Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

90results about How to "Improve attenuation characteristics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

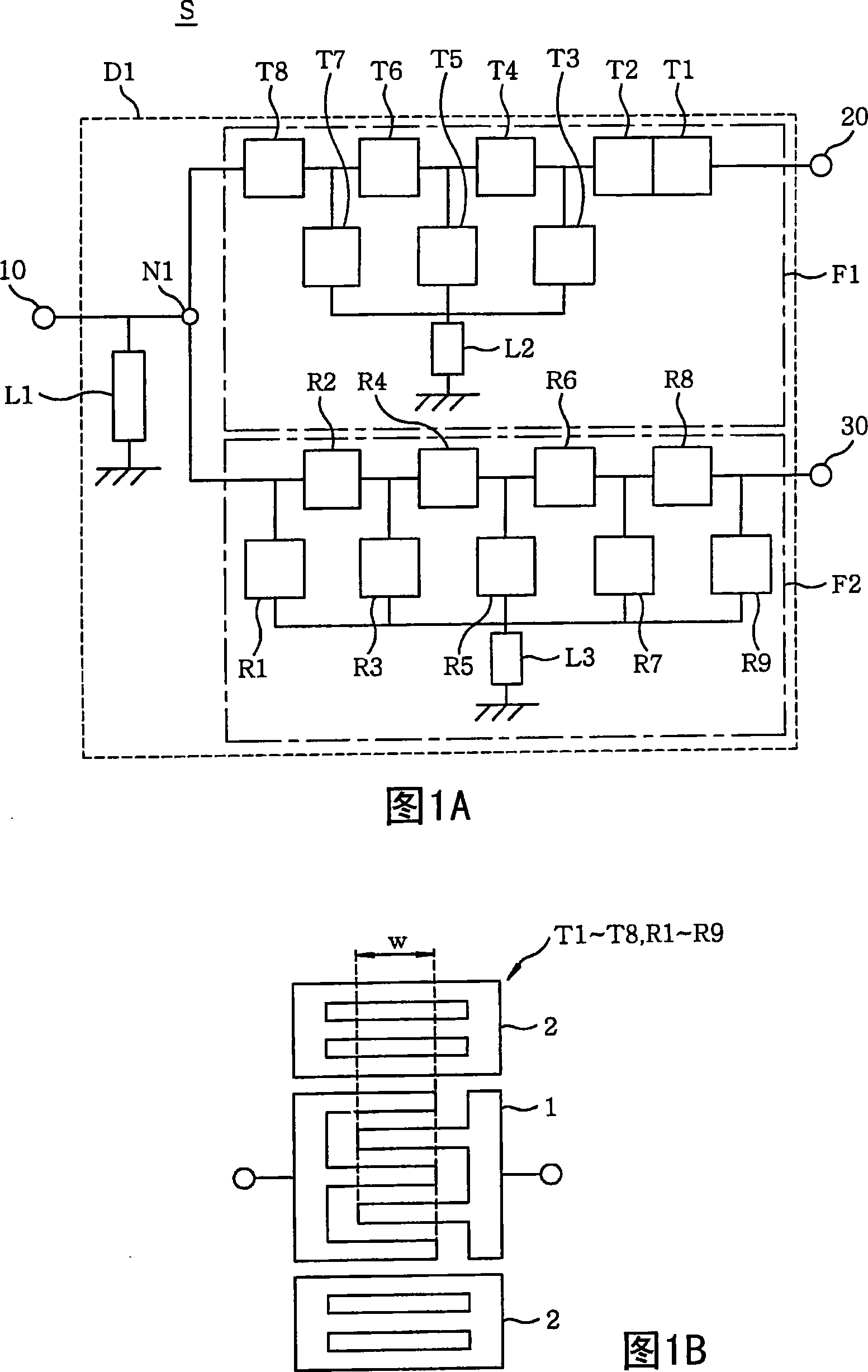

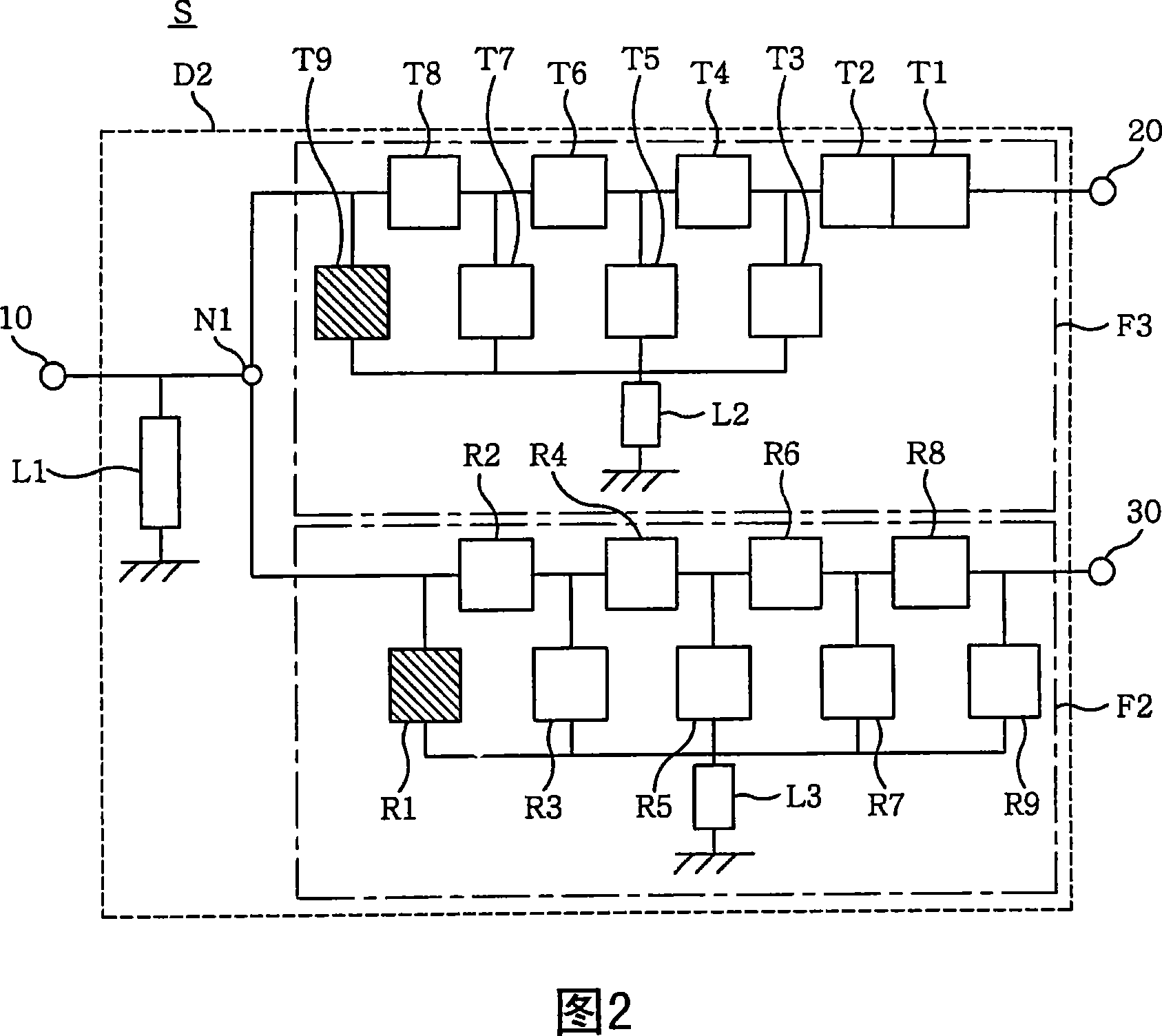

Duplexer

ActiveUS7941103B2Improve attenuation characteristicsReduced characteristicsMultiple-port networksTransmissionEngineeringInductance

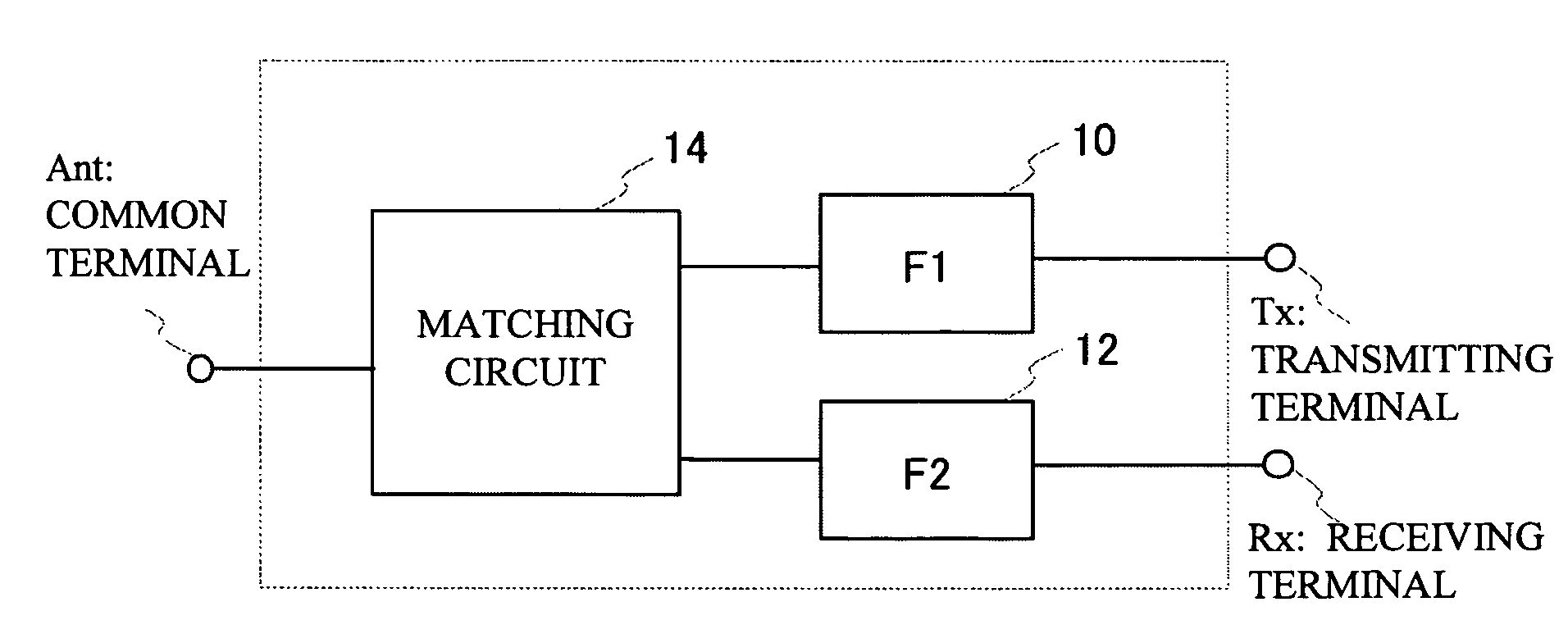

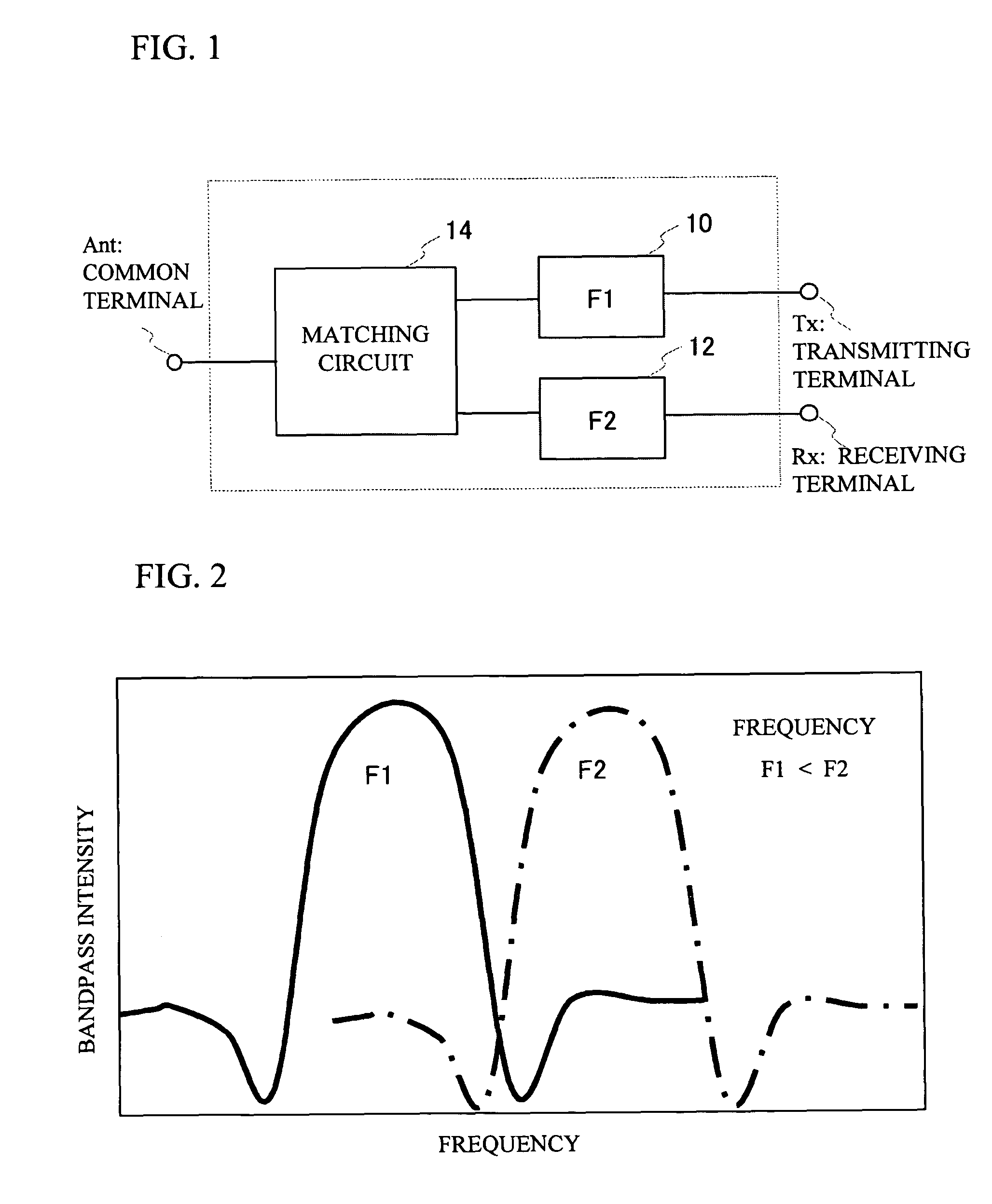

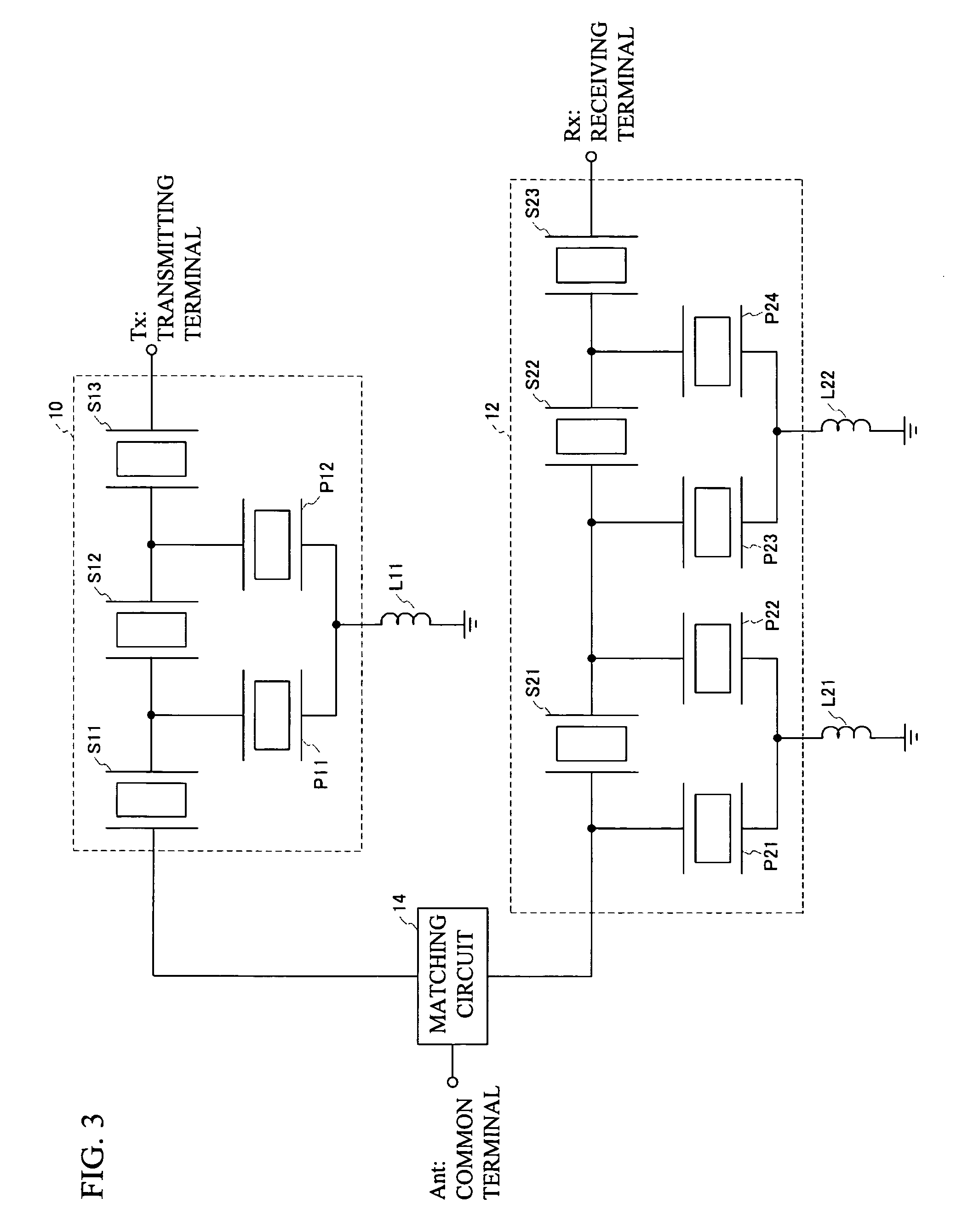

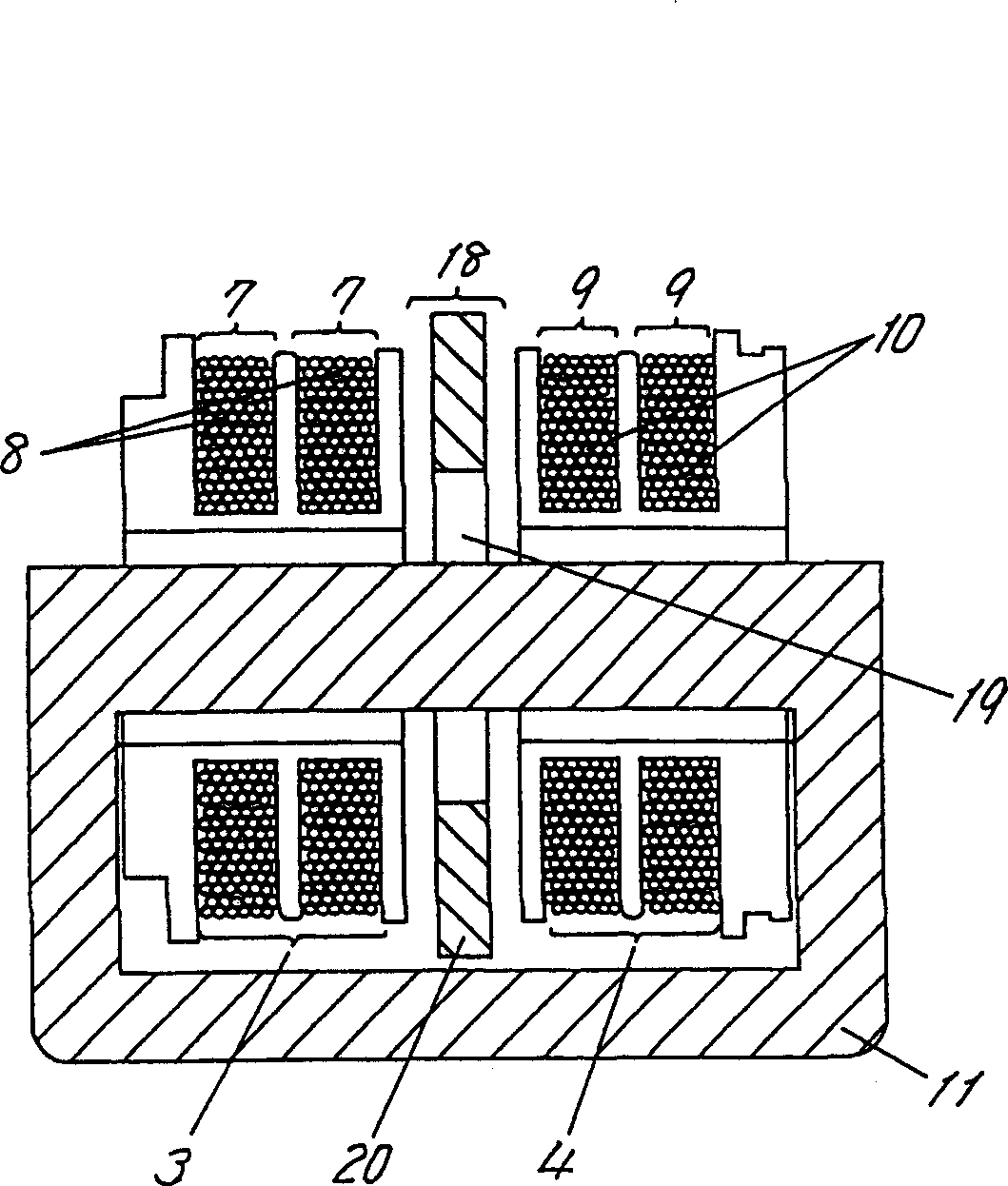

A duplexer includes a transmit filter of a ladder type filter, connected between a common terminal and a transmitting terminal, and a receive filter of the ladder type filter, connected between the common terminal and a receiving terminal. One or more parallel resonators in the transmit filter are grounded through a transmitting inductance, and a portion of multiple parallel resonators are grounded through a first receiving inductance and a remaining portion of the multiple parallel resonators are grounded through a second receiving inductance.

