCN self-healing layers are alternately deposited to form an anti-oxidative protection system with layers of protection, and therefore the thin film sensor can work for a long time under the condition of high temperature of 600-1500DEG C and has the advantages of high temperature resistance, corrosion resistance, oxidation resistance, fast response, etc.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

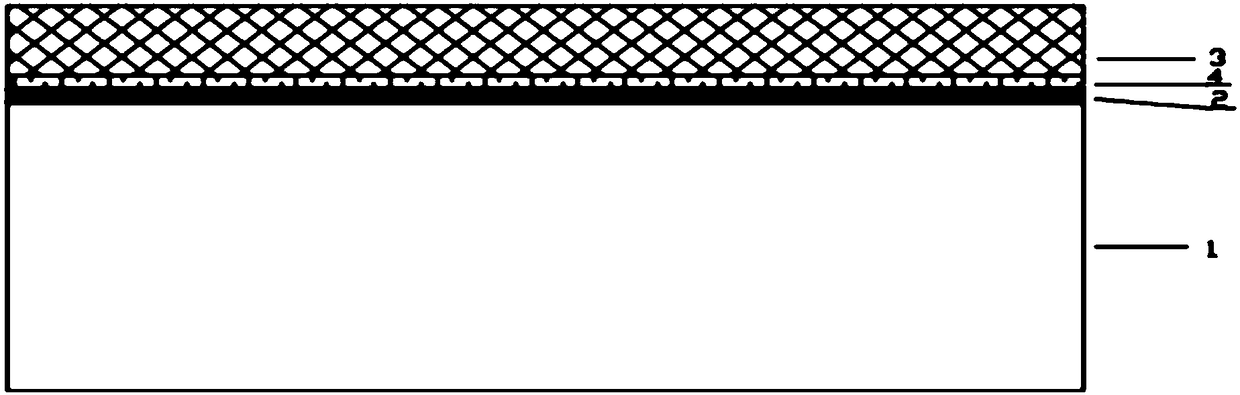

High-barrier polyimide composite film with shell-like dense structure and preparation method and application thereof

ActiveCN111499913AExtended Diffusion PathHigh barrierSemiconductor/solid-state device detailsSolid-state devicesPolymer scienceComposite film

The invention discloses a high-barrier polyimide composite film with a shell-like dense structure and a preparation method and application thereof, and belongs to the field of flexible electronic device film packaging. The preparation method comprises the following steps: filling a polyimide base material with a high-mass-fraction layered nano material; to prepare the polyimide composite materialwith good gas barrier property; carrying out polycondensation or copolymerization on one or more diamine monomers and one or more dianhydride monomers; preparing a polyimide substrate film with an alkali treatment surface, reacting with an organic alkali to prepare a polyamic acid salt solution, adding the polyamic acid salt solution into a uniformly dispersed nano layered material with a requiredmass concentration to obtain a composite material glue solution, coating the polyimide substrate film with the alkali treatment surface with the composite material glue solution, and carrying out thermal imidization treatment to obtain the film material with good barrier properties. The preparation method is a solution state process and does not involve a vacuum process. The added nanosheet layermaterial is wide in source, low in price and suitable for large-scale industrial manufacturing. The prepared polyimide composite film has good barrier property to gases such as water vapor and the like.

Owner:SUN YAT SEN UNIV

Rechargeable battery and electrode thereof

ActiveUS20190386331A1Extended Diffusion PathIncrease profitFinal product manufactureElectrode carriers/collectorsRechargeable cellEngineering

A rechargeable battery and an electrode thereof are provided. The rechargeable battery includes two electrodes and an ionic conduction layer. The ionic conduction layer is disposed between the two electrodes. At least one electrode includes a diffusion-assisting structure facing to the ionic conduction layer. The diffusion-assisting structure has a concaved pattern.

