Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

175results about How to "Extend the distribution path" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

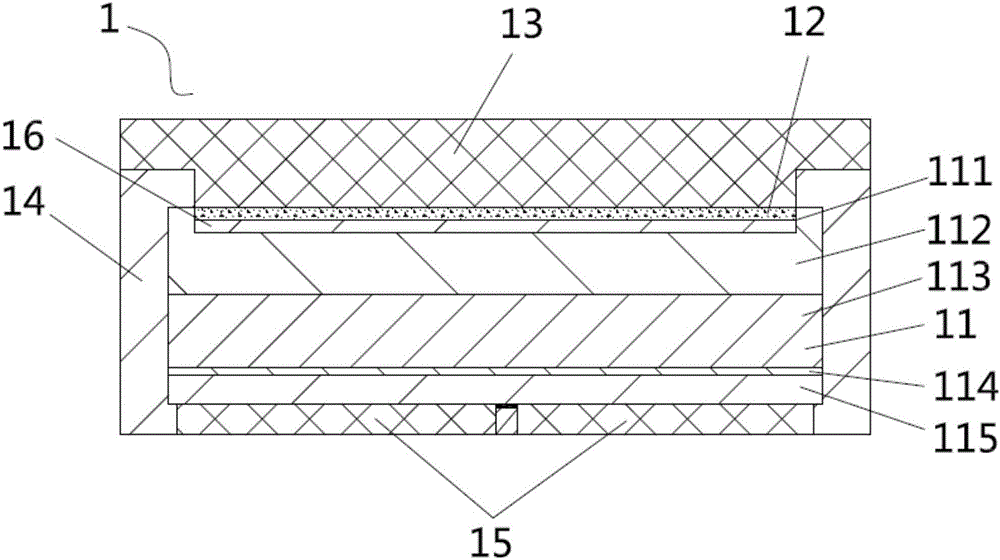

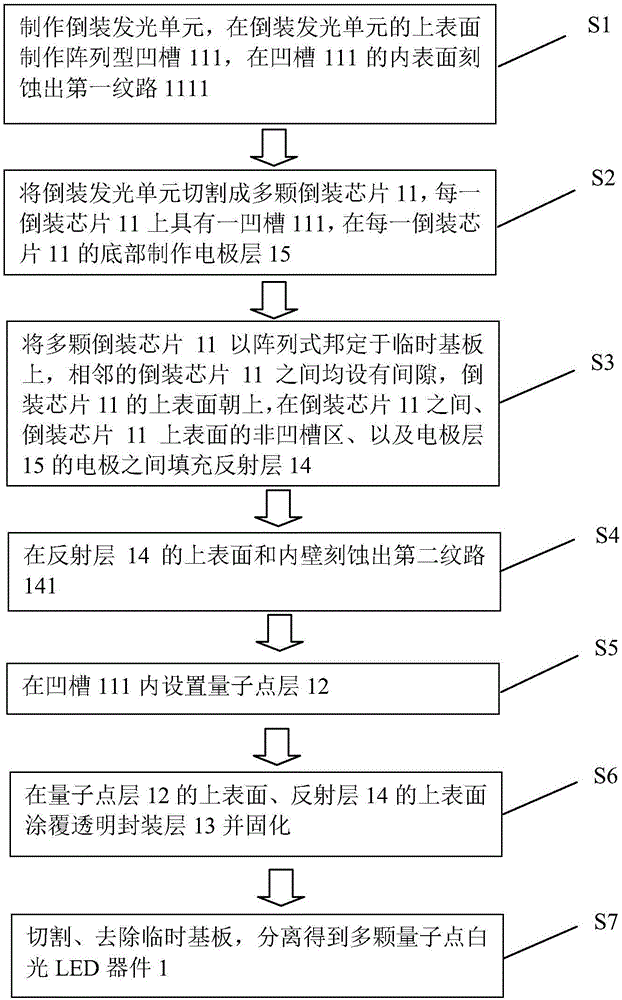

Quantum dot white light LED device and preparation method therefor

ActiveCN106505134AImprove reliabilityExtended service lifeSemiconductor devicesQuantum dotReflective layer

The invention discloses a quantum dot white light LED device. The quantum dot white light LED device comprises a flip chip, a quantum dot layer, a transparent packaging layer, a reflective layer and an electrode layer, wherein a groove is formed in the upper surface of the flip chip; first lines are arranged on the inner surface of the groove; the quantum dot layer is arranged in the groove; the electrode layer is arranged at the bottom of the flip chip; the reflective layer coats the side wall of the flip chip, a non-groove region on the upper surface of the flip chip, and the side wall of the electrode layer; the spaces between electrodes of the electrode layer is filled with the reflective layer; second lines are arranged on the upper surface and the inner wall of the reflective layer; and the exposed region of the quantum dot layer and the upper surface of the reflective layer are coated with the transparent packaging layer. The invention also correspondingly discloses a preparation method for the quantum dot white light LED device. The quantum dot white light LED device is high in airtight property, excellent in heat dissipation, high in reliability, and high in color rendering; and the preparation method is free of a packaging link, simple in preparation process and easy to implement, mature, and high in preparation efficiency.