Owner:TAIYO YUDEN KK

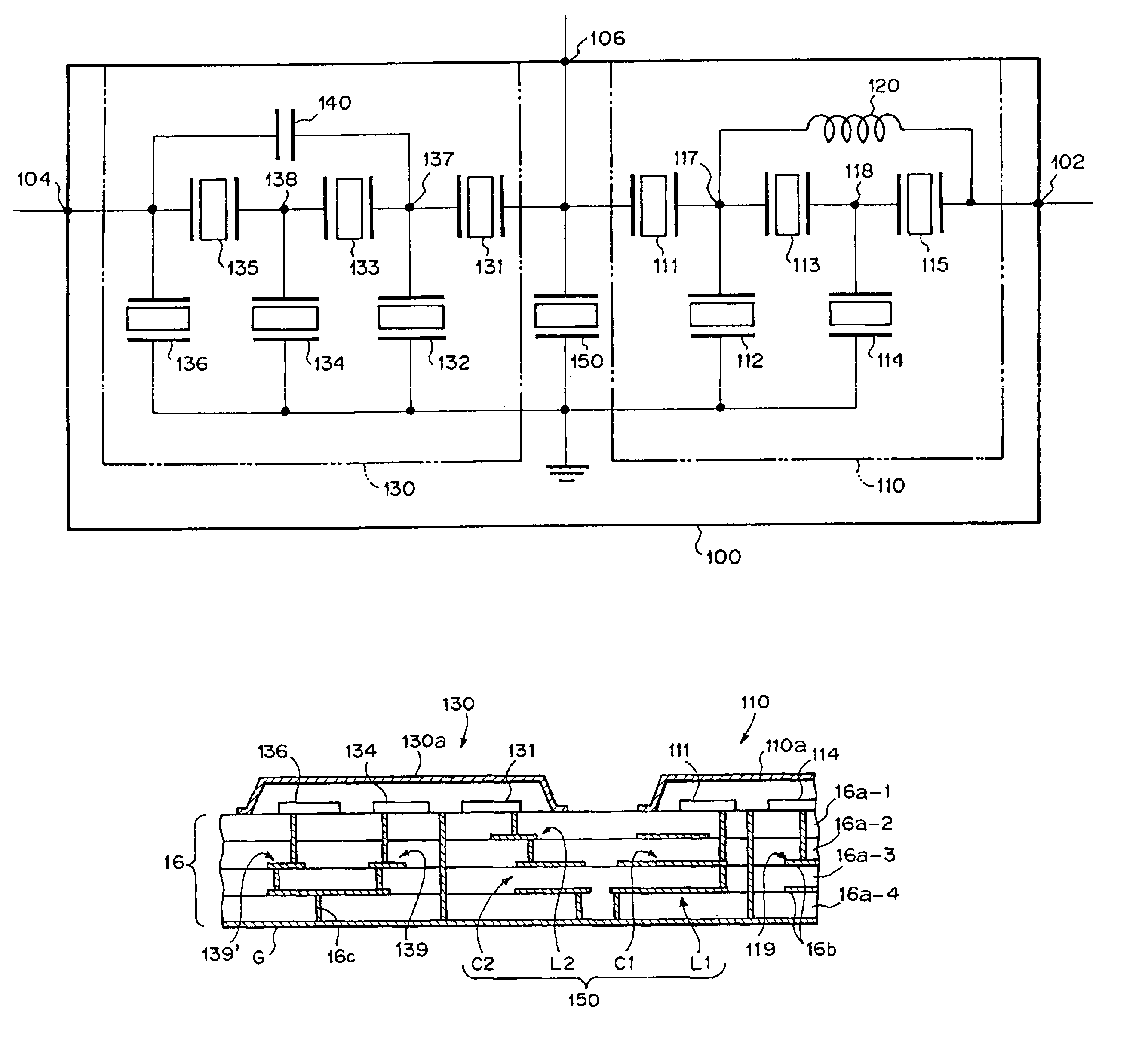

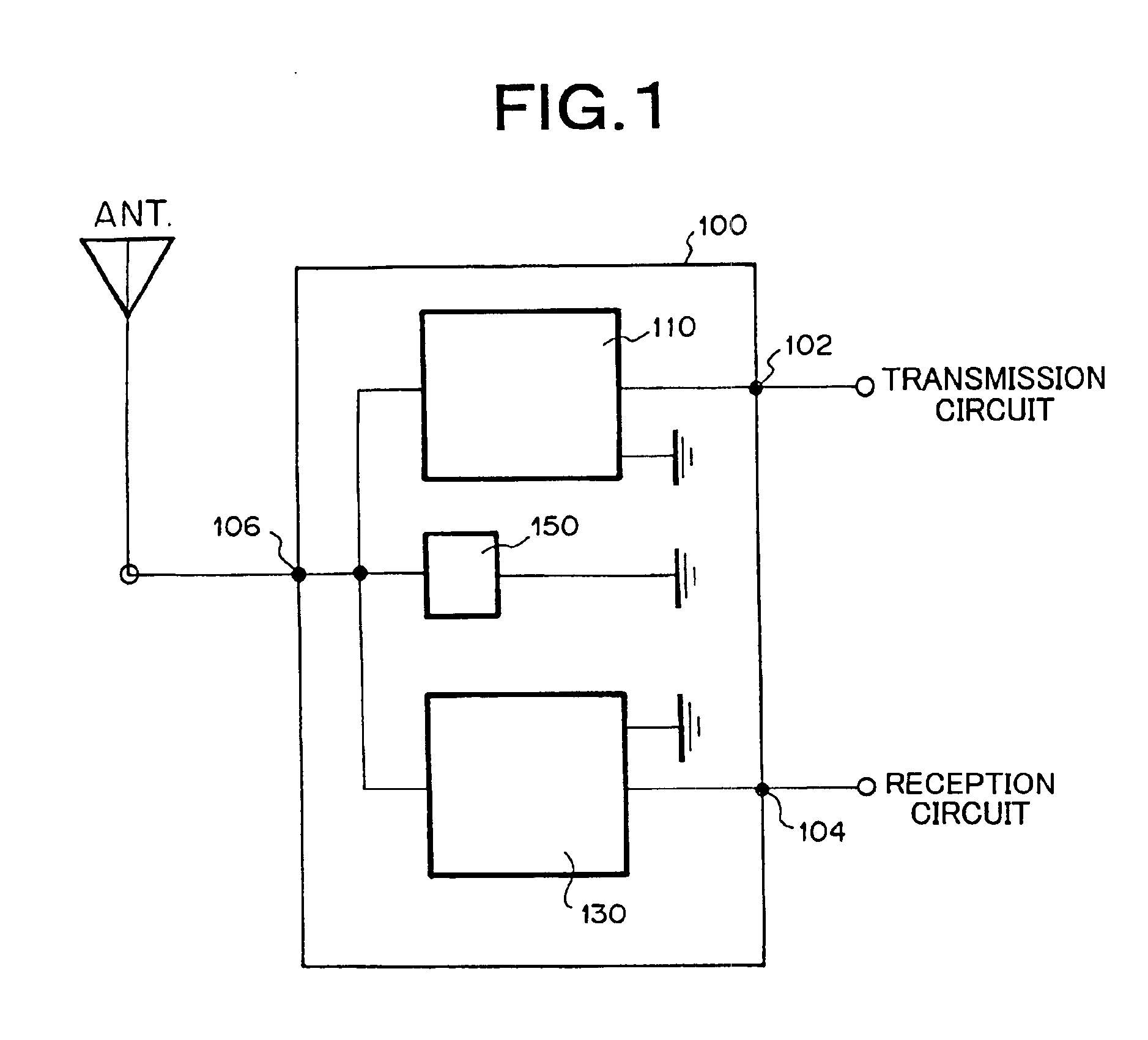

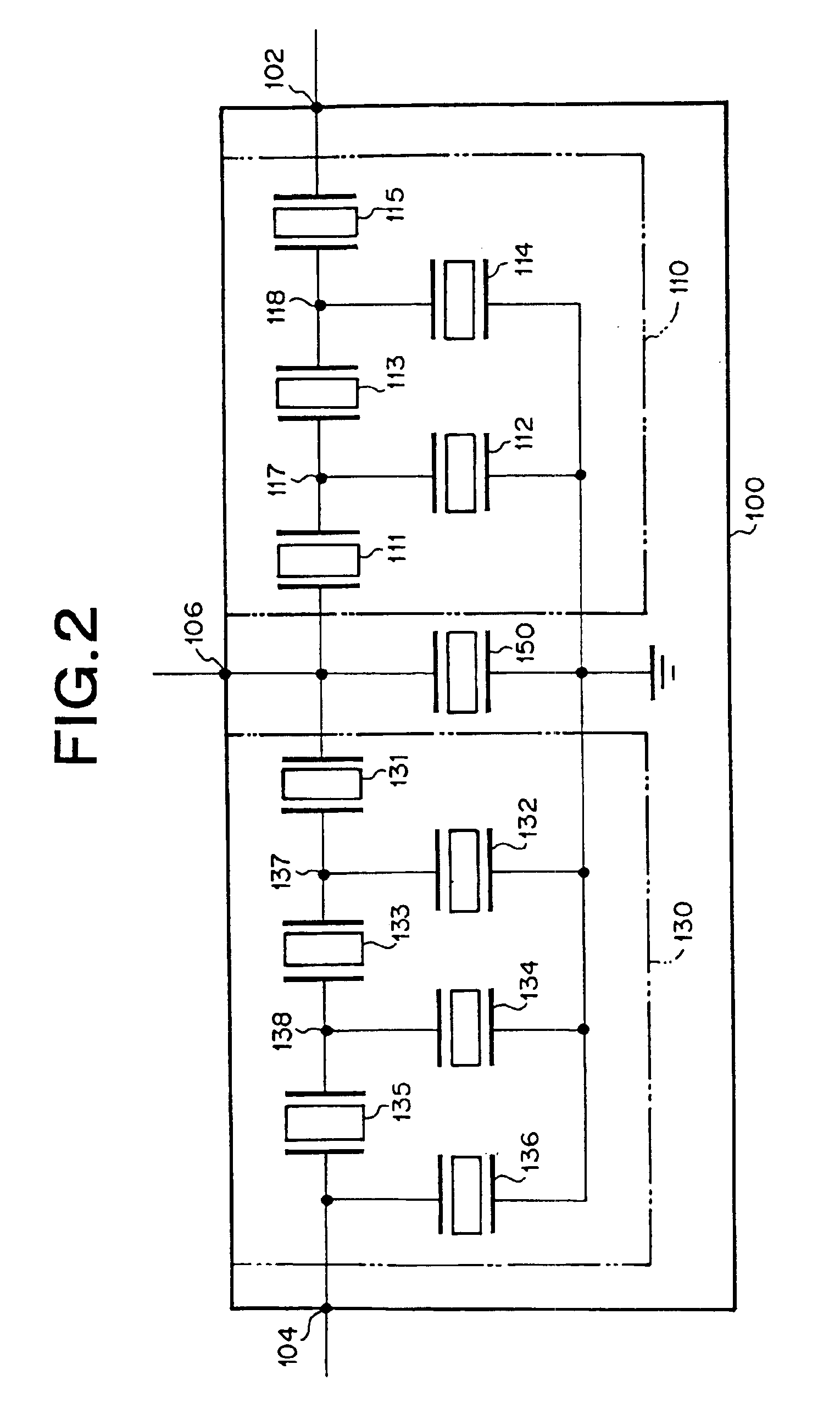

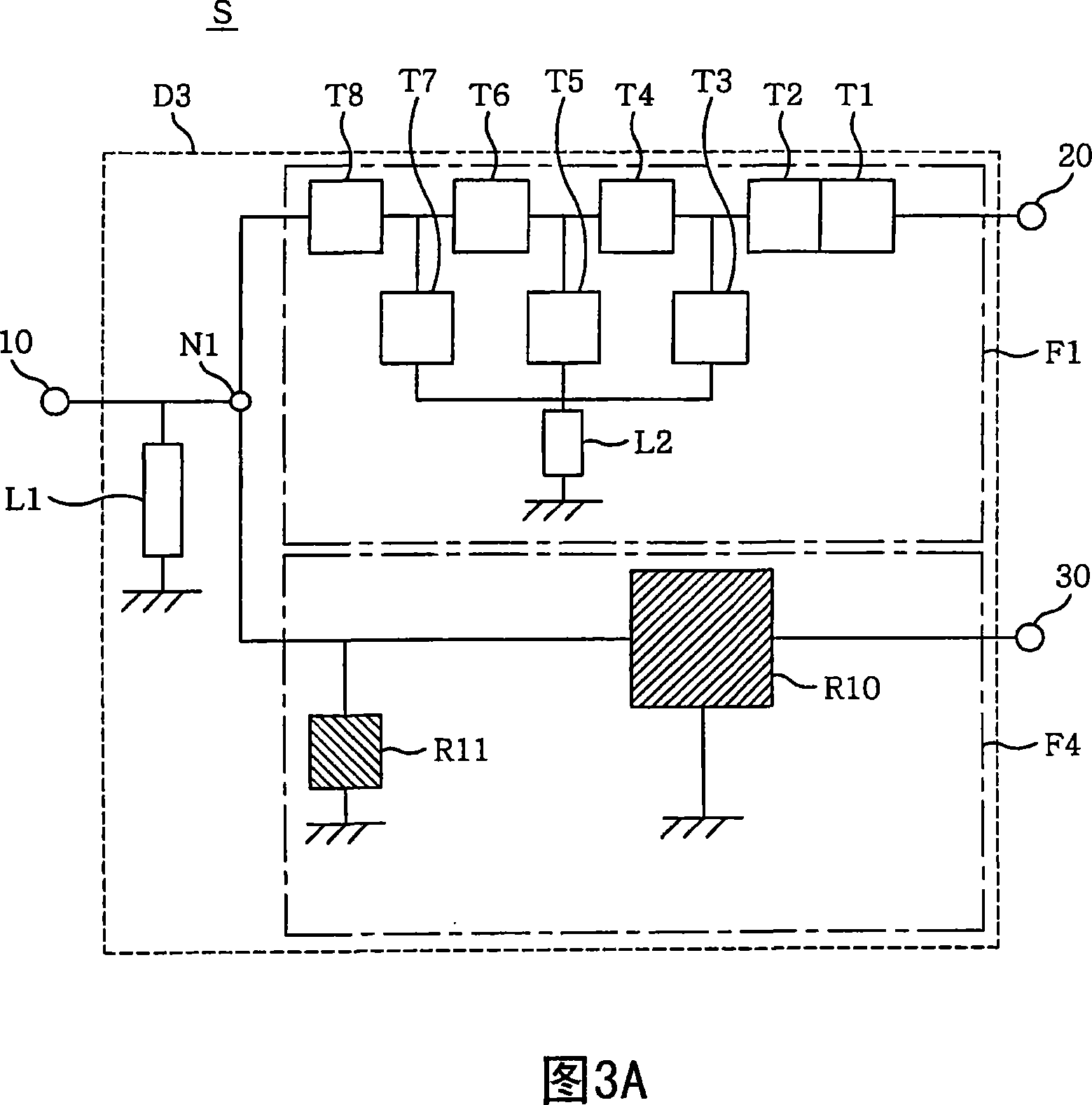

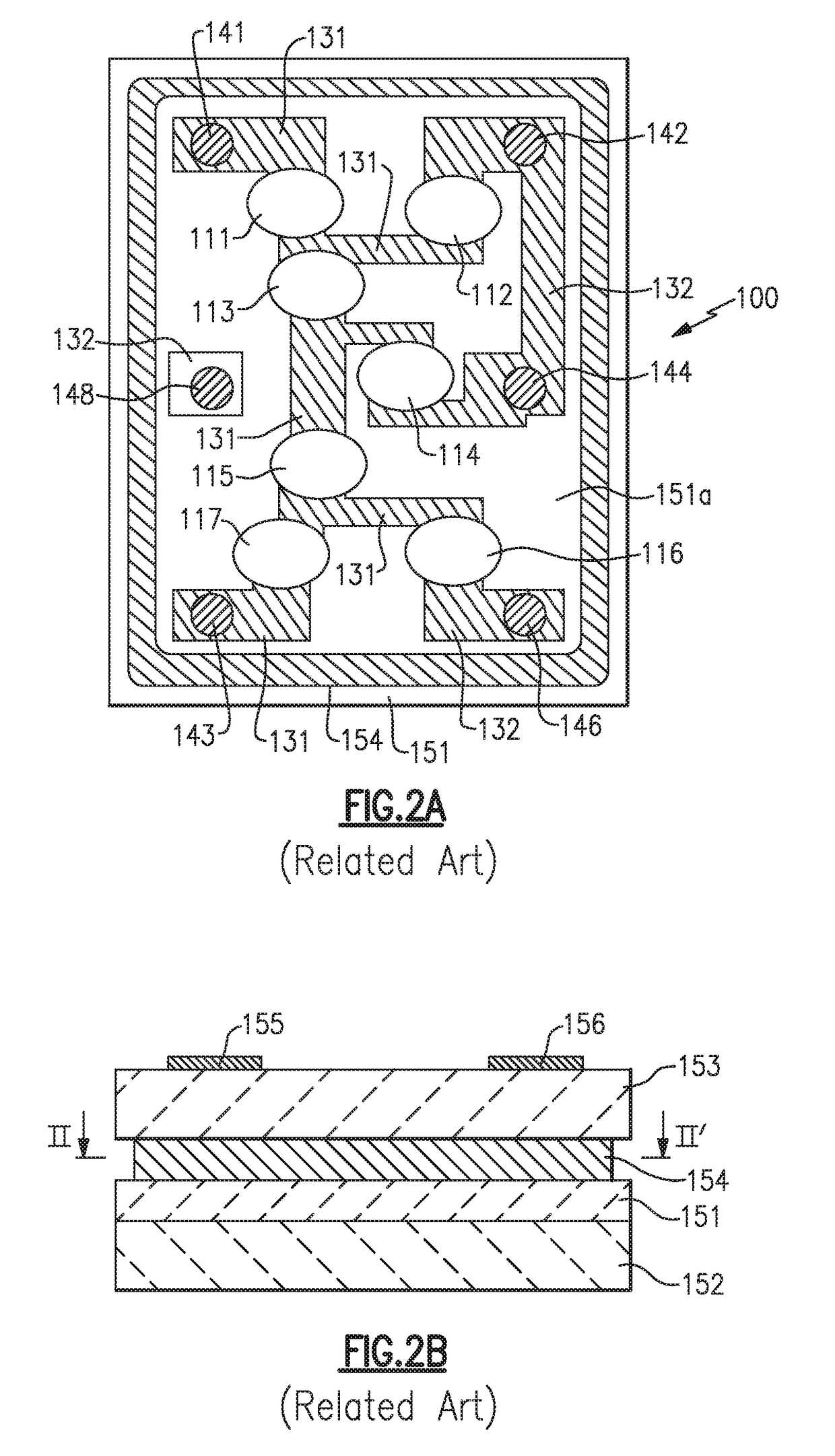

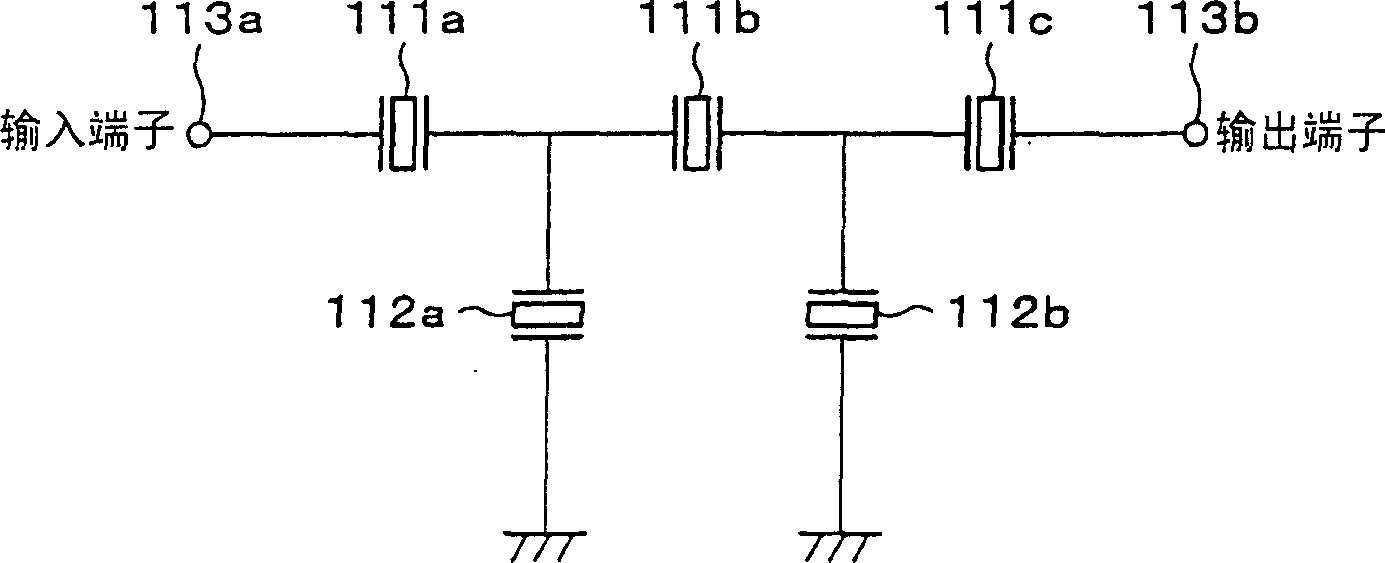

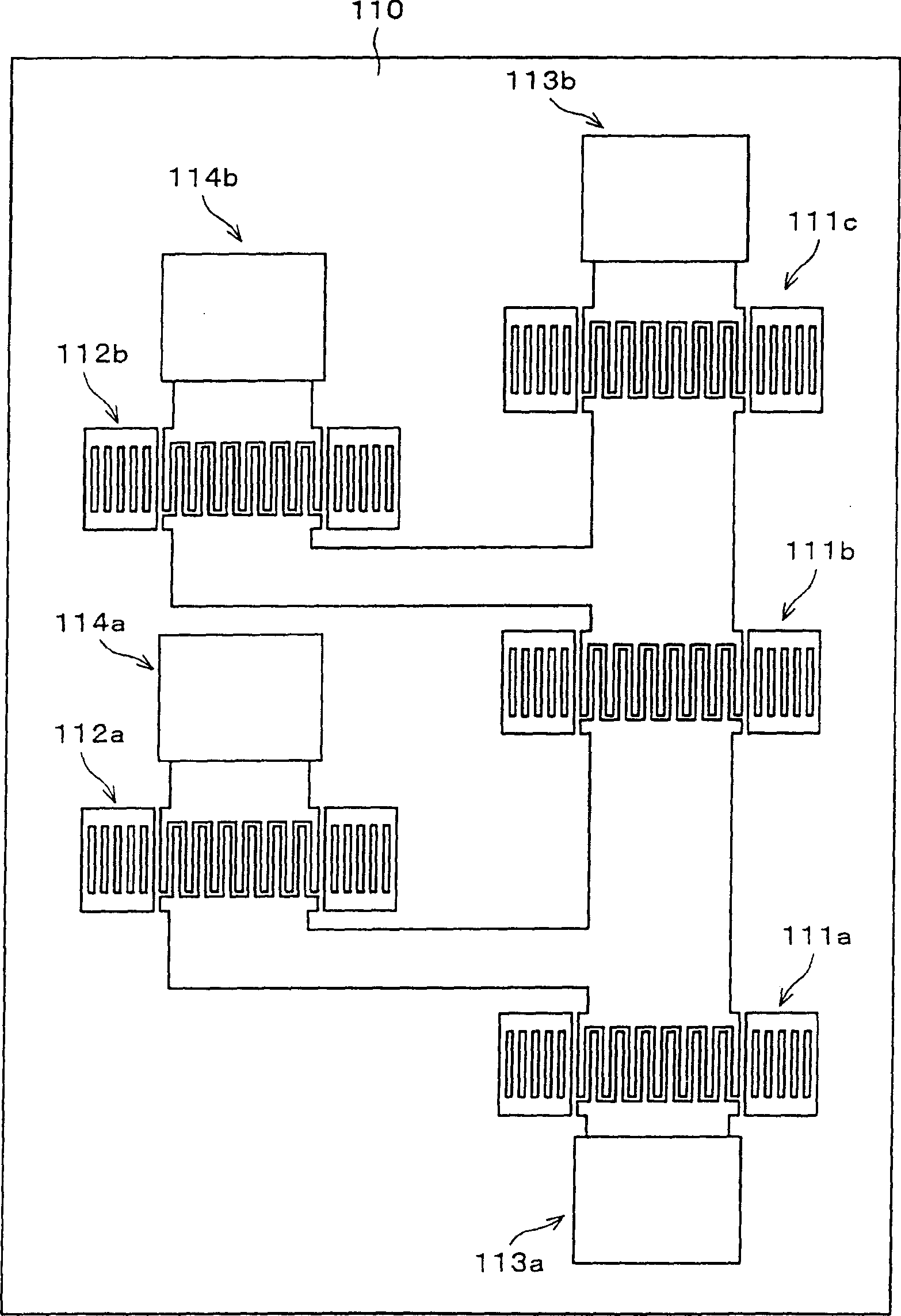

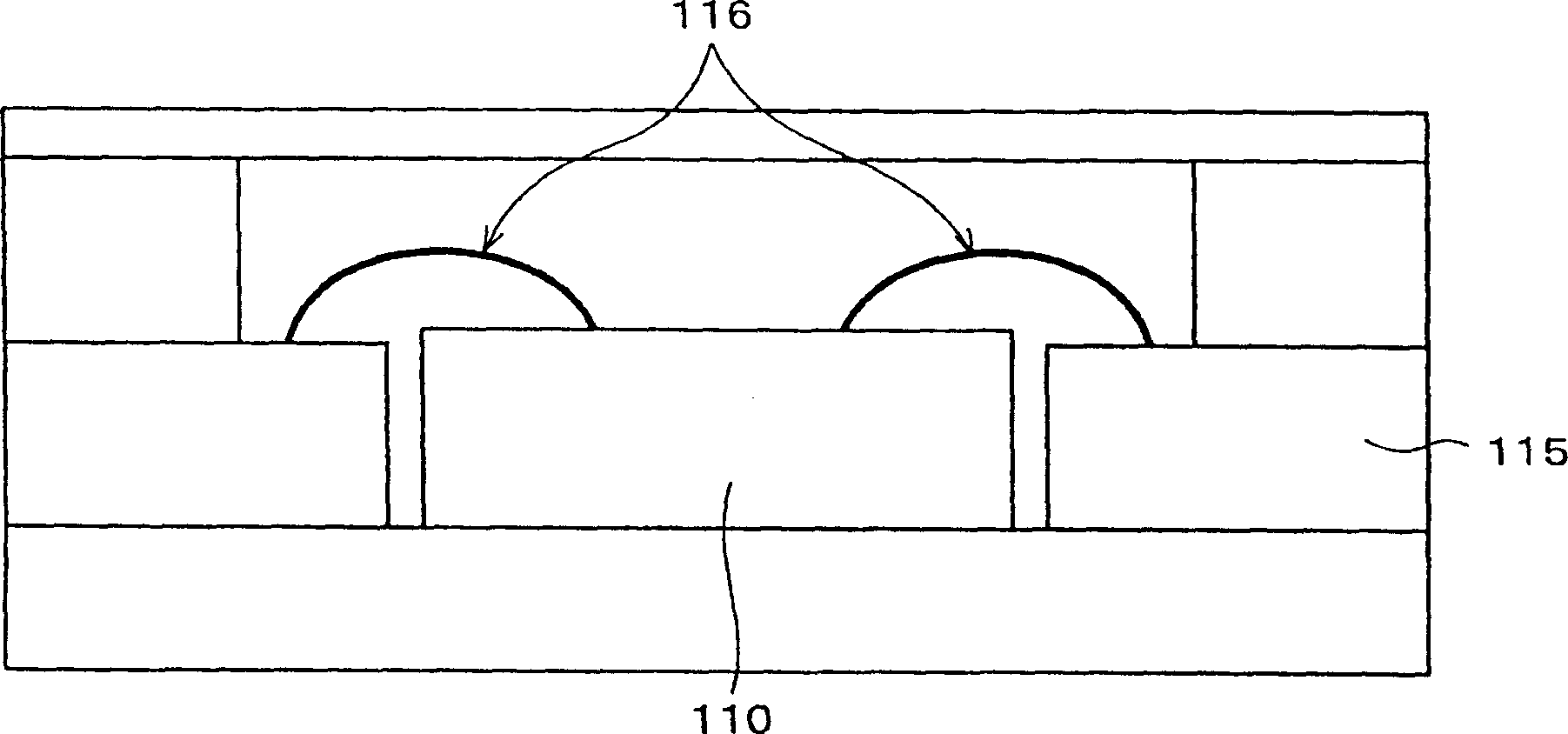

Filter using film bulk acoustic resonator and transmission/reception switch

InactiveUS6885260B2Improve attenuation characteristicsMultiple-port networksPiezoelectric/electrostrictive/magnetostrictive devicesLower limitThin-film bulk acoustic resonator

A transmission band filter (110) having a series of elements (111, 113, 115) each composed of a film bulk acoustic resonator and grounded shunt elements (112, 114) each composed of a film bulk acoustic resonator is connected between a transmission port (102) and an antenna port (106). A reception band filter (130) having a series of elements (131, 133, 135) each composed of a film bulk acoustic resonator and grounded shunt elements (132, 134, 136) each composed of a film bulk acoustic resonator is connected between a reception port (104) and the antenna port (106). A film bulk acoustic resonator (150) for adjustment is connected between the antenna port (106) and the ground. The resonance frequency of the adjusting film bulk acoustic resonator (150) lies between the upper limit frequency of the transmission frequency pass band of the transmission band filter (110) and the lower limit frequency of the reception frequency pass band of the reception band filter (130). Therefore a duplexer such that it can be a monolithic element, the power handling capability is good, the size is small, and the cost is low is provided.

Owner:MEMS SOLUTIONS INC

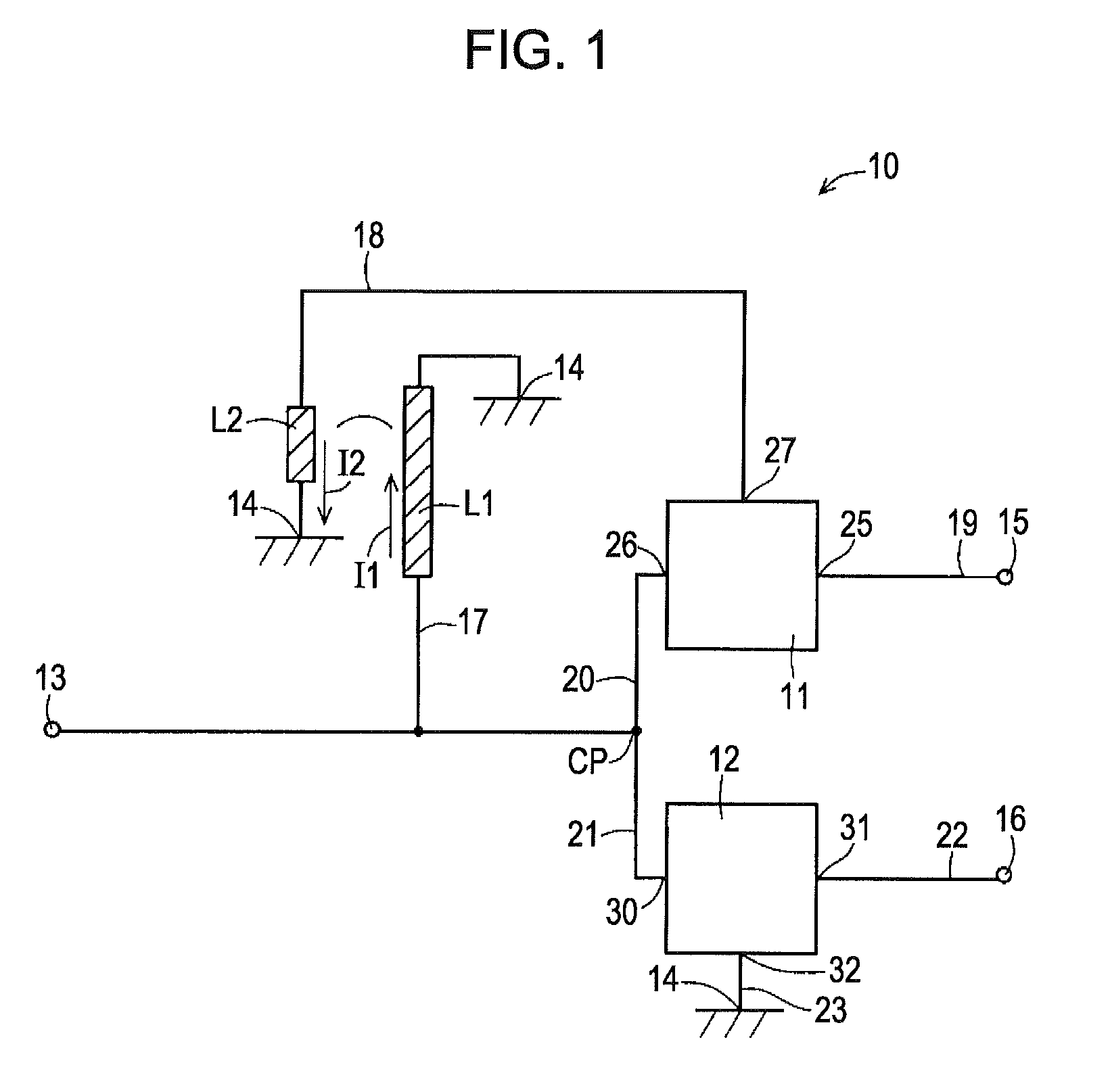

Demultiplexer and communication device

ActiveUS20090147707A1Improve attenuation characteristicsImprove isolation characteristicsMultiple-port networksTransmissionCommunication deviceHigh frequency

Provided is a demultiplexer capable of improving attenuation characteristic and isolation characteristic of a filter having a lower transmission frequency band among two filters having different transmission frequency bands, outside the transmission frequency band of a high-frequency side. A communication device using the demultiplexer is also disclosed. A first spiral wiring portion (55) and a sixth wiring portion (56) are formed so that an angle defined by a direction of a part (L1) of the first spiral wiring portion (55) and a direction of a part (L2) of the sixth spiral wiring portion (56) on a predetermined virtual plane is, for >example, 0 degree and the direction of the current flowing in the part (L1) of the first spiral wiring portion (55) is opposite to the direction of the current flowing in the part (L2) if the sixth wiring portion (56).

Owner:KYOCERA CORP

Duplexer and communications equipment

ActiveCN101212211AImprove attenuation characteristicsImpedence networksResonanceCommunication device

A duplexer includes a piezoelectric substrate, a transmitting filter, and a receiving filter. The transmitting filter includes a ladder filter having a first resonator group which has one or more resonators in one or more series arms and one or more resonators in one or more parallel arms. The receiving filter has a passband higher than that of the transmitting filter, and includes a second resonator group which has one or more resonators in one or more series arms and one or more resonators in one or more parallel arms. A node connects both the transmitting filter and the receiving filter. The receive-side closest resonator closest to the node in the parallel arm is closer to the node than a resonator which is closest to the node in the series arm, and a resonance frequency of the receive-side closest resonator is lower than the passband of the transmission filter.

Owner:KYOCERA CORP

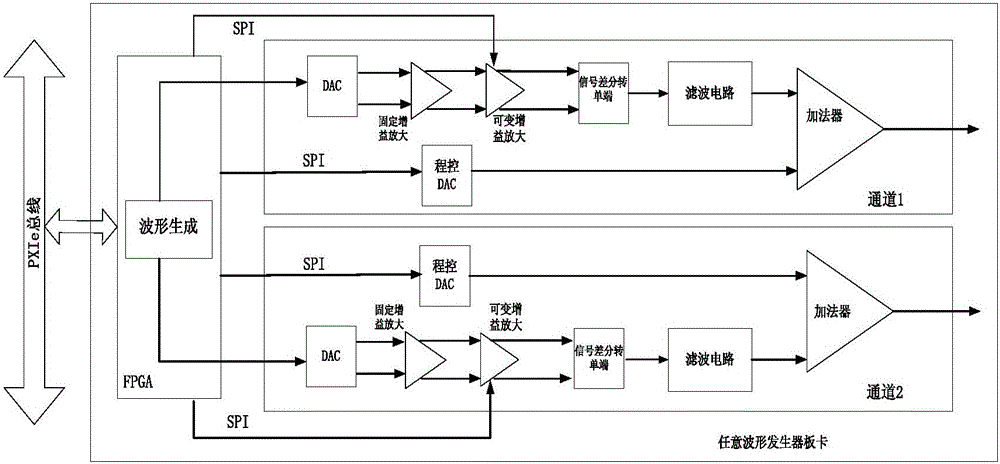

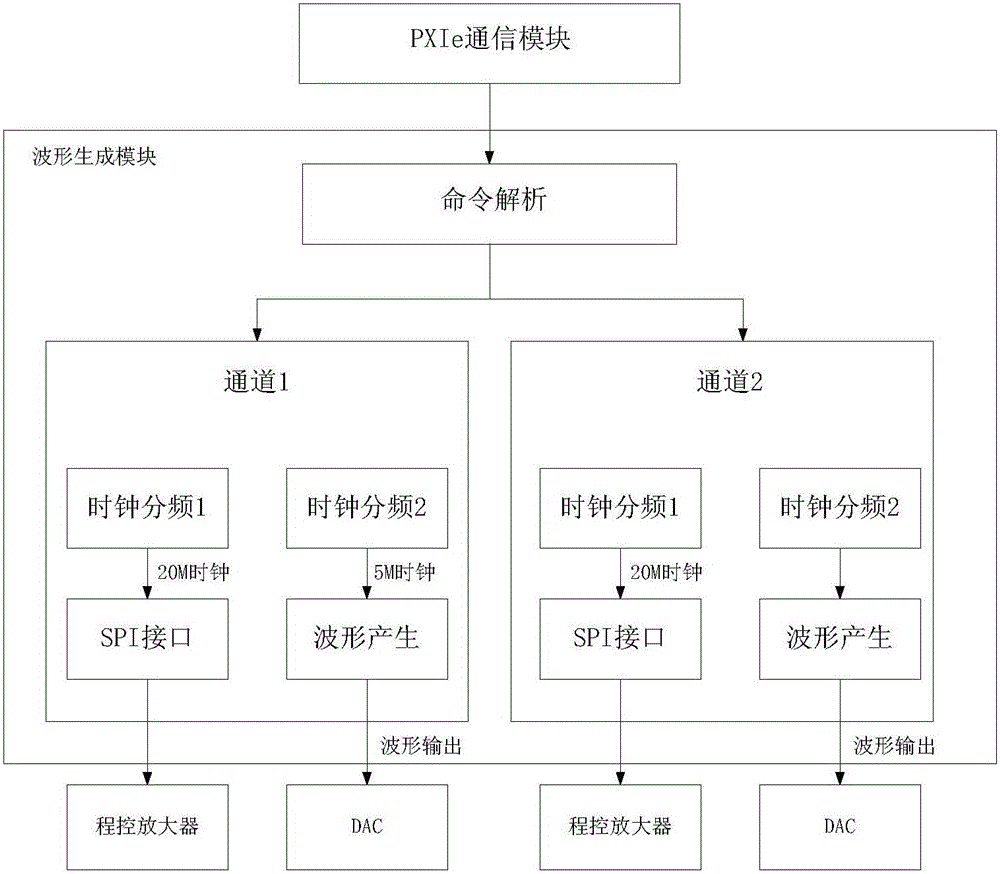

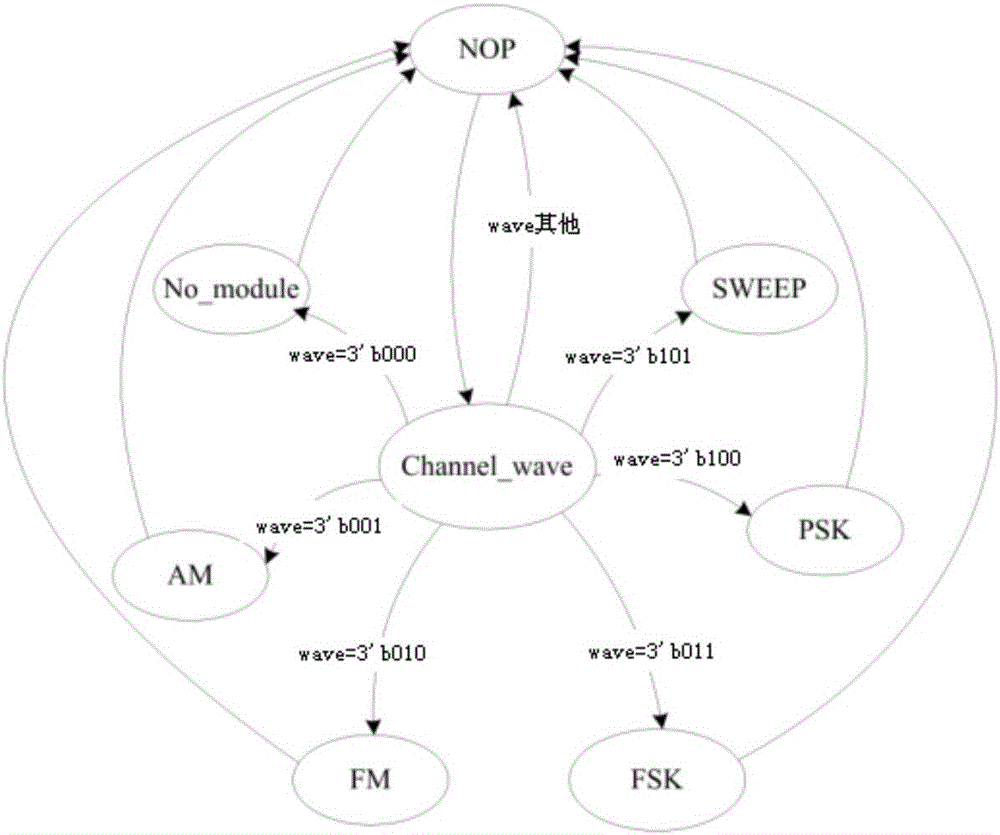

Arbitrary waveform generator based on PXIe bus

ActiveCN105866482AGuaranteed integrityGood attenuation characteristicsElectrical measurement instrument detailsElectrical testingSmall amplitudeSignal quality

The invention relates to the field of signal generator, and specifically relates to an arbitrary waveform generator based on a PXIe bus. The generator comprises a waveform generation part and a waveform conditioning part. The waveform generation part comprises an FPGA and a crystal oscillator. The waveform conditioning part comprises a 16-bit DAC, an operational amplifier, an SPI program control amplifier, a filter circuit, an SPI program control DAC, a differential operational amplifier, and a subtracter. The generator employs the PXIe bus as a channel which is used by an upper computer for transmitting waveform data. The FPGA continuously process the waveform data transmitted by the upper computer in a waveform generation process, so as to guarantee the integrity of high-frequency signal quality. In a waveform conditioning process, the generator respectively employs a Bessel filter and an elliptic filter according to the frequency characteristics of signals and the difference of anti-noise capabilities, and meets the filtering requirements of different types of signals. For a signal with the amplitude being less than 50mV, a small signal processing branch circuit is designed, thereby guaranteeing that a signal with a small amplitude value cannot be flooded by noise. The generator employs a mode of internal and external synchronization adjustment for signal amplitude and bias, and guarantees the accuracy of a signal.