Owner:GOLD CARBON CO LTD

Vacuum drying device

ActiveCN108344254AExtend the distribution pathStable and uniform changeDrying solid materials without heatDrying gas arrangementsEngineeringVacuum drying

The invention relates to a vacuum drying device. The vacuum drying device comprises a drying chamber, a sample table and a flow stabilizing channel, wherein the drying chamber is provided with a vacuum cavity, the sample table is arranged in the vacuum cavity, the flow stabilizing channel is arranged in the vacuum cavity, one end of the flow stabilizing channel is used for communicating with an air extracting device, and the other end of the flow stabilizing channel is arranged towards the sample table and is provided with an airflow inlet. Compared with a conventional vacuum drier, a stable layer flow is formed on the surface of a sample by adopting the vacuum drying device, so that the situation of turbulence formed in a membrane layer or the situation that intermediate drying speed is small while the peripheral drying speed is high in the membrane layer can be avoided, water in ink and other materials to be volatilized can be uniformly volatilized as much as possible, the uniformityof membrane forming is effectively improved, and the performance of the device is further improved.

Owner:GUANGDONG JUHUA PRINTING DISPLAY TECH CO LTD

Method for removing heavy metal lead ions from water mass by absorbing with sodium alginate-hydrotalcite-graphene gel balls

InactiveCN106944013AHigh mechanical strengthIncreased mechanical toughnessOther chemical processesAlkali metal oxides/hydroxidesLone electron pairSorbent

The invention provides a method for removing heavy metal lead ions from a water mass by absorbing with sodium alginate-hydrotalcite-graphene gel balls. The method comprises the following steps of adding the sodium alginate-hydrotalcite-graphene gel balls into the water mass which contains the heavy metal lead ions, and vibrating to absorb the heavy metal lead ions. Unsaturated ions and chemical groups, such as carboxyl and hydroxyl, which have lone electron pairs, are on the surface of sodium alginate, on one hand, ion exchange reaction occurs between the unsaturated ions of the sodium alginate and the lead ions, and on the other hand, complexation occurs between the groups, such as carboxyl and hydroxyl on the surface of sodium alginate and the lead ions. As oxidized grapheme is added into the sodium alginate, the mechanical strength and tenacity of the gel balls are improved, functional groups which can be reacted with the metal ions, in the adsorbent are also increased, and the removal rate of the method is higher than that of the method for removing lead by sodium alginate gel balls. The method provided by the invention is simple in step, convenient in operation and high in practicability.