Owner:APT ELECTRONICS

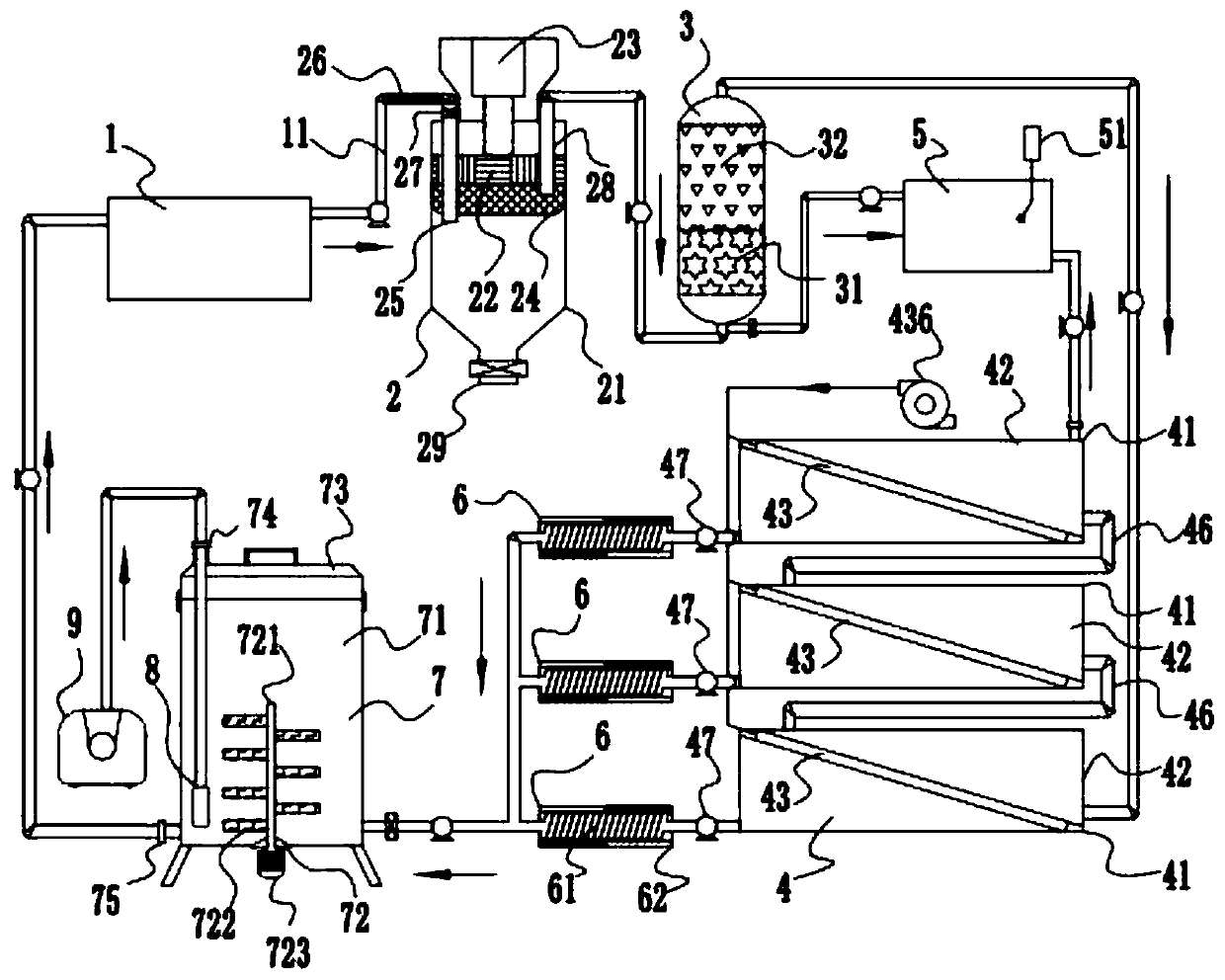

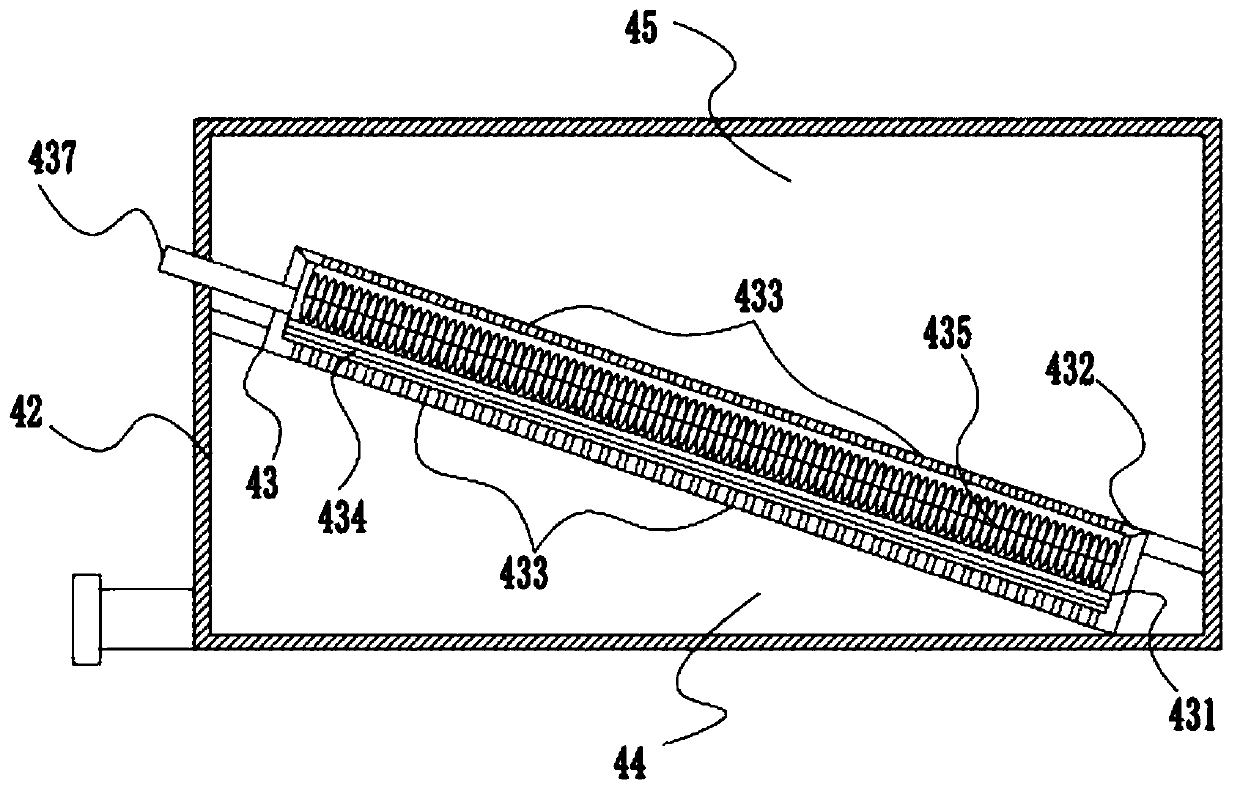

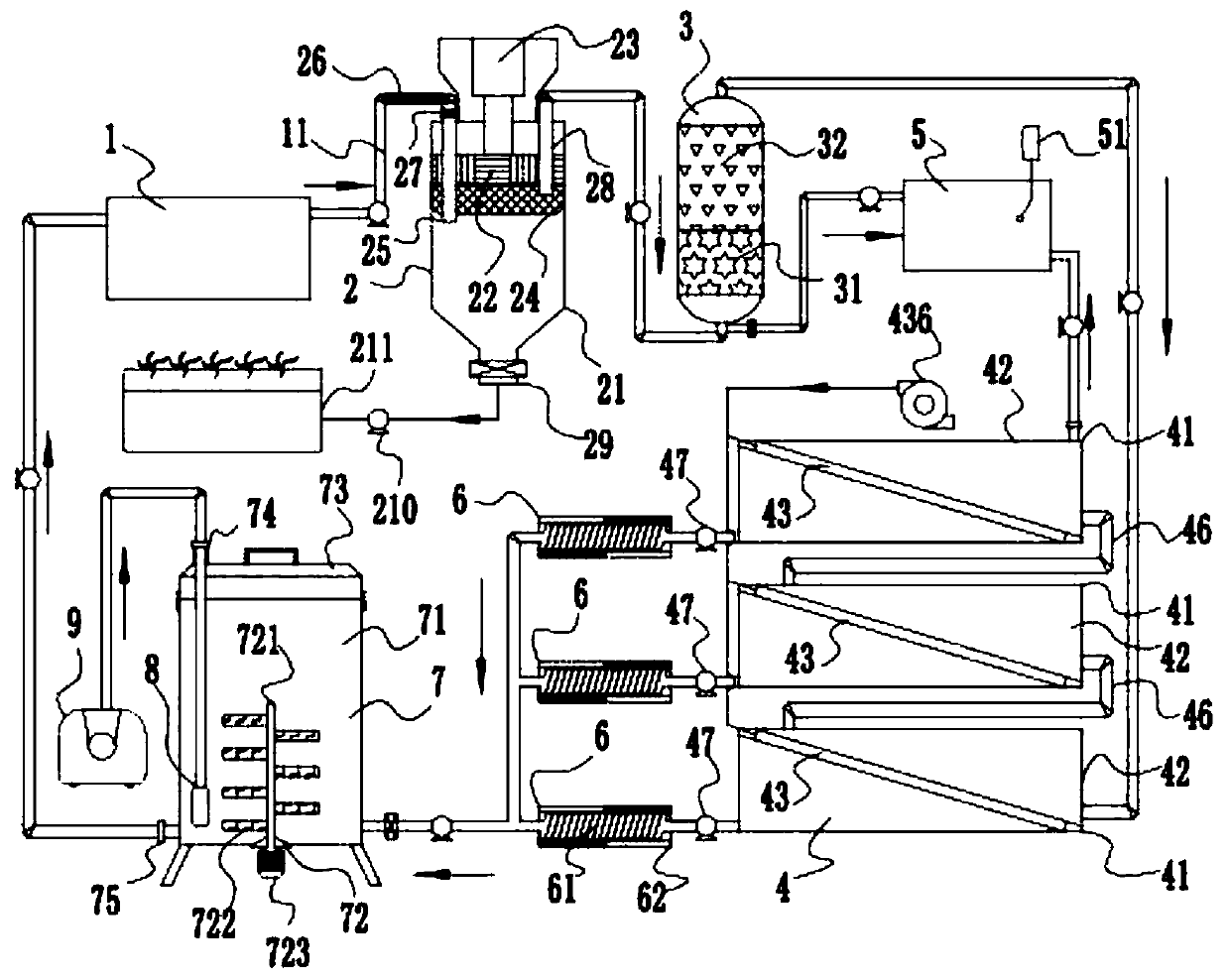

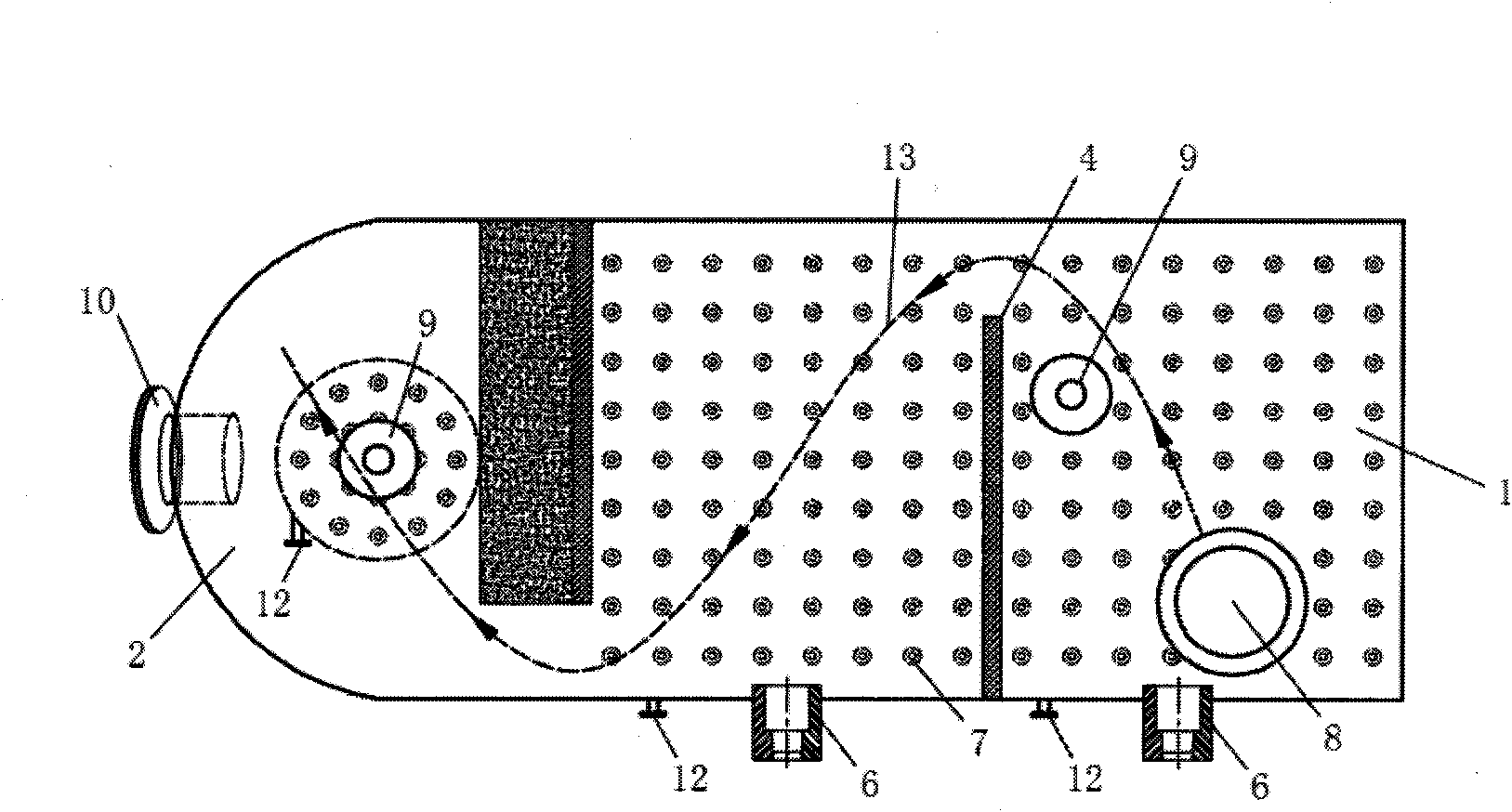

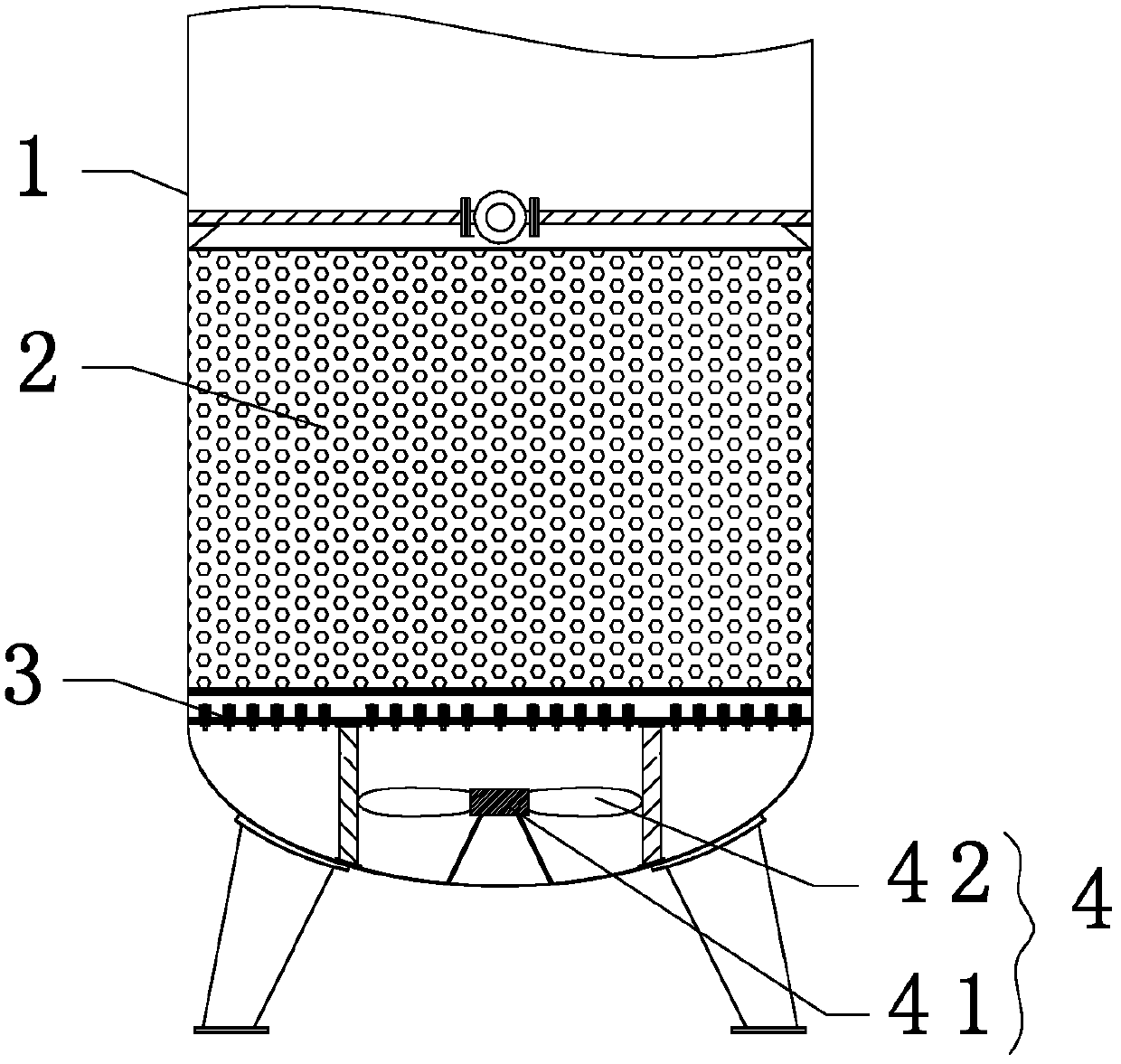

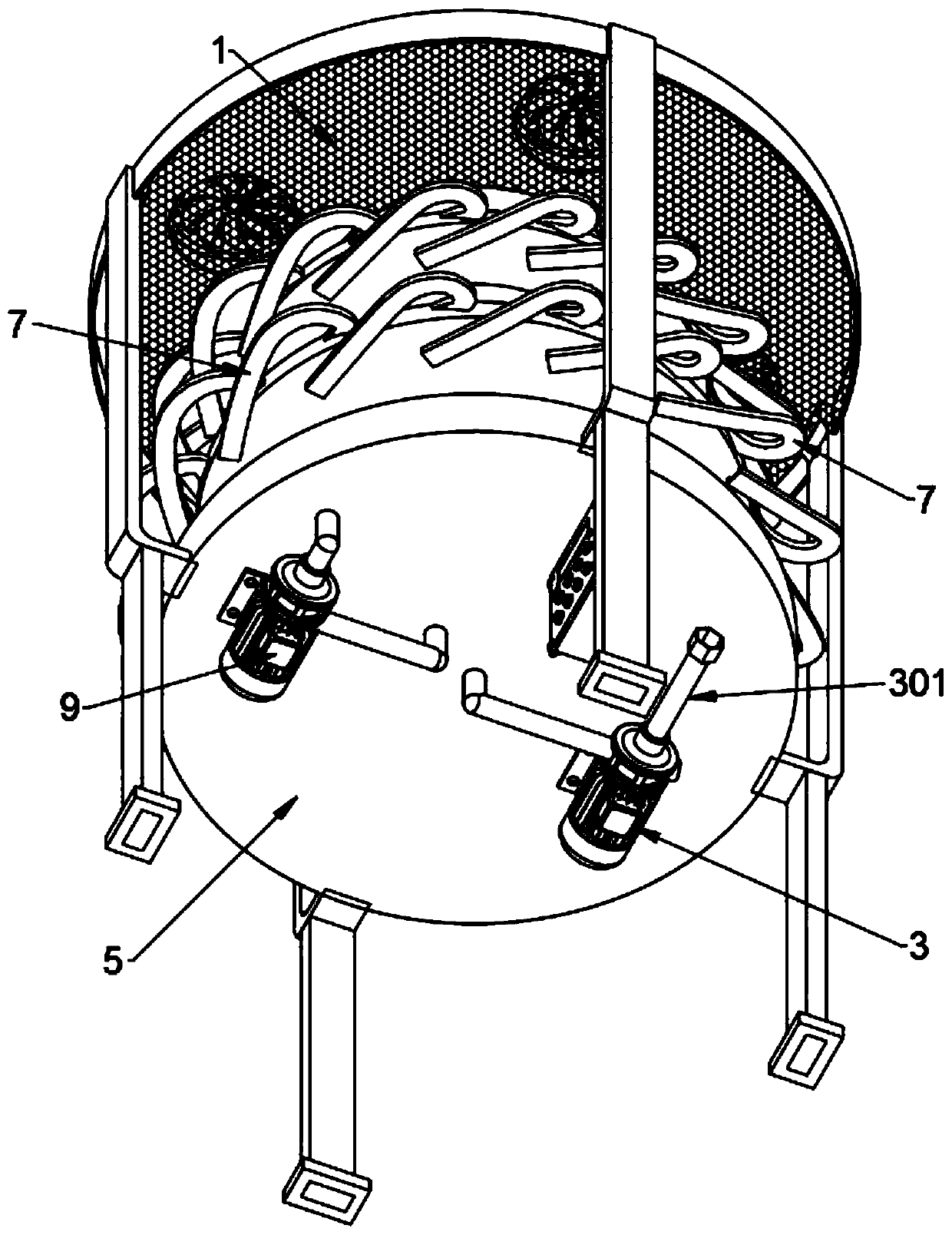

Water quality circulating purification and oxygen supply device for aquaculture pond

ActiveCN110651752AReduce pollutionIncrease oxygen contentWater contaminantsWaste water treatment from animal husbandryWater resourcesEnvironmental engineering

The invention discloses a water quality circulating purification and oxygen supply device for an aquaculture pond. The water quality circulating purification and oxygen supply device comprises a waterdecanter connected to the aquaculture pond through a suction pipe, a filter connected to the water decanter, and a membrane separation and purification mechanism connected to the filter and used fordeep wastewater purification. The membrane separation and purification mechanism is composed of a plurality of membrane purification components connected in series. After being treated by the membranepurification components, wastewater flows into a circulating water tank and then enters the filter to circulate. After being treated by the membrane purification components, purified water is sterilized and disinfected by an ultraviolet lamplight component, then flows into an aeration mechanism, and finally returns to the aquaculture pond. The water quality circulating purification and oxygen supply device has the advantages that the purification rate of aquaculture wastewater and the oxygen content are high, water resources are recycled, and water pollution is reduced.

Owner:广州市金佰达生物环保科技有限公司

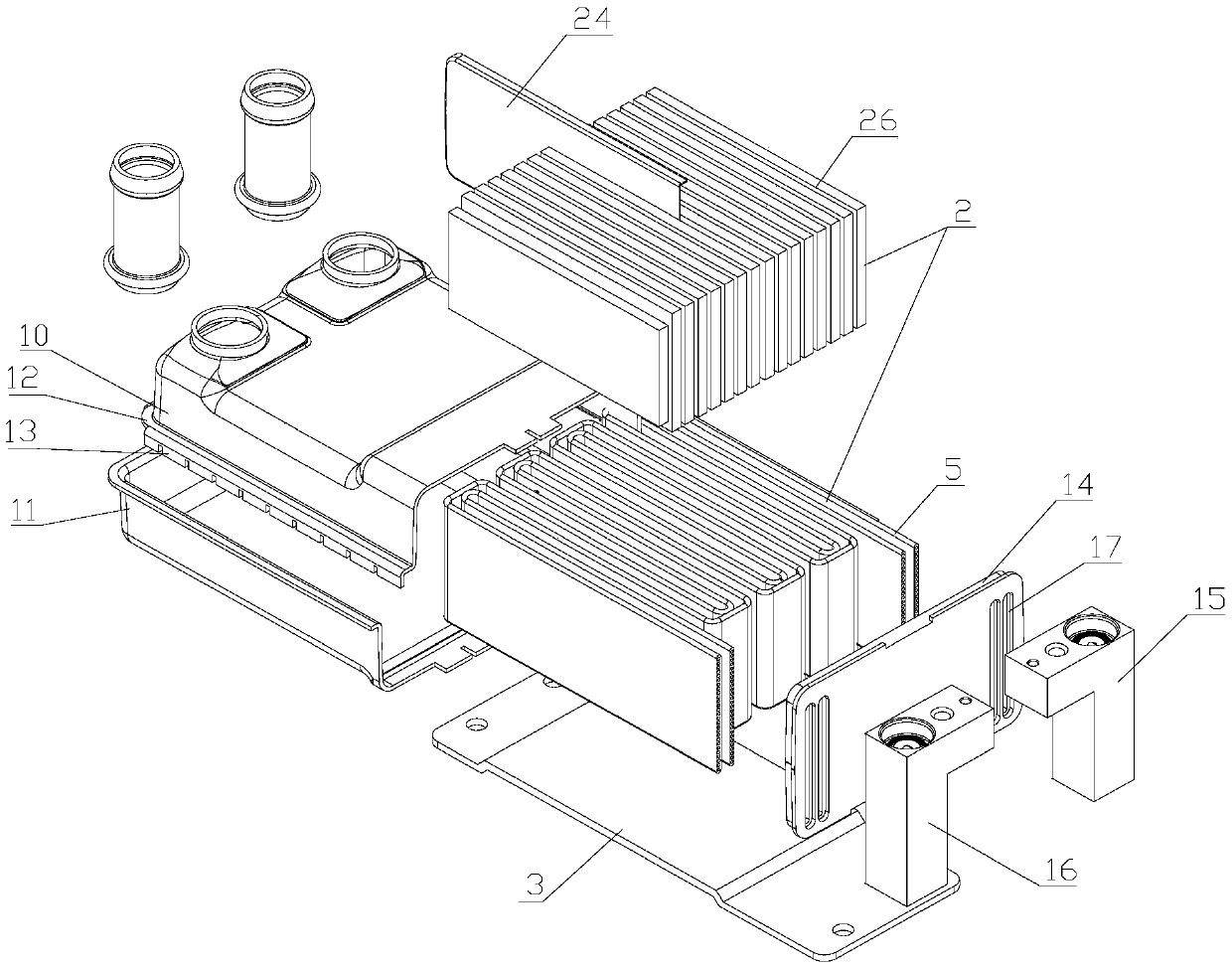

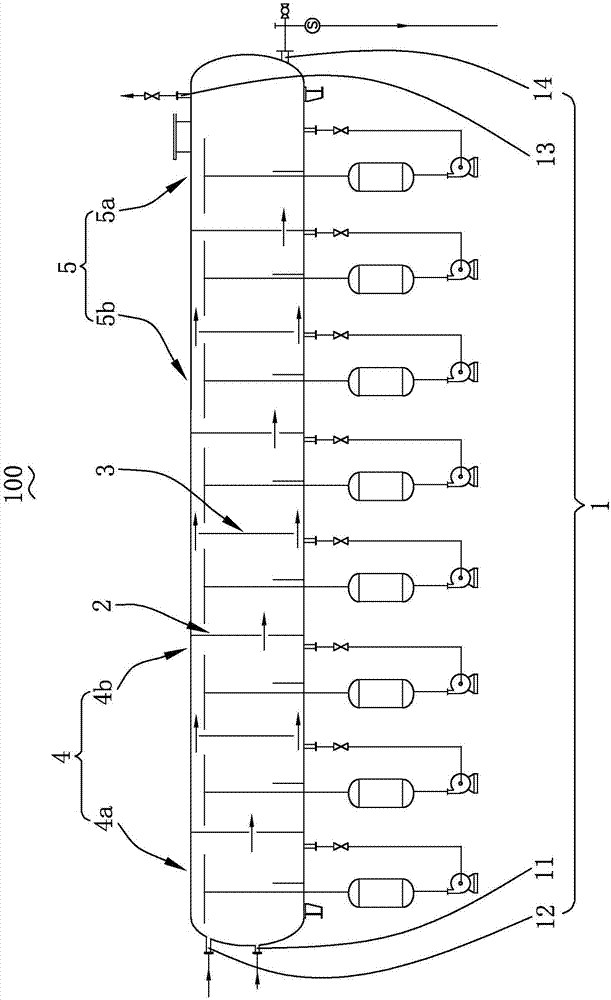

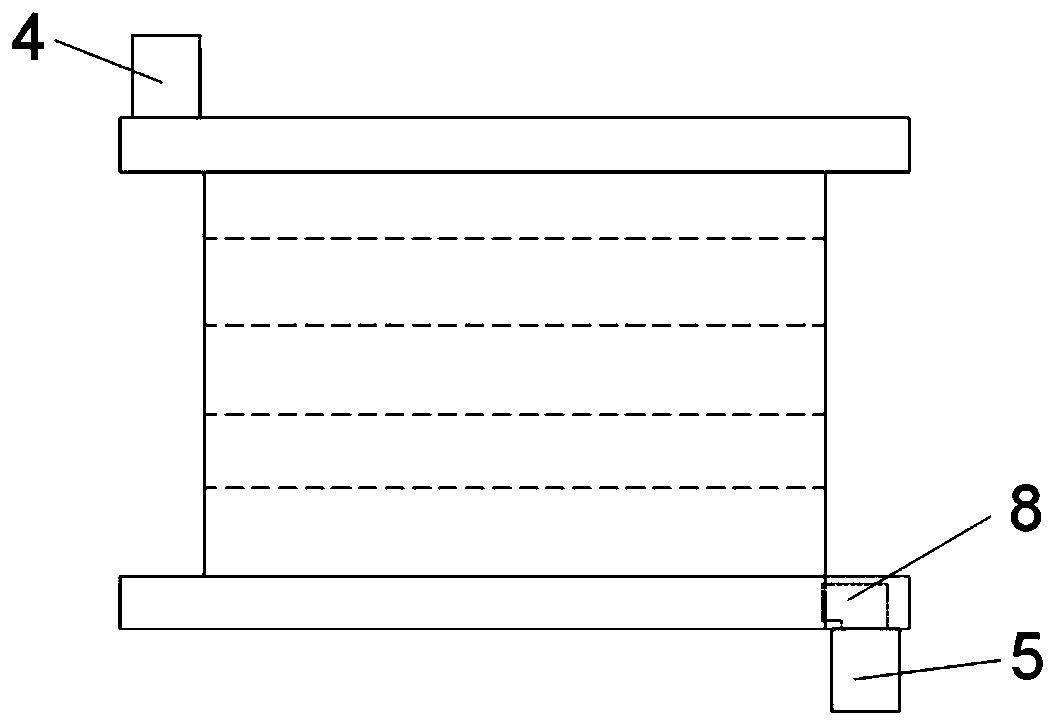

Multi-channel switchable electric heating dryer

InactiveCN102290199AExtended service lifeDry in timeTransformers/inductances coolingHeater elementsTransformerEngineering

The invention relates to a multi-passage switchable electric heating dryer, which comprise a first passage switcher, a plurality of moisture-absorbing barrels and a second passage switcher; one end of the first passage switcher is connected with the inlets of the moisture-absorbing barrels, the other end of the first passage switcher communicates with the atmosphere, and the first passage switcher is used for switching passages between the moisture-absorbing barrels and the atmosphere, so that part of the moisture-absorbing barrels can communicate with the atmosphere and the rest of the moisture-absorbing barrels cannot communicate with the atmosphere; one end of the second passage switcher is connected with the outlets of the moisture-absorbing barrels, the other end of the second passage switcher respectively communicates with the atmosphere and a drying destination, and the second passage switcher is used for switching passages between the moisture-absorbing barrels and the atmosphere as well as the drying destination, so that part of the moisture-absorbing barrels can communicate with the atmosphere and the rest of the moisture-absorbing barrels can communicate with the dryingdestination; and a barrel body of each moisture-absorbing barrel is provided with a heating part for drying the moisture-absorbing barrel. The multi-passage switchable electric heating dryer can dry the silica gel and the air in the dryer in a switching manner, thus prolonging the service life of the silica gel, solving the problem of complex process switching and enhancing the safety stability of a transformer.

Owner:EAST CHINA UNIV OF SCI & TECH

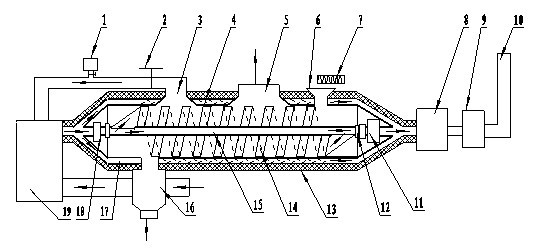

Large spiral low-order lignite quality improving system

InactiveCN102627991ADoes not affect movementLow particle size requirementSolid fuelsCombustion chamberPlate heat exchanger

A large spiral low-order lignite quality improving system comprises a spiral heat exchanger, a combustion chamber, a lignite feeding device, a quenching box and a dedusting device. The spiral heat exchanger is horizontally placed and composed of an outer sleeve, a rotating shaft and a motor, wherein the rotating shaft and the motor are sleeved in the outer sleeve, and the rotating shaft is in transmission connection with the motor. A spiral blade is axially arranged along the rotating shaft, the wall of the outer sleeve, the rotating shaft and the spiral blade are all of hollow structures, tow ends of the spiral blade are communicated with a hollow cavity of the rotating shaft, the inlet end of a hollow cavity of the wall of the outer sleeve and the inlet end of the hollow cavity of the rotating shaft are communicated with the combustion chamber, and the outlet end of the hollow cavity of the wall of the outer sleeve and the outlet end of the hollow cavity of the rotating shaft are communicated with the dedusting device. The lignite feeding device is arranged on the upper portion of the spiral heat exchanger and close to the side of the dedusting device, and the quenching box is arranged on the lower portion of the spiral heat exchanger and close to the side of the combustion chamber. The large spiral low-order lignite quality improving system requires no pre-drying process, is strong in adaptability of coal types and particularly suitable for improving quality of sticky lignite, only needs to pre-break raw coal, is safe in operation, simple in structure and high in heat exchange efficiency, can perform large-scale continuous production easily and can obtain semi-coke, tar and coal gas with high quality.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