Owner:AVIC BEIJING CHANGCHENG AVIATION MEASUREMENT & CONTROL TECH INST +2

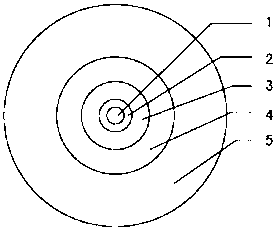

Optical fiber large in effective area

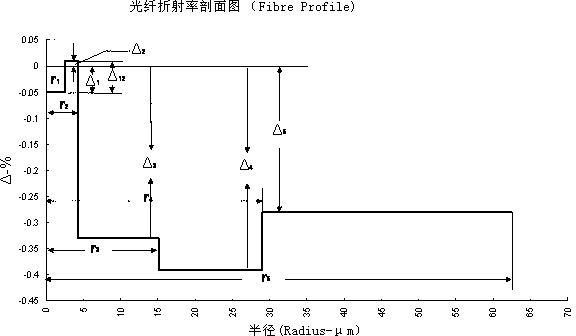

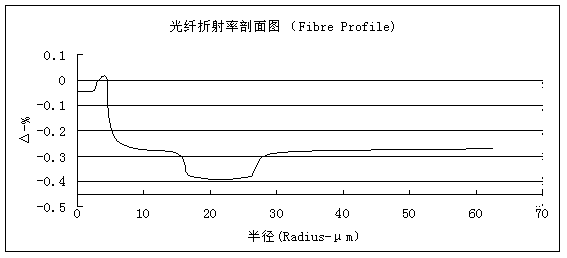

ActiveCN103257393AImprove bending characteristicsGood bending propertiesOptical fibre with graded refractive index core/claddingOptical fibre with multilayer core/claddingCommunications systemRelative refractive index

The invention relates to an optical fiber large in effective area. The optical fiber large in the effective area comprises a fiber core layer and a covering layer. The optical fiber large in the effective area is characterized in that the fiber core layer comprises an inner core layer and an outer core layer, the radius r1 of the inner core layer is 1 to 4 microns, a relative refractive index difference delta 12 of the inner core layer to the outer core layer meets the condition that -0.2% <= delta 12 < 0%, the relative refractive index difference of the inner core layer to the outer core layer is invariant or gradually increased along with increasing of the radius, the radius r2 of the outer layer is 4 to 7 microns, and the relative refractive index difference delta 2 of the outer core layer is -0.15 % to 0.05 %; the covering layer comprises an inner covering layer, a sunk concave covering layer and an outer covering layer, the inner covering layer covers the fiber core layer, the radius r3 of the inner covering layer is 7 to 20 microns, the relative refractive index difference delta 3 is within the range of -0.5 % to -0.1 %, the radius r4 of the sunk concave covering layer is 12 to 40 microns, the relative refractive index difference delta 4 is within the range of -1.0 % to -0.3 %, and the relative refractive index difference delta 5 is within the range of -0.2% to -0.4%. The optical fiber large in the effective area has a large effective area, quite low transmission loss and good curve characteristics, and is particularly suitable for application of a long-distance high-speed large-volume communication system.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

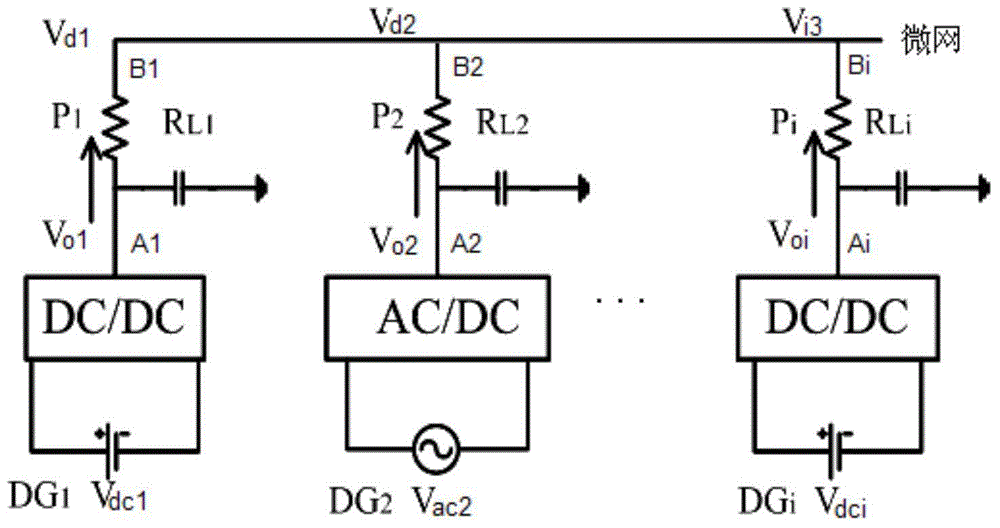

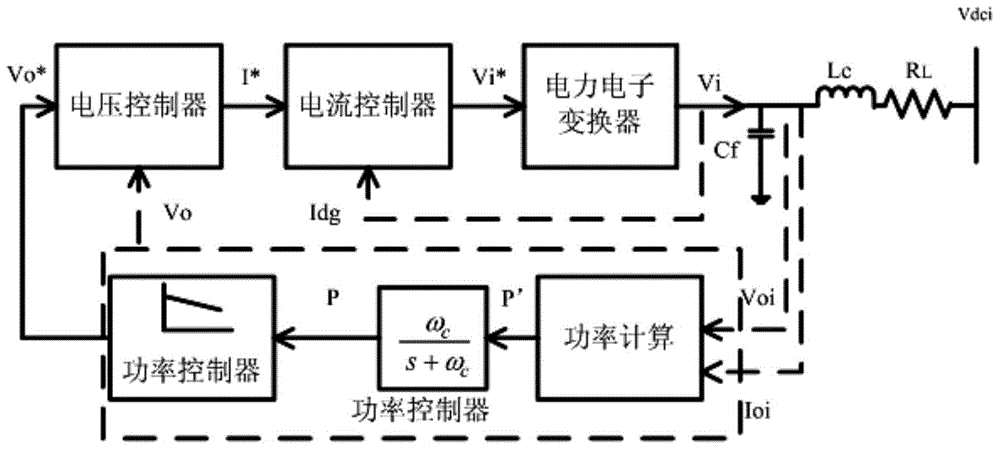

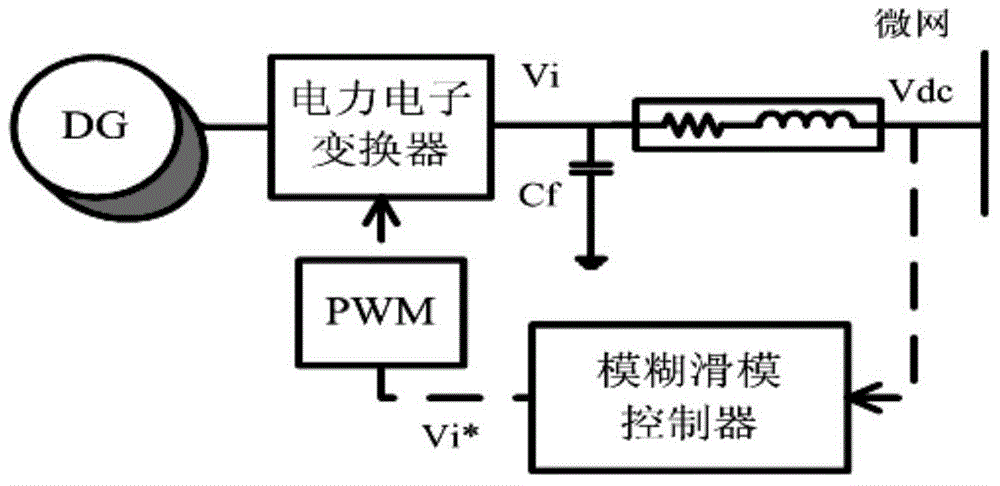

Intelligent power distribution method of independent direct-current microgrid

ActiveCN104578045AImprove attenuation characteristicsEffective power distributionLoad balancing in dc networkDc source parallel operationVoltage amplitudePower control

The invention relates to an intelligent power distribution method of an independent direct-current microgrid. The intelligent power distribution method comprises the following steps of: accurately describing the relation between voltage and output power by adopting a nonlinear droop characteristic to obtain a relational expression of a direct-current voltage amplitude value and active power; designing a droop power controller by utilizing the obtained nonlinear droop characteristic, and applying to microgrid control; establishing a state space model of a direct-current microgrid control system, carrying out integral fuzzy modeling on the obtained state space model through a T-S fuzzy method, and designing a sliding model droop controller on the basis of the established T-S fuzzy state space model to automatically distribute the output power of various direct-current sources. According to the intelligent power distribution method, the state space model established by adopting the nonlinear characteristic can more accurately simulate the actual operating characteristic of a distributed power generation unit; in addition, a non-matched robust droop controller is designed on the basis of the T-S fuzzy model by utilizing a sliding model control method, so that the adaptability of a system on disturbance can be ensured, and the uncertainty and intermittence of renewable energy can be neglected to a certain degree.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

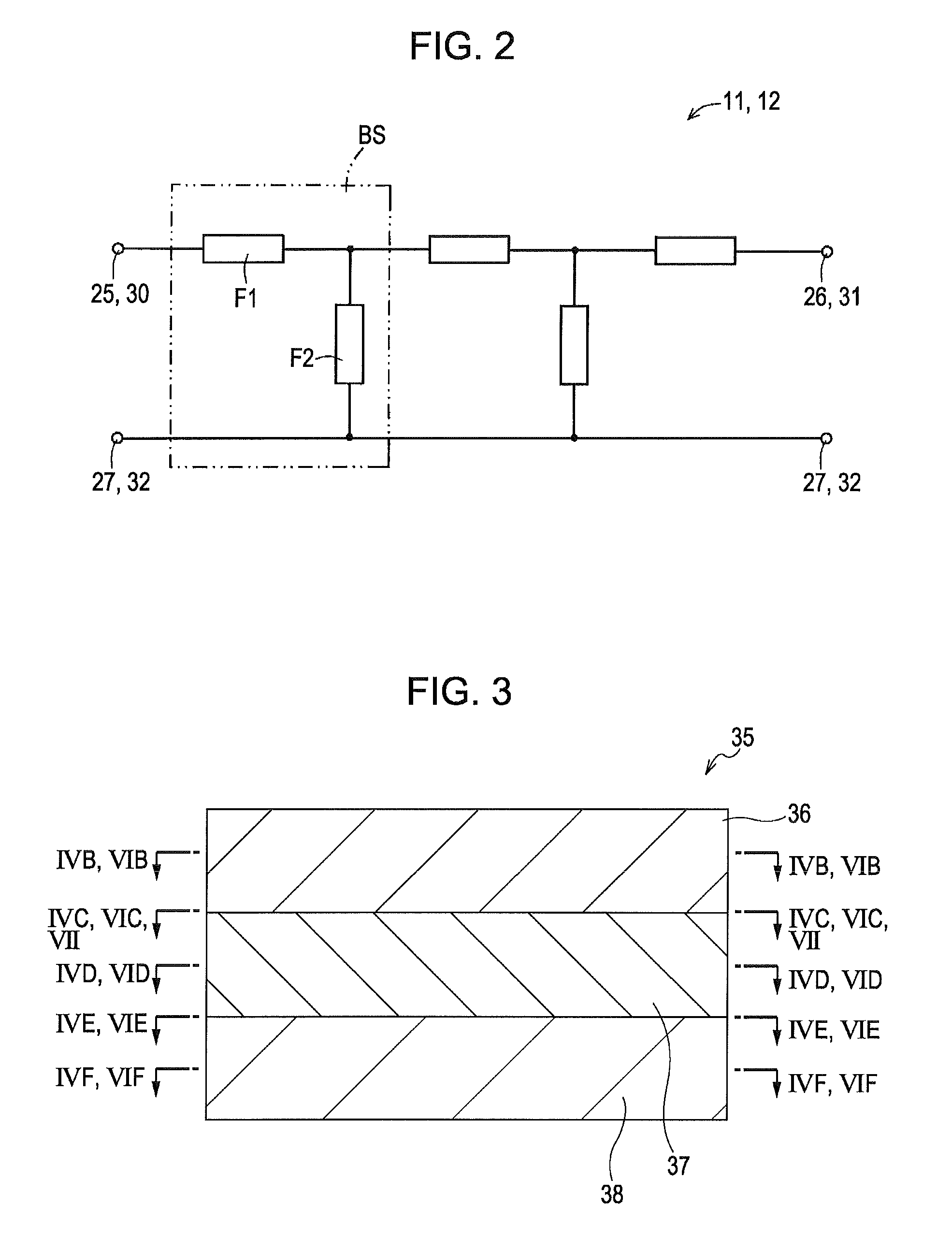

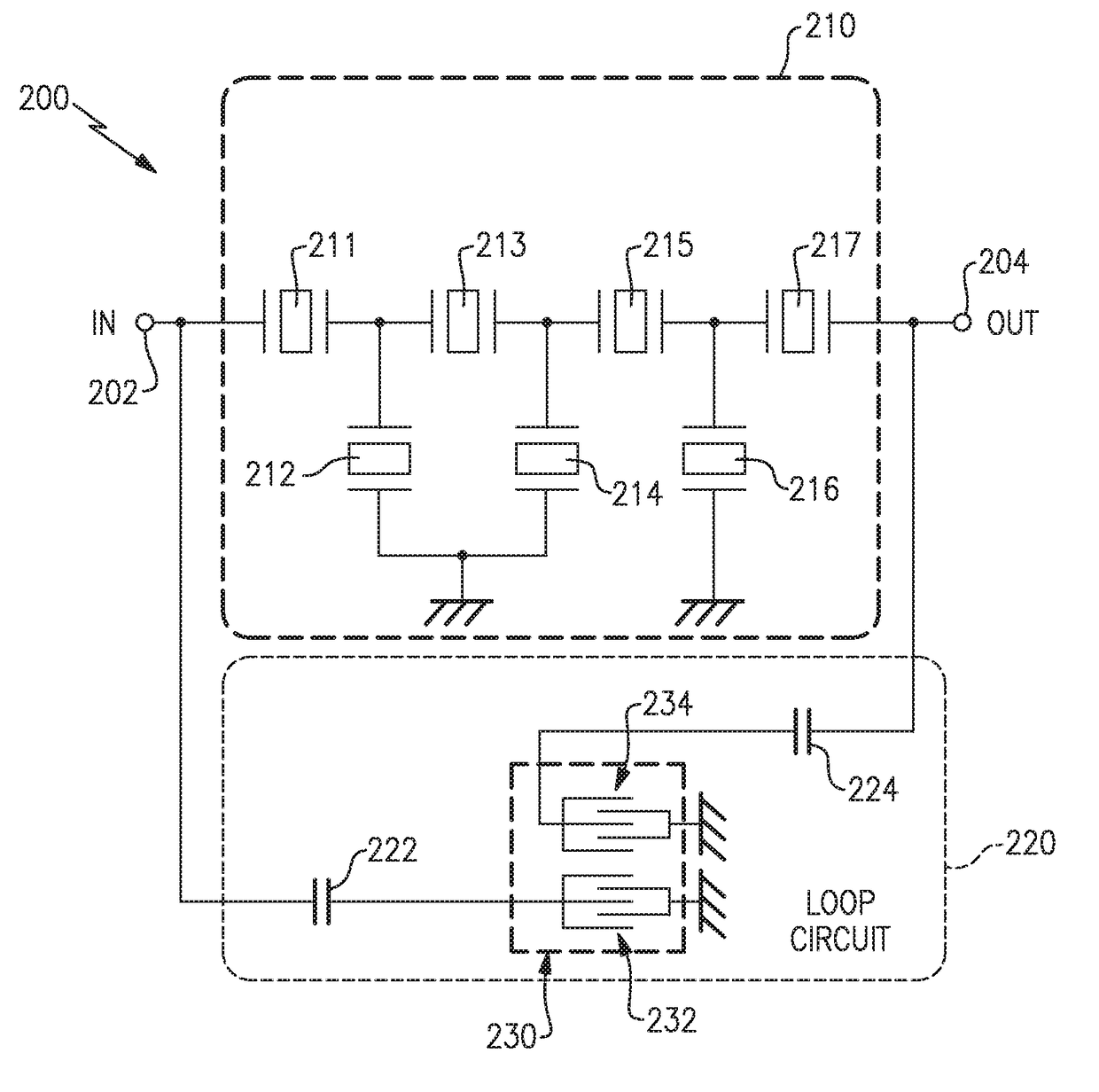

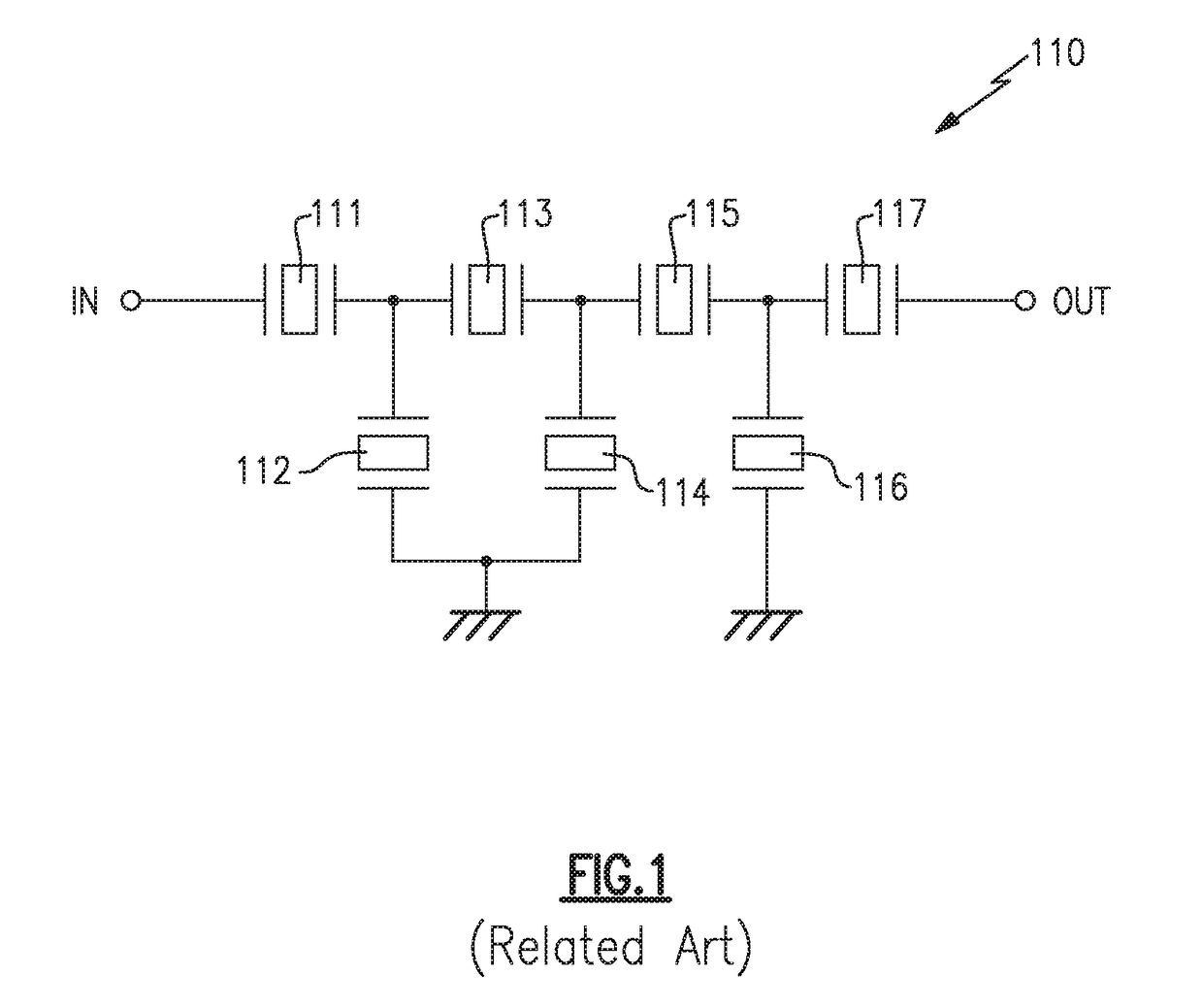

Filters including loop circuits for phase cancellation

ActiveUS20180152191A1Increases level of attenuationExcellent characteristicsPulse automatic controlImpedence networksUltrasound attenuationPhase cancellation

Aspects and examples provide improvement in the attenuation level near the passband within the stopband of the bandpass-type filter using a ladder-type circuit formed by a BAW resonator. In one example the filter includes a ladder-type circuit formed by a bulk acoustic wave (BAW) resonator, and a loop circuit connected between two distinct points on a signal path extending from an input to an output of the ladder-type circuit for phase-cancellation of signals at the two distinct points. The two distinct points may be the input and the output of the ladder-type circuit. The loop circuit may include a SAW resonator or a BAW resonator. The BAW resonator may be a film bulk acoustic resonator (FBAR) or solidly mounted resonator (SMR).