Owner:NEW MATERIAL INST OF SHANDONG ACADEMY OF SCI

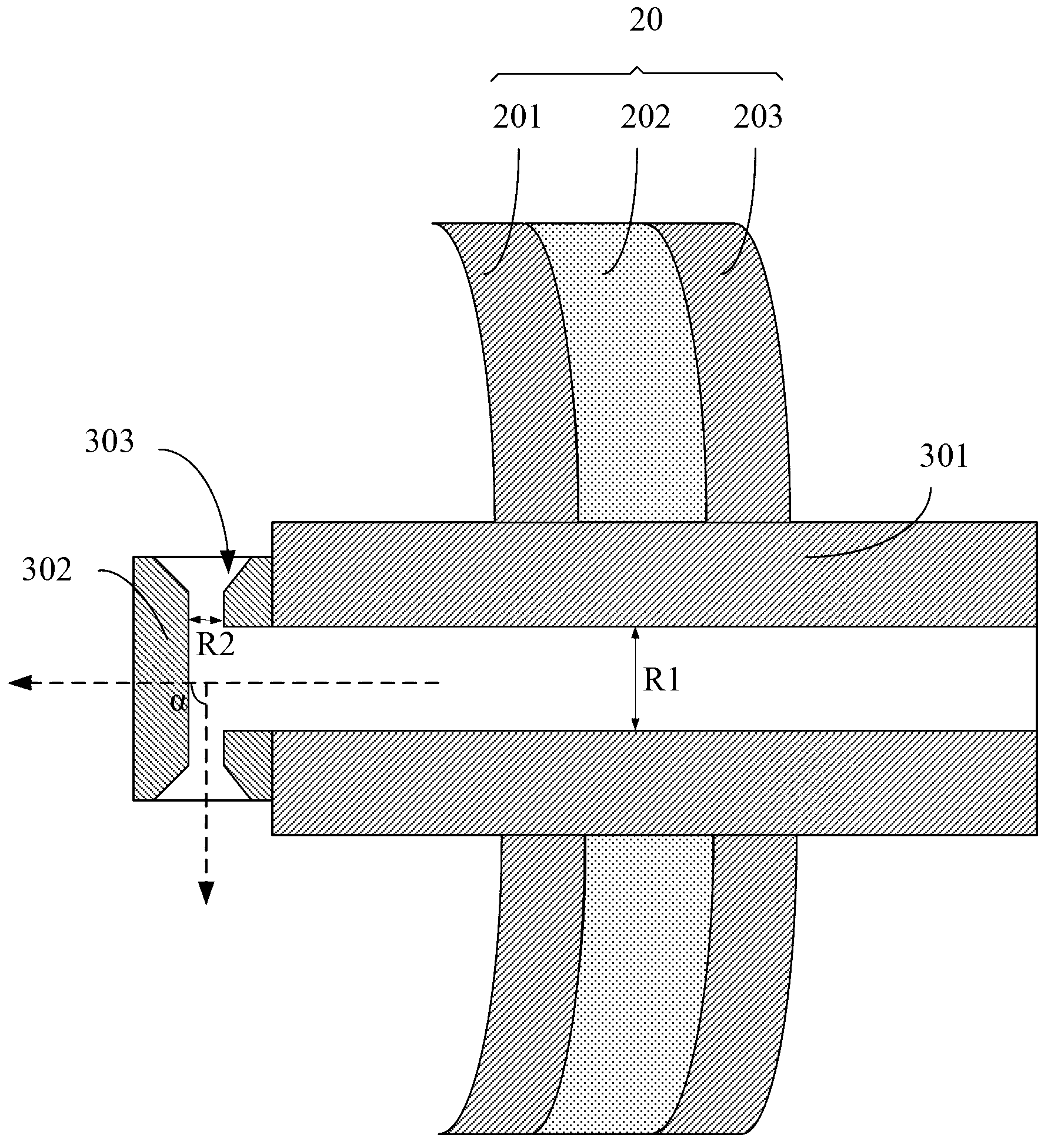

Reaction cavity

InactiveCN103266307AExtended Diffusion PathIncrease the areaChemical vapor deposition coatingShortest distanceCooling effect

The invention discloses a reaction cavity which comprises a cavity inner liner, a cooling cavity and a purging structure, wherein the purging structure comprises a first air inlet pipe passing through the cooling cavity from the outside of the cooling cavity; the first air inlet pipe is provided with an air outlet at the end arranged towards the cavity inner liner; the direction of the connecting line from the air outlet of the first air inlet pipe to the shortest distance between the cavity inner liner and the surface of the cooling cavity is taken as the first direction; the direction in which the purge gas is guided out from the air outlet is taken as the second direction; an included angle is formed between the second direction and the first direction, so that the diffusion path of the purge gas can be prolonged, the contact area of the inner liner is enlarged, and the cooling effect is reduced; and therefore, the phenomenon of low local temperature of the cavity inner liner can be reduced, and the even airflow field can be formed. Furthermore, the space between the cavity inner liner and the inner wall of the cooling cavity is protected and maintained to be stable, so that the reaction cavity is beneficial to maintaining the reaction to be carried out normally.

Owner:光垒光电科技(上海)有限公司

Coal-fired boiler exhaust gas absorption and purification device

InactiveCN107744711AExtended Diffusion PathAvoid enteringCombination devicesGas treatmentFiltrationSpiral blade

The invention provides a coal-fired boiler exhaust gas absorption and purification device. The device comprises a dust removal unit, an oxidation unit and an adsorption unit. The dust removal unit includes a first exhaust gas inlet and a first exhaust gas outlet separately disposed at the bottom and the top of the dust removal unit. The opposite inner sides of the inner wall of the dust removal unit are symmetrically provided with mutually parallel baffle plates. The dust removal unit communicates with the oxidation unit through a first connection pipe, the oxidation unit is internally provided with a first spiral blade spirally wound on a fixed shaft, and the first spiral blade and the side wall of the oxidation unit form a first spiral airflow passage, the periphery of the first spiral blade is provided with a nanometer titanium dioxide coating, and the side wall of the oxidation unit is provided with a UV lamp. The oxidation unit communicates with the adsorption unit through a second connecting pipe, and the adsorption unit is an alkaline adsorption unit. The device filters, oxidizes and adsorbs gaseous pollutants discharged from a coal mining furnace, effectively reduces the concentration of acidic pollutants and improves the environmental quality.