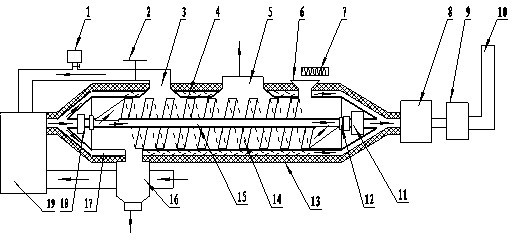

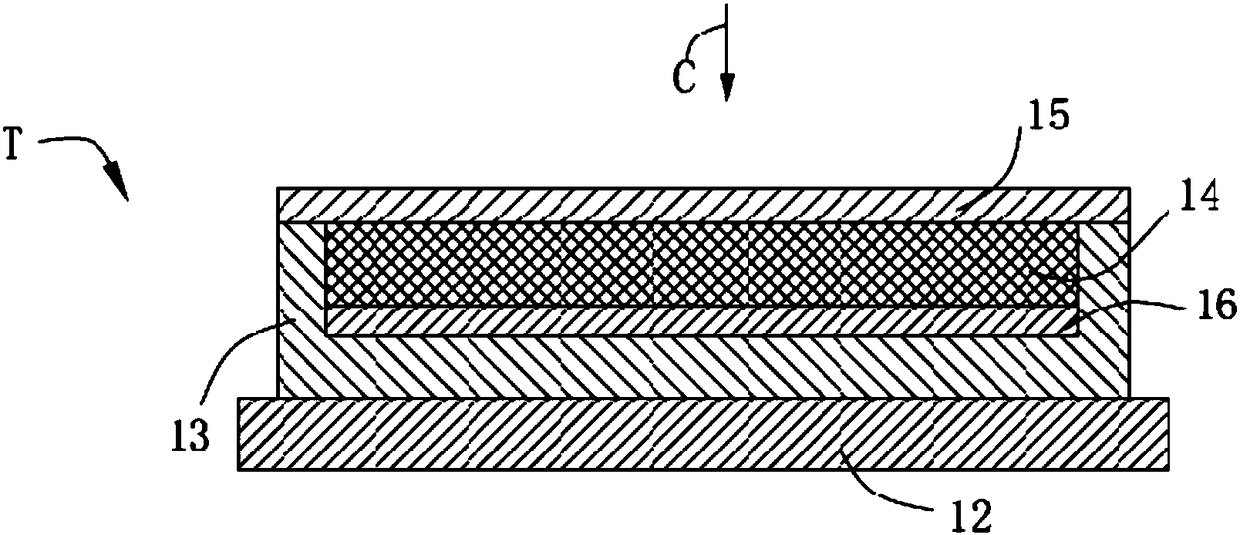

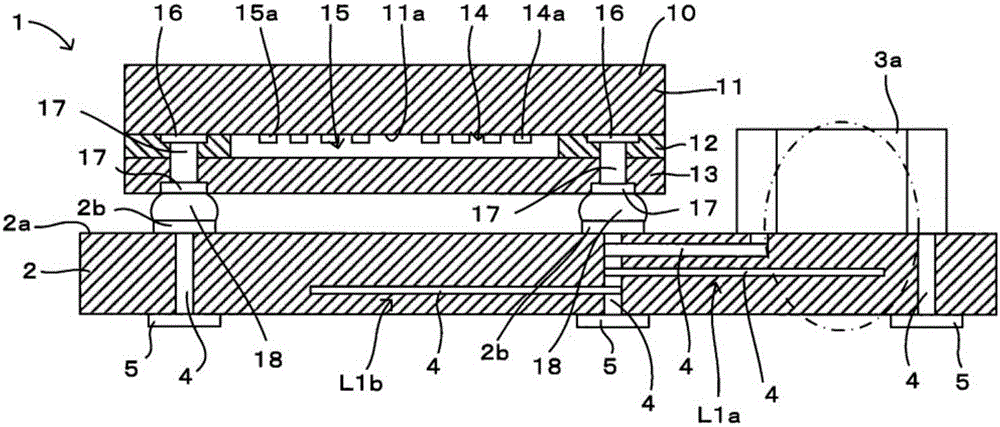

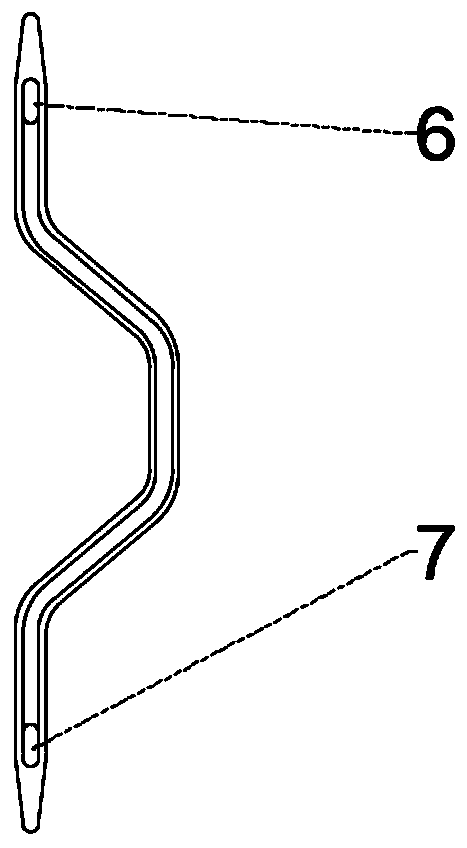

Neutron capture therapy system and target material for particle line generation apparatus

PendingCN109381802AExtend your lifeIncrease beam intensityDirect voltage acceleratorsNuclear targetsCooling channelNeutron capture therapy of cancer

The invention provides a neutron capture therapy system and a target material for the neutron capture therapy system, which can enhance the heat radiation performance of the target material, reduce bubbling, and prolong the lifetime of the target material. The neutron capture therapy system comprises a neutron generation apparatus and a beam shaping body, the neutron generation apparatus comprisesan accelerator and the target material, charged particle lines generated by acceleration of the accelerator and the target material produce an effect to generate neutron lines, the target material comprises an action layer, a base layer and a heat dissipation layer, the action layer acts with the charged particle lines to generate neutron lines, the base layer supports the action layer, and the heat dissipation layer comprises a zigzag cooling channel.

Owner:NEUBORON MEDTECH

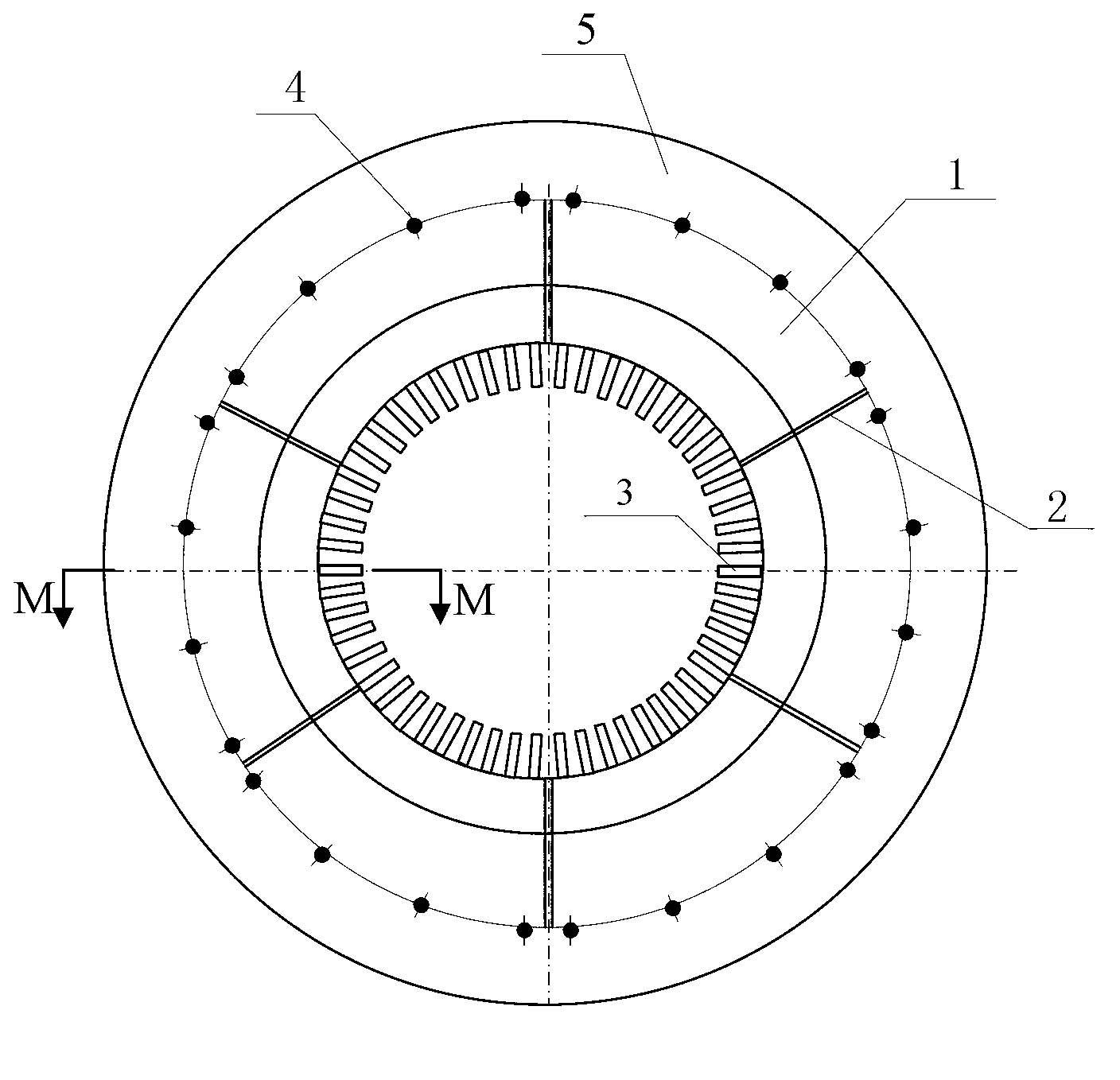

Split piano type shielding device on end part of steam-turbine generator

ActiveCN103078436AReduce eddy currentLower your temperatureSupports/enclosures/casingsThree stageEngineering

The invention discloses a split piano type shielding device on the end part of a steam-turbine generator, which relates to a metal shielding device and aims to solve the problems that a metal shielding structure on the end part of the existing large steam-turbine generator has the disadvantages of high eddy current loss and poor heat dissipation effect and the self temperature cannot be effectively reduced. The split piano type shielding device comprises a ring wind screen, a pressure ring, a pressure finger and at least two shielding plates, wherein the pressure ring is pressed on the pressure finger and positioned on the end part of the steam-turbine generator; each shielding plate is a three-stage bending plate and in a piano type structure; the at least two shielding plates which are circumferentially arranged form a shielding body; the first stage of each shielding plate is adjacent to the ring wind screen; the shielding body is in a ring shape; the ring wind screen and the shielding body are coaxially arranged; the shielding body is positioned between the ring wind screen and the pressure ring, and the shielding body, the ring wind screen and the pressure ring are connected in a detachable mode; and same gaps are left between every two adjacent shielding plates. The split piano type shielding device is used for reducing the self temperature of the steam-turbine generator.

Owner:HARBIN UNIV OF SCI & TECH

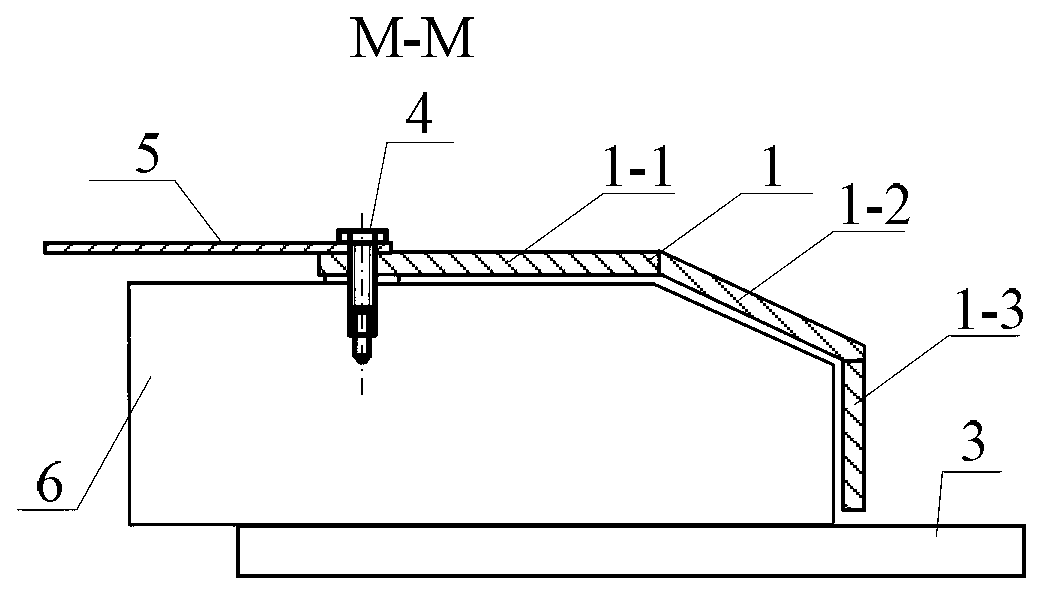

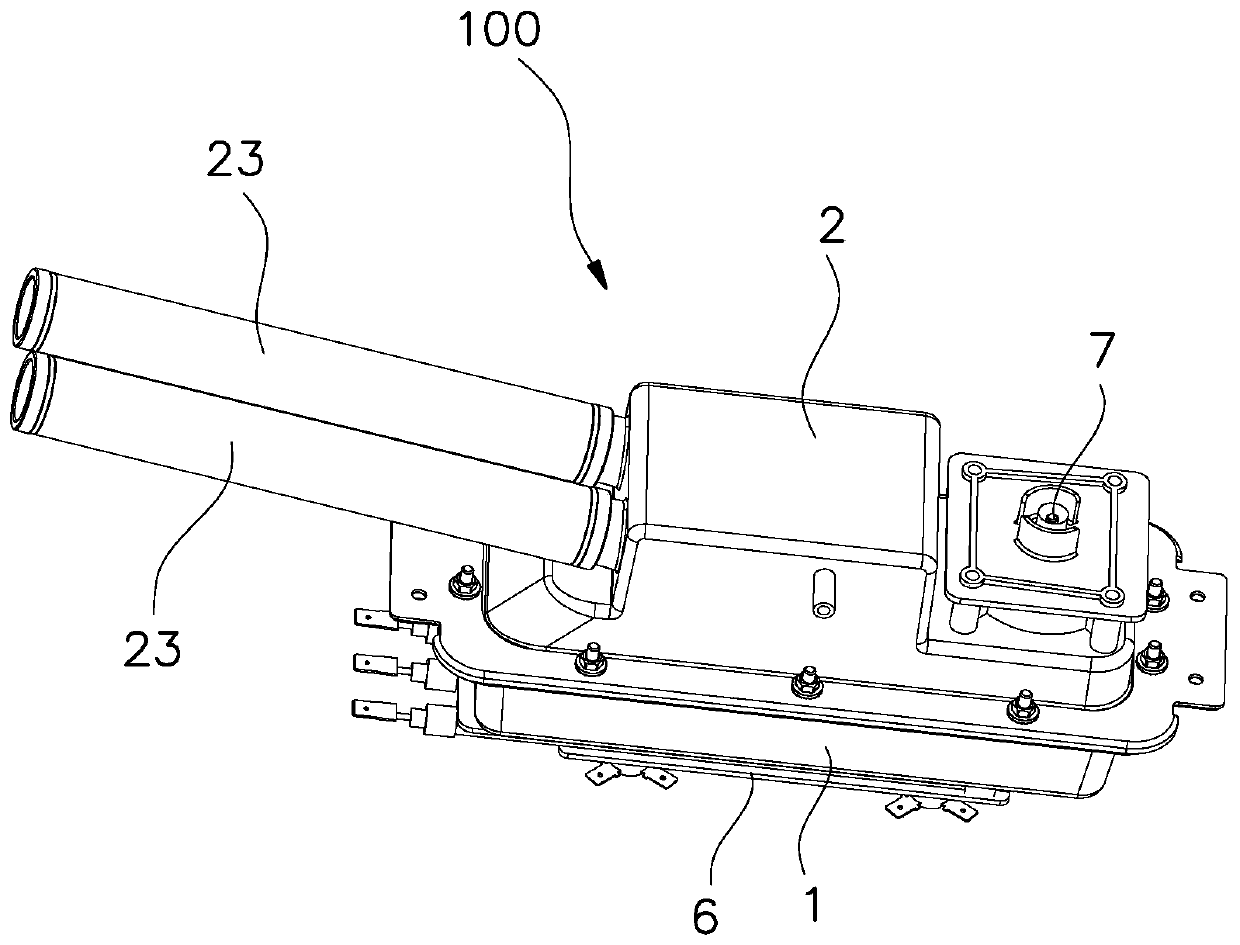

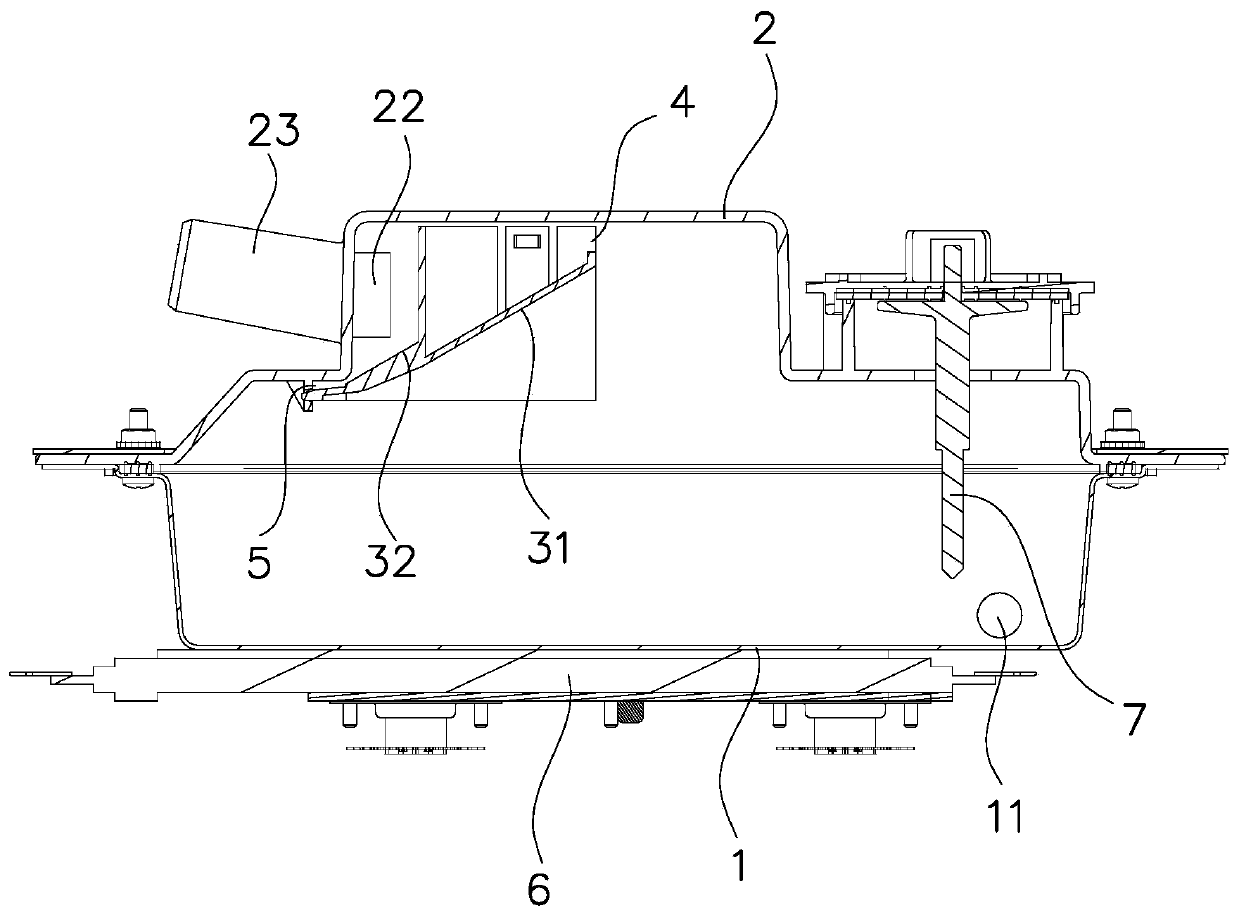

Electric heater, shell of electric heater, and electric vehicle

ActiveCN103423871AHigh thermal efficiencyEffective absorptionFluid heatersAir-treating devicesContact timeElectric cars

The invention provides a shell of an electric heater. The shell comprises a heating chamber, a circulating chamber, an inlet, an outlet, a first shell and a second shell. The heating chamber is used for accommodating PTC electric heating elements. The circulating chamber is used for accommodating medium and admitting flowing and passage of the medium. The second shell comprises connecting walls and partition walls. The heating chamber comprises a plurality of heat transfer channels partitioned by the partition walls. The circulating chamber comprises a plurality of circulating units. The first shell comprises a first side wall and a second side wall. The heat transfer channels with the first side wall or the second side wall form passages respectively. The circulating units are communicated with the passages. The circulating units of the shell of the electric heater are communicated through the passages to form the circulating chamber with a curved path; the medium flows through the circulating chamber in a circulating manner; flow path is long; the medium flows around the heat transfer channels; contact time is long, contact area is large, and heat absorption is highly efficient; accordingly, the heat efficiency of the electric heater with the shell is improved effectively, and the electric heater can be well used for heat supply, defrosting and demisting in electric vehicles.