Owner:SKYWORKS SOLUTIONS INC

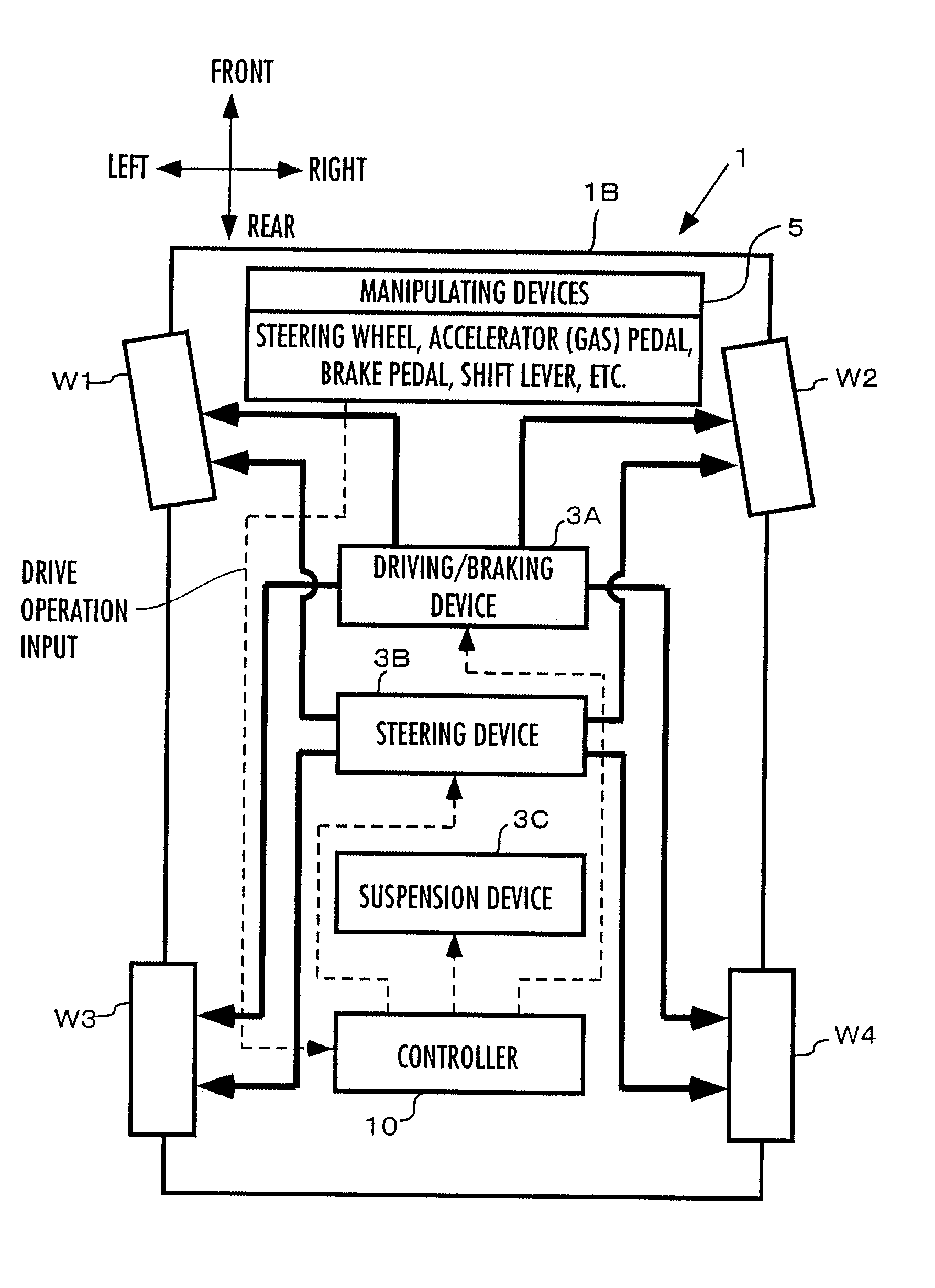

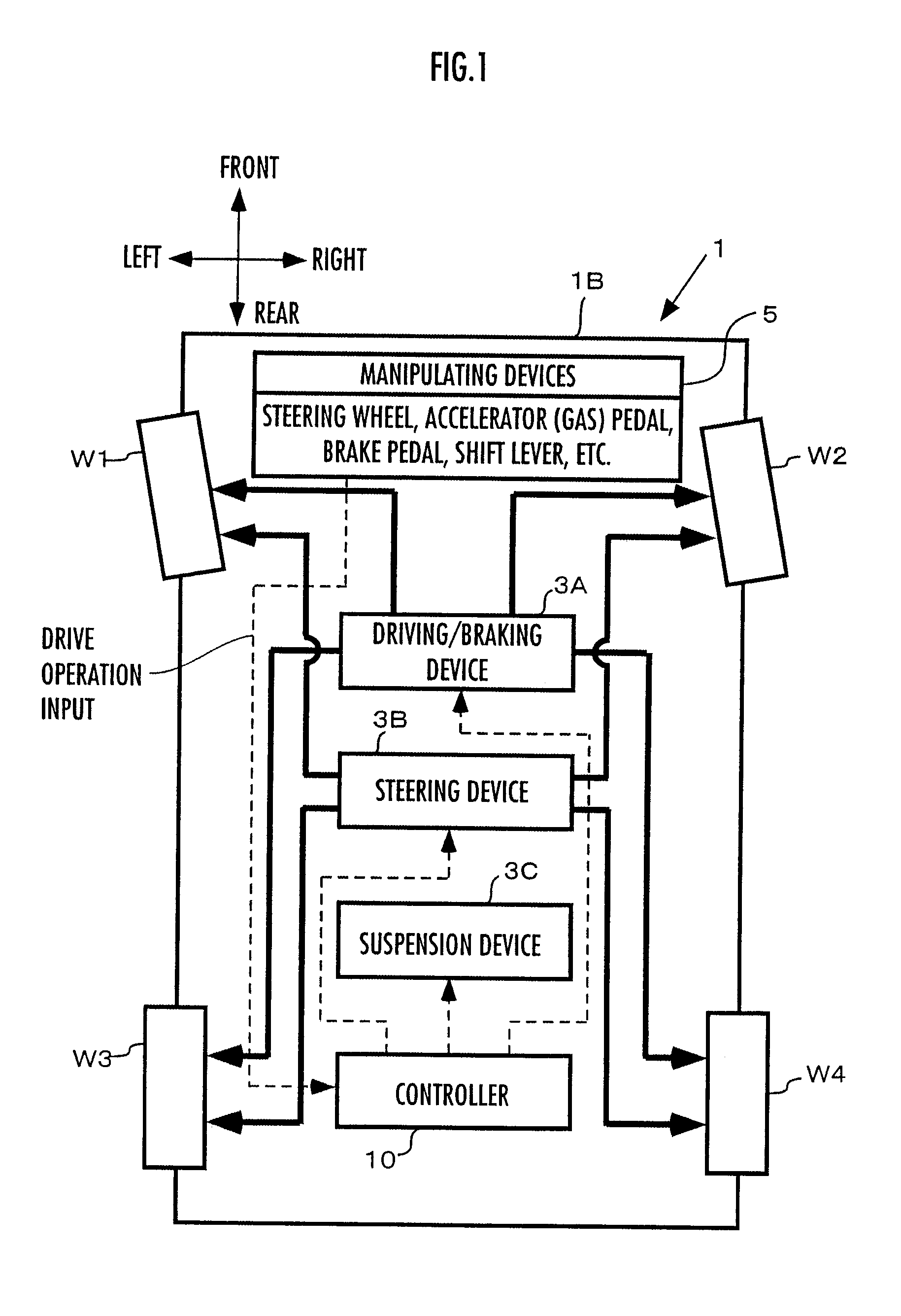

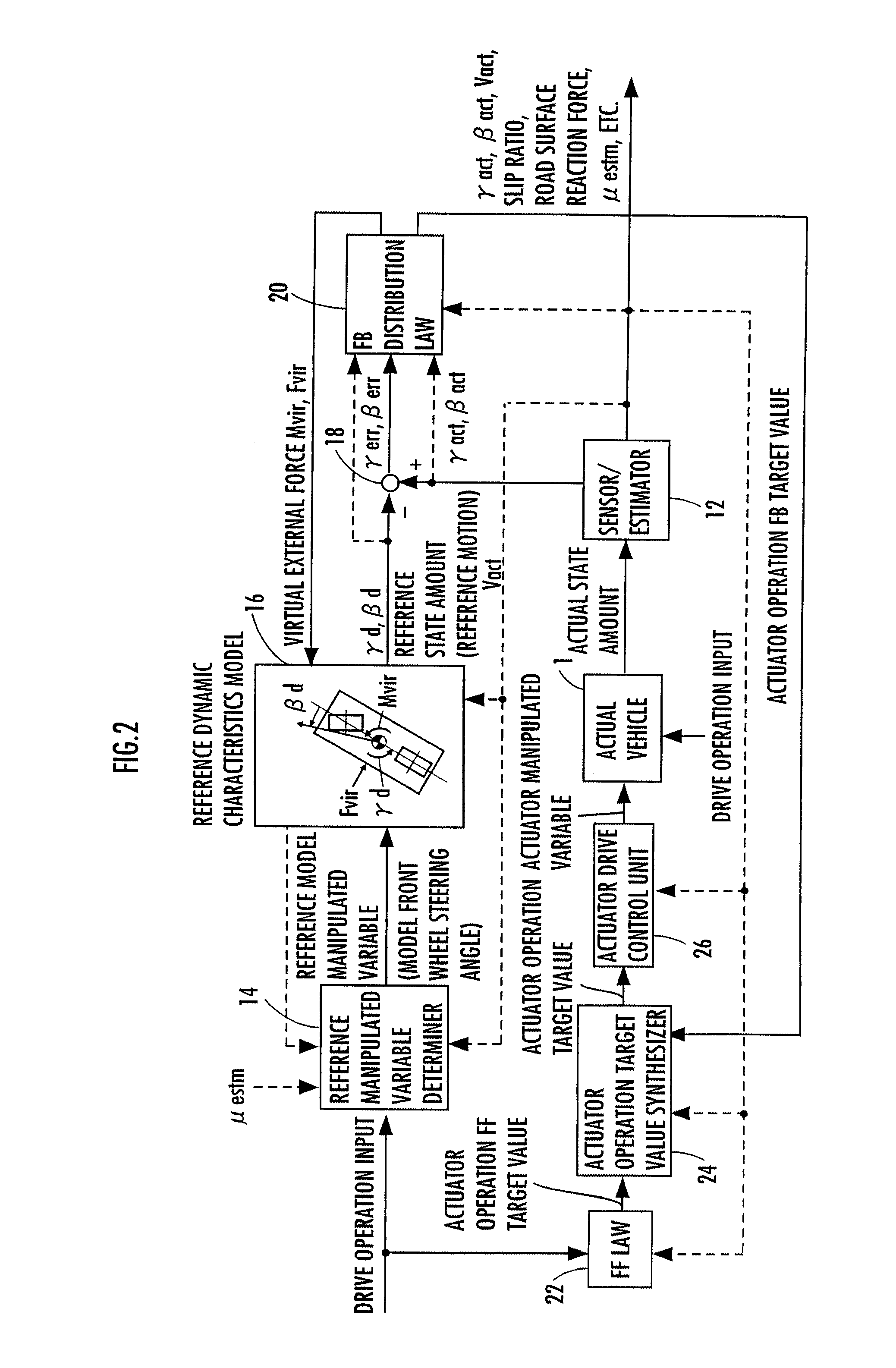

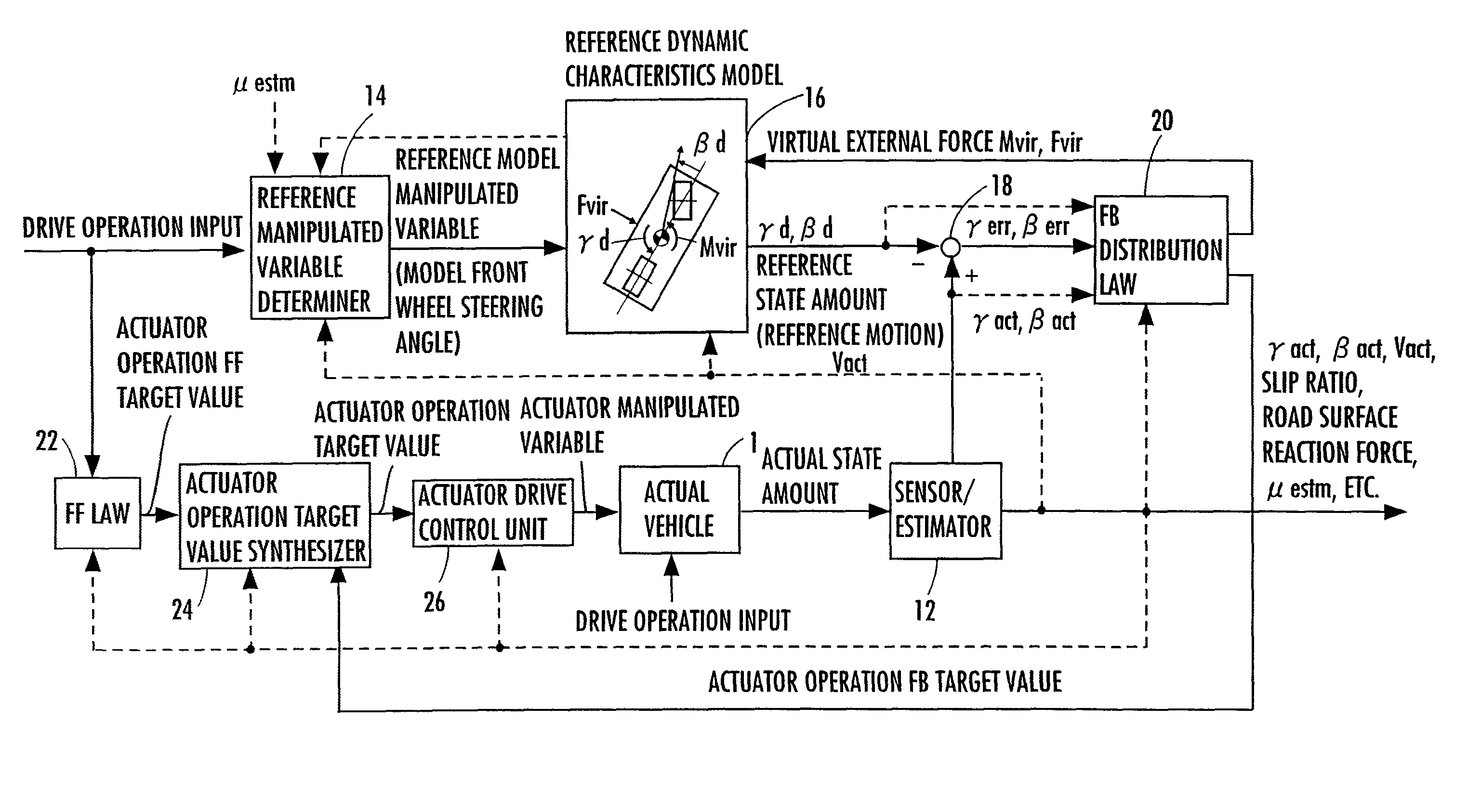

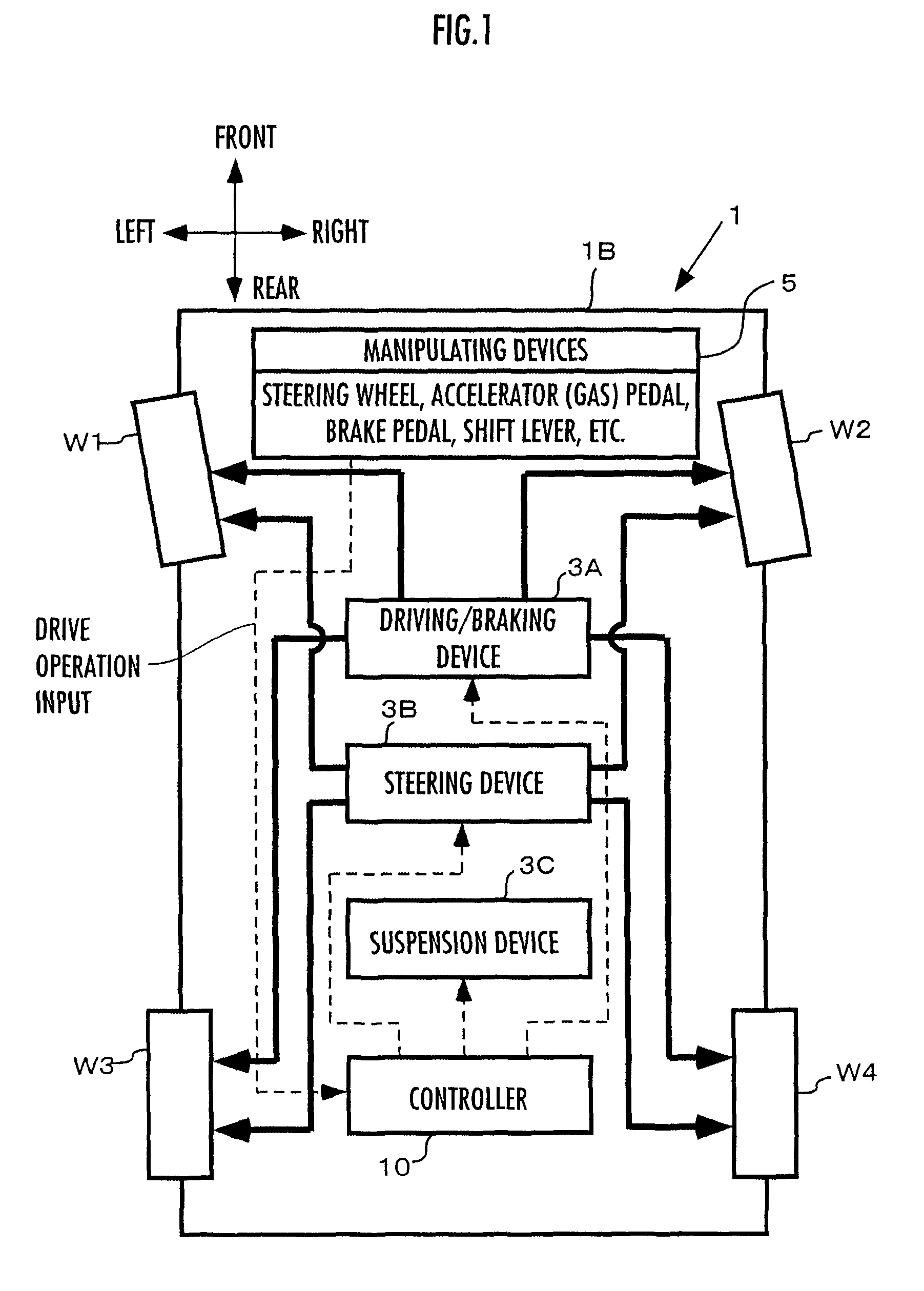

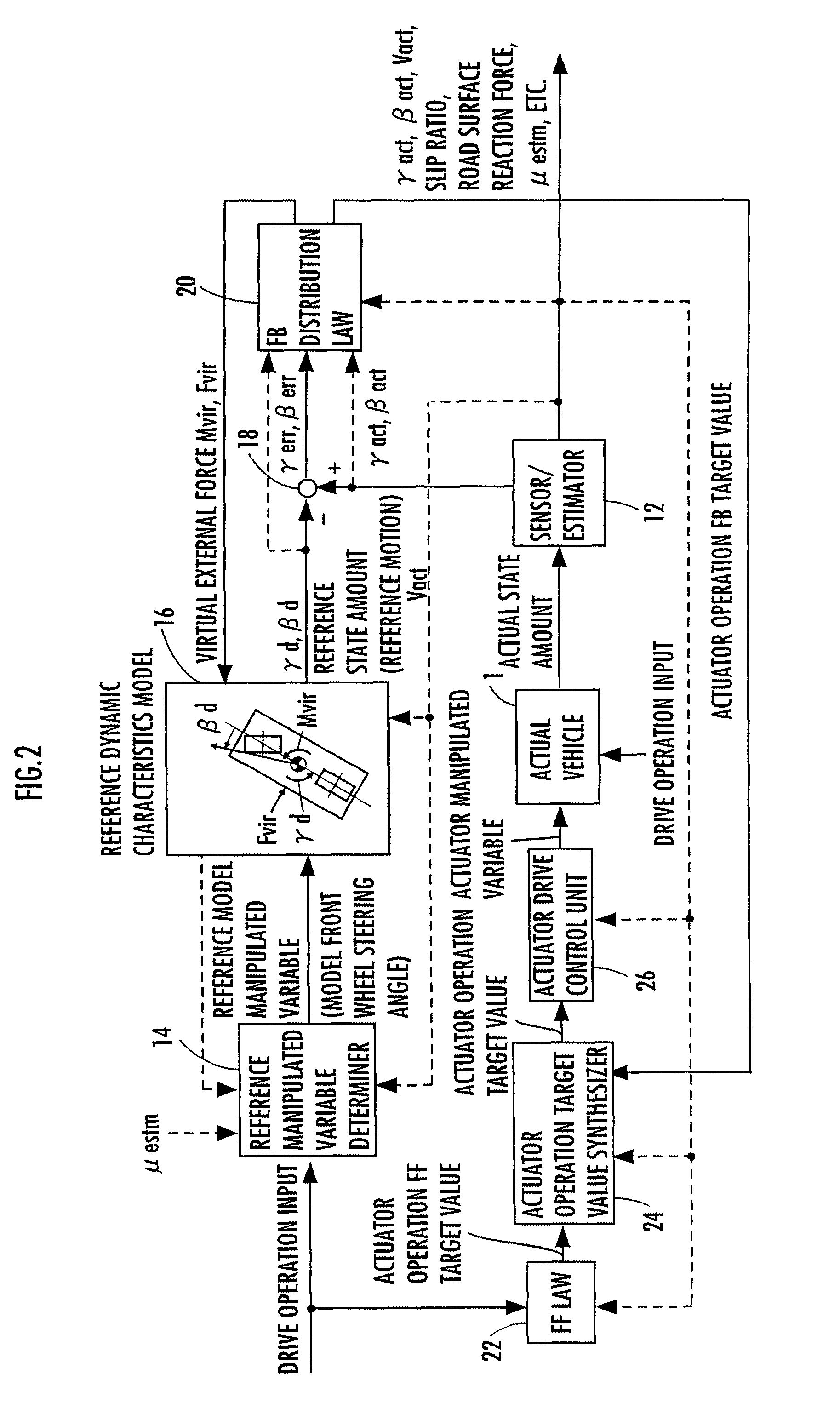

Vehicle Control Device

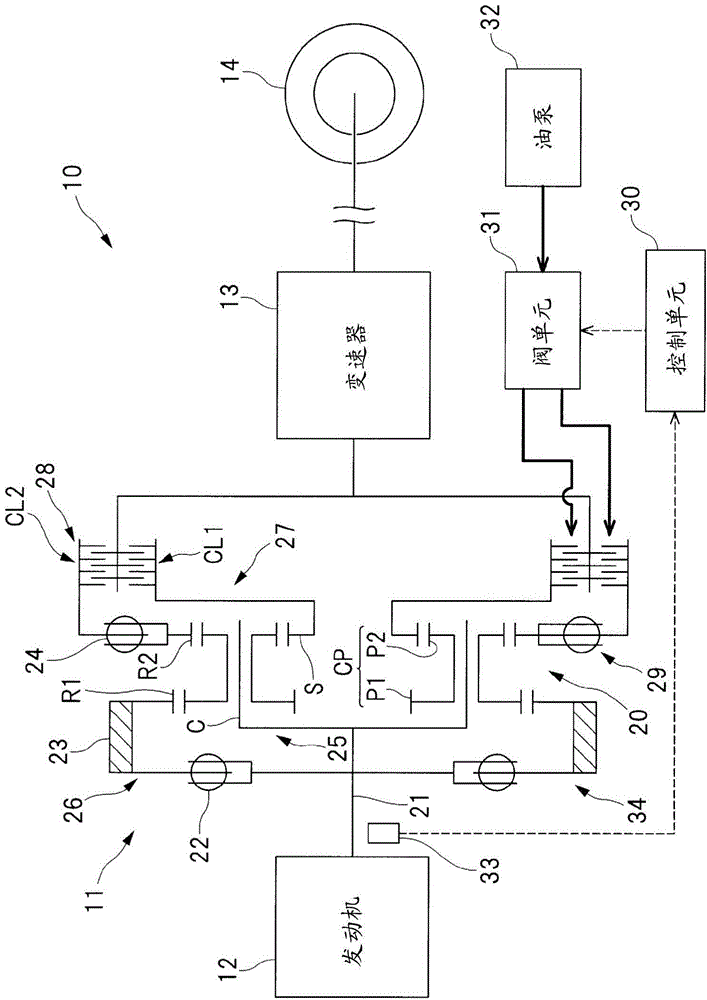

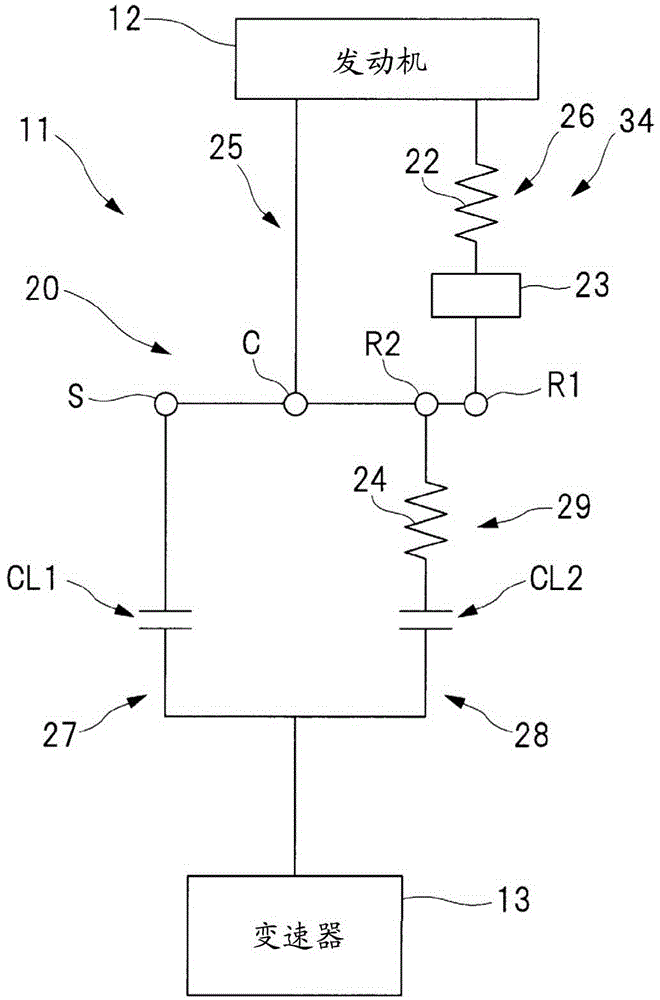

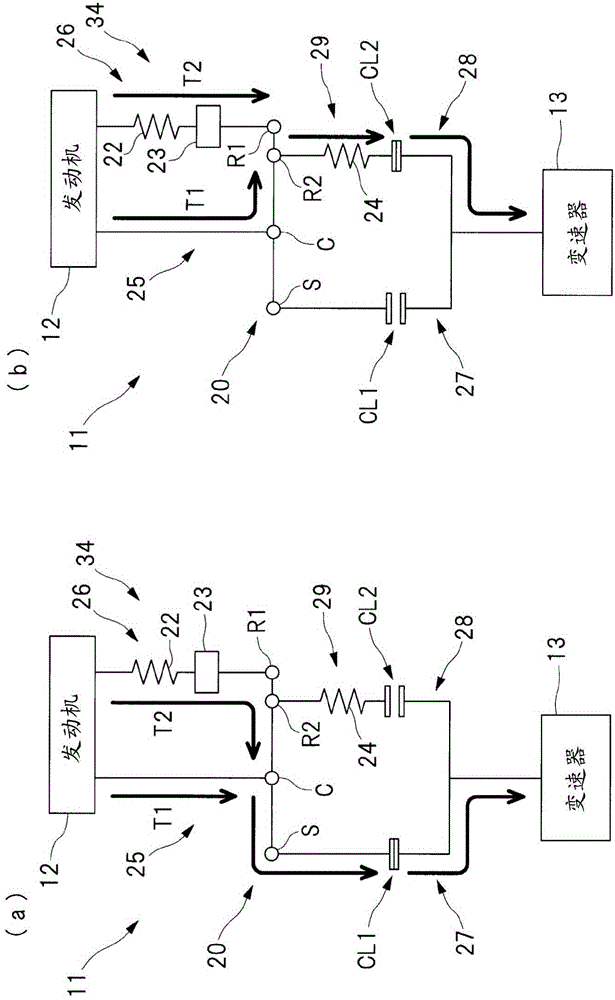

ActiveUS20090024293A1Minimal controlControl inputDigital data processing detailsWheel adhesionUltrasound attenuationActuator

An actual vehicle actuator operation control input and a model operation control input are determined by an FB distribution law such that the difference between a reference state amount determined in a vehicle model and an actual state amount of an actual vehicle approximates zero, and then an actuator device of the actual vehicle and the vehicle model are operated on the basis of the control inputs. The value of a parameter of the vehicle model is set according to an actual vehicle motional state such that the attenuation property of a reference state amount when a drive manipulated variable is changed is higher than the attenuation property of an actual state amount. Accordingly, the actual vehicle actuator device is properly controlled independently of an actual vehicle motional state such that a state amount related to an actual vehicle motion approximates a vehicle state amount on a dynamic characteristic model.

Owner:HONDA MOTOR CO LTD

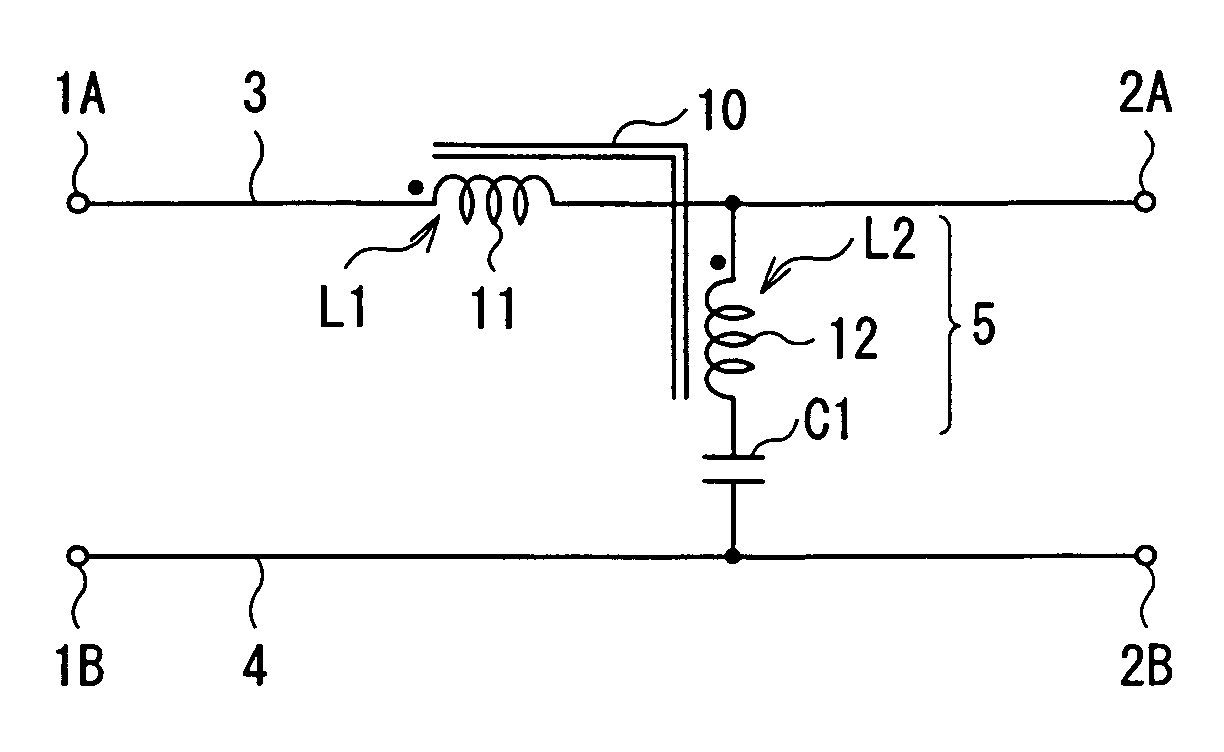

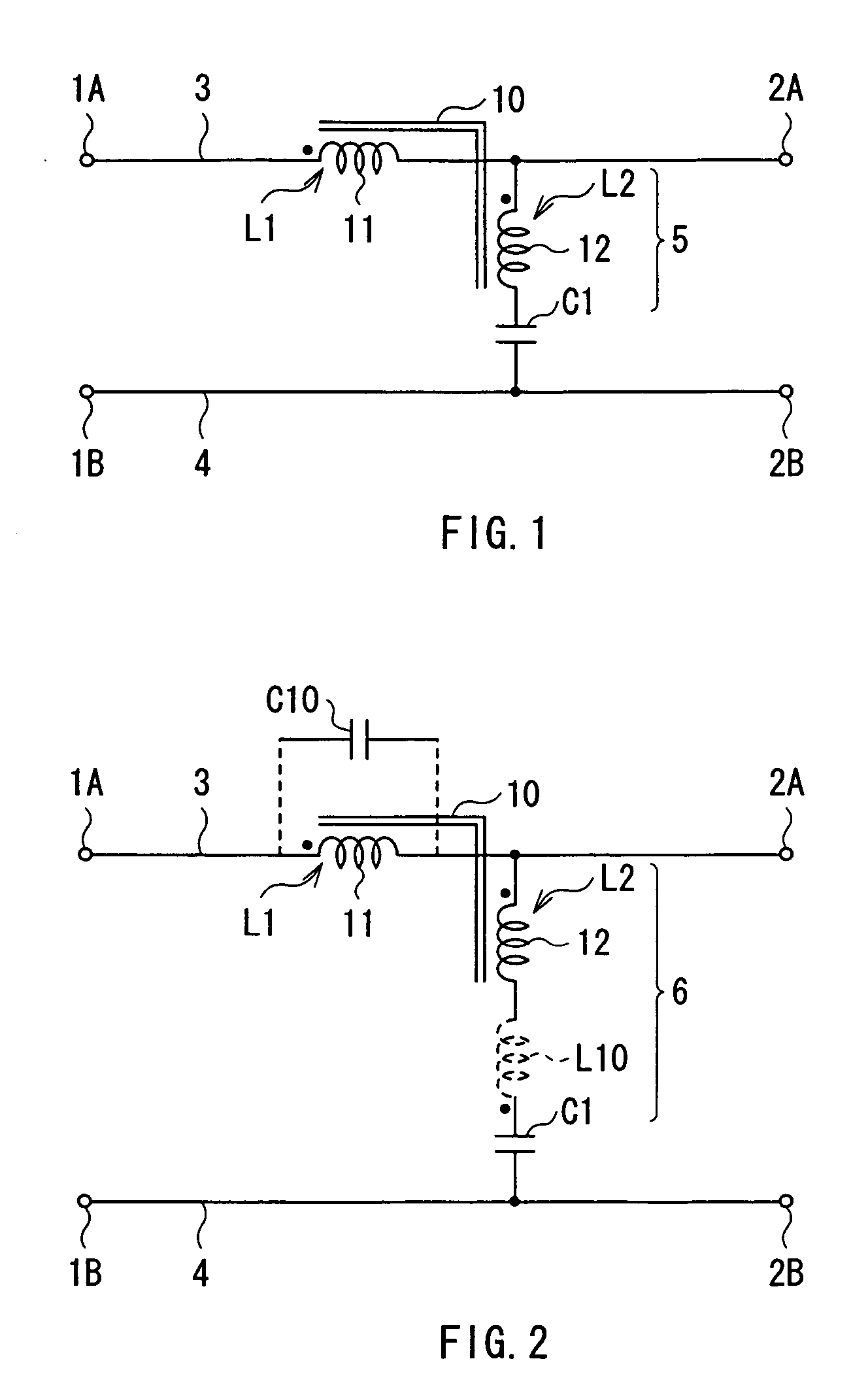

Noise suppressor

InactiveUS20060220972A1Reduce inductanceImprove attenuation characteristicsMultiple-port networksConversion with intermediate conversion to dcUltrasound attenuationSuppressor

A noise suppressor capable of preventing degradation in an attenuation characteristic by a parasitic component so as to obtain a favorable attenuation characteristic is provided. The noise suppressor includes a first winding wire disposed on a first current-carrying wire and a series circuit including a capacitor and a second winding wire which are connected to each other in series. The first winding wire and the second winding wire are magnetically coupled to each other. The inductance xL of the whole second winding wire is smaller than the inductance LL of the whole first winding wire (xL<LL). Moreover, it is desirable that the inductance xL of the whole second winding wire is equal to or smaller than the inductance LL1 per turn in the first winding wire (xL≦LL1).

Owner:TDK CORPARATION

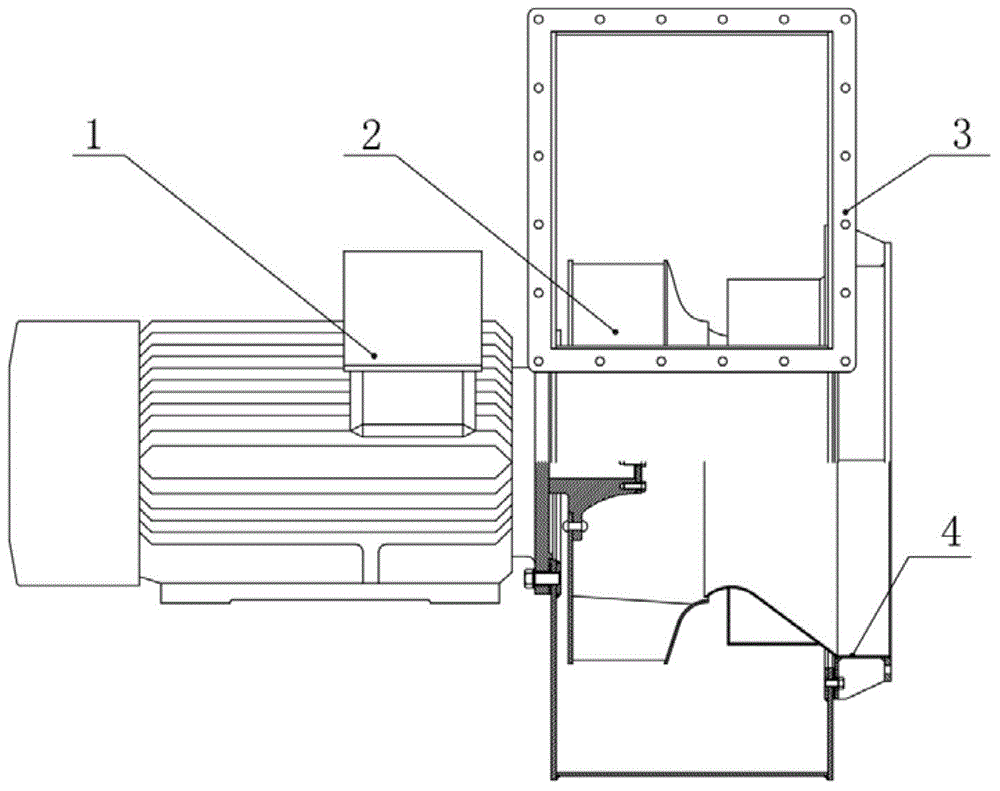

Method for preparing centrifugal ventilator impeller with carbon fiber composite materials

ActiveCN104791297AReduce unbalanced incentivesReduce vibrationPump componentsPump installationsDirectivityImpeller

A method for preparing a centrifugal ventilator impeller with carbon fiber composite materials is characterized in that the impeller is decomposed into three independent parts, namely an impeller cover, a blade and an impeller disk, the three parts are formed individually, and then the three parts are assembled into a whole; the impeller cover, the blade and the impeller disk are made of T300 orthogonal carbon fiber sheet prepreg and T700 homotaxial carbon fiber sheet prepreg which are laid into multiple layers in a certain laying direction sequence in a circulating mode; after the layers are laid ready, the impeller cover, the blade and the impeller disk are vacuumized and sent into a furnace to be cured at a medium temperature, and finally the integral whole is formed. The impeller is made of the carbon fiber composite materials, carbon fibers in the structure of the carbon fiber composite materials serve as main materials for bearing the force, the fibers are different in bearing capacity in different directions, and therefore the carbon fiber composite materials has designability. The 'fiber orientation' design aims to utilize the directivity of carbon fiber materials and maintain the continuity of a force transmission path in the structure to the maximum extent, and a laminated board subjected to in-plane loads can be designed into layers in different directions in the structural design process so that structure demands can be met.