Owner:天津聚居科技有限公司

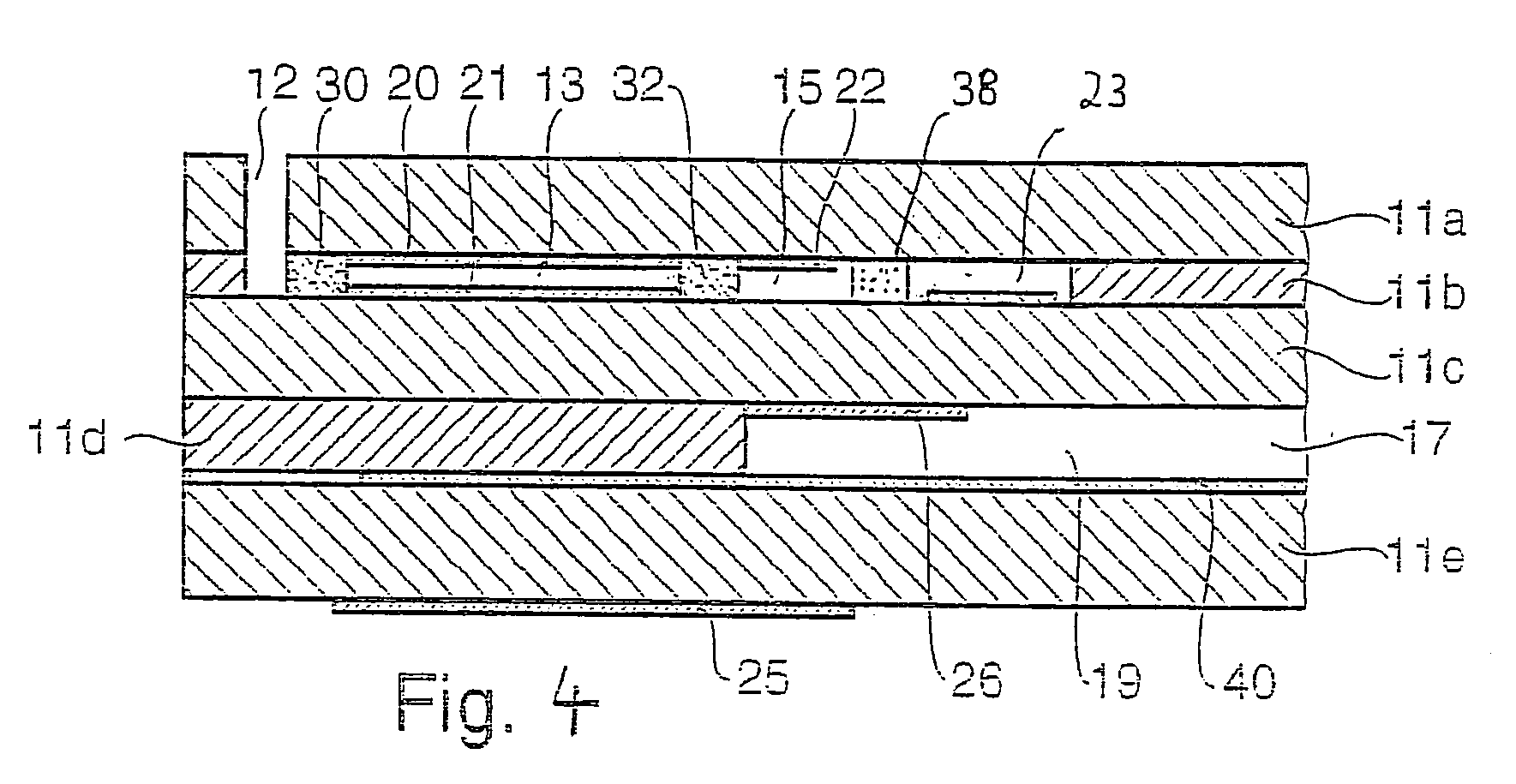

Sensor element of a gas sensor

InactiveUS20040089054A1Prevent metal diffusionHigh sensitivityMaterial analysis by electric/magnetic meansTesting metalsExhaust gasDiffusion

A sensor element of a gas sensor is described, this sensor being used to determine the concentration of at least one component of a gas mixture, in particular in exhaust gases of internal combustion engines. It includes at least two electrodes (22, 23) which are situated in an internal gas space (15) which is in direct contact with the gas mixture, the one electrode (22) containing a first material and the second electrode (23) containing a second material. The internal gas space (15) contains a means (34, 26, 38, 39) which acts physically and / or chemically to prevent diffusion of metal between the electrodes (22, 23).