Owner:BYD CO LTD

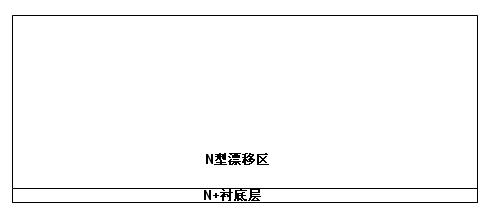

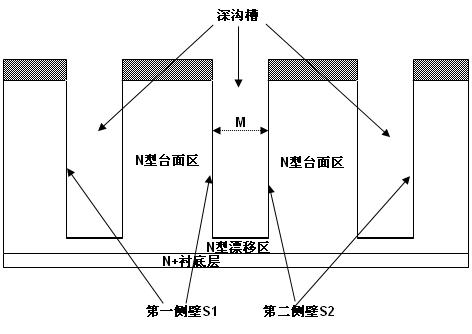

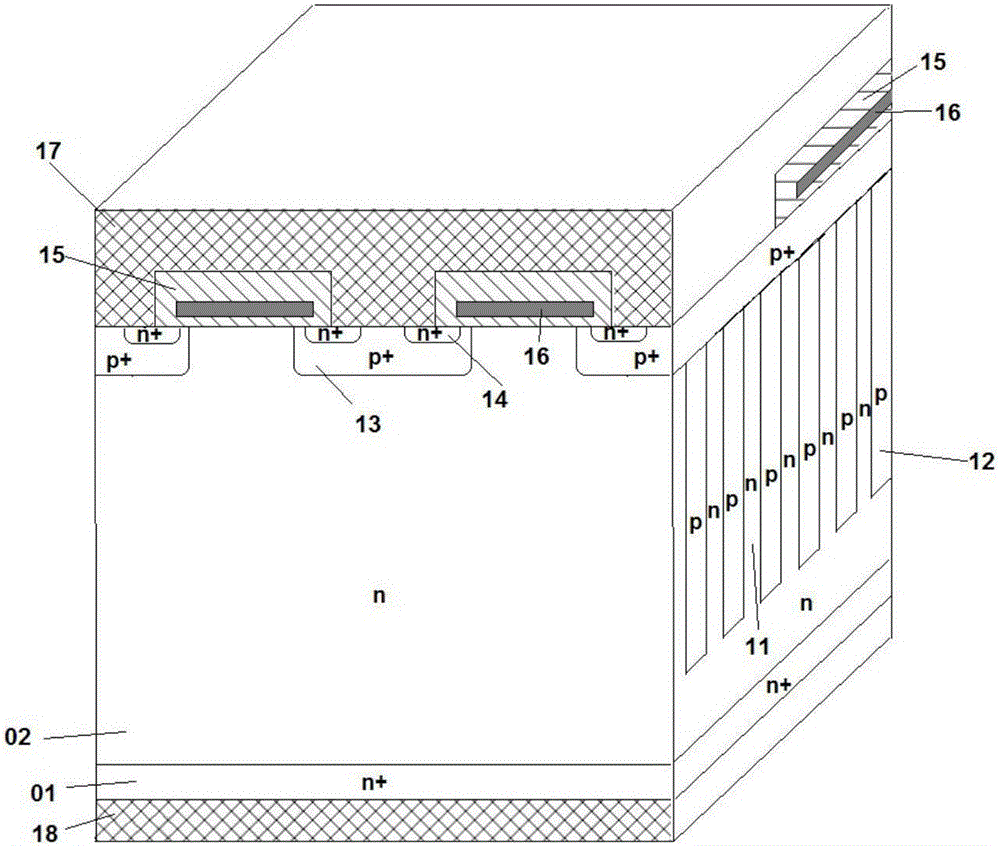

Manufacturing method for semiconductor devices with super junction structures

InactiveCN102623350AControl concentrationReduce widthSemiconductor/solid-state device manufacturingIon implantationSemiconductor

The invention discloses a manufacturing method for semiconductor devices with super junction structures. Second conductive type columns are achieved through a tilt angle implantation technology; the concentration, width and depth of the second conductive type columns can be more easily controlled by adjusting the implantation dose, the implantation energy and the implantation angle; and the width of the second conductive type columns can be greatly decreased; so that the width of whole P-N column pairs is reduced, simultaneously, the proportion of the width of first conductive type columns accounting for the width of P-N column pairs is increased, and the purpose of reducing on-resistance is reduced. First conductive type epitaxial layers are filled in deep grooves, and the first conductive type epitaxial layers and first conductive type mesa areas among the second conductive type columns form the first conductive type columns to improve the current flow path together when devices power on, accordingly, the flow path of current is increased greatly, and further the on-resistance is effectively reduced.

Owner:WUXI NCE POWER

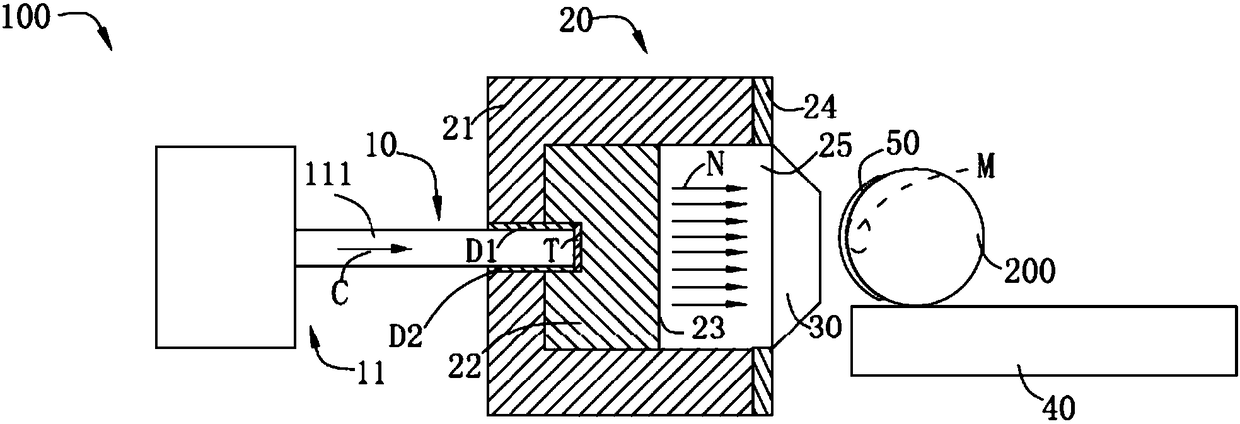

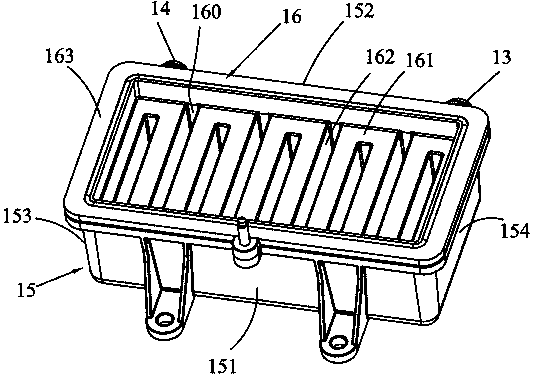

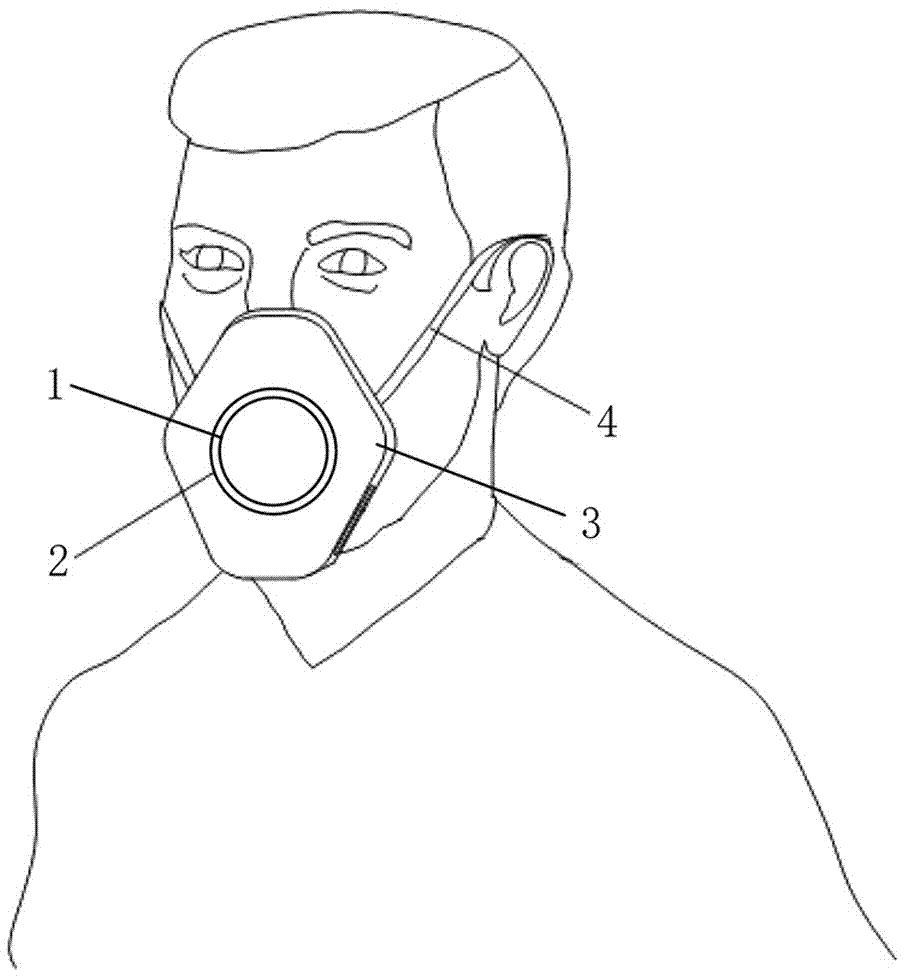

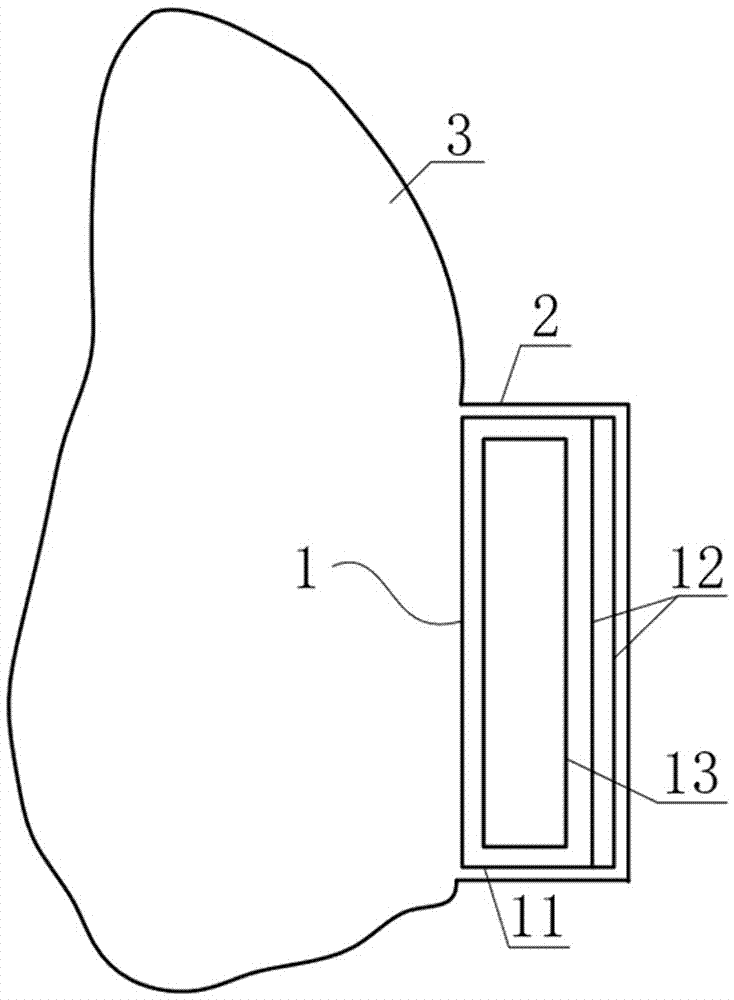

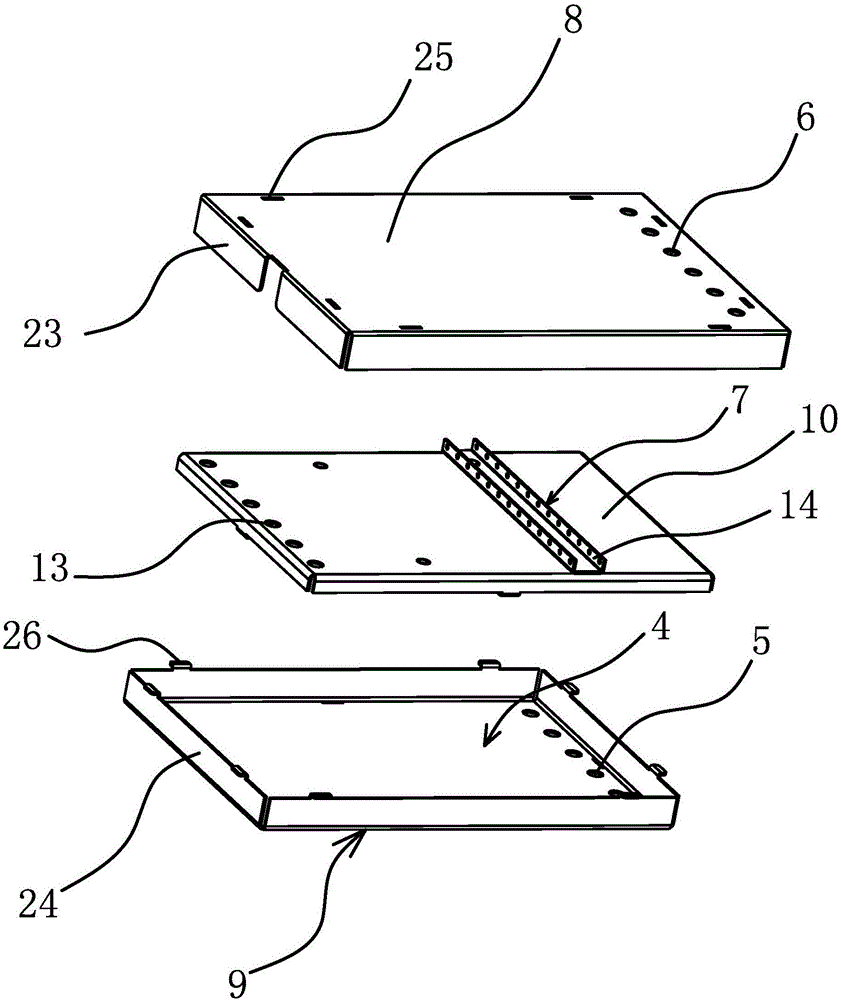

Filter mask for harmful particulate pollutants

ActiveCN106890402AExtend the distribution pathKill completelyBreathing filtersFire rescueParticulatesFiltration

The invention discloses a filter mask for harmful particulate pollutants. The filter mask comprises a gas filter unit, a surface cup and a mask shield, and one end of the surface cup is hermetically docked with one end of the mask shield; the gas filter unit comprises a filter barrel, a filter membrane and a sterilization unit arranged in the filter barrel; the filter membrane is arranged at one end of the filter barrel; the filter membrane comprises a hydrophilic spinning bonded nonwoven fabric layer, a first melt-blowing nonwoven fabric layer, a wood pulp layer, a nuclear pore membrane filtration layer and a water-repellent spinning bonded nonwoven fabric layer which are laminated and composited in sequence from the position close to the inner side of the mask shield to the outer side of the mask shield; the sterilization unit comprises a gas inlet distribution disc, a capillary gas-guide tube, a gas outlet collection disc and an ultraviolet lamp; two ends of the capillary gas-guide tube are communicated with the gas inlet distribution disc and the gas outlet collection disc, and the capillary gas-guide tube is arranged in a spiral winding manner between the gas inlet distribution disc and the gas outlet collection disc; the ultraviolet lamp is used for performing ultraviolet irradiation on the capillary gas-guide tube. The filter mask has the advantages of use comfort, good user experience, thorough sterilization and safety in use.

Owner:东方万佳科技有限公司

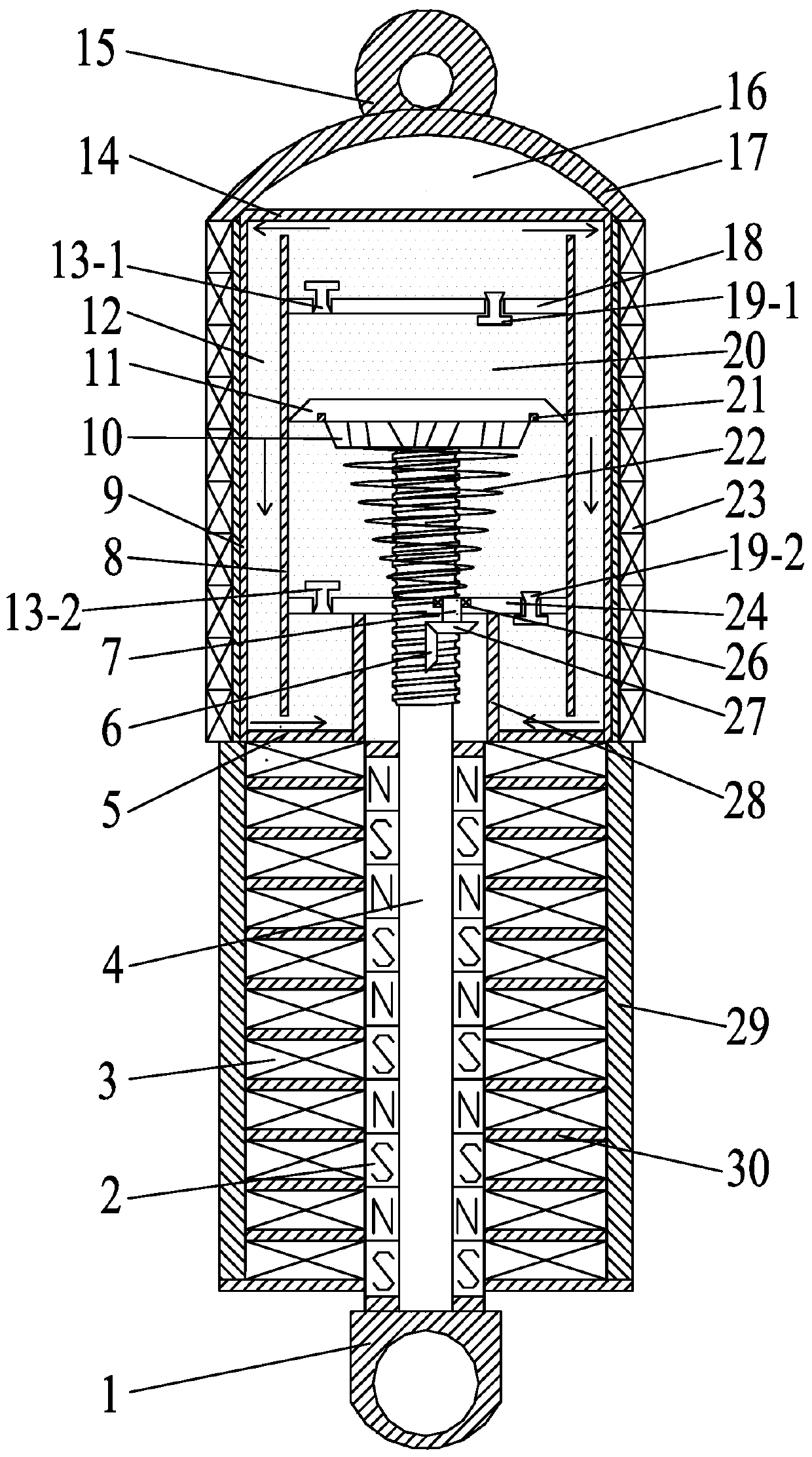

Electromagnetic integrated type energy feedback suspension actuator of electric vehicle and control method of electromagnetic integrated type energy reclaiming suspension actuator of electric vehicle

ActiveCN109808437AReasonable designSimple structureResilient suspensionsElectric machineData acquisition

The invention discloses an electromagnetic integrated type energy feedback suspension actuator of an electric vehicle and a control method of the electromagnetic integrated type energy feedback suspension actuator of the electric vehicle. The suspension actuator comprises a magnetorheological damper, a linear motor and an actuator monitoring device, wherein the magnetorheological damper comprisesa cylinder, a magnetorheological fluid, an inner chamber upper partition board and an inner chamber lower partition board, wherein the linear motor comprises a linear motor shell, a secondary part anda primary part; the actuator monitoring device comprises an actuator controller. The control method of the suspension actuator comprises the following steps: 1, data acquisition and transmission; 2,control of the suspension actuator by the actuator controller in an energy feedback mode, a primary damping mode, a secondary damping mode and an active mode according to sample data. The suspension actuator is reasonable in design, multi-mode switching of a suspension system can be realized according to different road conditions of vehicle traveling, energy waste of the electric vehicle is reduced, driving mileage of the electric vehicle can be increased, and the promotion and application values are high.