Owner:SINOMACH +1

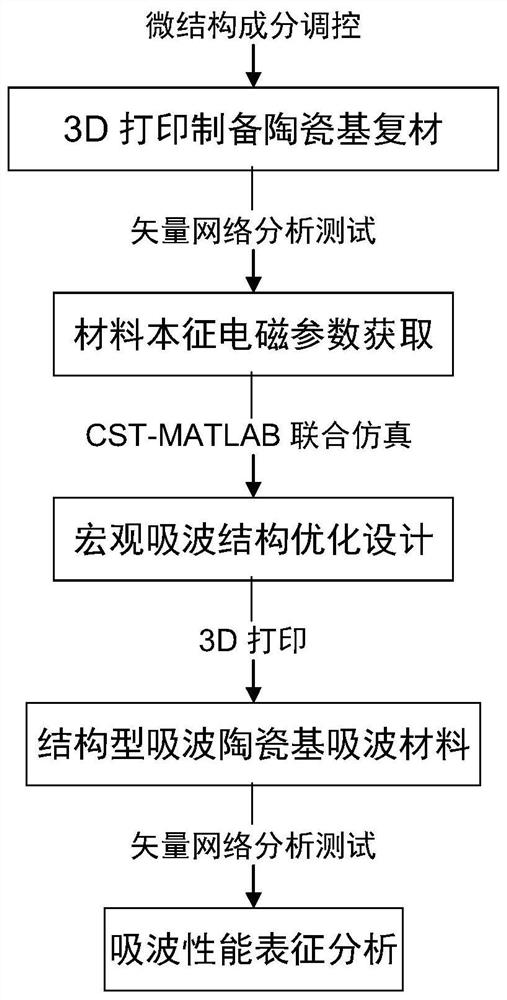

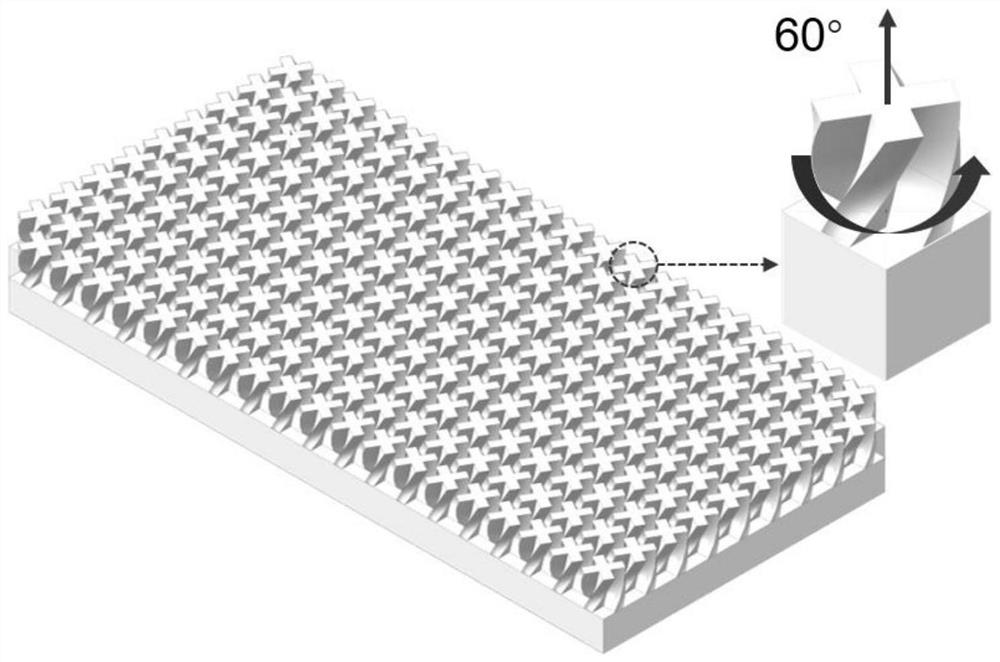

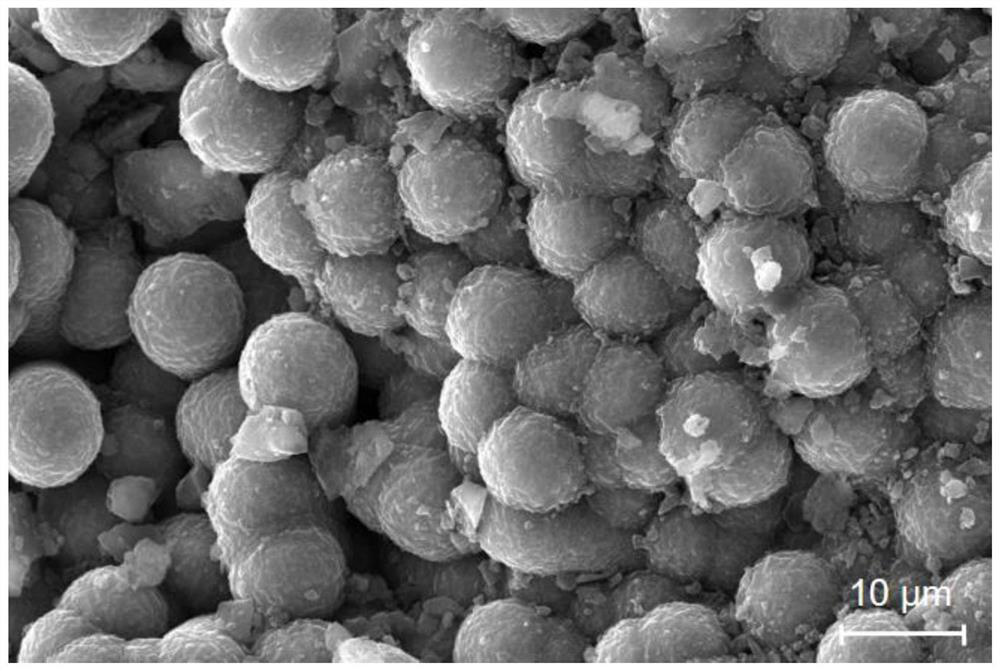

Broadband adjustable light and thin structure type ceramic-based wave-absorbing material and cross-scale design and preparation method thereof

ActiveCN112960972AFlexible Electromagnetic DesignabilityImproved Impedance Matching CharacteristicsAdditive manufacturing apparatusMacroscopic scaleEngineering

The invention relates to a broadband adjustable light and thin structure type ceramic-based wave-absorbing material and a cross-scale design and preparation method thereof. The electromagnetic performance of the wave-absorbing material is regulated and controlled by combining macro-structure optimization with micro-structure component regulation and control through cross-scale collaborative design. On the basis of an existing wave-absorbing material, a flexible 3D printing technology and microstructure component regulation and control processes such as chemical vapor impregnation (CVI) and polymer impregnation and pyrolysis (PIP) are utilized to realize organic combination of a ceramic wave-transparent phase and a wave-absorbing agent medium; and finally, the high-compression-ratio ceramic-based wave-absorbing material which has good impedance matching characteristics and high attenuation characteristics and is thin in thickness, light in weight, wide in frequency band and adjustable in frequency is prepared, a new thought is provided for design and preparation of the structure-function-integrated broadband-adjustable light and thin structural wave-absorbing material, and the urgent requirement of modern combat aircrafts for novel stealth materials is met.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

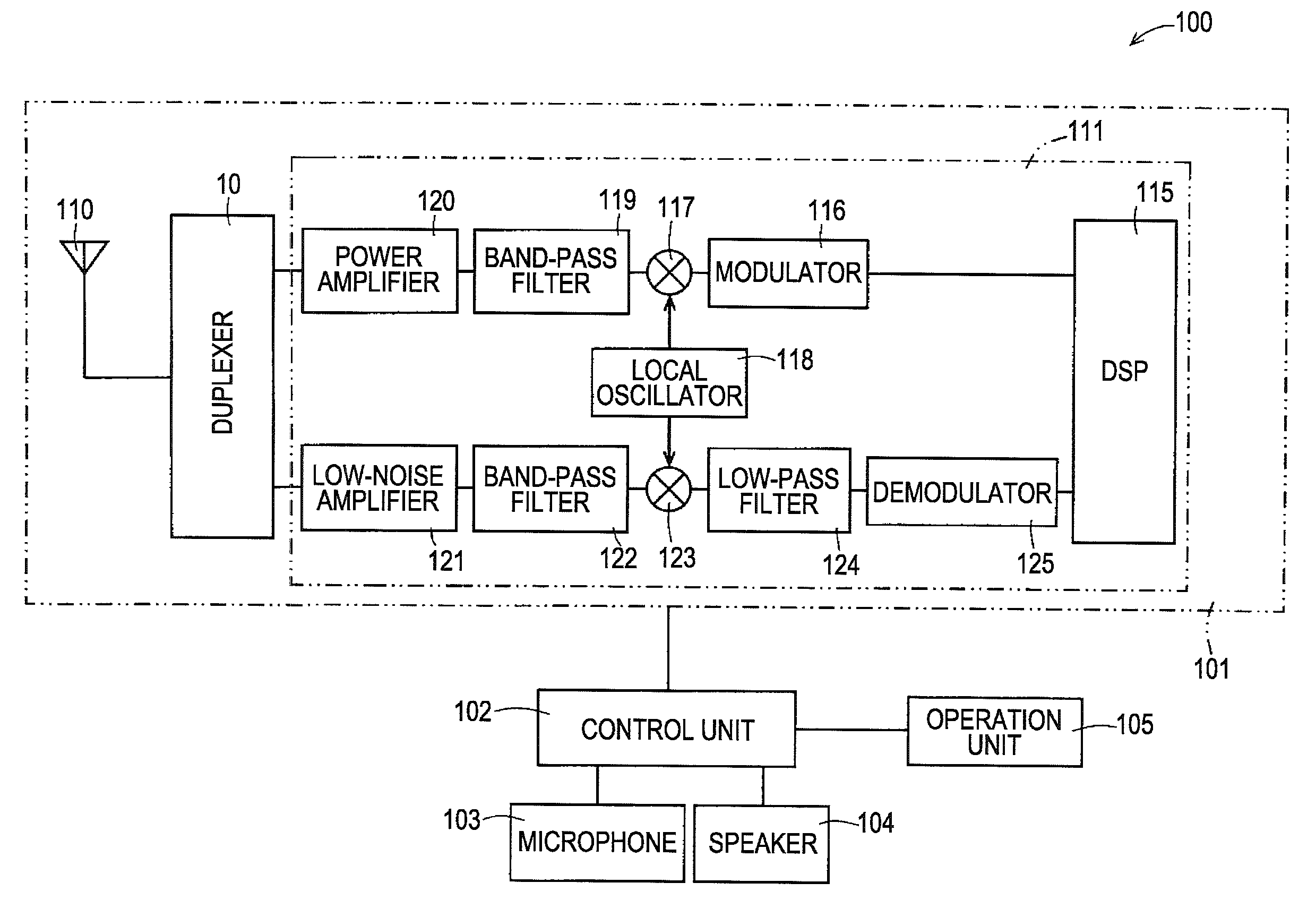

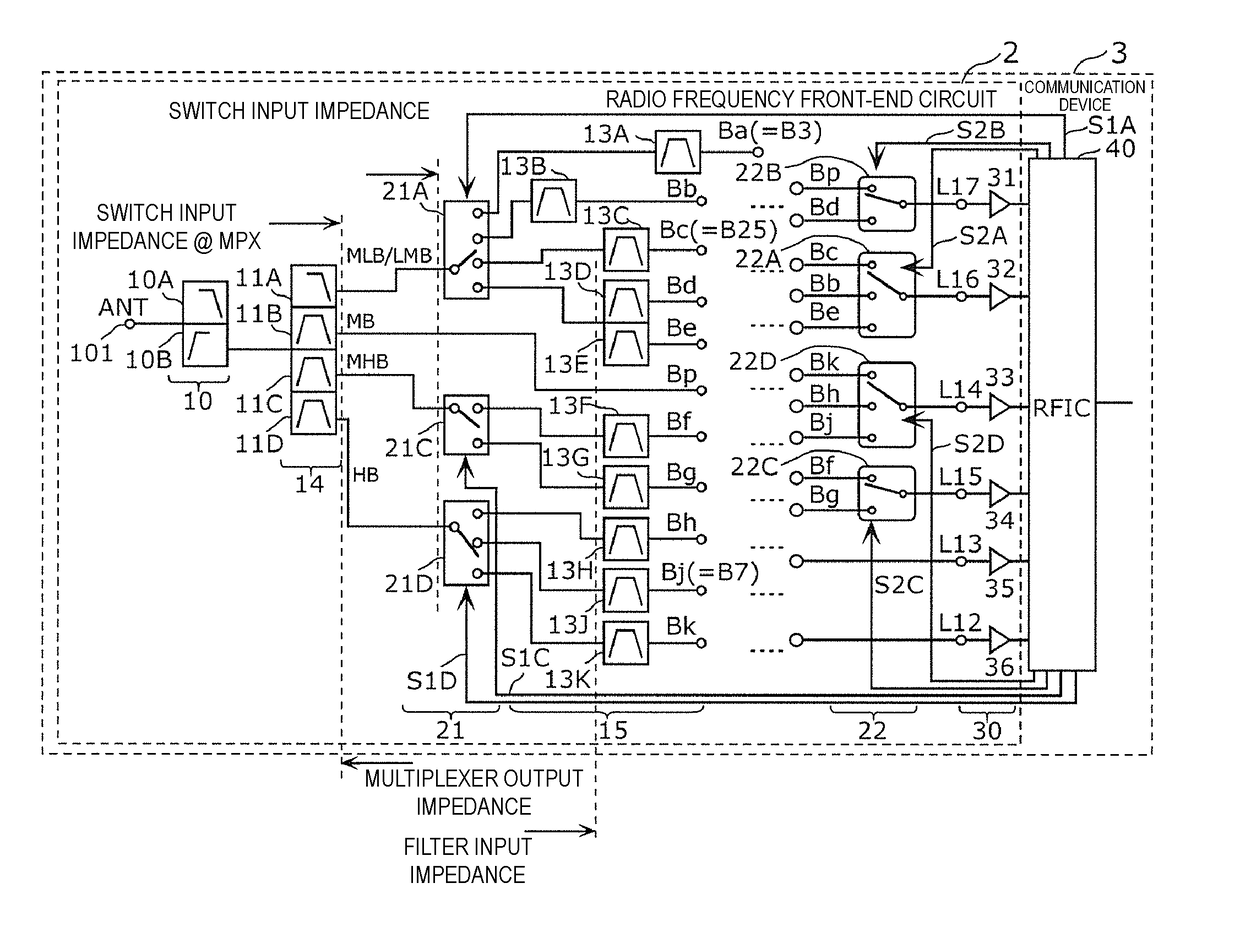

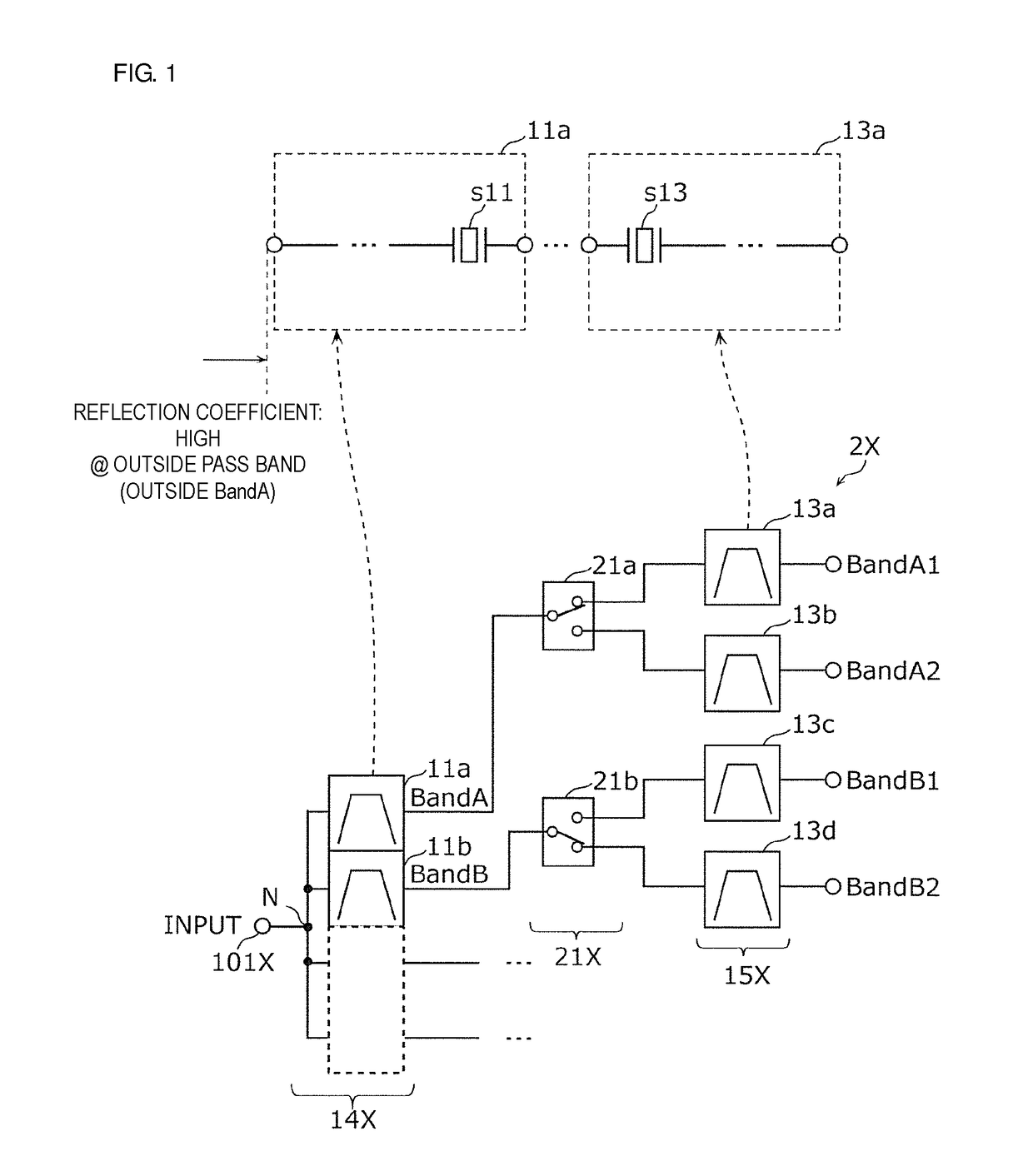

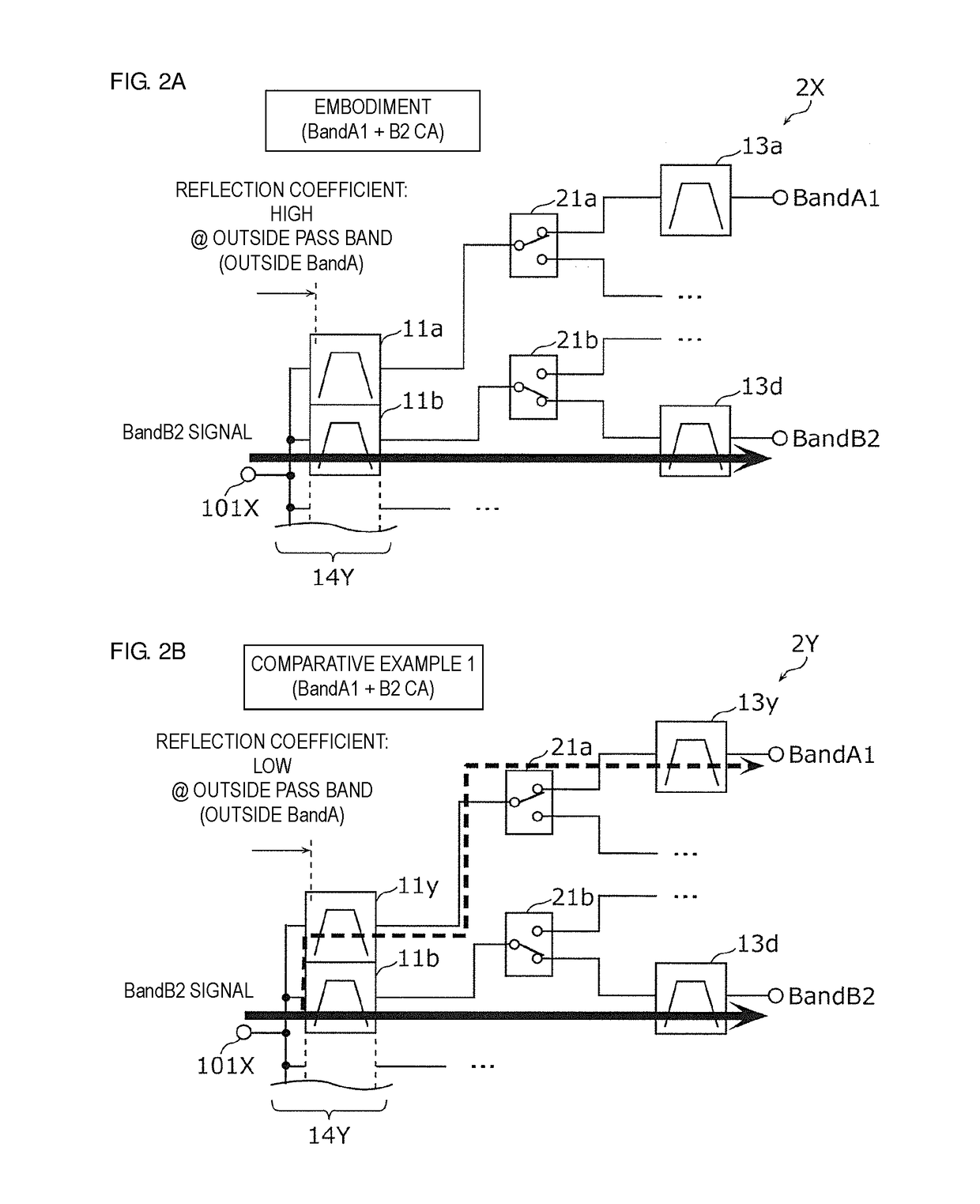

Radio frequency front-end circuit and communication device

ActiveUS20180152172A1Reduced characteristicsImprove attenuation characteristicsImpedence networksTransmissionResonatorRadio frequency front end

A radio frequency front-end circuit includes a multiplexer including filters with different pass bands and including a first acoustic wave filter and a first terminal of each of the filters being connected in common, a second acoustic wave filter including a pass band within the pass band of the first acoustic wave filter, and a switch including a common terminal connected to a second terminal of the first acoustic wave filter and selective terminals including a selective terminal connected to the second acoustic wave filter. Each of an acoustic wave resonator of the first acoustic wave filter located closest to the switch and an acoustic wave resonator of the second acoustic wave filter located closest to the switch, is a serial arm resonator.

Owner:MURATA MFG CO LTD

Vehicle control device

ActiveUS8135528B2Control inputEasy maintenanceDigital data processing detailsAutomatic steering controlUltrasound attenuationEngineering

An actual vehicle actuator operation control input and a model operation control input are determined by an FB distribution law such that the difference between a reference state amount determined in a vehicle model and an actual state amount of an actual vehicle approximates zero, and then an actuator device of the actual vehicle and the vehicle model are operated on the basis of the control inputs. The value of a parameter of the vehicle model set according to an actual vehicle motional state such that the attenuation property of a reference state amount when a drive manipulated variable is changed is higher than the attenuation property of an actual state amount. Accordingly, the actual vehicle actuator device is properly controlled independently of an actual vehicle motional state such that a state amount related to an actual vehicle motion approximates a vehicle state amount on a dynamic characteristic model.

Owner:HONDA MOTOR CO LTD

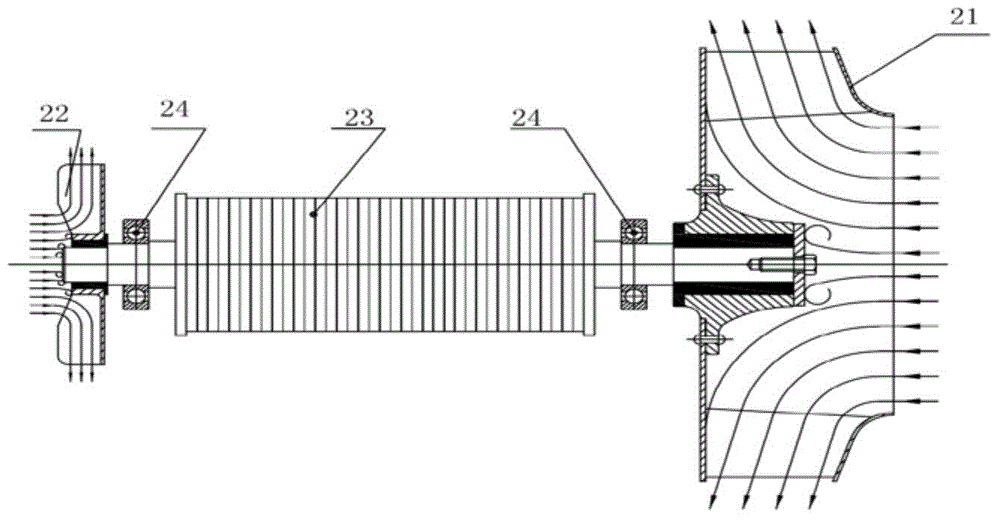

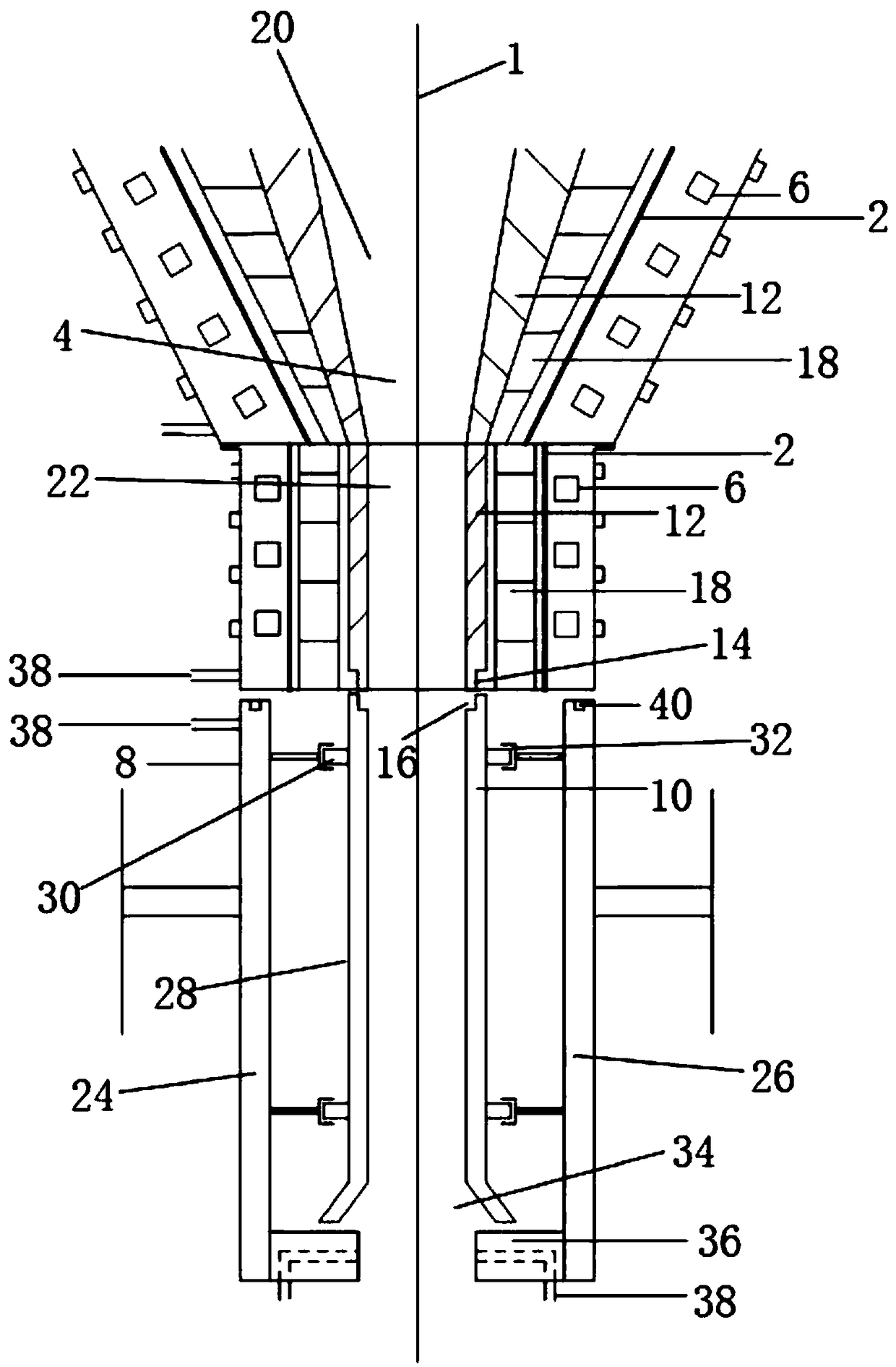

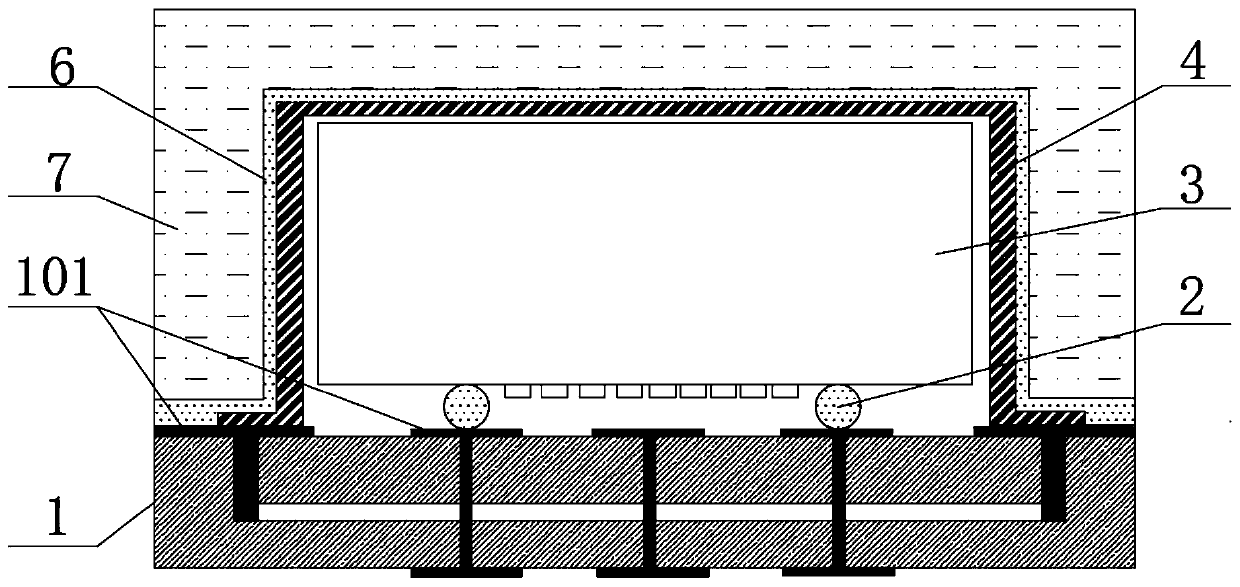

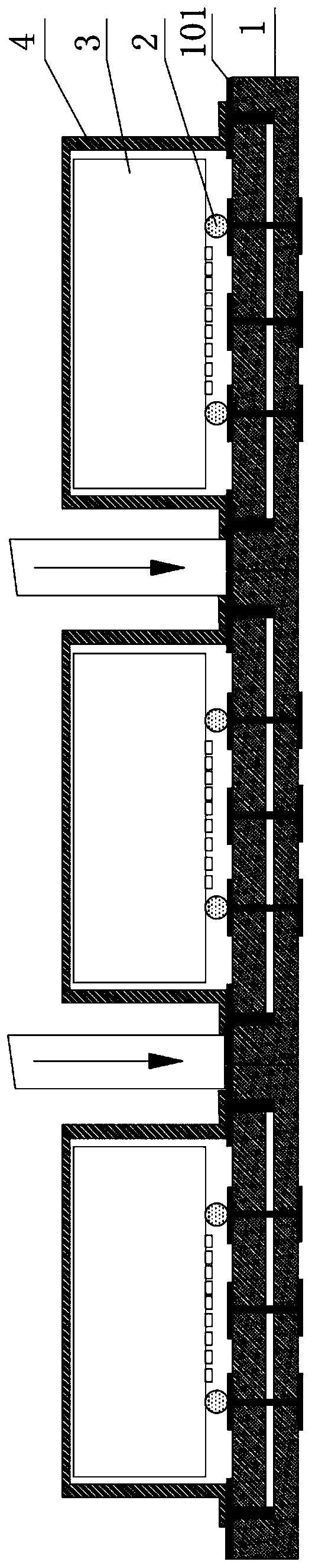

Fiber drawing and annealing device

PendingCN108409130AImprove attenuation characteristicsImproved warpage characteristicsGlass making apparatusUltrasound attenuationWorking temperature

The invention discloses a fiber drawing and annealing device, comprising an annealing tube. An axial cavity for a fiber to pass through is arranged in the annealing tube; an electric heater is arranged in a tube body of the annealing tube and is arranged around the axial cavity; by adjusting the working temperature of the electric heater, the temperature in the axial cavity decreases gradually from the direction of the fiber passing in the axial cavity to the direction of the fiber passing out of the axial cavity. The fiber drawing and annealing device also includes an annealing assistor hermetically connected to the fiber outgoing end of the annealing tube; a lining is arranged in the annealing assist and is coaxial to the axial cavity. The fiber drawing and annealing device of optical structural design is abutted to a drawing furnace; after the fiber is drawn and fed out of the furnace, the fiber enters the annealing device having the temperature slowly decreasing; attenuation features, warping characteristics and fiber internal stress can be improved for the fiber, and fiber quality is improved in a whole.