Owner:ROBERT BOSCH GMBH

Ultra-light graphene foam material with effects of sound absorption and noise reduction and preparation method of ultra-light graphene foam material

The invention relates to an ultra-light graphene foam material with effects of sound absorption and noise reduction and a preparation method of the ultra-light graphene foam material, and belongs to the technical field of graphene based three-dimensional materials. The material is of a three-dimensional structure formed by regular macropores, irregular micropores between the macropores and throughpores in the pore walls, and by means of the three pore structures, all parts are relatively independent and are also communicated one another, a diffusion path of sound waves and a contact area withmaterial walls are increased and dissipation of sound energy is increased. Besides, the three-dimensional framework of the material consists of thinner graphene walls and ultrafine graphene fibers, so that bending vibration of the material in the presence of sounds is facilitated, and the sound energy is converted into kinetic energy for further consumption. The preparation method of the materialis simple, safe and environmentally friendly, the material has an excellent sound absorption effect in the whole frequency band, especially in the low-mid frequency band, the efficient sound absorption frequency band is in a range of 600 Hz-6300 Hz, and the material has great application prospects.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Nickel-tungsten graphene oxide (GO) composite plating solution, plated film and preparation method thereof

InactiveCN104726907AImprove mechanical propertiesEffective dispersionElectrolytic coatingsComposite plateMechanical property

The invention discloses a nickel-tungsten graphene oxide (GO) composite plating solution, a plated film and a preparation method thereof. According to the plating solution, GO which has good mechanical properties and can be effectively dispersed is introduced into the plating solution and is effectively deposited and dispersed in a Ni-W matrix during electroplating. A Ni-W-GO composite plated film is successfully prepared on a carbon steel base body by a pulse electroplating codeposition method. Graphene oxide is dispersed in the Ni-W matrix, so that the coefficient of friction is effectively lowered. The competitive relation between crystal nucleation and growth is effectively changed during codeposition, so that the structure of the plated film is improved, a deposited film layer can become more uniform and denser, intercrystalline corrosion is weakened, the diffusion path of a corrosive medium is prolonged, the self-corrosion potential is increased, local corrosion is effectively inhibited, the stability of a passivation film is improved, and thus, the corrosion resistance of the composite plated film is improved.

Owner:SOUTHWEST PETROLEUM UNIV

Nickel, tungsten and graphene composite plating solution, plated film and making method of plated film

InactiveCN104911652AImprove mechanical propertiesEffective dispersionElectrolytic coatingsComposite plateNucleation

The invention discloses a nickel, tungsten and graphene composite plating solution, a plated film and a making method of the plated film. GE with good mechanical performances and effective dispersion property is introduced into the plating solution, and the GE is effectively deposited and dispersed in a Ni-W matrix in the electroplating process. The Ni-W-GE composite plated film is successfully made on a carbon steel matrix through a pulse plating codeposition technology. Graphene is dispersed in the Ni-W matrix, and the structure of the plated film is improved by effectively changing the competition relation between crystal nucleation and growth in the codeposition process in order to make a deposited film layer uniform and compact, so the intercrystalline corrosion is weakened, the diffusion path of a corrosion medium is prolonged, the self-corrosion potential is improved, local corrosion is effectively inhibited, and the stability of a passive film is improved, thereby the corrosion resistance of the composite plated film is improved.