Owner:XIAN UNIV OF SCI & TECH

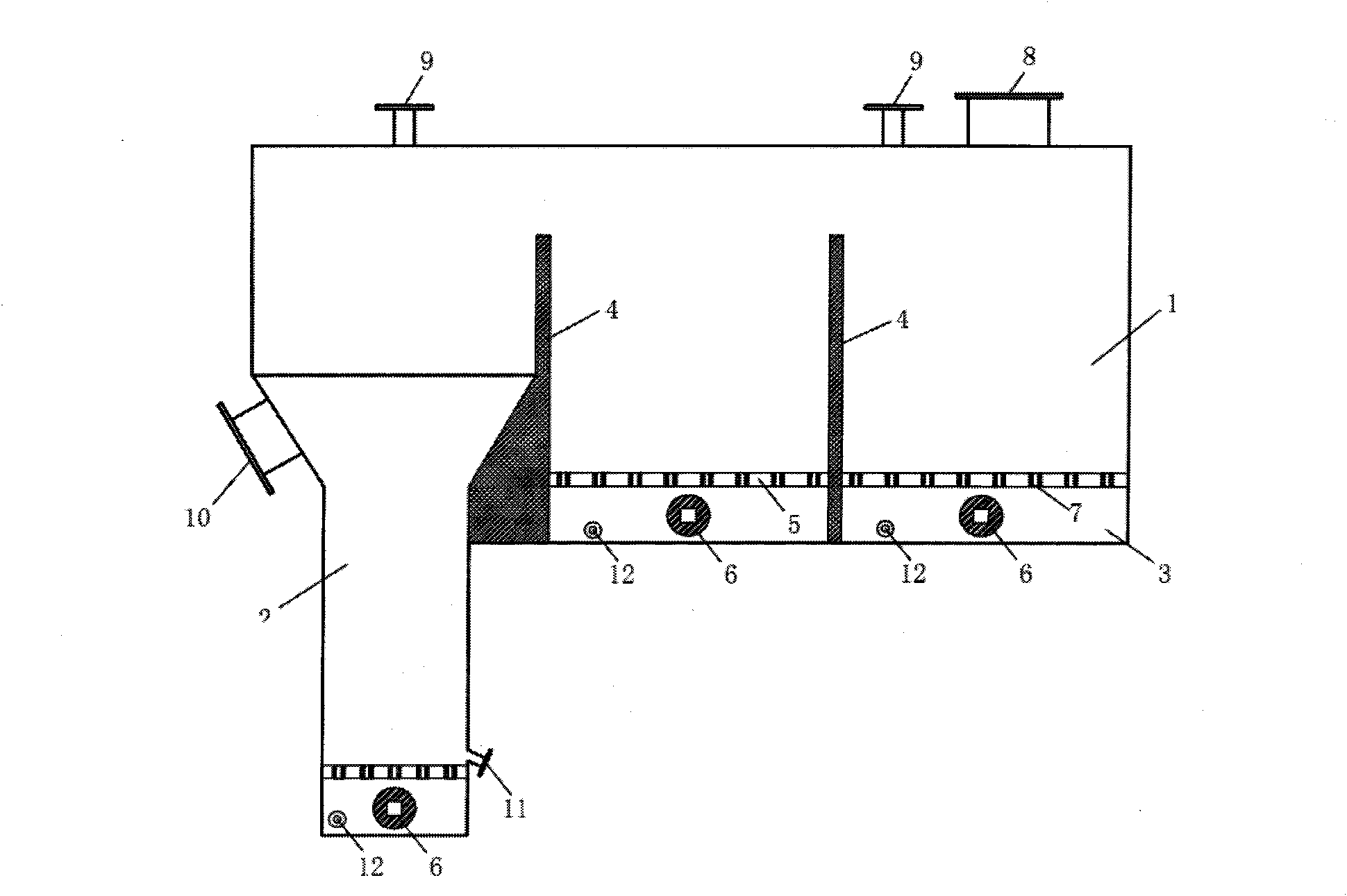

Fluidized bed deacidification purification device and process

The invention discloses a fluidized bed deacidification purification device and process, and belongs to the field of inorganic fine chemical engineering. The device is generally divided into a horizontal fluidized bed part and a vertical fluidized bed part, wherein each part is divided into an upper layer and a lower layer; each upper layer is a fluidized bed part for conveying materials; each lower layer is a combustion chamber of hydrogen and air; each combustion chamber is internally provided with a combustor; the upper layers and the lower layers are separated by partition plates; each partition plate is provided with a gas channel; the upper layer of the horizontal fluidized bed is separated into a plurality of chambers by a plurality of baffles; through channels are formed among the chambers, so that the materials can pass through from a feeding chamber to the following chambers sequentially until the materials flow into the vertical fluidized bed and are discharged from a discharge port of the vertical fluidized bed; and a vapor-phase silicon dioxide material after being deacidified by the horizontal fluidized bed enters the vertical fluidized bed for deacidification. Compared with the prior art, the deacidification technology disclosed by the invention enables the pH of white carbon black to be stabilized in a range from 4.3 to 4.6 by utilizing two-stage deacidification and improves product quality of SiO2 by using a vapor phase method.

Owner:赤峰盛森硅业科技发展有限公司

Manufacturing method of super small unit size vertical super-junction semiconductor device

ActiveCN107342226ALower on-resistanceReduce widthSemiconductor/solid-state device manufacturingSemiconductor devicesUnit sizeEtching

The invention relates to a manufacturing method of a super small unit size vertical super-junction semiconductor device. The method comprises steps that a hard mask layer is utilized to carry out deep groove etching on a first conductive type semiconductor substrate; a second conductive type epitaxial layer is deposited; anisotropy etching is carried out, and a bottom epitaxial layer of a deep groove is removed; first conductive type impurity injection is carried out; a first conductive type epitaxial layer is deposited to fill the deep groove; planarization of a first main surface of the semiconductor substrate is carried out, the hard mask layer is further removed, the second conductive type epitaxial layer of the side wall of the deep groove forms a second conductive type column of a vertical super-junction structure, and the first conductive type substrate and the first conductive type epitaxial layer respectively form a first conductive type first column and a first conductive type second column. The method is advantaged in that the unit size of the super-junction structure can be substantially reduced on the condition that process difficulty does not increase, and width restrictions of the technology capability in the prior art for the second conductive type column can be broken through.

Owner:WUXI NCE POWER

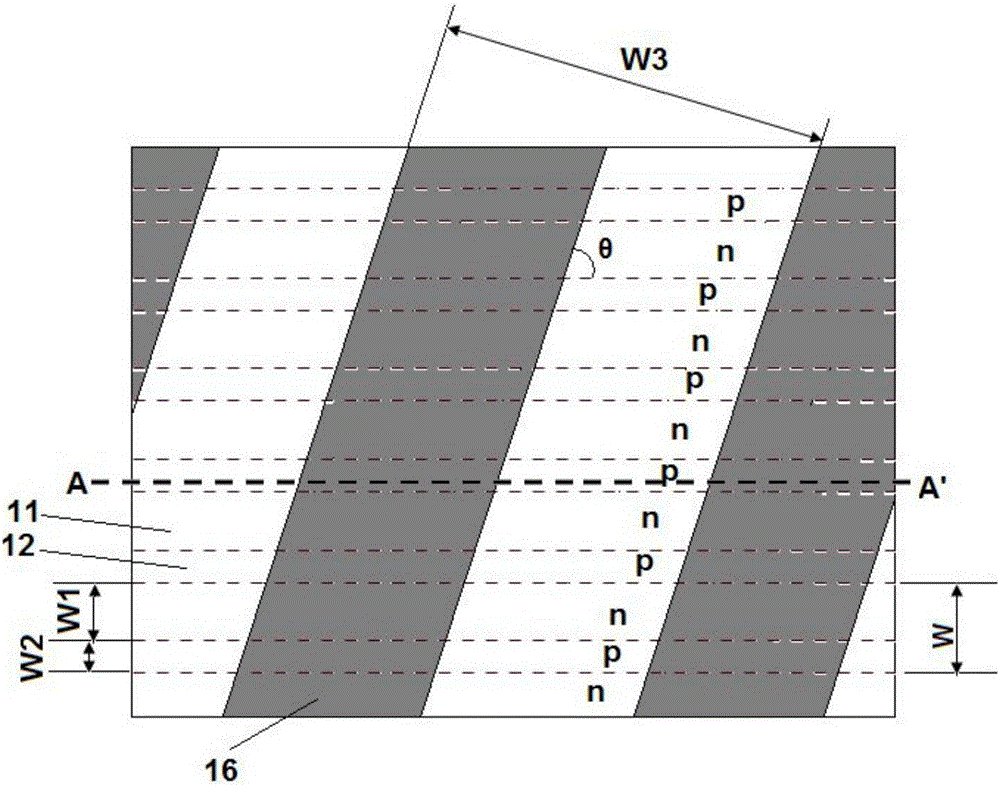

Super-junction semiconductor device and manufacture method thereof

InactiveCN105006484ALower on-resistanceSmall cell sizeTransistorSemiconductor/solid-state device manufacturingEngineeringBody region

The invention relates to a super-junction semiconductor device and a manufacture method thereof. The pitch of the super-junction structure of the super-junction semiconductor device is W. The width of a first conductive type column in the super-junction structure is W1. The width of a second conductive type column in the super-junction structure is W2. The W=W1+W2. The pitch of a device cell is W3. Any second conductive type column in the super-junction structure is in contact with at least one second conductive type body region. The pitch W of the super-junction structure is less than the pitch W3 of the device cell. The width W1 of the first conductive type column in the super-junction structure is not less than the width W2 of the second conductive type column. The super-junction semiconductor device effectively solves a direct contradiction between a decrease in the pitch of the super-junction structure in a drift region and the device cell, further reduce device on-state resistance, has a better switching characteristic, and obviously decreases the pitch of the super-junction structure while process cost and process difficulty are not increased.

Owner:WUXI NCE POWER

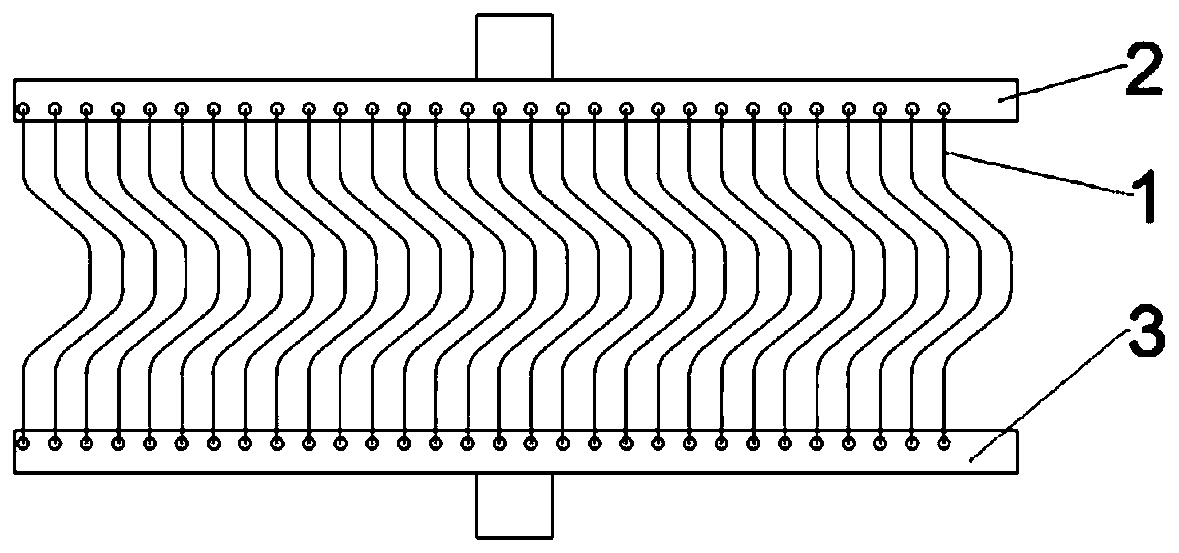

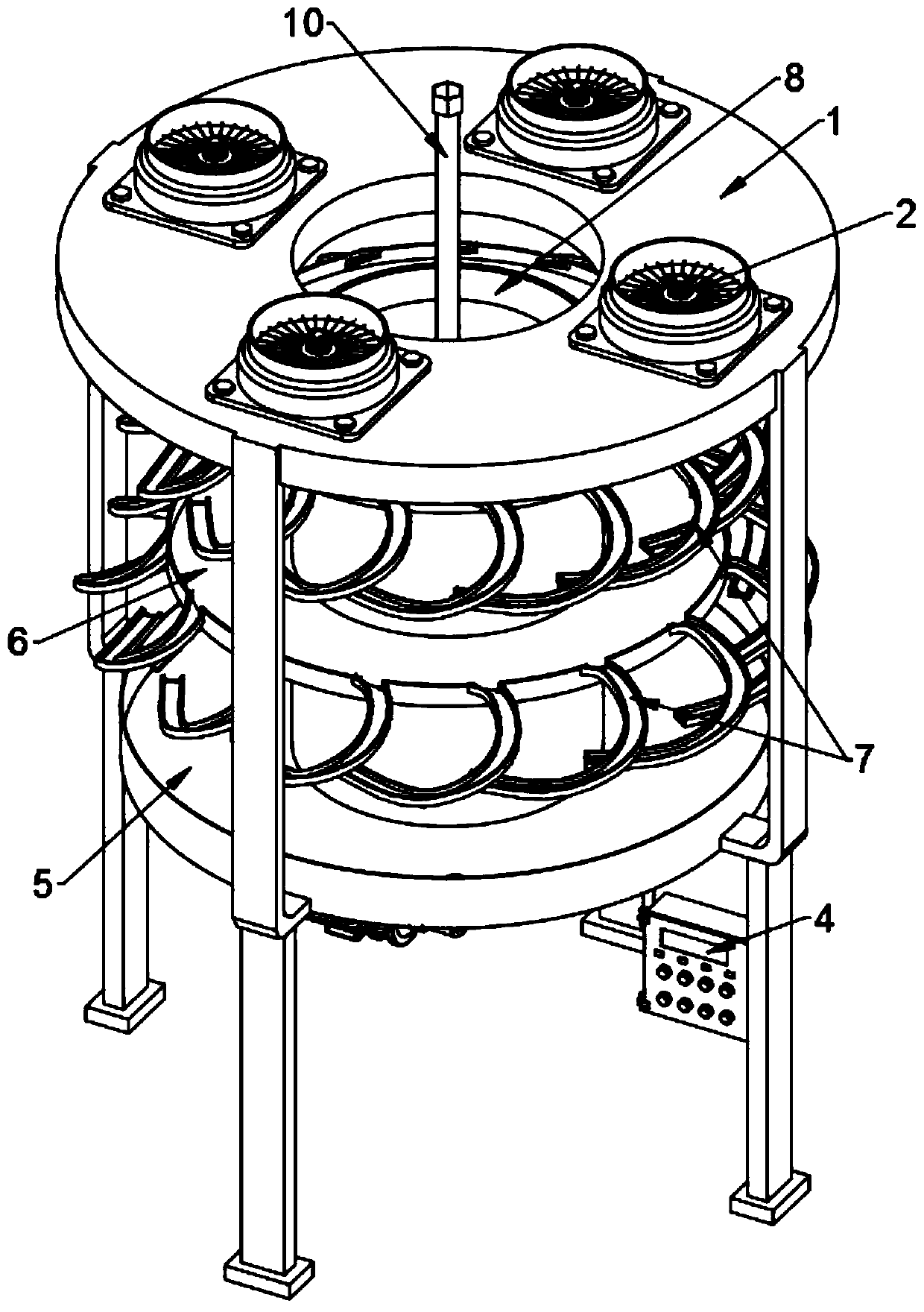

Heat exchanger

ActiveCN111256389AExtend the distribution pathImprove heat transfer effectEvaporators/condensersHeat exchanger casingsCooling fluidThermal efficiency

The invention discloses a heat exchanger. The heat exchanger comprises a housing and a heat exchange core body, wherein the heat exchange core body comprises a flat tube with a refrigerant runner therein; the flat tube is provided with a plurality of flat parts which are parallel to each other and bending parts for connecting adjacent two flat parts in a transitional mode; at least one part of each flat tube is positioned inside the housing; a cooling liquid runner is formed inside the housing; the part of the cooling liquid runner of the housing is divided into at least two cooling liquid flow paths which are arranged side by side in a direction parallel to the flat parts of the flat tube, and flow directions of the adjacent two cooling liquid flow paths are reverse; the portion, at a turning position of the adjacent two cooling liquid flow paths, of the housing is provided with a hollow bulged part, and the bulged part is positioned above or below the turning position of the flat tube; and an inner cavity of the bulged part communicates with the adjacent two cooling liquid flow paths with reverse two directions. The heat exchanger disclosed by the invention can prolong the cooling liquid flow paths, improves heat exchange efficiency, and is relatively high in pressure bearing capacity.

Owner:ZHEJIANG SANHUA AUTOMOTIVE COMPONENTS CO LTD

air-cooled refrigerator

InactiveCN102269500ADistribute quicklyImprove cooling efficiencyLighting and heating apparatusDomestic refrigeratorsCold airEngineering

The present invention proposes an air-cooled refrigerator, comprising: a box body, the box body has a compartment; an air duct is arranged in the box body and communicates with the compartment; and a fan assembly is arranged in the compartment. The box is used to blow the cold air in the air duct to the compartment, and the fan assembly further includes: a fan; a first motor that controls the fan to rotate at a first speed; a fan cover, inside the fan cover An accommodation space for accommodating the fan is defined; a turning page, the turning page is rotatably arranged on the fan cover for changing the blowing direction of the fan; Two motors. With the fan assembly of the present invention, the cold air can be blown out from different angles through the rotating leaf, so that the cold air can be quickly distributed to all corners of the refrigerator, thereby greatly improving the cooling efficiency.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD +1

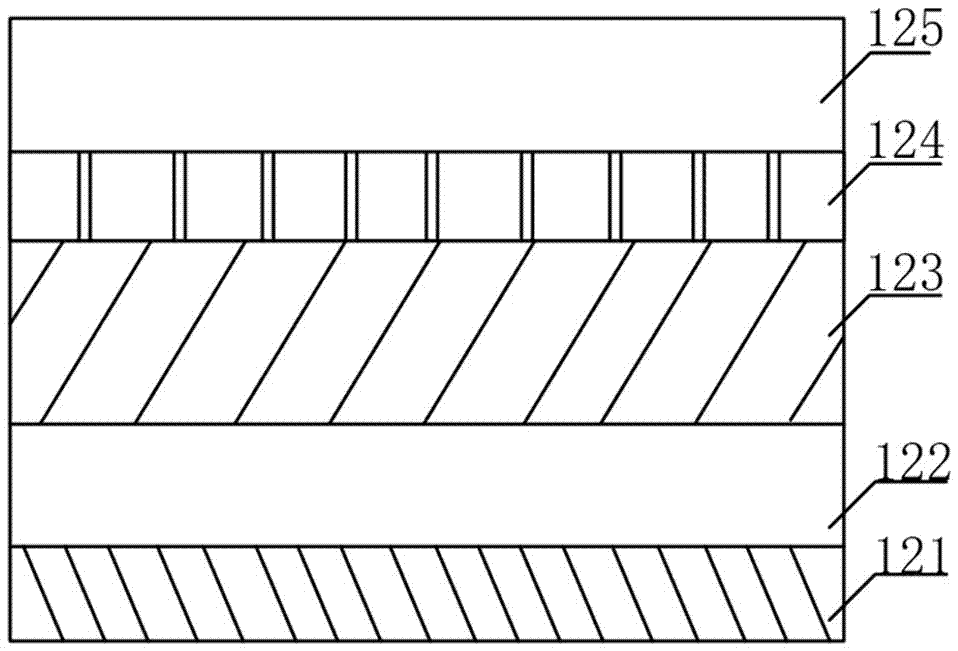

Composite nanofiber filter membrane

InactiveCN108619827ALarge specific surface areaIncreased air flow pathsPersonal careDispersed particle filtrationPolyvinylidene fluorideFiltration membrane

The invention provides a composite nanofiber filter membrane. The composite nanofiber filter membrane is prepared by electrospinning, and sequentially comprises a membrane supporting layer, a nonwovenlayer, a coarse filter layer, a nanofiber layer and a polyvinylidene fluoride coating layer which are mutually connected, wherein the filter hole diameter of the coarse filter layer is 0.1-1mm; the nanofiber layer sequentially comprises a first nanofiber layer, a second nanofiber layer and a third nanofiber layer; the first nanofiber layer is formed on the surface of the coarse filter layer; thediameter of holes between nanofibers in the first nanofiber layer is 20-50 microns, the diameter of holes between nanofibers in the second nanofiber layer is 1-20 microns, and the diameter of holes between nanofibers in the third nanofiber layer is 0.01-1 micron. The nanofiber filter membrane structure is large in specific surface area, an air circulating path is increased, the storage space of particulate matters is increased, and the service life is prolonged while the filtration efficiency of the filter membrane is improved, and the air resistance is lowered.

Owner:FOSHAN RIRISHENG TECH CO LTD

Combined-type flexible ureteroscope sheath part capable of conducting continuous lavaging and sucking

The invention discloses a combined-type flexible ureteroscope sheath part capable of conducting continuous lavaging and sucking. The combined-type flexible ureteroscope sheath part solves the problemthat blood clots and broken calculi in the kidney cannot be effectively discharged in ureteroscopic lithotripsy. A continuous lavaging system formed by an inner sheath canal and an outer sheath body has the advantage of efficiently removing the calculi, the operation success rate for the first time is increased so that the ureteroscopic lithotripsy can process the renal calculi of 2 cm or above, and the operation indication is expanded. According to the technical scheme, the combined-type flexible ureteroscope sheath part comprises the outer sheath body, the inner sheath pipe is detachably andcombinedly arranged in the outer sheath body, and the working end of the inner sheath pipe stretches out of the working end of the outer sheath body for a certain length; a negative pressure suctionopening is formed in the non-working end of the outer sheath body; the outer sheath part and the inner sheath pipe form the continuous lavaging system of which the inner sheath pipe conducts continuous lavaging inwards and the outer sheath body conducts continuous negative pressure suction, and foreign matter in the ureteroscopic lithotripsy is taken out.