Owner:JIANGSU HENGTONG OPTICAL FIBER TECH +1

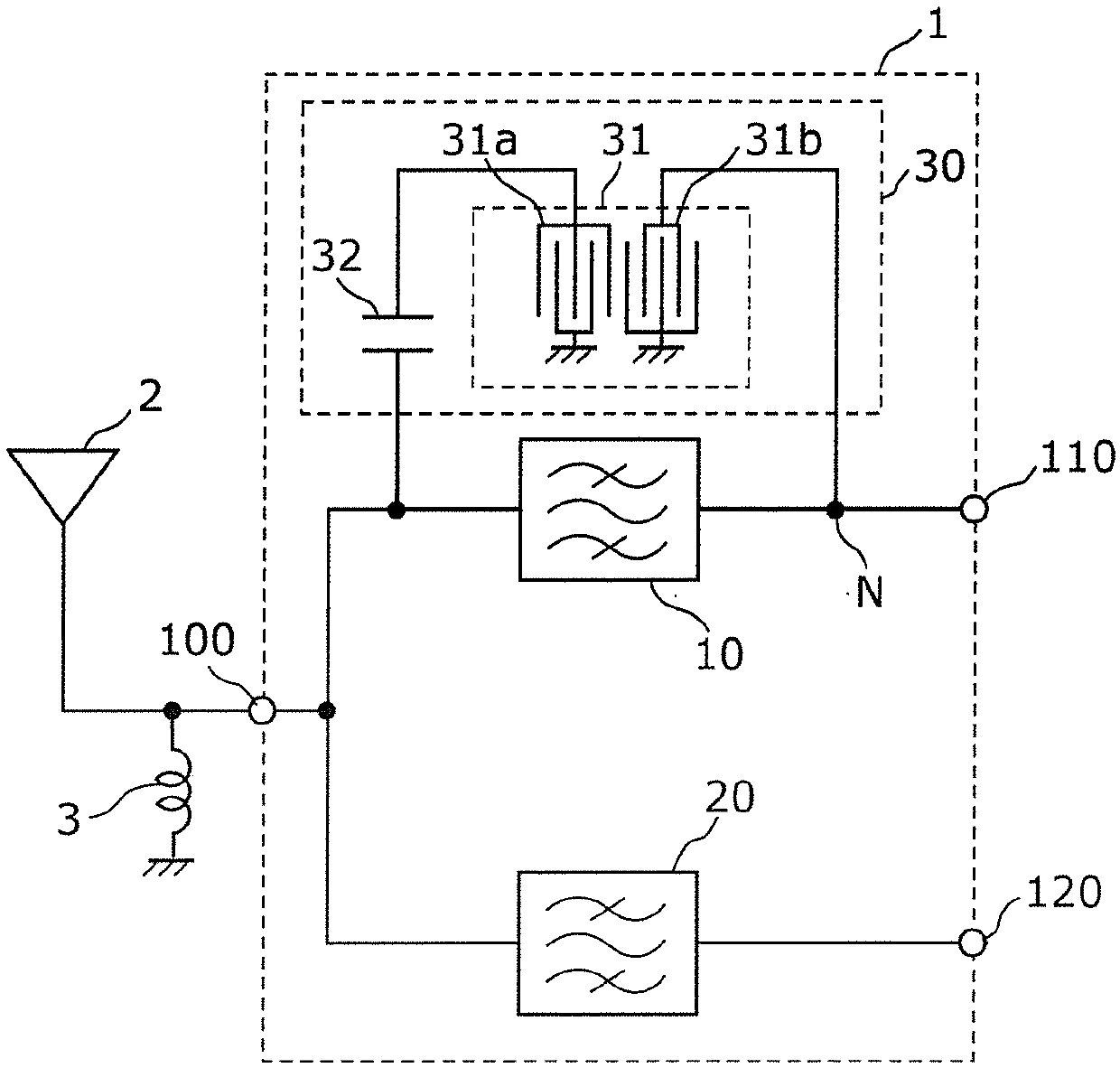

Multiplexer

ActiveCN108023570AImprove attenuation characteristicsImprove pass characteristicsImpedence networksFrequency bandUltrasound attenuation

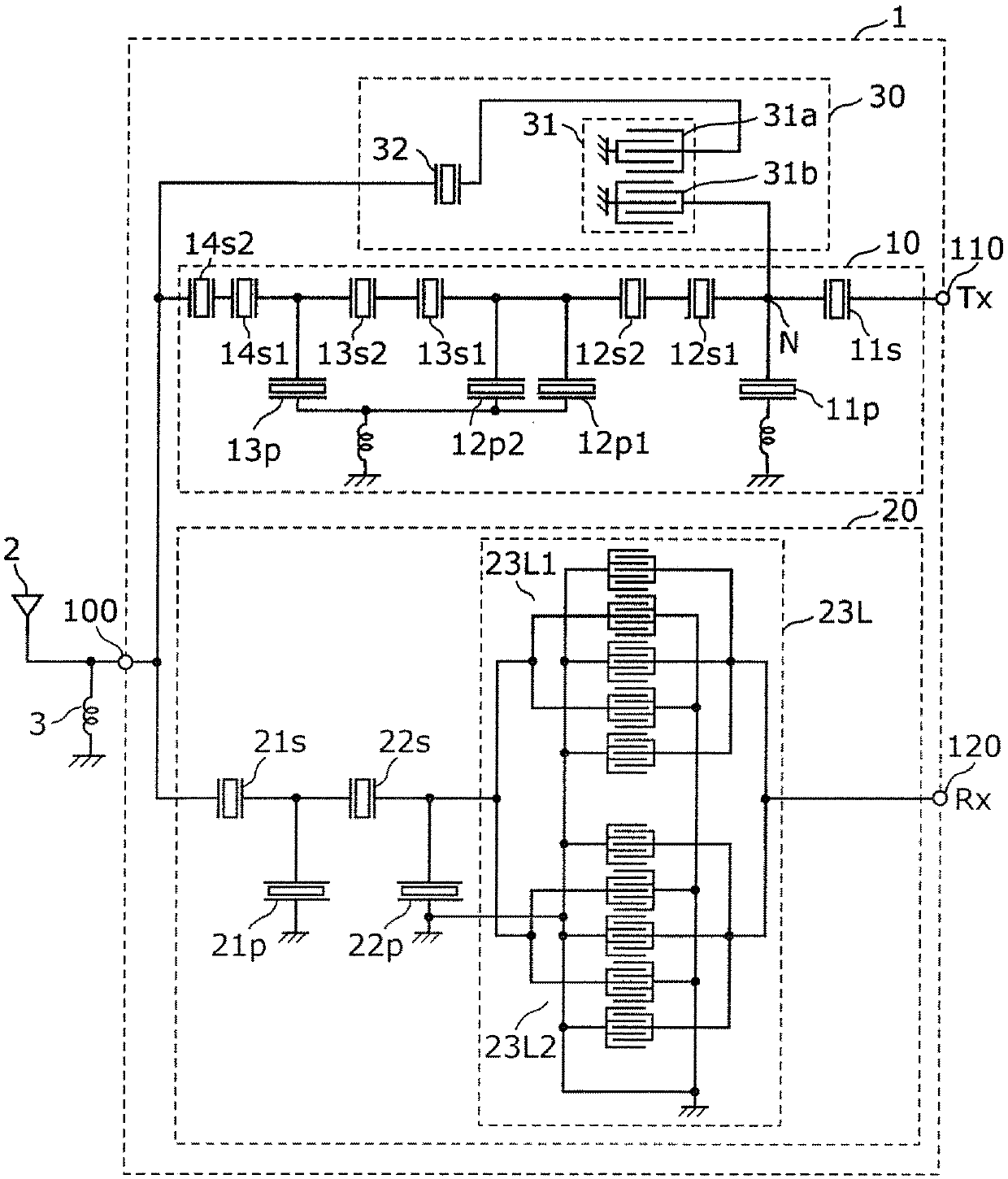

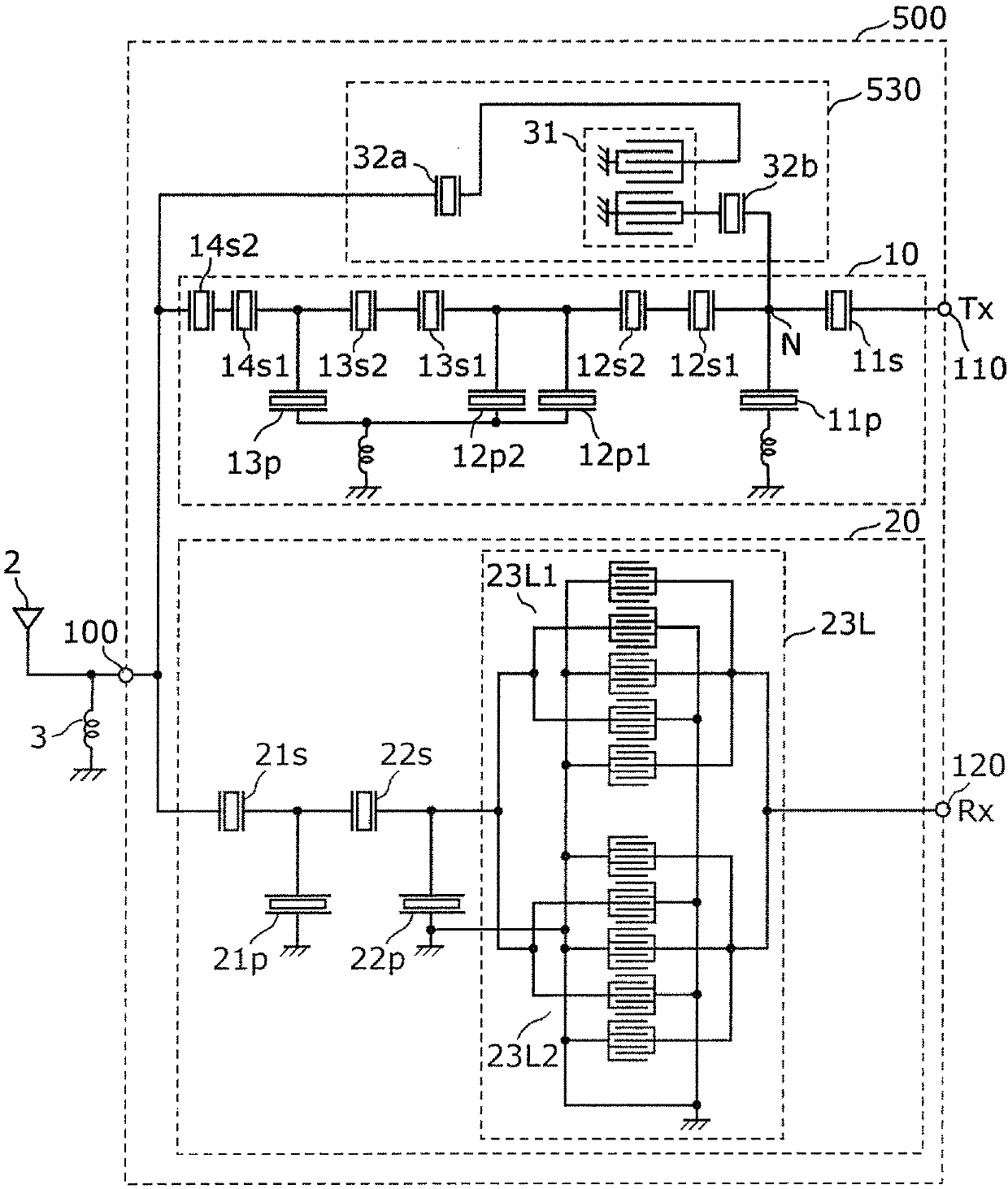

The present invention provides multiplexers that improve attenuation characteristics of a first filter circuit, and improve the bandpass characteristics of a second filter circuit connected to the first filter circuit. A multiplexer 1 includes a transmission filter 10 and a reception filter 20 that are connected to a common terminal 100, and a cancellation circuit 30 that is connected to the common terminal 100 and a node N on a transmission path and that offsets a component in a certain frequency band flowing through the transmission filter 10. The cancellation circuit 30 includes a capacitive element 32 connected to the common terminal 100, and a longitudinally-coupled resonator 31 including a first end connected to the capacitive element 32 and a second end connected to the node N withno capacitive element interposed therebetween. An impedance in a reception band when viewing the cancellation circuit 30 from the common terminal side 100 is higher than an impedance in the receptionband when viewing the cancellation circuit 30 from the node side N.

Owner:MURATA MFG CO LTD

Line filter

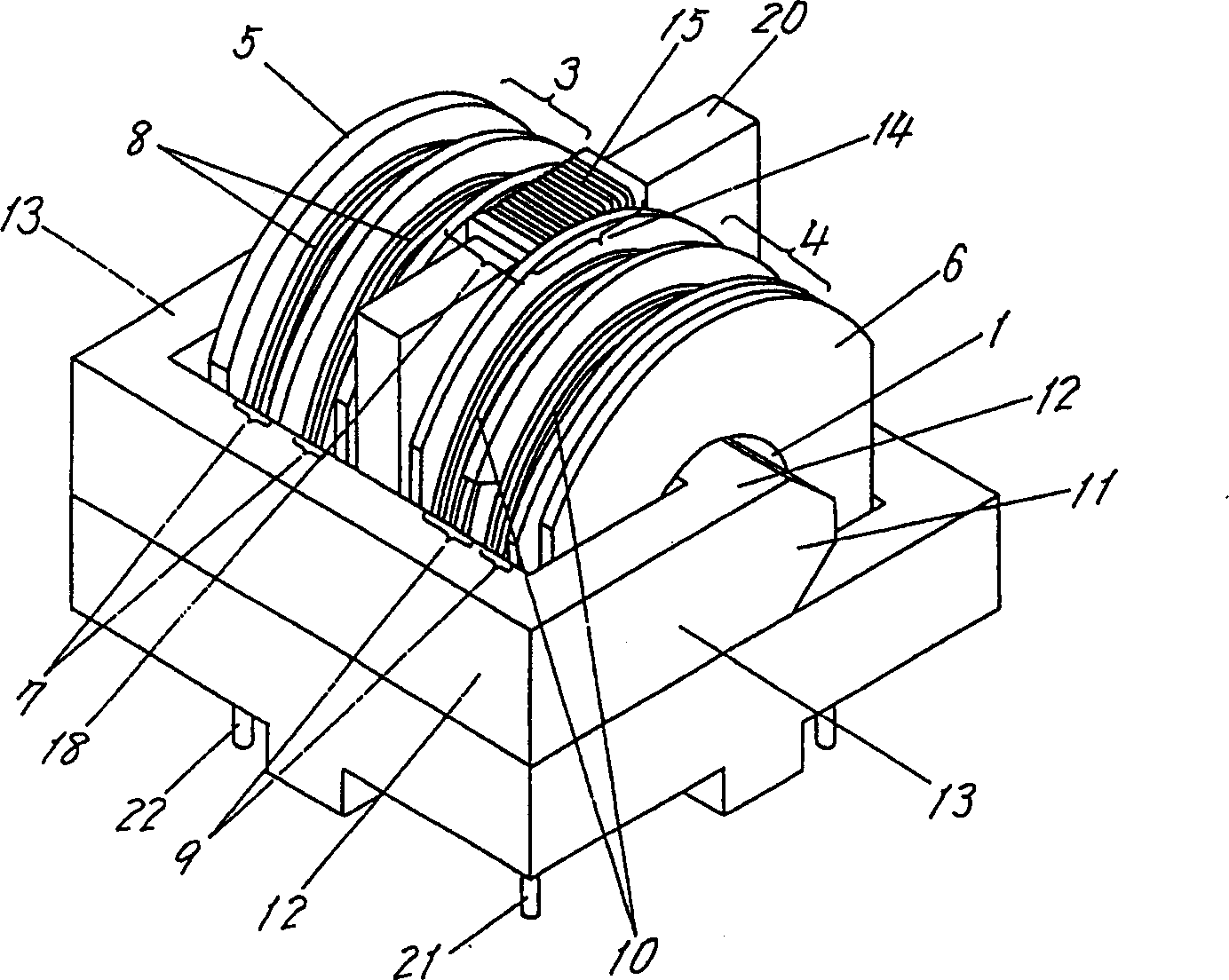

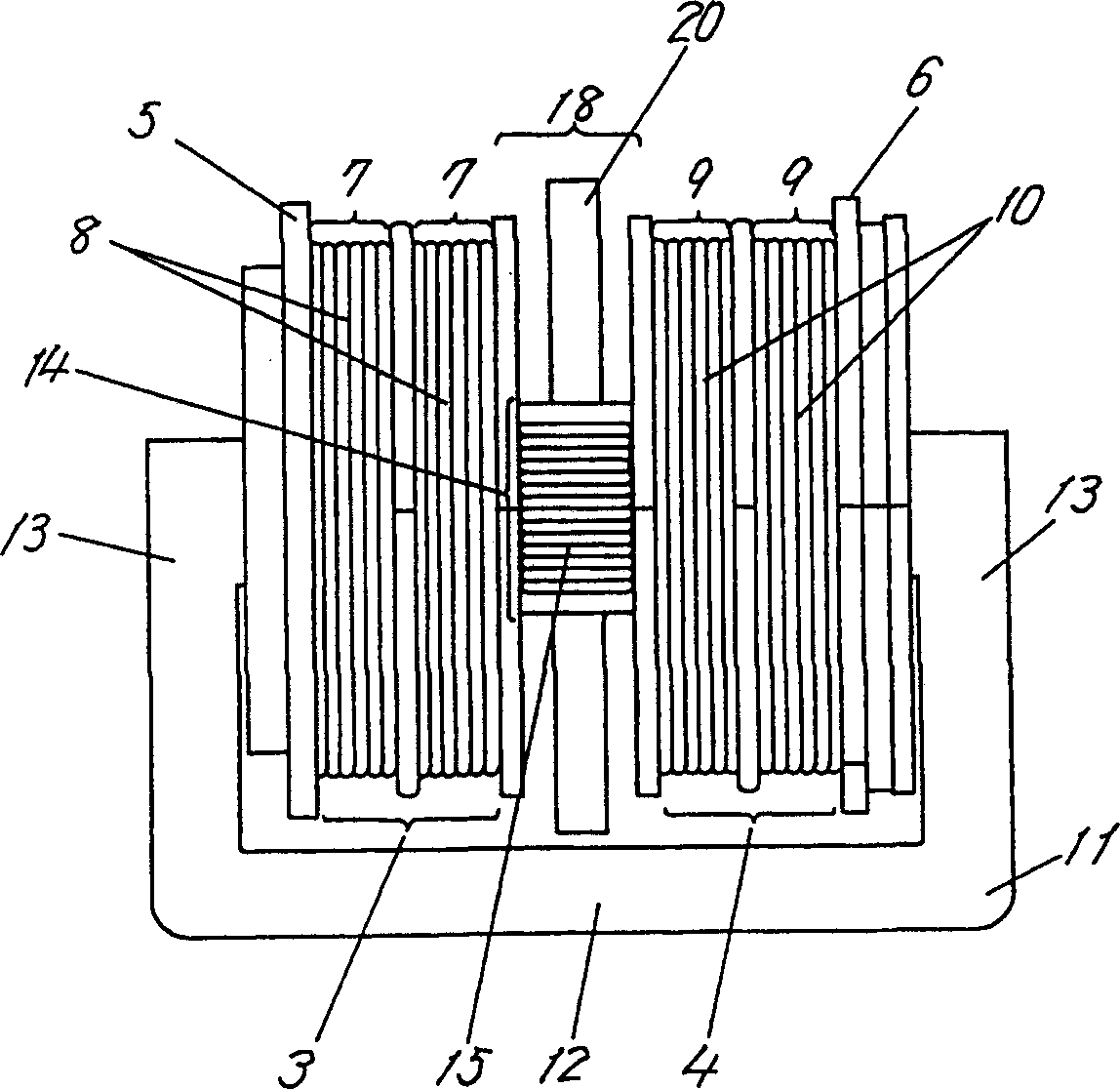

InactiveCN1358318AWide attenuation characteristicsImprove attenuation characteristicsTransformersFixed signal inductancesUltrasound attenuationLow frequency band

The present invention is intended to provide a line filter having an outstanding attenuation characteristic over a wide frequency band from low frequency band to high frequency band, with an improved elimination characteristic for common mode noises. To achieve this object, the invention incorporates a structure wherein a first coil unit (14) for second band and a second coil unit (16) for second band are disposed vertically to a closed-loop magnetic core (11).

Owner:PANASONIC CORP

Damper device

InactiveCN104047992AIncreased torsional vibrationImproved damping characteristics of torsional vibrationToothed gearingsEngine controllersTorsional vibrationClutch

Owner:SUBARU CORP

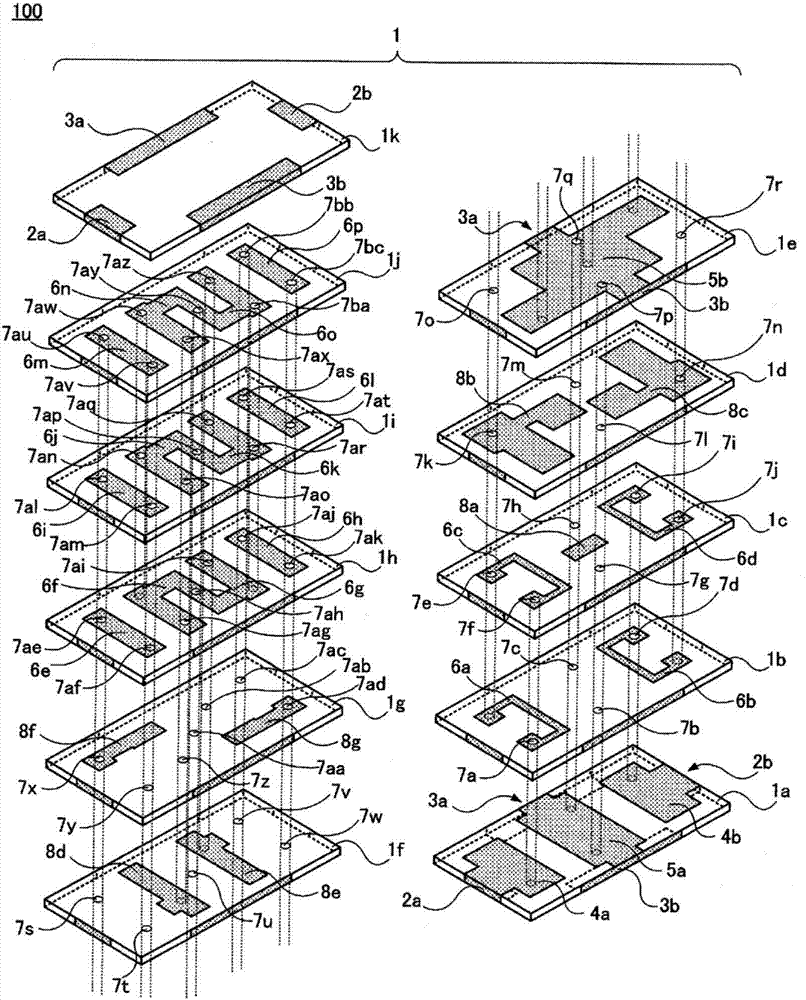

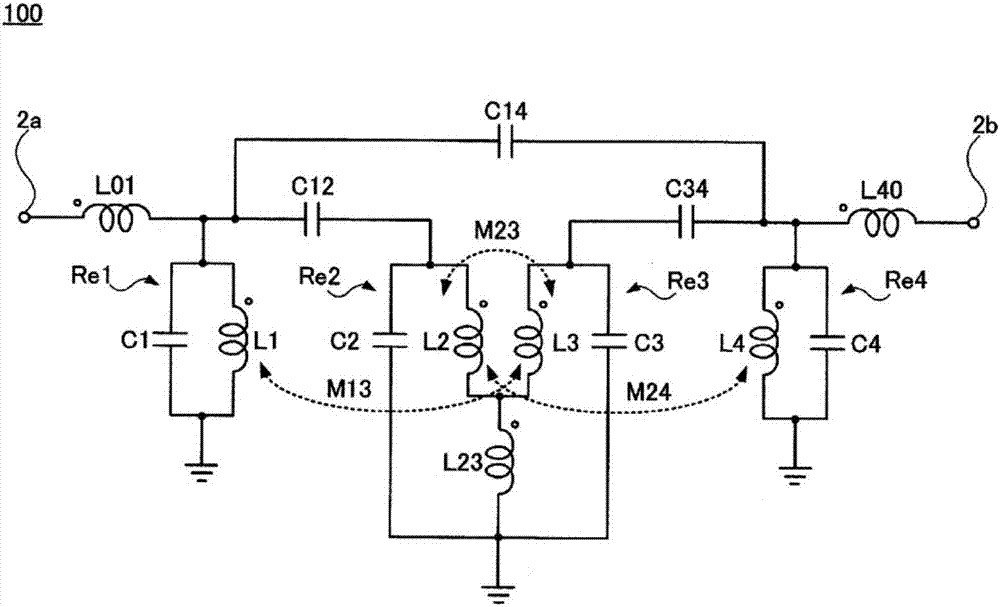

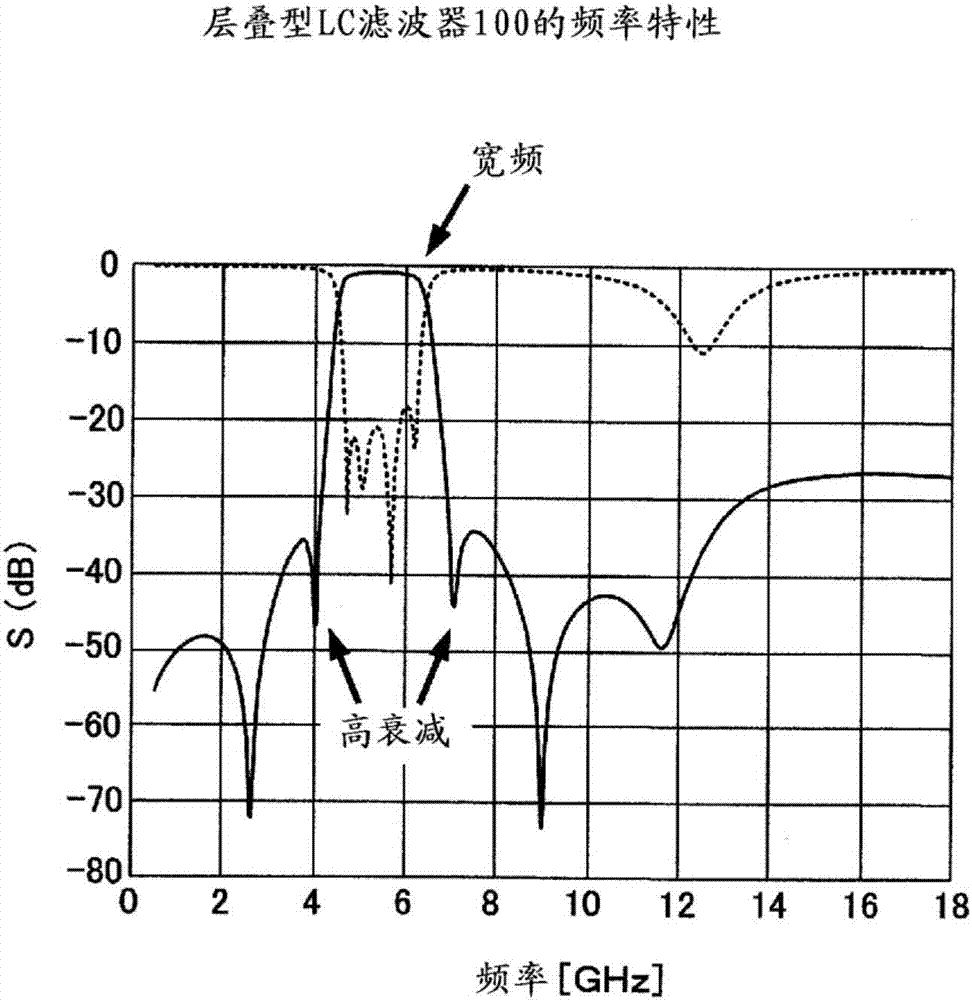

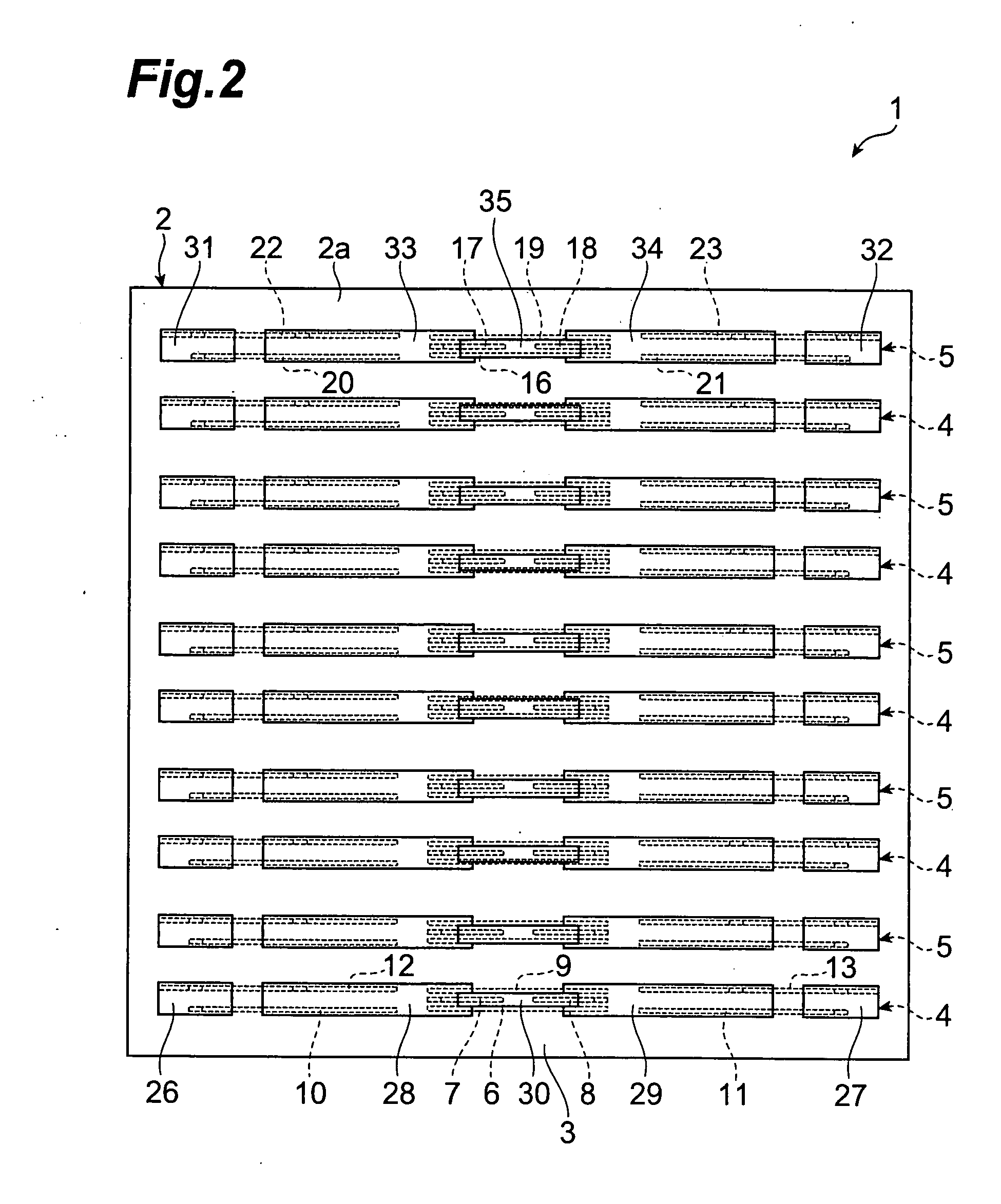

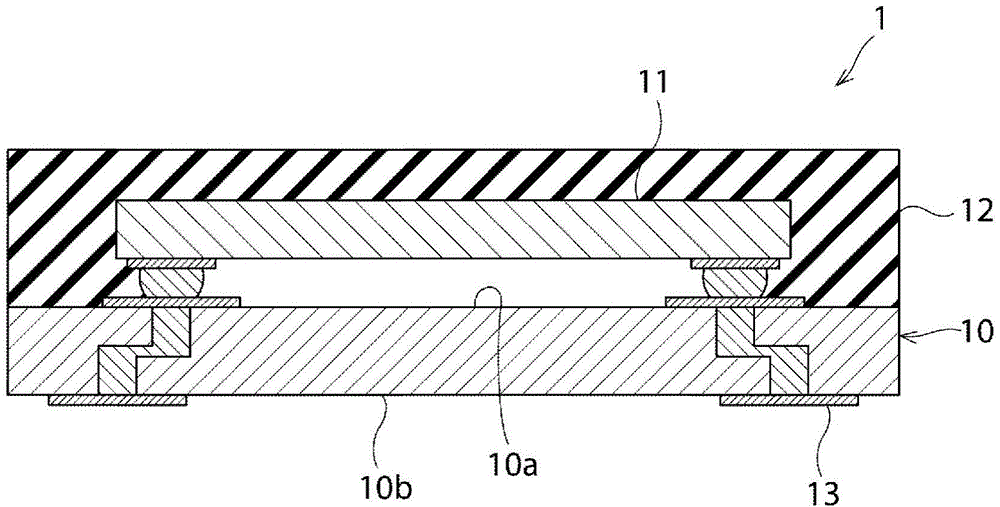

Laminated lc filter

ActiveCN107026628AImprove attenuation characteristicsFull attenuationMultiple-port networksFixed capacitor electrodesInductorResonator

The invention provides a laminated LC filter having wide passband and having an attenuation pole equipped with enough decrement surround the pass band. At least four LC parallel resonators (Re1-Re4) are provided inside a multilayer body. At least a pair of loops of inductors (L1,L3) in odd numbered-stage LC parallel resonators (Re1,Re3) among the at least four LC parallel resonators (Re1-Re4) are disposed at an angle at which magnetic coupling is obtained therebetween, and winding directions thereof are the same, so as to obtain magnetic coupling (m13) between the inductors (L1, L3). In addition, magnetic coupling (M24) may also be obtained between a pair of loops of inductors (L2,L4) in even numbered-staged LC parallel resonators among the at least four LC parallel resonators.