Owner:SOUTHWEST PETROLEUM UNIV

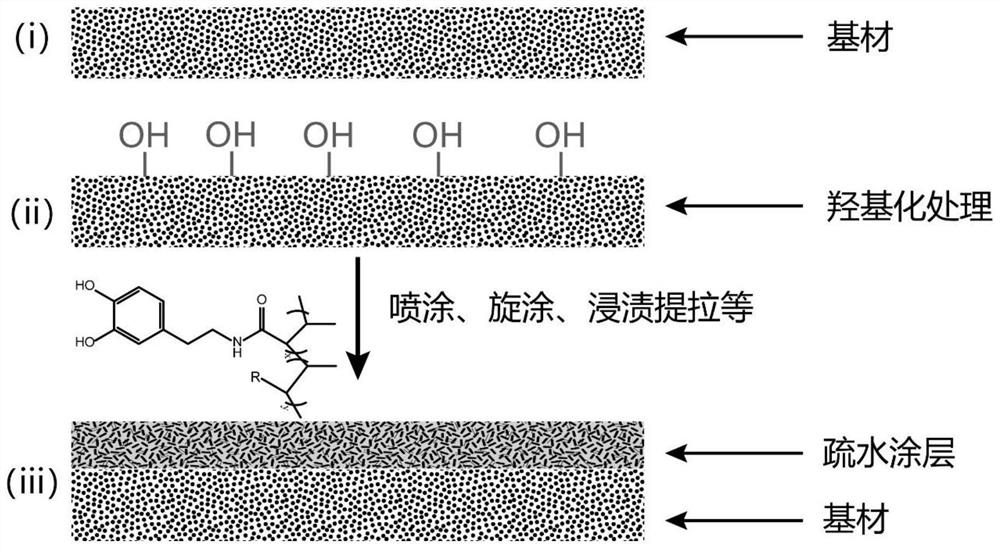

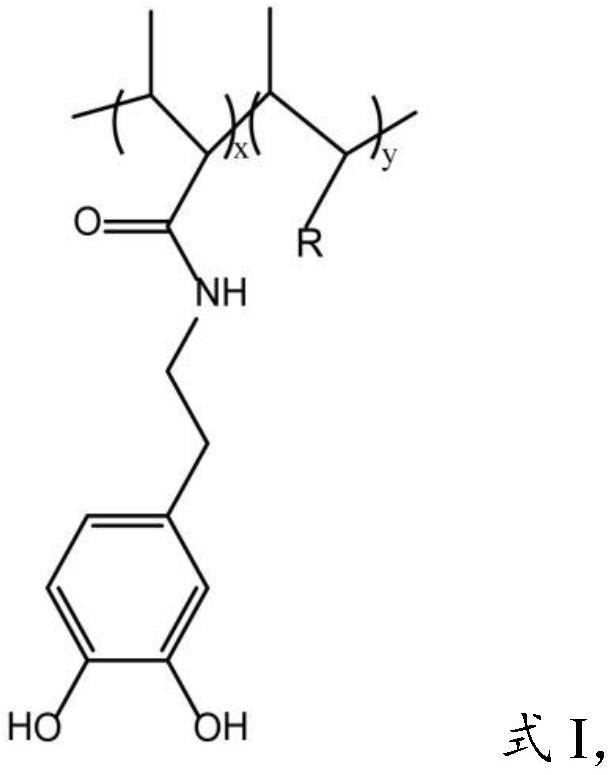

Hydrophobic moisture-resistant coating as well as preparation method and application thereof

The invention provides a hydrophobic moisture-resistant coating as well as a preparation method and application thereof, and belongs to the technical field of coatings. The prepared dopamine copolymer has an excellent adhesion characteristic, the coating and the surface of a pretreated base material are combined together through chemical covalent bonds, excellent bonding performance is given to the hydrophobic moisture-resistant coating and a substrate, and the bonding strength of the coating and the substrate is greatly enhanced; by adding the filler, the diffusion path of water molecules is increased, the diffusion rate of the water molecules is effectively reduced, meanwhile, the interaction between the hydrophobic moisture-resistant coating and the water molecules is weak, the moisture adsorption capacity is low, and therefore the function of blocking moisture for a long time is achieved. The hydrophobic moisture-resistant coating provided by the invention can be applied to the surface and interface fields of building external wall thermal insulation, roof waterproof and thermal insulation integration, building boards, thermal insulation and moisture-resistant materials of refrigerator cars and refrigeration houses, external protective layers of precise instruments and the like, and can effectively avoid oxidation and swelling deformation of wrapped materials due to moisture absorption of the materials, and influences on the dimensional precision of precision parts.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Rotational flow gas-liquid uniform distribution type sewage treatment device, sewage treatment system and sewage treatment method

PendingCN112919612AEvenly distributedImprove uniformityWater treatment parameter controlWater contaminantsPtru catalystFluid phase