Owner:张建军

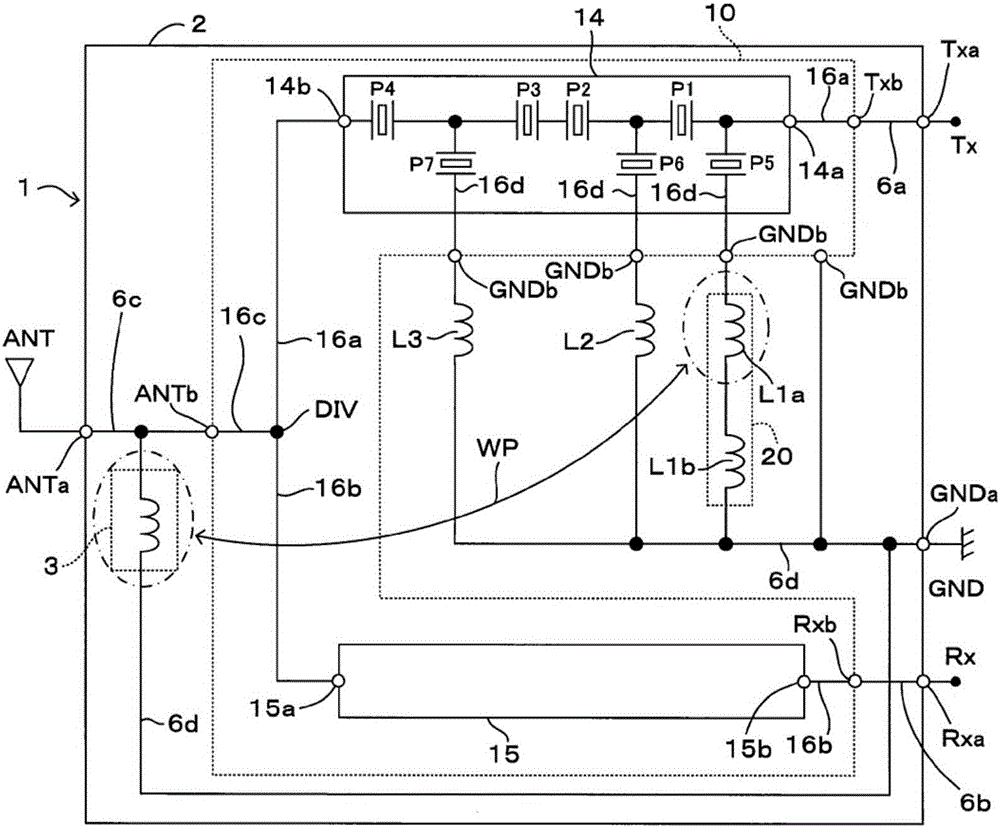

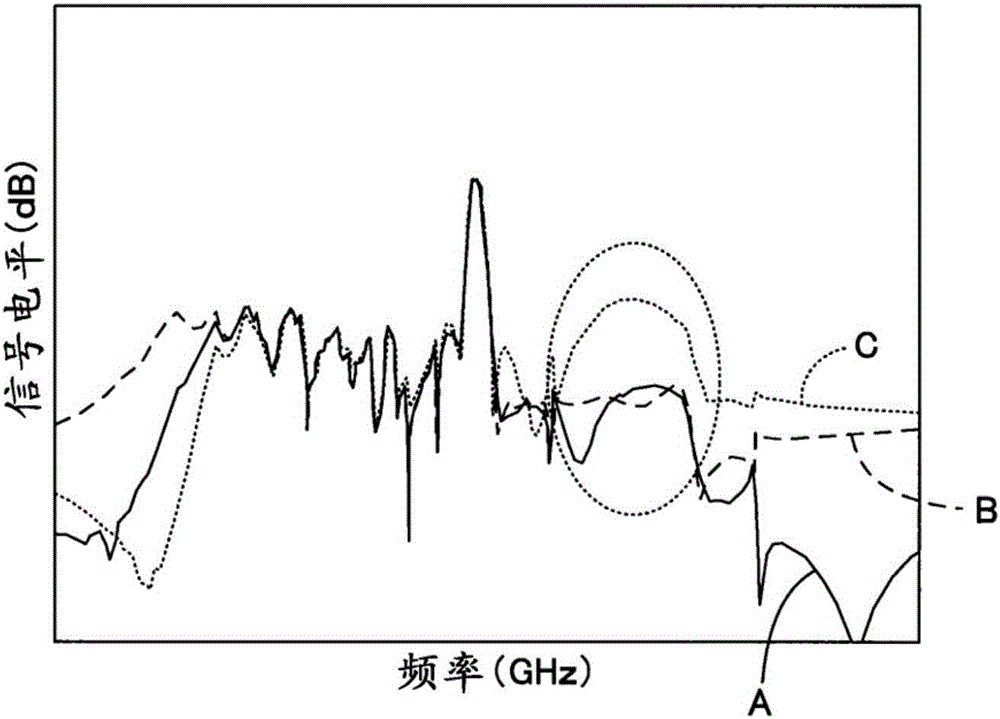

Radio frequency module

ActiveCN106464294AImprove attenuation characteristicsImprove isolation characteristicsMultiple-port networksOne-port active networksUltrasound attenuationRadio frequency

Provided is a configuration capable of improving an attenuation characteristic of an RF signal outside a frequency band of a transmitting signal inputted to a transmitting terminal, and improving an isolation characteristic between a transmitting filter and a receiving filter without increasing the size of a radio frequency module. A propagation path WP for further improving a filter characteristic without deteriorating an attenuation characteristic outside a pass band of a transmitting filter 14 can be formed by a simple configuration, and consequently an attenuation characteristic of an RF signal outside a frequency band of a transmitting signal can be improved without increasing the size of a radio frequency module 1. Further, an RF signal outside the frequency band of the transmitting signal and within approximately the same frequency band as a received signal is prevented from going around from a signal path on the output terminal 14b side of the transmitting filter 14 to the receiving filter 15 side and being outputted from a receiving terminal Rxa, and consequently an isolation characteristic between the transmitting filter 14 and the receiving filter 15 can be improved.

Owner:MURATA MFG CO LTD

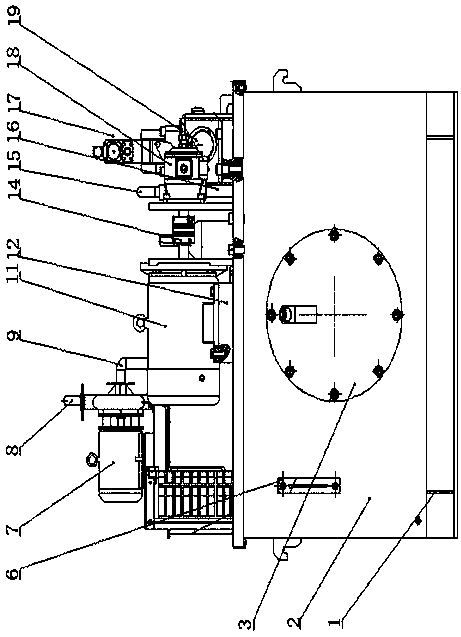

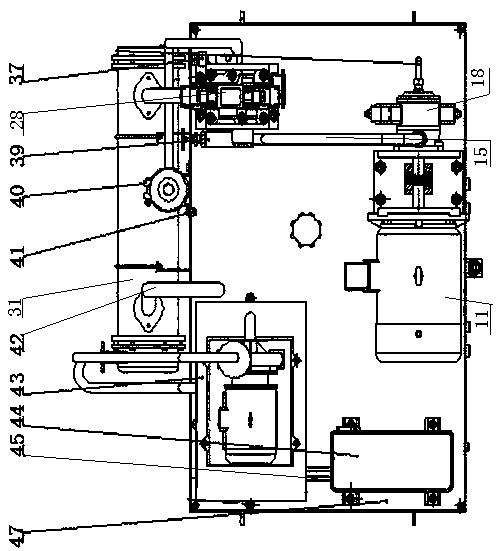

Constant temperature adjusting method for air conditioning type constant temperature hydraulic oil tank

InactiveCN110925275APrevent high temperature emulsificationExtended service lifePump assembliesRefrigeration devicesTemperature controlAir conditioning

The invention discloses a constant temperature adjusting method for an air conditioning type constant temperature hydraulic oil tank. According to the constant temperature adjusting method for the airconditioning type constant temperature hydraulic oil tank, an evaporator coil pipe of an air conditioning system is connected into a water tank; the temperature of the cooling water in the water is controlled through heating or refrigerating; the cooling water is introduced into a red copper pipe of a heat exchanger to perform heat exchange with high-temperature hydraulic oil in a heat exchanger,so that precise control of oil temperature is realized. The air conditioning system and the water tank of the air conditioning type constant temperature hydraulic oil tank are arranged at the upper part of an oil tank, and the heat exchanger is arranged on the side surface of the oil tank, so that the space position is greatly reduced. The refrigerating efficiency of the air conditioning type constant temperature hydraulic oil tank is much higher than that of the existing conventional hydraulic station; the hydraulic oil temperature is controlled between 32 and 34 DEG C, so that the power performance of the hydraulic oil is improved; the hydraulic oil is prevented from being emulsified at high temperature; the service life of the hydraulic oil is prolonged; the using amount of the hydraulic oil is reduced; the heat exchange efficiency is high; the hydraulic oil in the oil tank is ensured to be in a constant temperature state; and therefore, the constant temperature adjusting method for the air conditioning type constant temperature hydraulic oil tank has great advantages.

Owner:ZHONGYUAN ENGINEERING COLLEGE

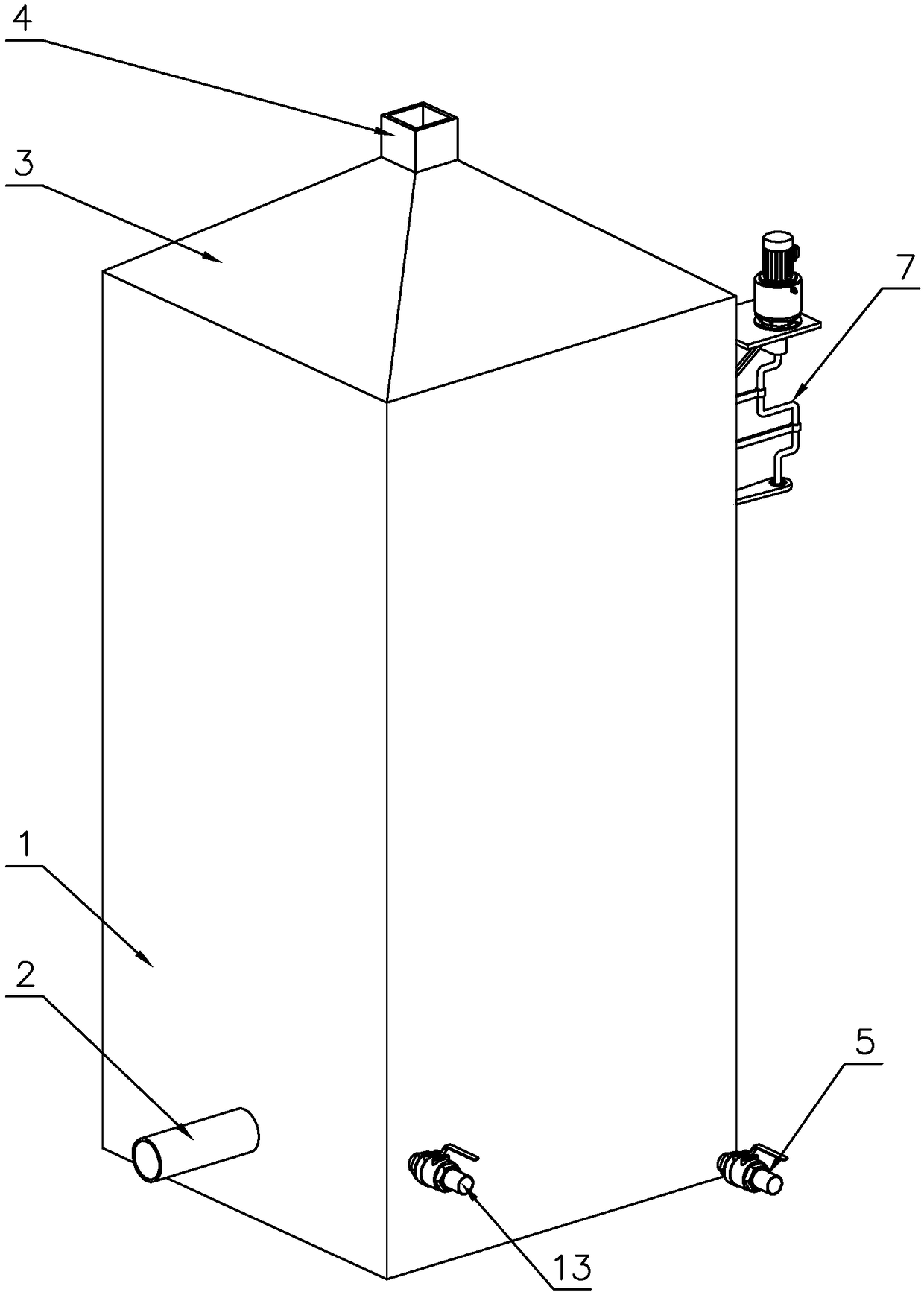

Wet type boiler flue gas desulfurization and dust removal device

The invention discloses a wet type boiler flue gas desulfurization and dust removal device. A bottom plate is arranged on one side of the lower part of a body, a gas feeding pipe is arranged on one side of the upper part of the bottom plate, washing liquid is arranged on the lower side in the body, a gas outlet of the gas feeding pipe is arranged in the washing liquid, a spray device is arranged on one side in the body, a defogging device is arranged on one side of the upper part of the spray device, a gas gathering hood is arranged on one side of the upper part of the body, the gas gatheringhood is in a reversed funnel shape, a gas discharging pipe is arranged on one side of the upper part of the gas gathering hood, a liquid feeding pipe is arranged on one side of the lower part of the body, a sewage draining pipe is arranged on one side of the liquid feeding pipe, and valves are arranged on the liquid feeding pipe and the sewage draining pipe. According to the wet type boiler flue gas desulfurization and dust removal device disclosed by the invention, a circular turnable type defogging device is utilized to change the flue gas flowing direction continuously, so that flue gas canstrike a defogging plate for multiple times, the washing liquid carried in the flue gas can be removed, the washing liquid is prevented from being drained out along with the flue gas, and environmental pollution is avoided; meanwhile, waste of the washing liquid is reduced.

Owner:临沂齐泽医药技术有限公司

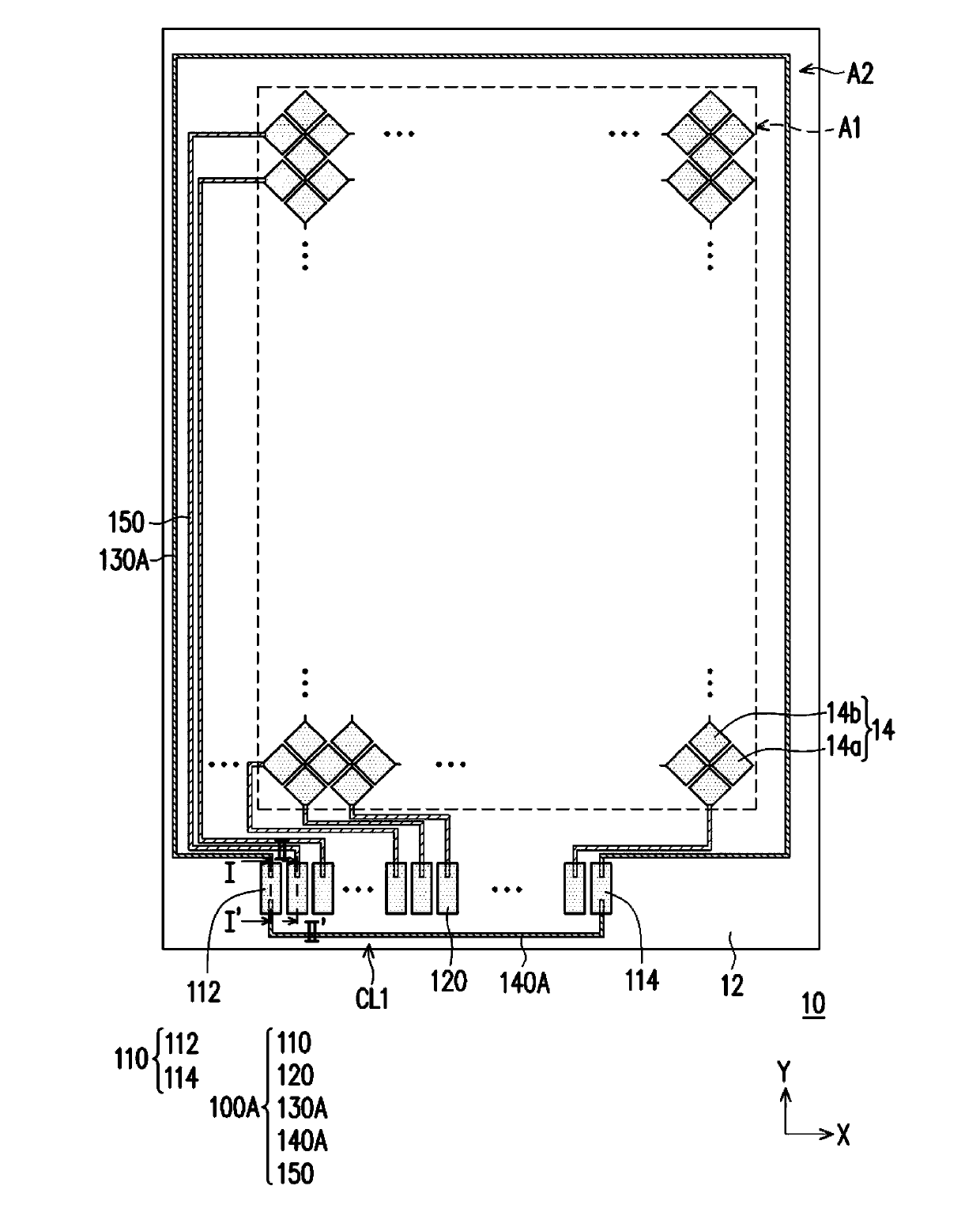

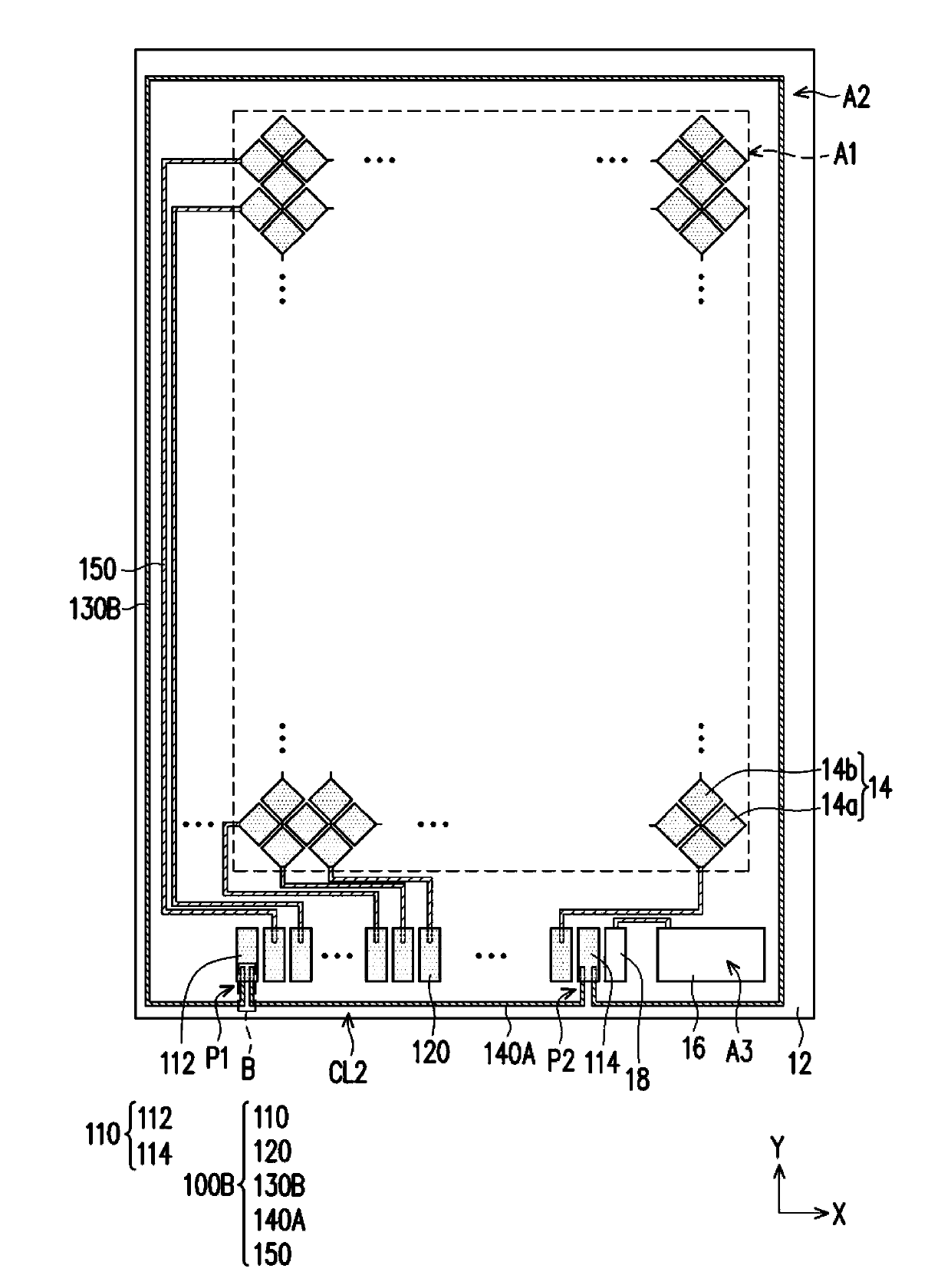

Peripheral circuit structure

ActiveCN103874318AExtend the distribution pathImprove anti-static discharge abilityPrinted circuit detailsElectrostatic chargesPeripheralElectrical and Electronics engineering

The invention provides a peripheral circuit structure which is arranged on a substrate. The substrate comprises a component region and a peripheral circuit region. The peripheral circuit structure in the peripheral circuit region comprises multiple first connecting pads, multiple second connecting pads, a first line, a second line and multiple third lines, wherein the multiple third lines are connected to components in the component region, and electrically connected with the second connecting pads. Each first connecting pad comprises a first grounding connection pad and a second grounding connection pad, and the second connecting pads are positioned between the first grounding connection pads and the second grounding connection pads. The two ends of the first line are respectively electrically connected with the first grounding connection pads and the second grounding connection pads. The two ends of the second line are also respectively electrically connected with the first grounding connection pads and the second grounding connection pads Thus, the second line, the first line, the first grounding connection pads and the second grounding connection pads form an enclosed loop.