Owner:MURATA MFG CO LTD

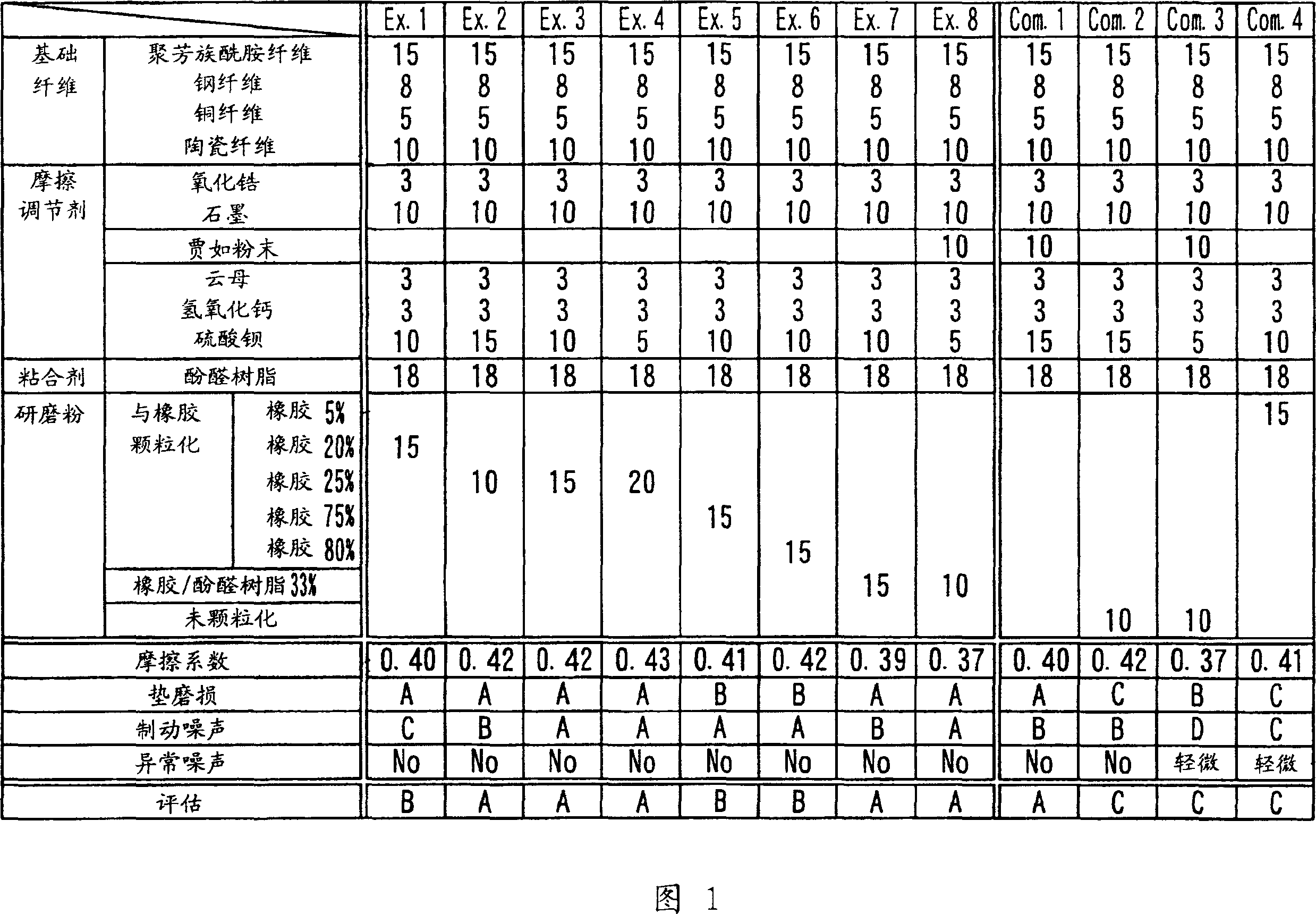

Friction material and method of manufacturing the same

A friction material includes base fibers, a friction conditioner, a binder and enlarged dust. The enlarged dust is a combination of grinding dust and an elastic material such as rubber.

Owner:ADVICS CO LTD

Radio frequency module

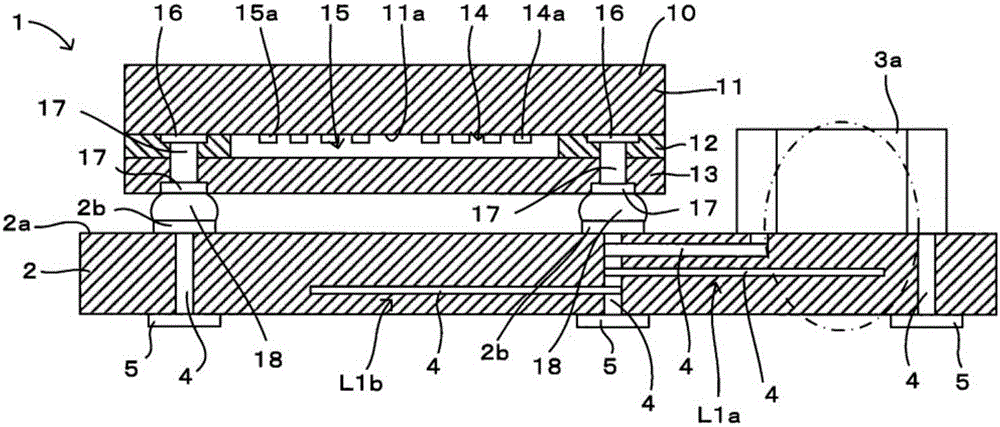

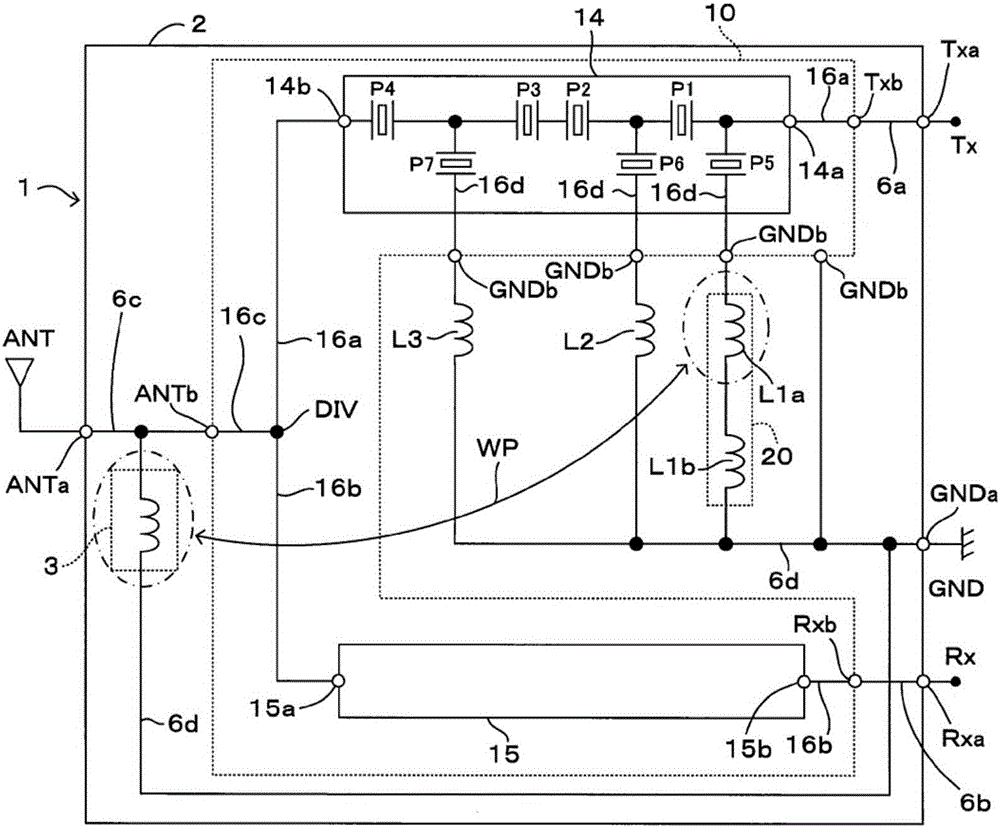

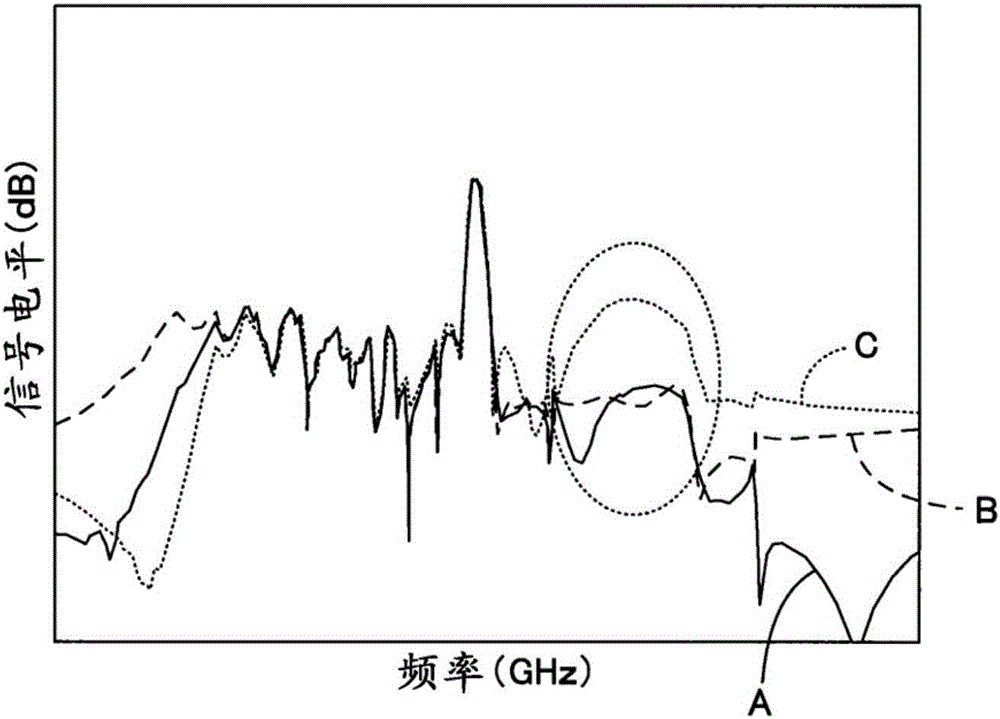

ActiveCN106464294AImprove attenuation characteristicsImprove isolation characteristicsMultiple-port networksOne-port active networksUltrasound attenuationRadio frequency

Provided is a configuration capable of improving an attenuation characteristic of an RF signal outside a frequency band of a transmitting signal inputted to a transmitting terminal, and improving an isolation characteristic between a transmitting filter and a receiving filter without increasing the size of a radio frequency module. A propagation path WP for further improving a filter characteristic without deteriorating an attenuation characteristic outside a pass band of a transmitting filter 14 can be formed by a simple configuration, and consequently an attenuation characteristic of an RF signal outside a frequency band of a transmitting signal can be improved without increasing the size of a radio frequency module 1. Further, an RF signal outside the frequency band of the transmitting signal and within approximately the same frequency band as a received signal is prevented from going around from a signal path on the output terminal 14b side of the transmitting filter 14 to the receiving filter 15 side and being outputted from a receiving terminal Rxa, and consequently an isolation characteristic between the transmitting filter 14 and the receiving filter 15 can be improved.

Owner:MURATA MFG CO LTD

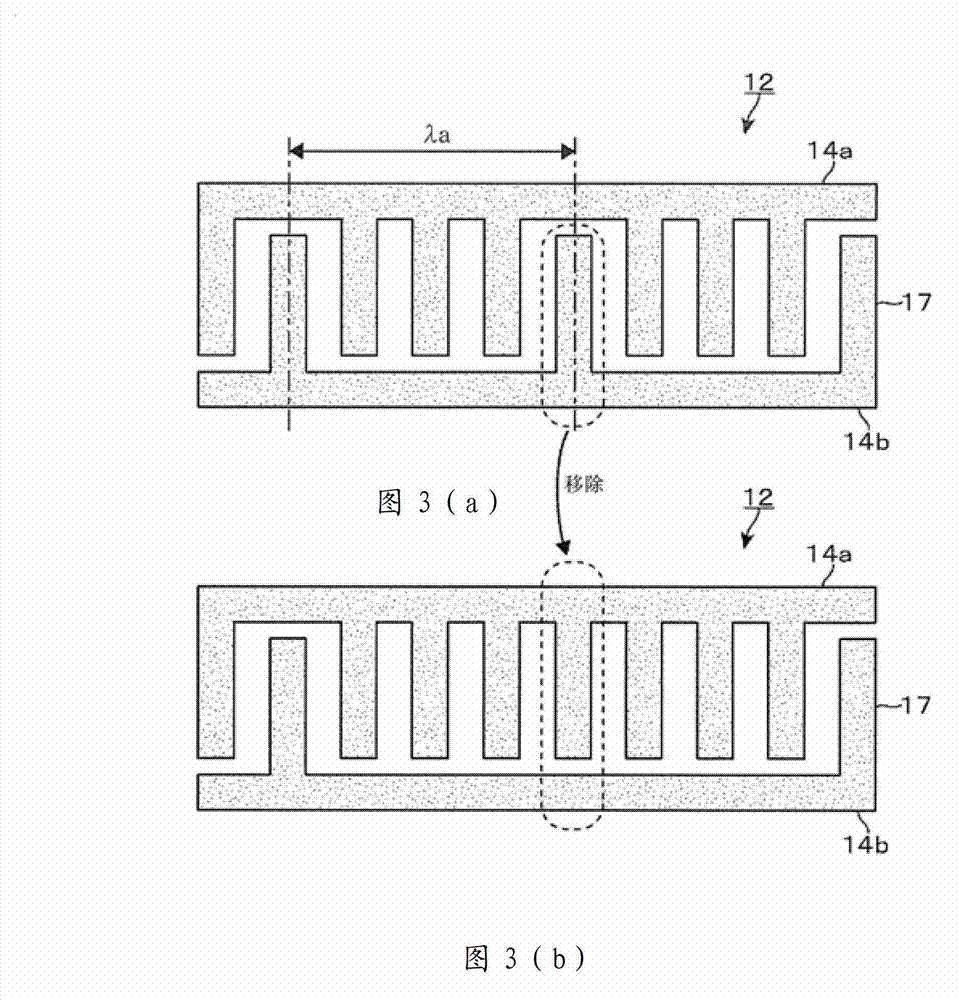

Elastic surface wave filter, wave divider and communication machine

InactiveCN1253042CGood reflective propertiesImprove attenuation characteristicsMultiple-port networksRadio/inductive link selection arrangementsSurface acoustic wave resonatorsSurface wave

A surface acoustic wave filter includes a piezoelectric substrate (110) and a plurality of one-terminal-pair surface acoustic wave resonators (111,112), which are disposed on the piezoelectric substrate in a ladder pattern and each of which includes an IDT electrode having a pair of comb electrodes. The one-terminal-pair surface acoustic wave resonators disposed in a ladder pattern include series resonators (111a-c), all of which are thinned-out. The electrode pitch of the IDT electrode of at least one (111b) of the series resonators is different from that of the IDT electrodes of the other series resonators (111a,c).

Owner:MURATA MFG CO LTD

Acoustic wave filter

InactiveCN103051303AAvoid excitationSuppresses degradation of transmission response characteristicsImpedence networksUltrasound attenuationAcoustic wave

Disclosed is a pass band type acoustic wave filter capable of obtaining an excellent attenuation characteristic in attenuation bands, in which an IDT electrode having a meander structure is used as at least one of the input-side electrode and the output-side electrode, and the attenuation band is provided over / under the pass band. An electrode having a meander structure in which a plurality of IDT blocks are connected to each other in series between the input port or the output port and the ground port is arranged as the input-side IDT electrode and the output-side IDT electrode, and the electrode finger between the neighboring IDT blocks is removed, so as to suppress excitation of an undesired acoustic wave.

Owner:NIHON DEMPA KOGYO CO LTD

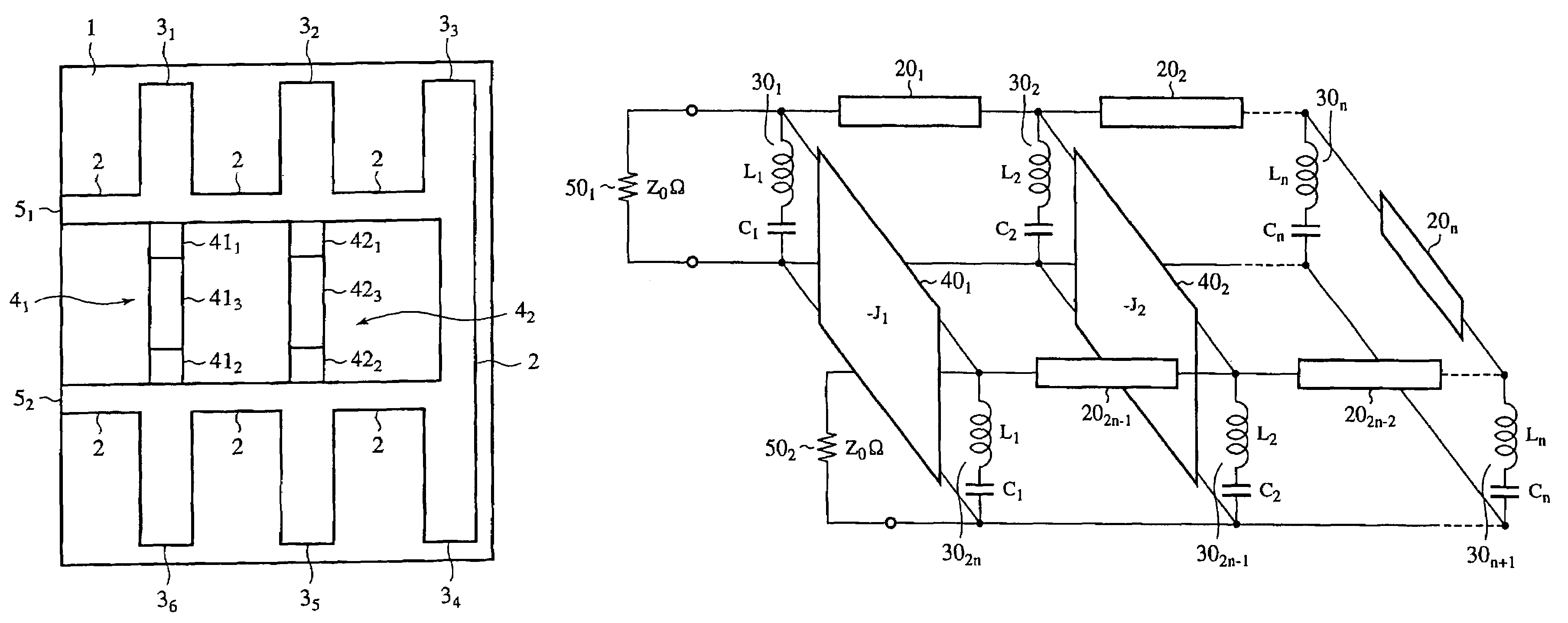

Band rejection filter with attenuation poles

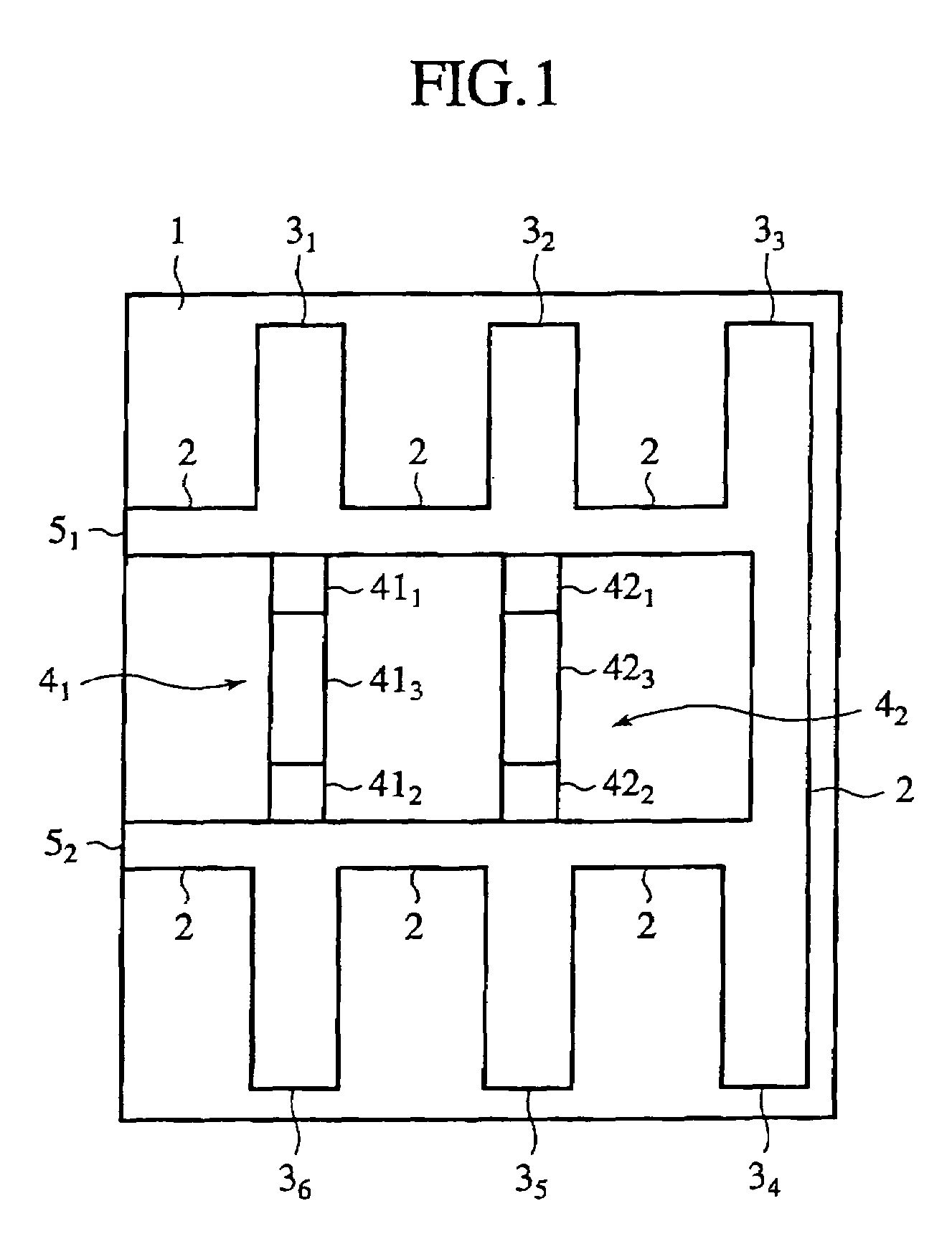

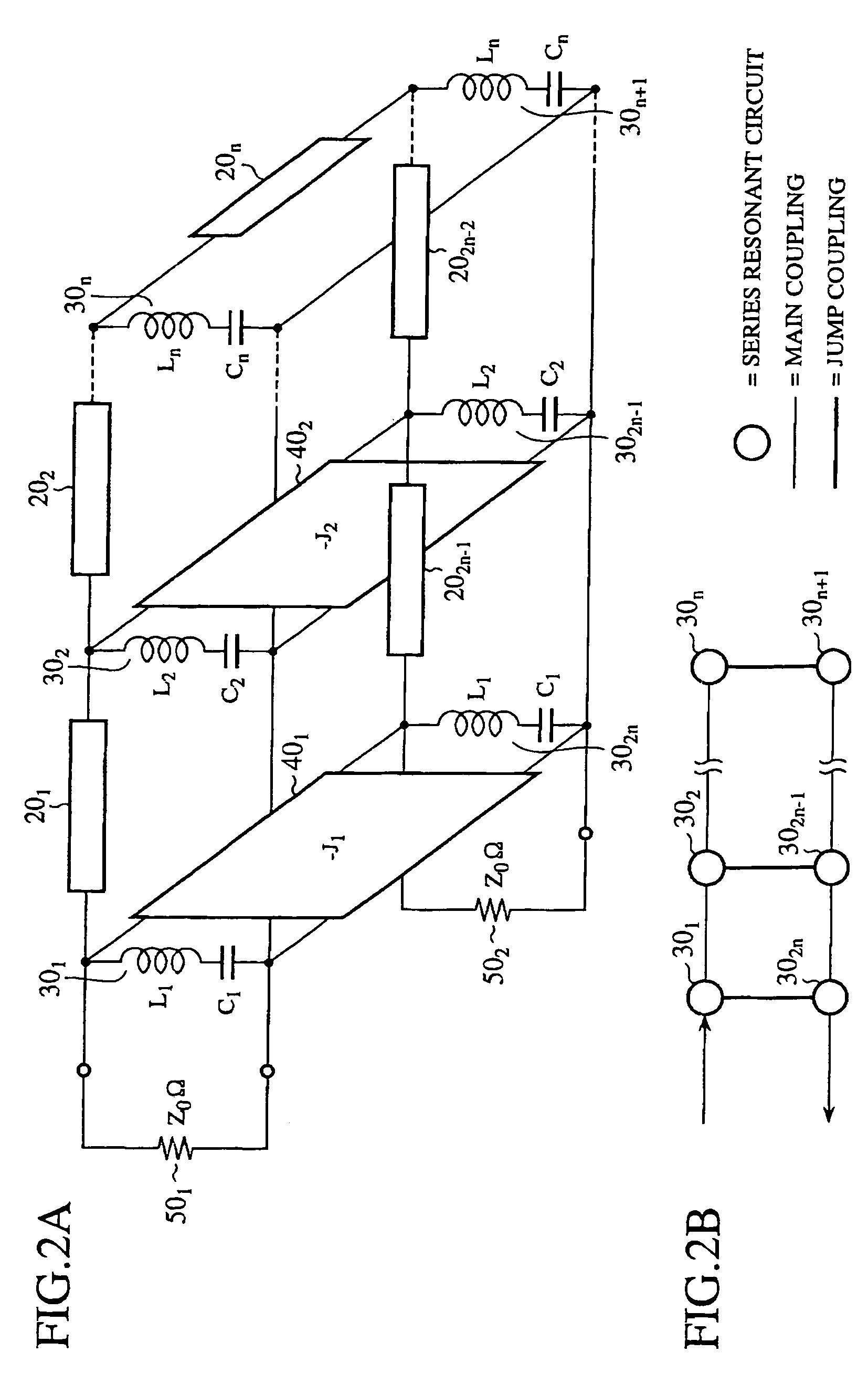

InactiveUS7256666B2Reduce in quantityImprove featuresElectrolysis componentsWaveguidesUltrasound attenuationResonance

A band rejection filter with attenuation poles includes a plurality of series resonant circuits having end terminals connected in common and other end terminals connected in series via a plurality of transmission lines each having a length that is an odd multiple of about the one-quarter wavelength at the resonance frequency of the plurality of series resonant circuits, and a jump-coupling circuit for roughly coupling two of the plurality of series resonant circuits, which are not adjacent to each other, to each other.

Owner:MITSUBISHI ELECTRIC CORP

Filter circuit and filter device

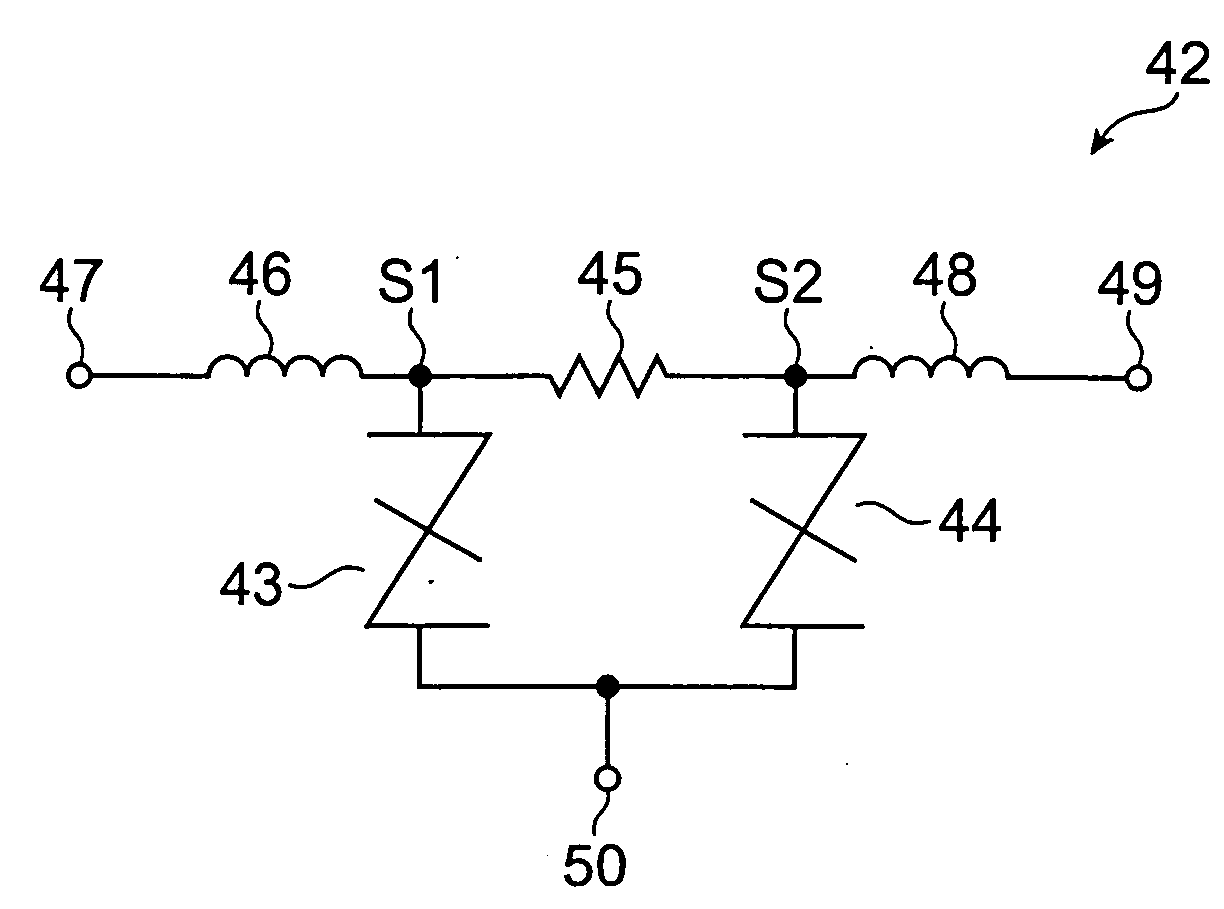

ActiveUS20070268647A1Improving attenuation characteristicReduce sizeMultiple-port networksEmergency protective arrangement detailsVaristorEngineering

A filter circuit has first and second varistors, a resistance, an input terminal, an output terminal, and a ground terminal. The resistance is connected between the first and second varistors. The input terminal is connected to a junction between the first varistor and resistance through a first coil. The output terminal is connected to a junction between the second varistor and resistance through a second coil. The ground terminal is connected to a side of the first varistor opposite from the resistance and a side of the second varistor opposite from the resistance.