The invention relates to a rotational flow gas-liquid uniform distribution type sewage treatment device, a sewage treatment system and a sewage treatment method. The device comprises a tower body, a gas-liquid inlet is formed in the bottom of the tower body, a sewage outlet and a tail gas outlet are formed in the top of the tower body, and a bearing pore plate is arranged in the tower body and divides the interior of the tower body into an upper catalytic oxidation chamber and a lower gas-liquid mixing chamber; a plurality of re-distribution holes are formed in the bearing pore plate; a rotational flow gas-liquid uniform distribution mechanism is mounted in the lower gas-liquid mixing chamber; flow baffles are arranged in the upper catalytic oxidation chamber, one side of each flow baffle is provided with a folded edge which is bent downwards, every two adjacent flow baffles are arranged in a staggered mode, the circumferential side walls of the flow baffles are tightly attached to the inner wall of the tower body, a liquid phase ascending channel is arranged between the folded edges and the inner wall of the tower body, and a plurality of air holes are formed in the upper surfaces of the flow baffles at intervals in the circumferential direction; and the upper catalytic oxidation chamber is also filled with a catalyst. Through the design of the rotational flow gas-liquid uniform distribution type sewage treatment device, the technical problems of low ozone catalytic oxidation efficiency and high operation cost in the prior art are solved.

Owner:北创清源(北京)科技有限公司

Novel composite tritium resisting coating and preparation method thereof

ActiveCN107217281AThe process is simple and matureIncrease productivityLiquid/solution decomposition chemical coatingSuperimposed coating processChromium sesquioxideHydrogen

The invention belongs to the related technical field of coating materials and discloses a novel composite tritium resisting coating. The novel composite tritium resisting coating comprises a basal layer and further comprises a graphene thin film, a chromium sesquioxide layer and an aluminum phosphate layer, wherein the graphene thin film is formed on the basal layer; the chromium sesquioxide layer is formed on the surface, away from the basal layer, of the graphene thin film; and the aluminum phosphate layer is formed on the surface, away from the graphene thin film, of the chromium sesquioxide layer. The invention further relates to a preparation method of the above novel composite tritium resisting coating. According to the novel composite tritium resisting coating, the characteristics that graphene is large in specific surface area, good in mechanical property, high in heat conductivity and hydrogen absorption capability, and the like are utilized, and the graphene thin film, the Cr2O3 ceramic coating and the AlPO4 ceramic coating are composited so that the novel multilayer composite tritium resisting coating can be formed; and on one hand, diffusion paths of tritium in the coating are increased, on the other hand, the capacity of the coating to capture escape tritium is improved, thus, the tritium resisting property of the coating is improved, and the coating is flat and compact.

Owner:HUAZHONG UNIV OF SCI & TECH

Graphene lithium battery cathode slurry and preparation method thereof, and lithium battery positive plate

ActiveCN110010897AImproved magnification performanceIncreased contraction gapElectrode manufacturing processesGrapheneSlurryConductive materials

The invention discloses a graphene lithium battery cathode slurry. The raw materials of the slurry comprises a cathode active material, a conductive agent, a binder and N-methyl pyrrolidone, wherein the conductive agent is composed of a carbon conductive material and a negative thermal expansion material, the carbon conductive material comprises graphene, and the negative thermal expansion material is ZrW2O8 and / or ZrW2O8 doped with heterogeneous metal ions. The negative thermal expansion material ZrW2O8 and / or the ZrW2O8 doped with heterogeneous metal ions is added into the lithium battery cathode slurry, in the charge-discharge state, the temperature of the battery rises, the cathode active material is heated and expanded, the micro cracks in the negative thermal expansion material and contraction gaps between the negative thermal expansion material and the cathode active material and the carbon conductive material are increased, the lithium ion diffusion paths are increased, the diffusion capacity of lithium ions in the cathode is improved, and the rate capability of the battery is improved. The invention also discloses a preparation method of the graphene lithium battery cathode slurry and a lithium battery positive plate.