Owner:WINTEK CHINA TECH LTD +1

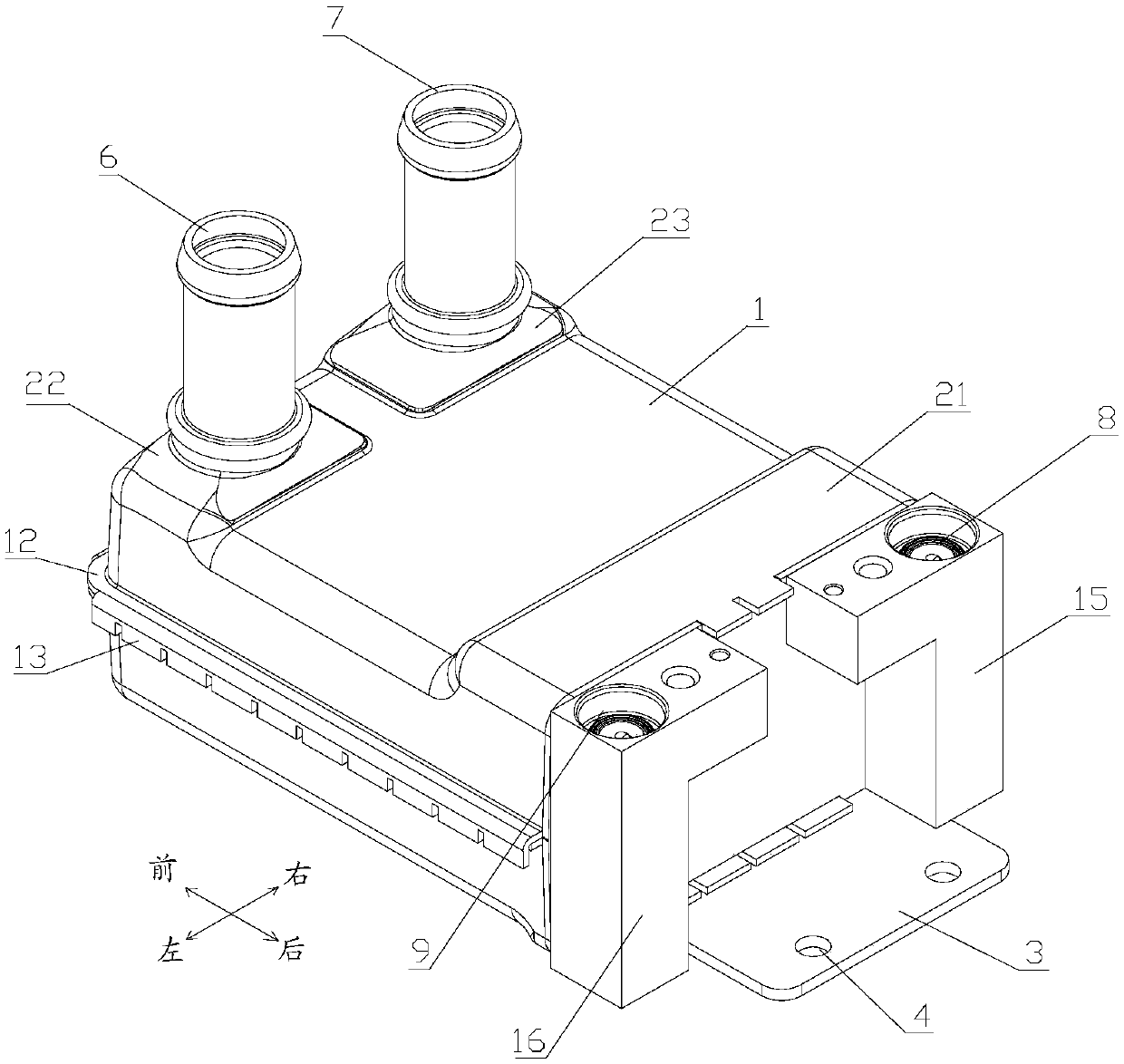

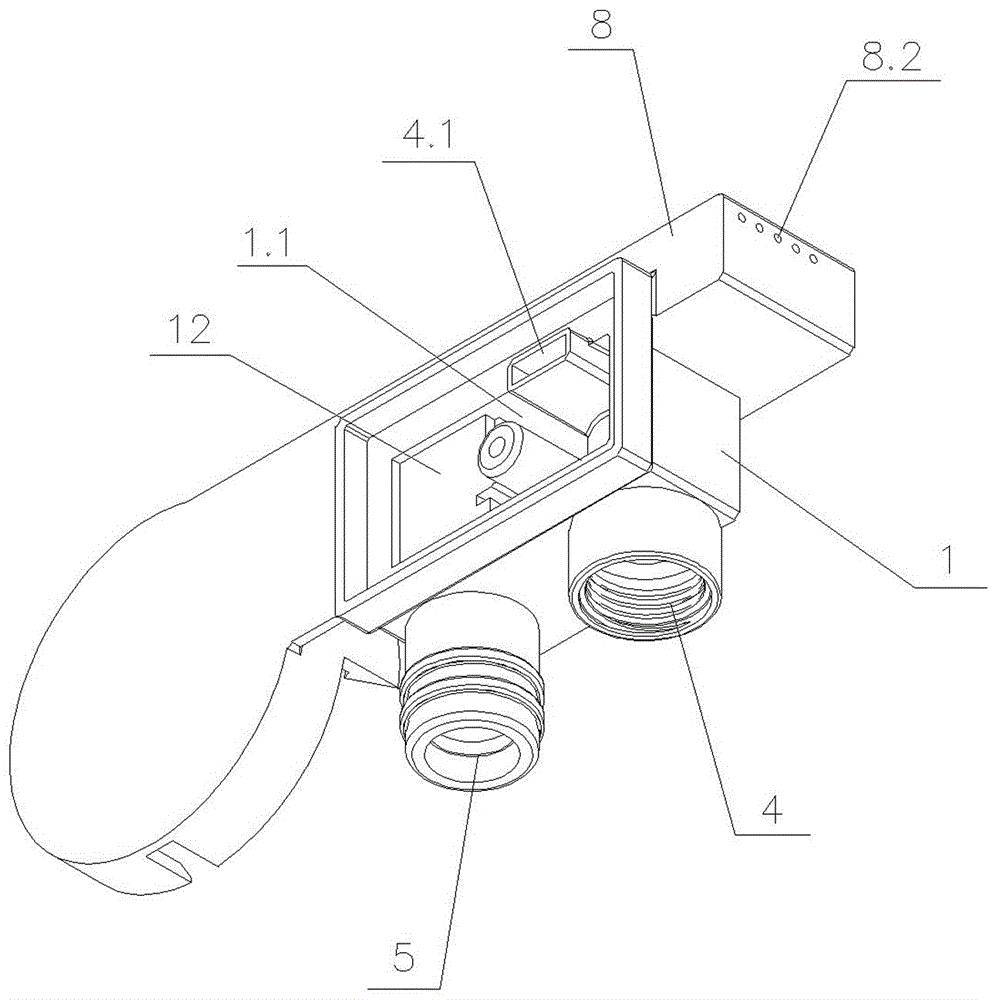

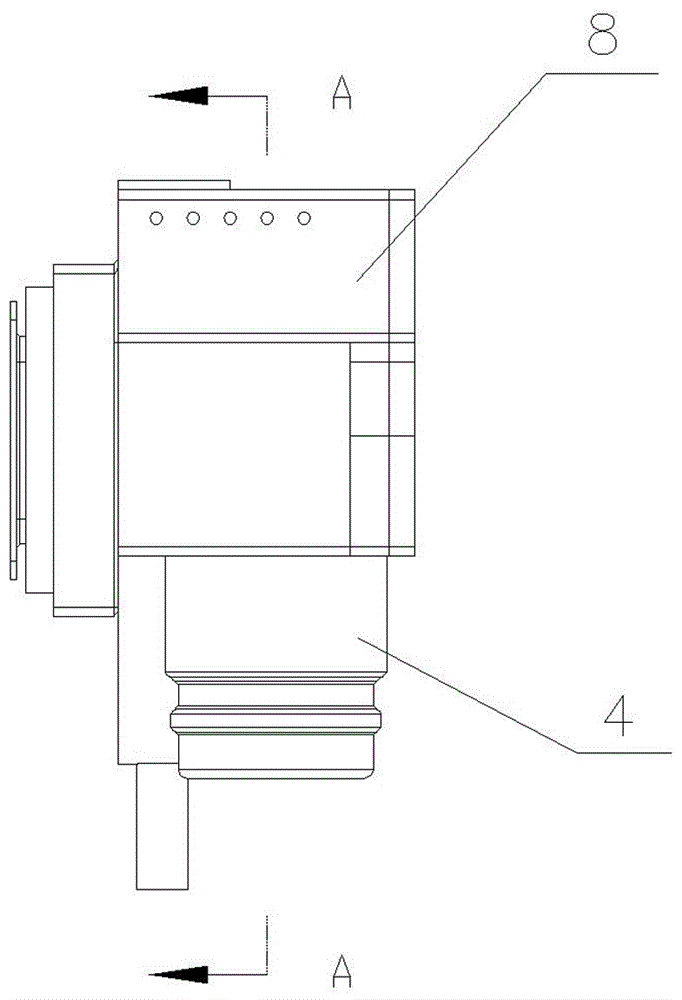

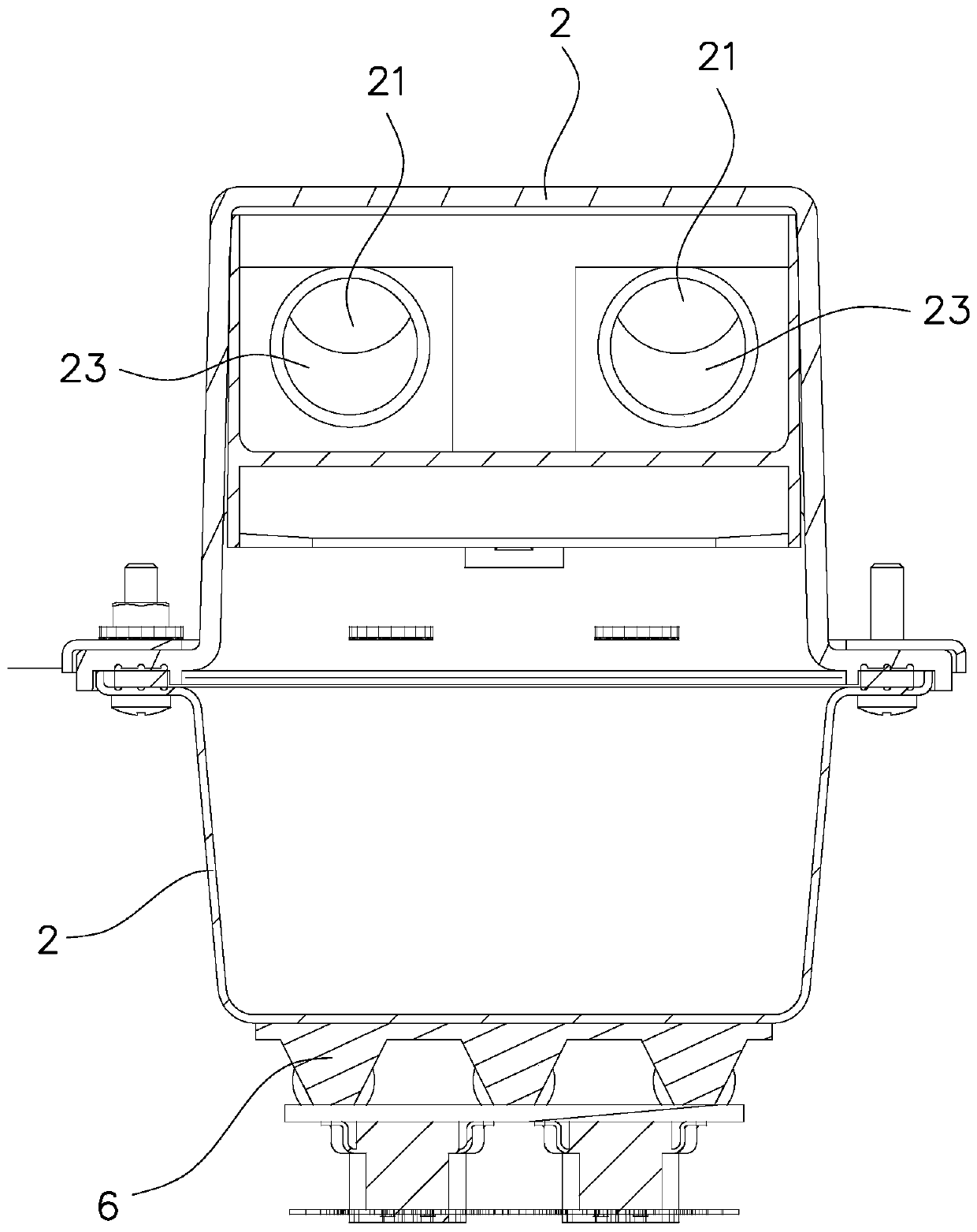

Water inlet device for cleaning machine

PendingCN106618431AExtend the water vapor circulation pathStay hygienic and unobstructedTableware washing/rinsing machine detailsPipingSteam condensation

The invention discloses a water inlet device for a cleaning machine. The water inlet device comprises a water inflow support, and the water inflow support is provided with a water inlet pipe and a water overflow pipe; a main cavity is formed in the water inflow support, and a first opening is formed in one side of the main cavity; a vent hole is formed in the upper side wall of the main cavity, the water inflow support is further provided with a condenser pipe with an air inlet and an air outlet, and the air inlet of the condenser pipe is connected with the vent hole; multiple partition boards are arranged in the condenser pipe and divide an inner cavity of the condenser pipe into multiple spaces, and the spaces are communicated with one another to form a steam condensation channel; the steam condensation channel is communicated with the air inlet and the air outlet. The steam circulation path is prolonged, and multiple barriers are arranged on a steam circulation pipeline, so steam frequently collides with all wall surfaces in the circulation process and the water inlet device achieves the natural condensation effect. The water inlet device can effectively condensate steam, can also keep the steam circulation pipeline hygienic and smooth, and makes the cleaning machine operate normally.

Owner:NINGBO ZHONGWU DONGFANG OPTOELECTRONICS TECH CO LTD

Fumigating box and electric fumigating oven with fumigating box

ActiveCN105662170AEvenly dehydratedImprove the heating effectRoasters/grillsEngineeringUtilization rate

The invention provides a fumigating box and an electric fumigating oven with the fumigating box, belongs to the technical field of electric fumigating ovens, and aims to solve the technical problems that the fume supply time is shortened, a relatively great amount of materials can be consumed, and the like as the flowing speed of fume generated from a fume generator of a conventional fumigator is too high. The fumigating box comprises a box body and a box cover, wherein a material storage cavity for accommodating a fume generating material is formed inside the box body; the top surface of the box body is opened; the box cover is detachably connected onto the top of the box body and is used for sealing the opening of the box body; a fume storage cavity is formed inside the box cover; fume inlets for communicating the fume storage cavity with the material storage cavity are formed in the bottom surface of the box cover; fume outlets communicated with the fume storage cavity are formed in the top surface of the box cover; a fume baffle structure for retarding fume in the fume storage cavity from being discharged out is arranged inside the box cover. By adopting the fumigating box and the electric fumigating oven, the utilization rate of a fume generating material can be effectively increased.

Owner:ZHEJIANG FUDEER ELECTRIC APPLIANCE

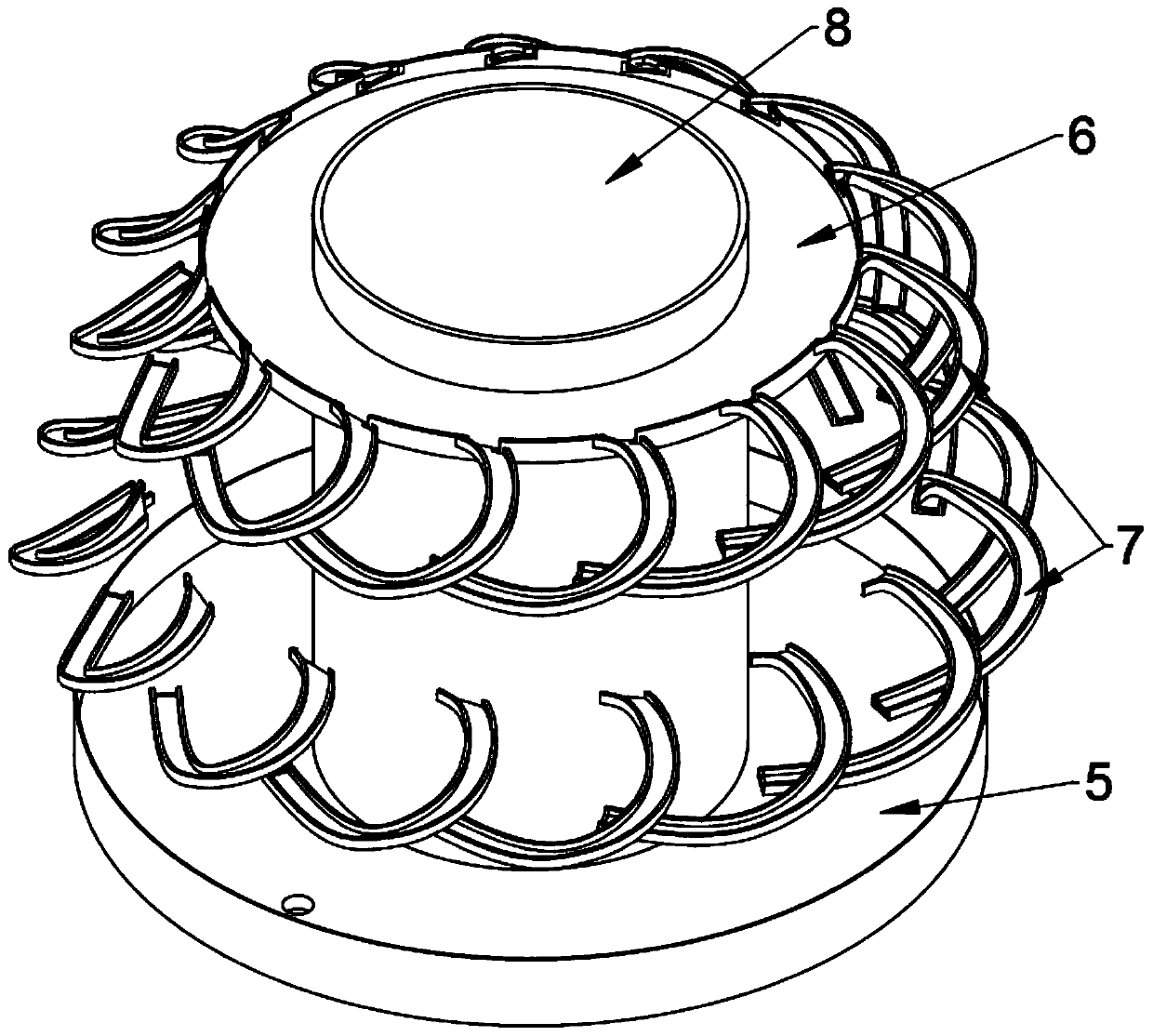

Anti-crushing device of resin filter

ActiveCN102600915AReduce the chance of breakageExtended service lifeIon exchange regulation/controlWater/sewage treatment by ion-exchangeWater flowEngineering

The invention discloses an anti-crushing device of a resin filter, which comprises a water-distributing spiral paddle and a water-distributing plate. The water-distributing spiral paddle is arranged at the bottom of the resin filter and is used for shunting to make water flow rise spirally, and the water-distributing plate is arranged between the water-distributing spiral paddle and a resin filler layer and is provided with a plurality of water-distributing holes. Water can be distributed uniformly, the flow area can be increased, and the impact on resin caused by water flow through the resin filler layer can be reduced. Meanwhile, due to common effects of the water-distributing spiral paddle and the water-distributing plate, the direction of water flow can be changed, so that the water flow can rise spirally, and the direction of water flow impact applied vertically upwards on resin particles can be changed, so that the water flow impact can be applied on the resin particles in the horizontal tangential direction. Resin layers can be expanded upwards layer by layer, the combination of the water flow impact and resin extrusion effects can be weakened, the possibility of resin crushing can be reduced, and the service life of resin can be prolonged.

Owner:海宁市德智环保科技有限公司

Continuous chlorination method for phenol and circulating flow spray type continuous gas-liquid reactor

ActiveCN106905118AImprove solubilityIncrease profitOrganic chemistryOrganic compound preparationSingle stageGas phase

The invention discloses a continuous chlorination method for phenol. Phenol and chlorine are taken as raw materials and react in a circulating flow spray type continuous gas-liquid reactor, wherein the circulating flow spray type continuous gas-liquid reactor comprises a casing, multiple first partition boards with gas-liquid mixing channels and multiple second partition boards with gas-phase channels and liquid-phase overflow channels, the multiple first partition boards and the multiple second partition boards are arranged in the casing and distributed alternately, and first single-stage reactors and second single-stage reactors are formed through surrounding of the first partition boards, the second partition boards and the casing, arranged alternately and communicated; gas-phase material flow and liquid-phase material flow in the first single-stage reactors are downstream, while gas-phase material flow and liquid-phase material flow in the second single-stage reactors are upstream. With adoption of the continuous chlorination method for phenol, the gas-phase utilization rate and the target product yield are high. The invention further provides the circulating flow spray type continuous gas-liquid reactor.

Owner:XIANGTAN UNIV

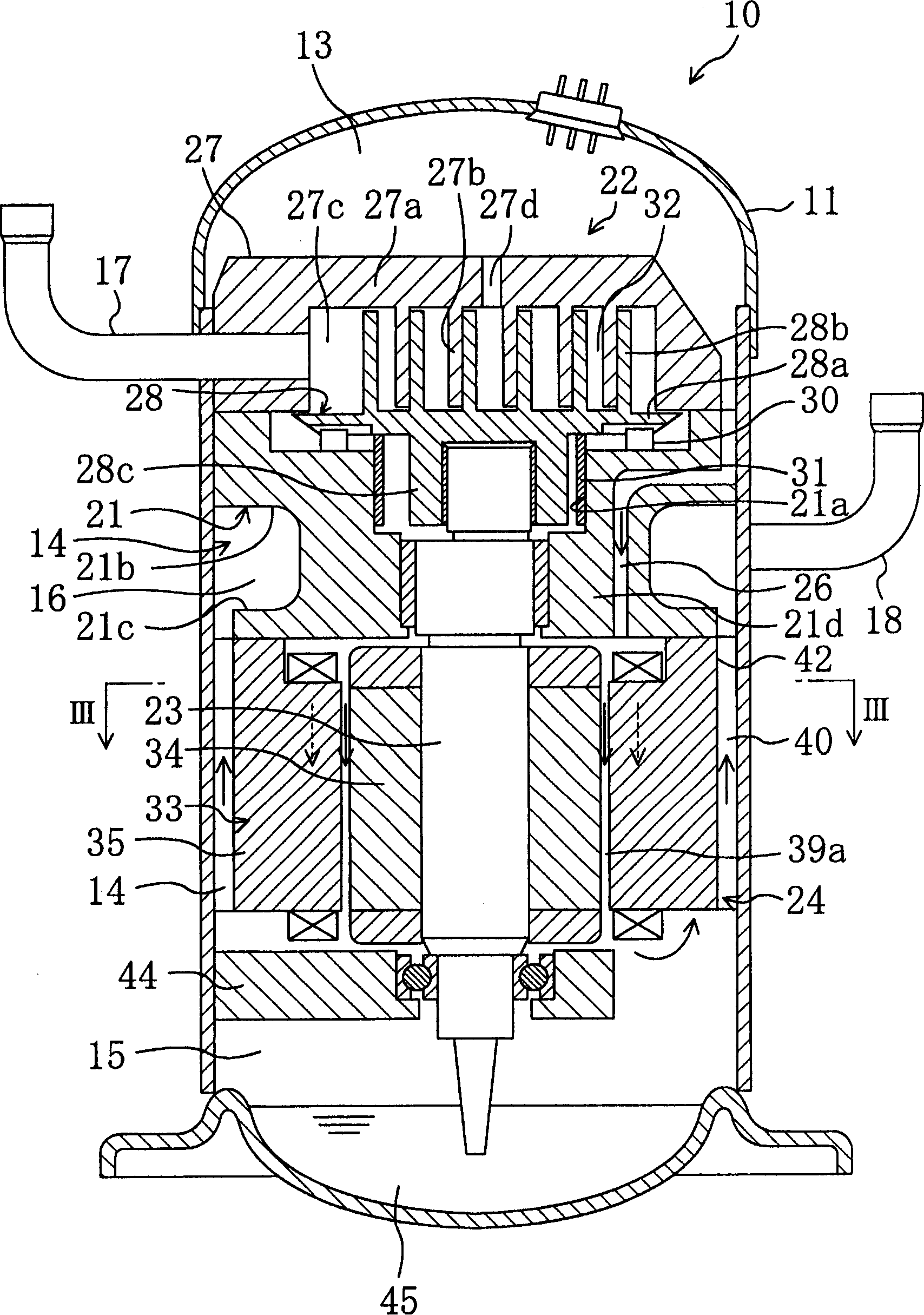

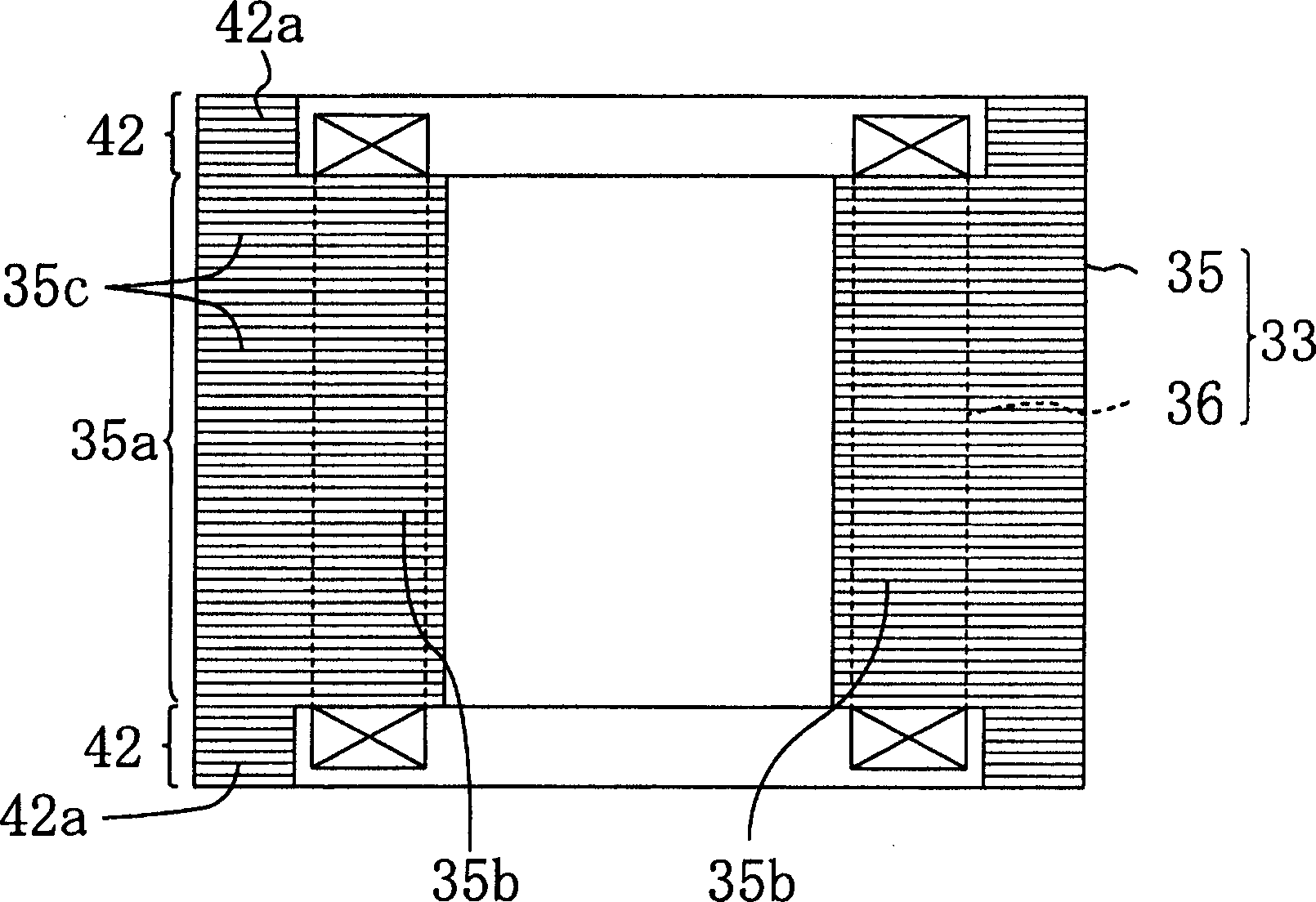

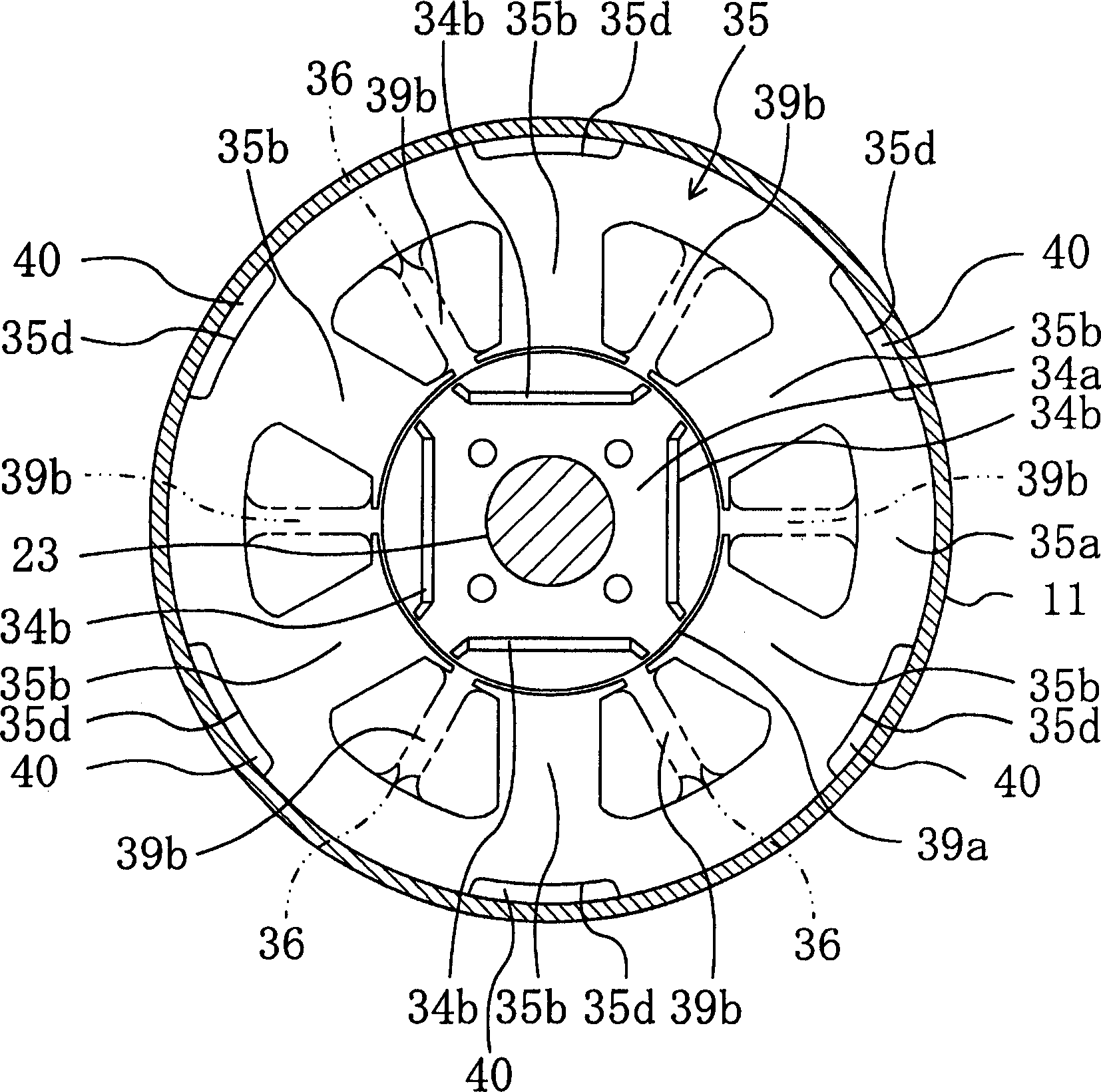

Compressor

InactiveCN1802506ASmooth circulationImprove cooling effectPositive displacement pump componentsWorking fluid for enginesEngineeringRefrigerant

A partition member (42) is installed between a frame (21) and the stator (33) of an electric motor (24). The partition member (42) establishes communication between a connection passage (26) and a gap (39a) and between a gas passage (40) and a delivery space (16). The refrigerant gas delivered from a compression mechanism (22) entirely flows into the gap (39a) and passes through a communication space (15) and then flows through the gas passage (40) so as to be delivered from a delivery pipe (18).

Owner:DAIKIN IND LTD

Condensation type demister having vanes with non-uniform wettability and preparation method of vanes

ActiveCN110772925AAmplify tiny dropletsUp to sizeGas treatmentUsing liquid separation agentMetal alloyDemister

The invention discloses a condensation type demister having vanes with non-uniform wettability and a preparation method of vanes. The condensation type demister comprises multiple sets of condensationdemisting vanes arranged at intervals, an upper frame, a lower frame, a cooling water inlet welded to the lower frame and a cooling water outlet welded to the upper frame, wherein the upper frame andthe lower frame are used for fixing the vanes and providing cooling water channels; the vanes are each of a hollow corrugated structure; and through holes connected with a cooling water outlet pipe and a cooling water inlet pipe are formed in the upper portions and the lower portions of the vanes respectively; and the vanes are metal or metal alloy vanes. According to the invention, the surfacesof the vanes are covered with mask plates; the exposed surfaces of the vanes are modified with a low-surface-energy substance for treatment after rough structures are constructed on the exposed surfaces, so the exposed surfaces have super-hydrophobicity and the covered parts have hydrophilicity; and therefore, the vanes have the characteristic of hydrophilicity-hydrophobicity combined non-uniformwettability.

Owner:XI AN JIAOTONG UNIV

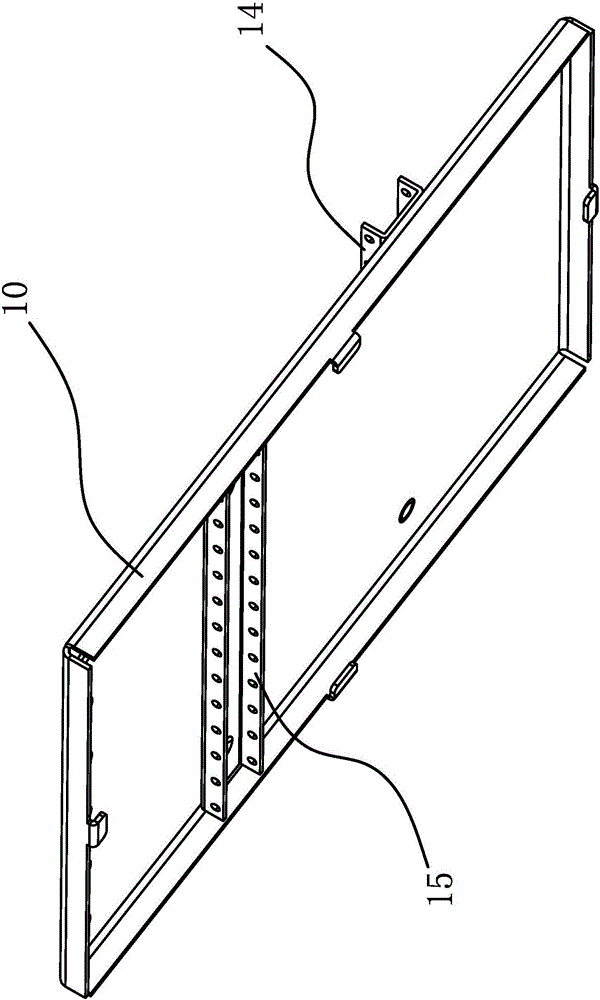

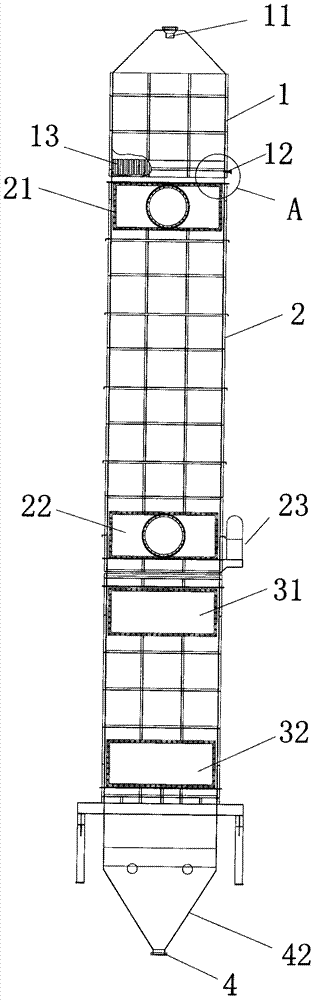

Reactive coke regeneration tower

PendingCN107335415AExtend the distribution pathEasy accessOther chemical processesCombustible gas purificationThermodynamicsCoke

The invention relates to a reactive coke regeneration tower. The reactive coke regeneration tower comprises a loading section, a heating section, a cooling section and an unloading section which are in sealed connection sequentially from top to bottom and are arranged in a shell body, wherein a plurality of material through pipes are vertically arranged in the heating section; and a plurality of baffle plates, which separately sleeve all the material through pipes, are further distributed in the heating section, a gap is reserved between at least one side of each baffle plate and the internal wall of the shell body of the heating section and serves as an air outlet, and thus, hot air with the temperature of 300 DEG C to 450 DEG C is subjected to repeated diversion in the shell body of the heating section and then flows out to carry out heating on reactive coke in the material through pipes. Due to the baffle plates, a circulating path of heat-exchange air in the heating section is prolonged, the efficiency of heat exchange is increased under equivalent conditions, and thus, the heat exchange is more thorough.

Owner:孙小平

Cooling device based on vehicle injection mold equipment machining

The invention provides a cooling device based on vehicle injection mold equipment machining. The cooling device comprises an inner way water inlet pipe, a heat exchange water disc, a water cover and abent heat exchange plate; a water cylinder is supported and welded in middle of a water receiving disc base plate; water overflow discs are sleeved and welded at the middle section and the top end ofthe water cylinder; four support plates are supported on the peripheral outer wall of the water receiving disc in an annular array mode; a mounting cover is supported and welded at the top ends of the four support plates; and the mounting cover is cake-shaped and opened in middle. The bent heat exchange plate is provided; through continuous bending of the bent heat exchange plate, a circulating path of inner way cooling water can be lengthened, and the heat exchange time with outer way cooling water can be prolonged; through cooperation between the bent heat exchange plate in multiple placesand the heat exchange water disc in five places for use, the heat exchange and the heat dissipating efficiency of the inner way cooling water can be effectively improved; and the water temperature islowered to guarantee a cooling effect on injection molds.

Owner:HUBEI SHUANGOU AUTOMOTIVE TRIM

Steam generator and steam box with steam generator

ActiveCN111271701AExtend the distribution pathAvoid enteringBoiler cleaning apparatusSteam separation arrangementsWater flowEngineering

A steam generator comprises a base and an upper cover on the base. An air outlet is formed in the upper cover, a flow baffle is installed in the upper cover, the flow baffle is close to the air outlet, and a flow baffle face which tilts towards the air outlet from top to bottom is formed on the bottom of the flow baffle. A steam inlet gap is reserved between the upper portion of the flow baffle and the upper cover, and a water steam backflow gap is reserved between the lower portion of the flow baffle and the upper cover. According to the steam generator, the flow baffle close to the air outlet is arranged in the upper cover, so that the steam generated when water is boiling passes through the tilted flow baffle face first, and then passes through the steam inlet gap between the flow baffle and the upper cover of the steam generator to flow towards the air outlet, and the steam circulating path is prolonged. The flow baffle reduces condensate water flowing towards the air outlet to a certain extent, moreover, due to the water steam backflow gap between the lower portion of the flow baffle and the upper cover and the tilted structure of the flow baffle face of the flow baffle, it isensured that the condensate water accumulated in the flow baffle can flow back into the steam generator, and therefore, the boiling water steam in an evaporator is effectively prevented from enteringan inner container.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com