Owner:江苏碳谷二维世界科技有限公司

Anti-abrasion protective coating for surface of metal substrate and preparation method and application of anti-abrasion protective coating

ActiveCN110438465AImprove corrosion resistanceReduce stressVacuum evaporation coatingSputtering coatingMechanical propertyDirect current magnetron sputtering

The invention discloses an anti-abrasion protective coating for the surface of a metal substrate and a preparation method and application of the anti-abrasion protective coating. The anti-abrasion protective coating comprises a Ti transition layer, a TiCx gradient layer, a first DLC layer, a TiCx / Ti / TiCx / DLC alternating layer stacking layer and a top layer which are sequentially formed on the surface of the metal substrate by adopting a linear ion source compound direct-current magnetron sputtering technology; the TiCx / Ti / TiCx / DLC alternating layer stacking layer is formed by alternately stacking a TiCx / Ti / TiCx sandwiched layer and a second DLC layer alternating layer; the TiCx / Ti / TiCx sandwiched layer comprises two TiCx layers and a Ti layer arranged between the two TiCx layers; the top layer comprises a third DLC layer; and the value range of the TiCx is 0.8-1.3. The anti- abrasion protective coating is of a structure of alternative multilayer, interfacial gradient and top layer extending and spreading, so that the coating has high comprehensive mechanical property and high corrosion resistance and abrasion resistance. The anti- abrasion protective coating can still maintain a good antifriction lubricating effect in a certain time after being worn out, and shows high abrasion failure tolerance.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Preparation method of high-barrier-property polylactic acid nano composite material

The invention discloses a preparation method of a high-barrier-property polylactic acid nano composite material. The preparation method comprises the following steps: (1) adding a caprolactone monomer and montmorillonite into a drying flask without oxygen, standing in a sealed way after ultrasonic vibration to ensure that the caprolactone monomer is fully inserted into lamellas of montmorillonite, adding an initiator into the flask, heating to perform intercalation polymerization reaction, dissolving an obtained product in methylbenzene, performing centrifugal separation after ultrasonic vibration, washing by using methylbenzene, and drying to obtain polycaprolactone modified montmorillonite; (2) mixing polylactic acid with silicon oil, adding polycaprolactone modified montmorillonite, performing high-speed mixing, and then performing extrusion granulation by using an extruder to obtain barrier master batches; and (3) uniformly mixing the barrier master batches with polylactic acid, and performing melt blending to obtain the high-barrier-property polylactic acid nano composite material. A caprolactone in-situ intercalation polymerization method is adopted to modify montmorillonite to ensure that nano lamellas of montmorillonite are effectively peeled off, and a master batch method is adopted to ensure that the nano lamellas of montmorillonite are uniformly distributed in a polylactic acid matrix to obtain relatively high barrier property.

Owner:常州龙骏天纯环保科技有限公司

Ribbon-shaped polyacrylonitrile carbon fiber and preparation method thereof

ActiveCN110331470AKeep or slightly reduce sizeReduce formationFibre chemical featuresStretch-spinning methodsPolymer scienceCarbon fibers

The invention discloses ribbon-shaped polyacrylonitrile carbon fiber and a preparation method thereof. The preparation method comprises steps as follows: (1), an acrylonitrile monomer, itaconic acid,methyl acrylate and a solvent are co-polymerized, and a polymer spinning solution is obtained; (2), the polymer spinning solution is subjected to jet spinning by a spinneret plate provided with ribbon-shaped spinneret holes and then subjected to coagulating draft forming in coagulating bath, ribbon-shaped polyacrylonitrile nascent fiber is obtained, and a ribbon-shaped polyacrylonitrile precursoris prepared from the ribbon-shaped polyacrylonitrile nascent fiber by primary drafting, washing, oiling drying densification, secondary drafting and heat setting; (3), the ribbon-shaped polyacrylonitrile precursor is subjected to pre-oxidation, low-temperature carbonization and high-temperature carbonization, and the ribbon-shaped polyacrylonitrile carbon fiber is obtained. Compared with traditional carbon fiber with circular cross section, the prepared ribbon-shaped polyacrylonitrile carbon fiber has advantages as follows: the long axis can reach 22.3-24.2 mu m, the minor axis is 5.1-.54 mum, the fineness can reach 0.154-0.174 tex, the tensile strength of monofilament is not lower than 5.4 GPa, and the tensile modulus can reach 294 GPa.

Owner:BEIJING UNIV OF CHEM TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com