Owner:TDK CORPARATION

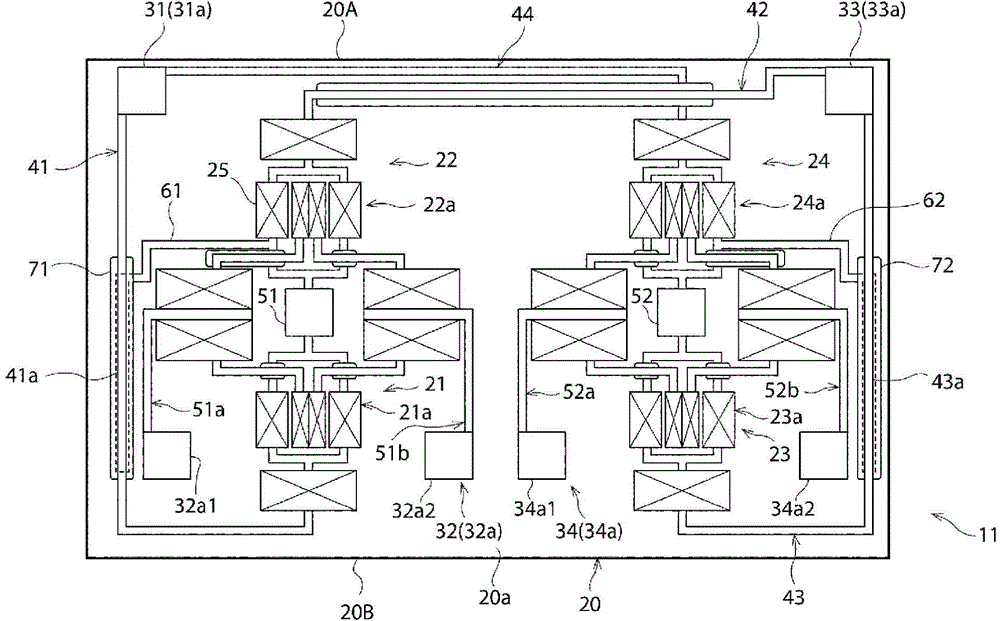

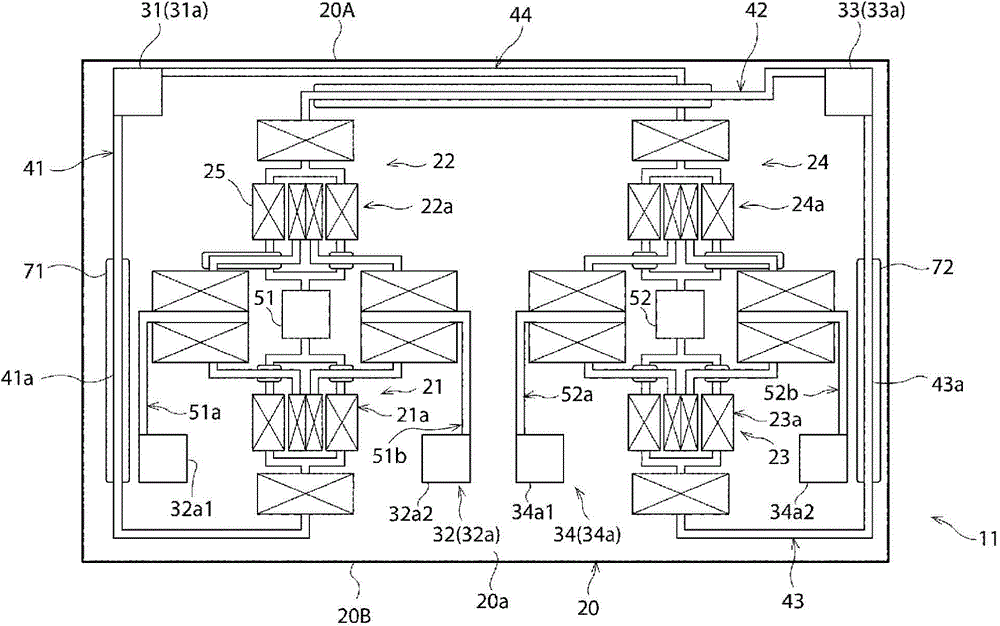

Elastic wave filter device

ActiveCN103609020AGood attenuation characteristicsImprove attenuation characteristicsImpedence networksUltrasound attenuationGround line

Provided is an elastic wave filter device that exhibits an excellent attenuation characteristics except within the passband. The elastic wave filter device (1) is equipped with filter electrode sections (21a-24a) that are provided on a piezoelectric substrate (20) and constitute elastic wave filter sections (21-24). Input signal lines (41, 43) have adjoining sections (41a, 43a) that adjoin output signal lines (51a, 52b). The distance between each adjoining section (41a, 43a) and a corresponding ground line (61, 62) that is connected to the ground potential is shorter than the distance between the adjoining section (41a, 43a) and the corresponding output signal line (51a, 52b).

Owner:MURATA MFG CO LTD

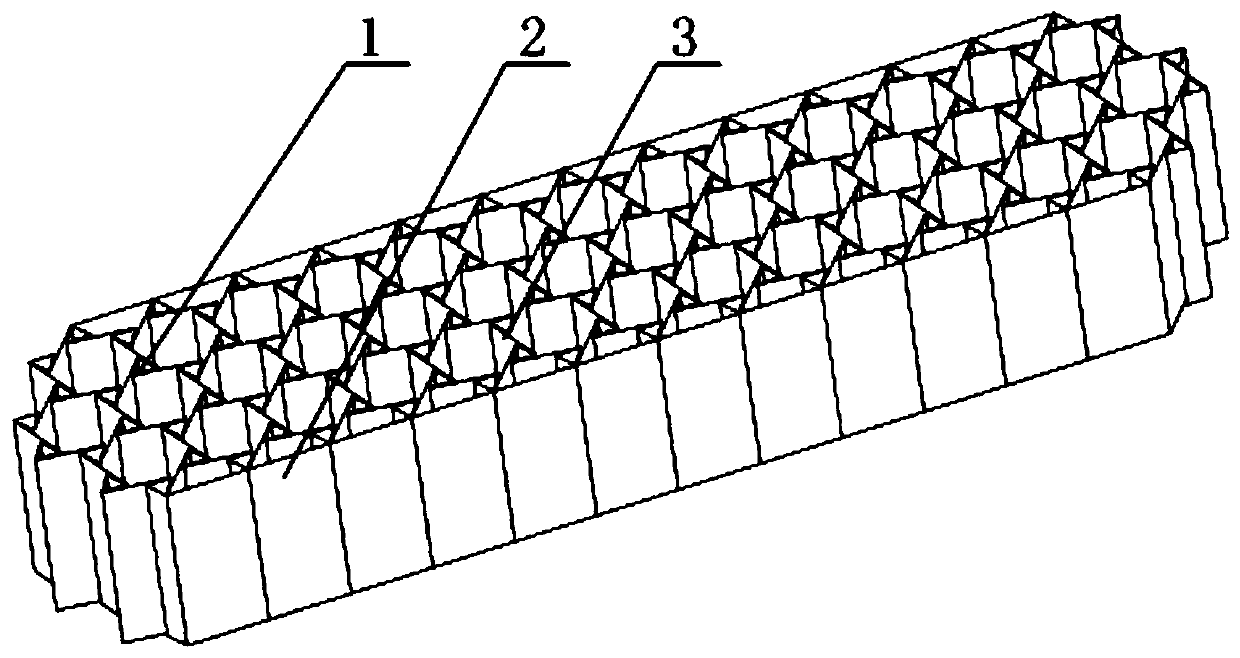

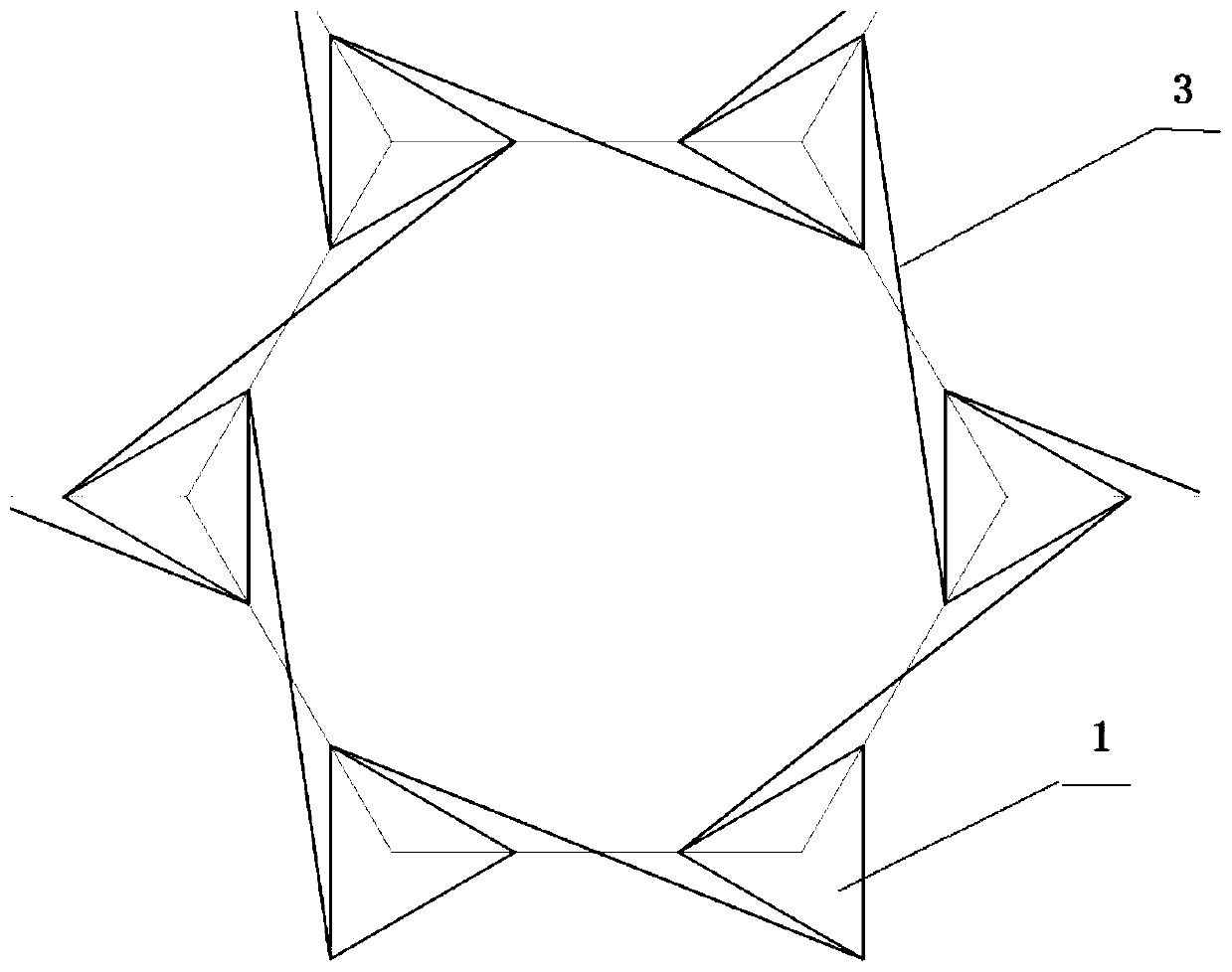

Novel 3D (three-dimensional) printed protective material in high-negative-Poisson-ratio interwoven structure

ActiveCN109825087ANegative Poisson's Ratio HighGood buckling strengthAdditive manufacturing apparatusManufacturing technologyEngineering

Owner:伊诺维(无锡)新材料科技有限公司

Surface acoustic wave filter ceramic package with special shielding effect and method

PendingCN110535450ACompact structureReasonable structureImpedence networksUltrasound attenuationGold ball

The invention relates to a surface acoustic wave filter ceramic package with a special shielding effect and a method. The surface acoustic wave filter comprises a ceramic substrate and a surface acoustic wave filter chip, the ceramic substrate is provided with a grounding metal part. An electrode is arranged on a circuit loop of the surface acoustic wave filter chip and is connected to a ground metal portion located on the ceramic substrate through a gold ball, wherein the surface of the surface acoustic wave filter chip is coated with a layer of white glue dry film, the edge of the white gluedry film is fixed on a grounding metal part on the upper surface of the ceramic substrate, a metal film layer is arranged outside the white glue dry film, the edge of the white glue dry film is alsofixed on the grounding metal part on the upper surface of the ceramic substrate, and a layer of black glue dry film is arranged outside the metal film layer. According to the invention, the shieldingeffect is good, the size application range is large, the cost is reduced and the product size is reduced by adopting a gold ball embedding mode, and the grounding metal part of the ceramic base is connected with the sputtering metal layer in series to realize the special shielding effect of ceramic packaging, so that the attenuation characteristic of the product is improved, and the product yieldis greatly improved.

Owner:无锡嘉硕科技有限公司

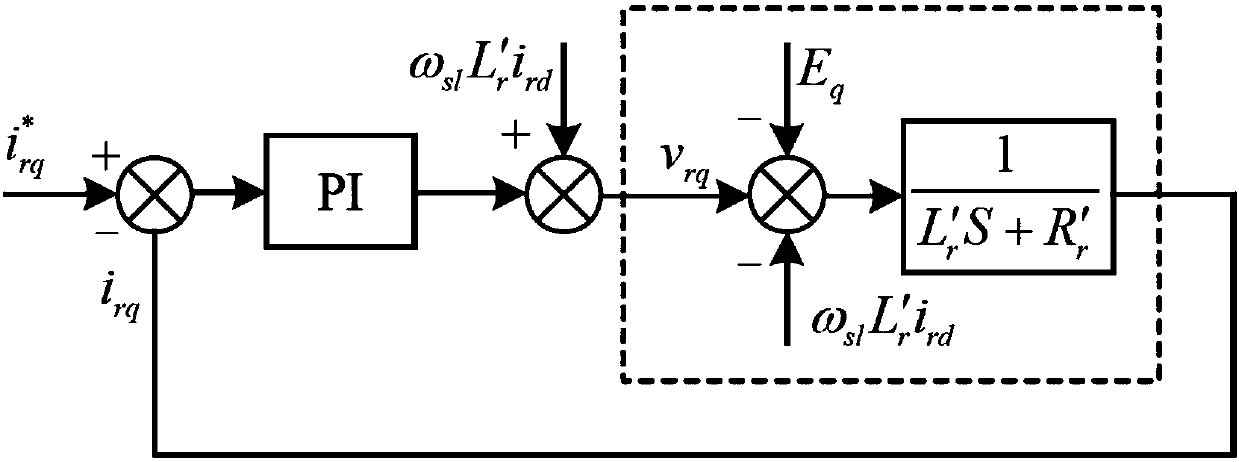

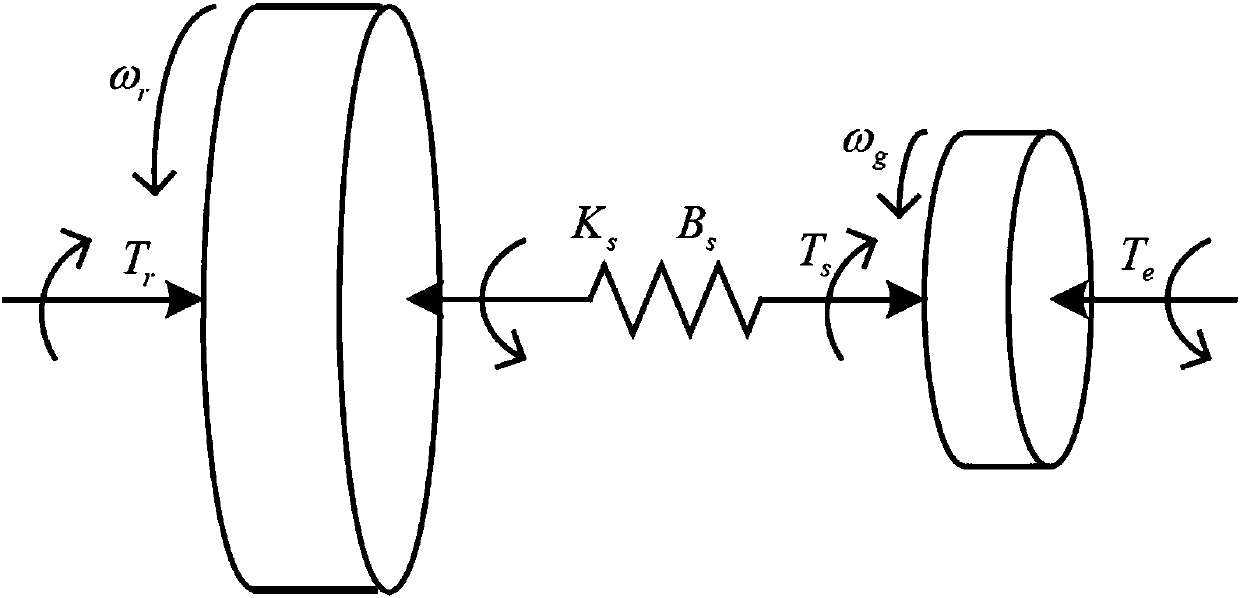

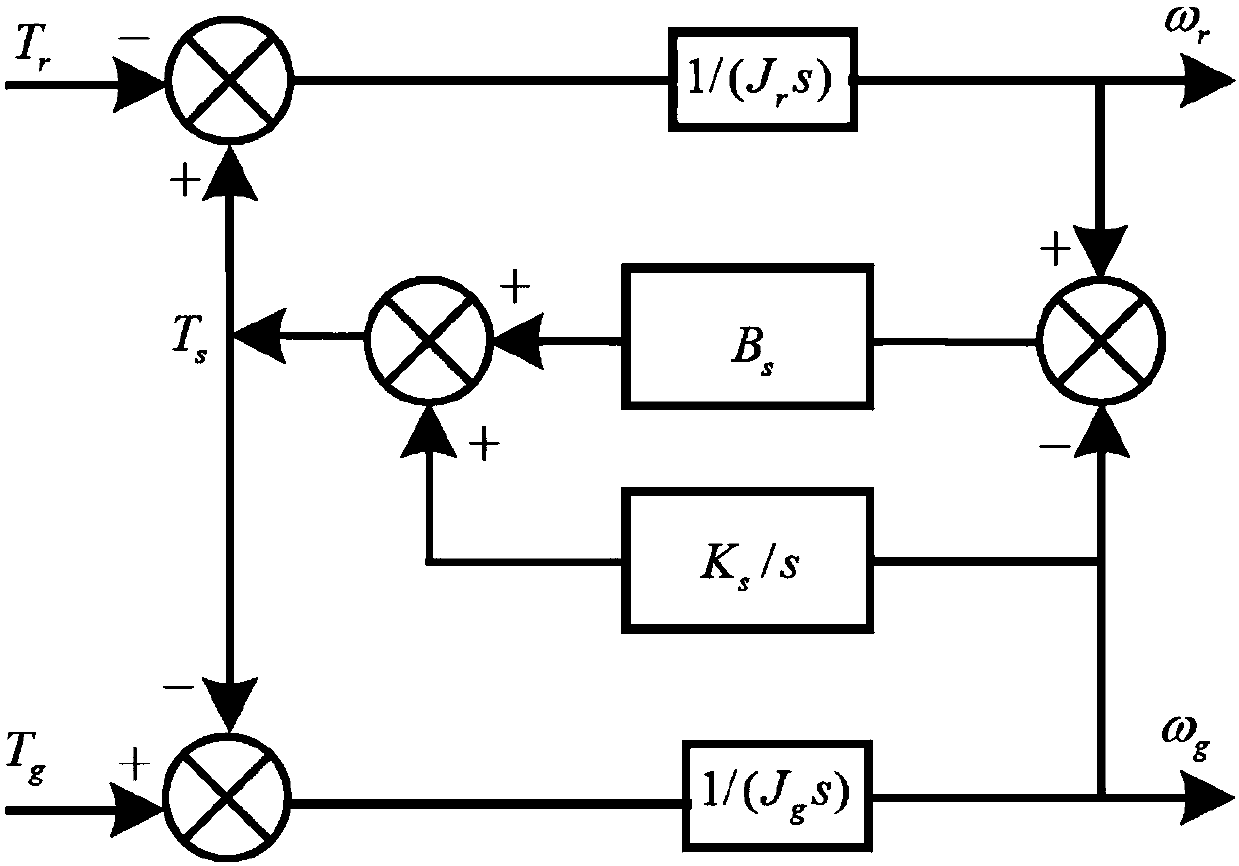

Improved control strategy for shaft system concussion inhibition of doubly-fed wind generators

InactiveCN107644112AEnhanced inhibitory effectImprove attenuation characteristicsSpecial data processing applicationsUltrasound attenuationSmall-signal model

The invention discloses an improved control strategy for shaft system concussion inhibition of doubly-fed wind generators. The strategy comprises the following steps of: firstly calculating a theoretical expression of an electromagnetic torque under the sudden rise of power grid voltage on the basis of a doubly-fed wind generator mathematic model with a mechanical transmission system, and analyzing a mechanism of causing torsional vibration of a shaft system by high-voltage faults by combining mathematic models of two quality blocks of the shaft system; and proposing a control strategy for compensating a compensation torque which is directly proportional with a torque differential in the electromagnetic torque so as to increase model damping of the two quality blocks. According to the strategy, feature values of speed ring small-signal models are solved, stability and a free attenuation characteristic of systems after increasing compensation torques are analyzed, and a torque observeris imported to extract to-be-overlapped compensation torques.

Owner:郭琳

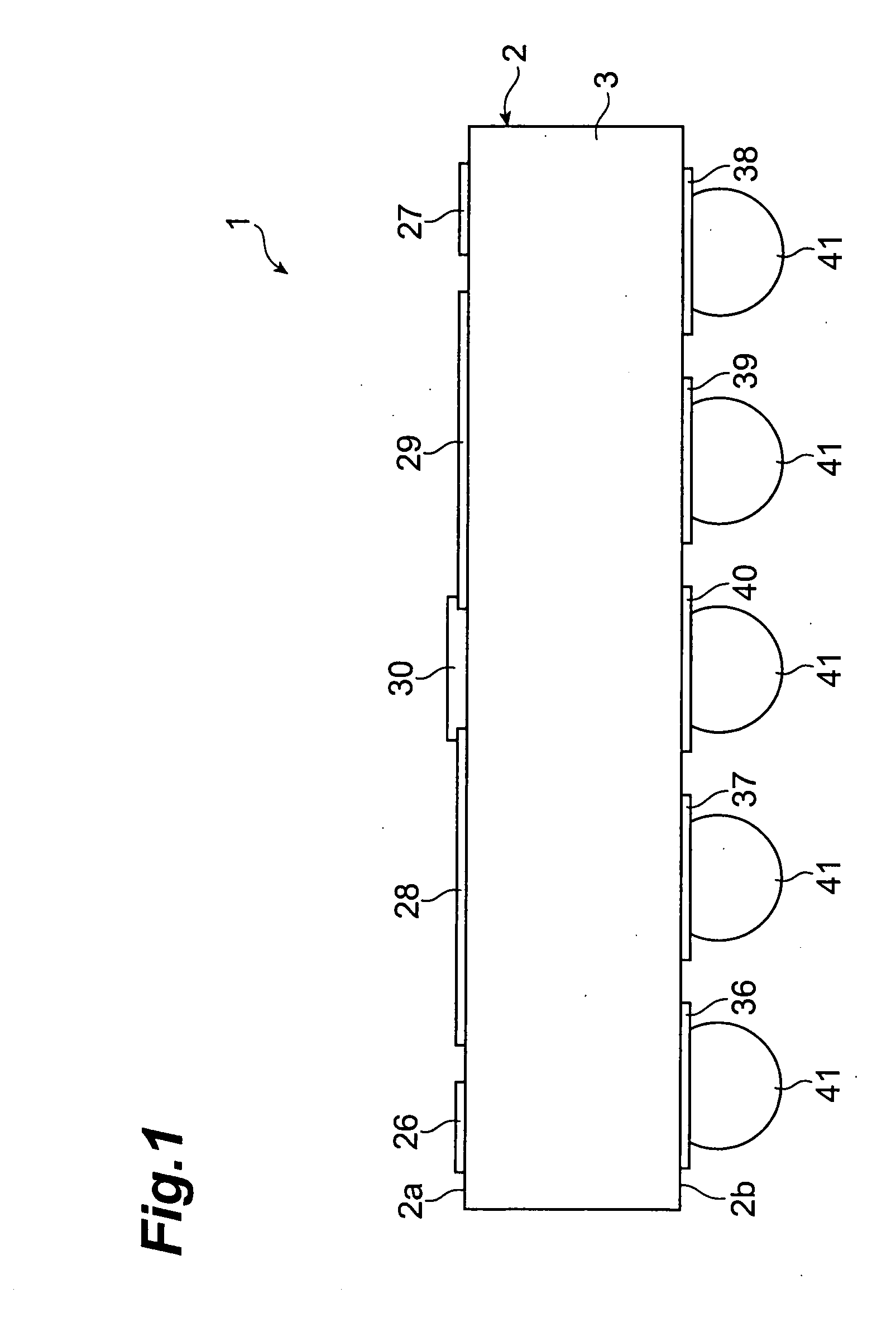

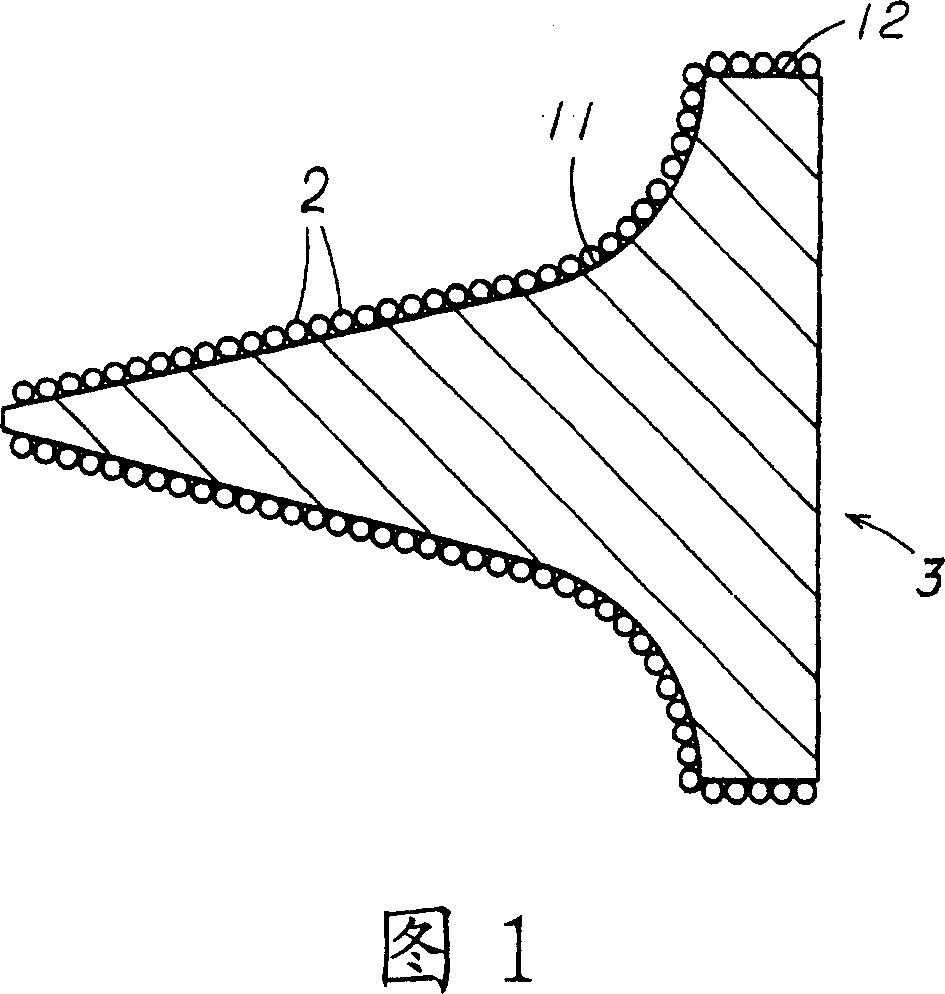

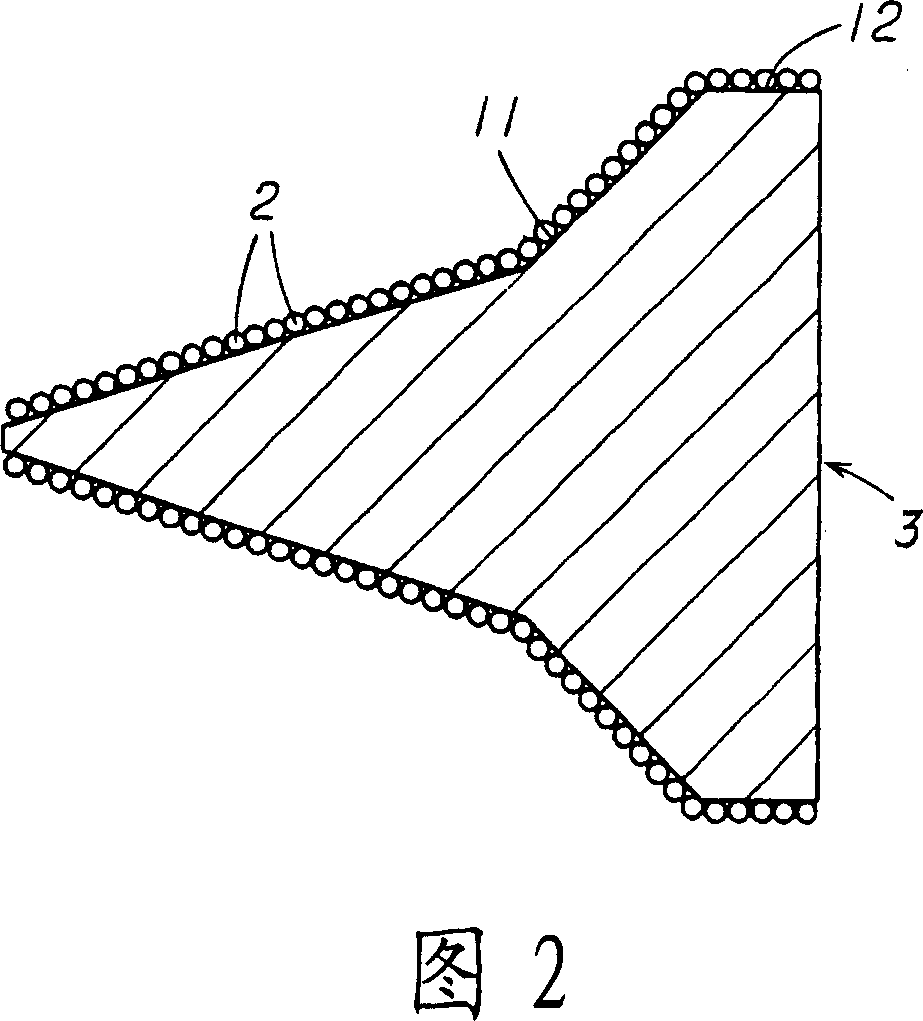

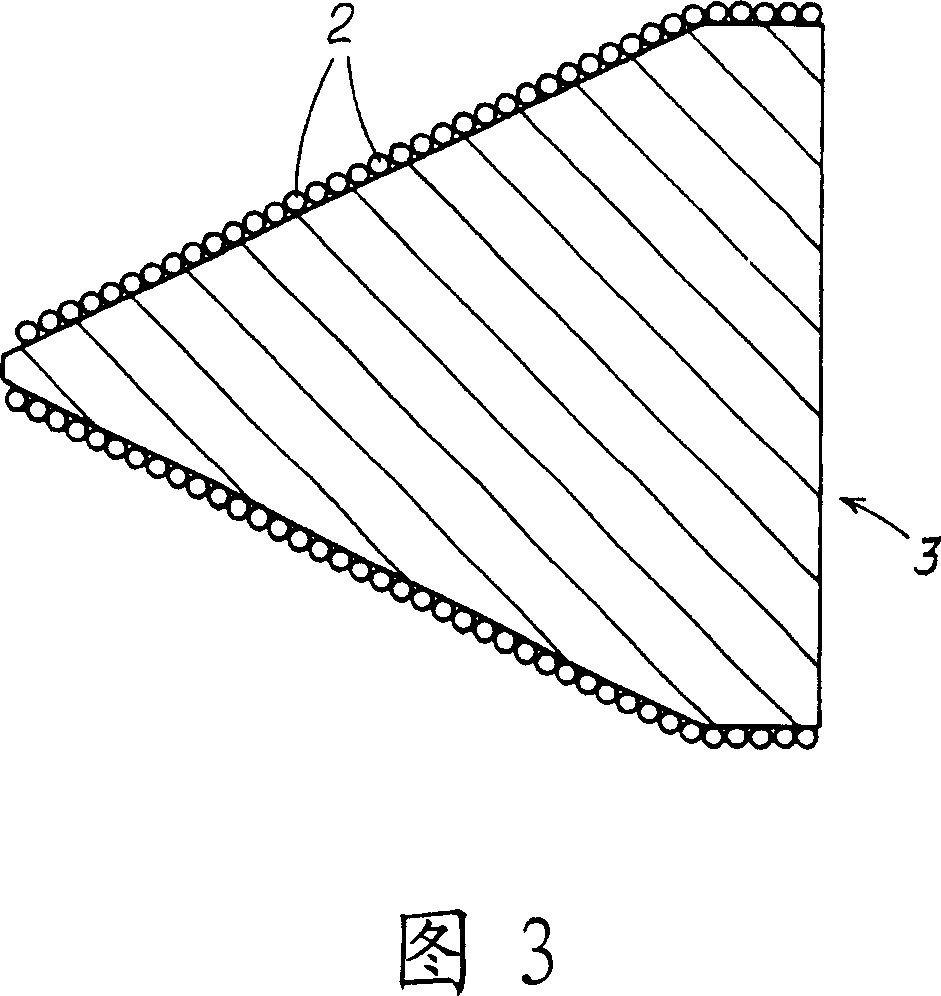

Wound coil type inductor

InactiveCN1967747AIncrease the attenuationEasy to achieve compactnessElectrical transducersTransformers/inductances magnetic coresHigh rateInductor

The present invention provides a wound coil with high attenuation characteristics across a wide frequency band, high uility, and high inducter characteristics across a wide frequency which is not existed so far. The wound coil is made by winding a conductive wire ( 2 ) around a core ( 3 ), wherein the core ( 3 ) is shaped having a tapered part ( 11 ) in which the outside diameter of the core ( 3 ) gradually decreases so that the diameter of the conductive wire ( 2 ) wound around the core ( 3 ) is not constant but instead gradually decreases; and the tapered part ( 11 ) is not tapered so that the outside diameter of the core ( 3 ) decreases at a constant rate from a large proximal end to a small distal end of the tapered part ( 11 ), but rather the tapered part ( 11 ) is formed into a tapered shape wherein the rate of decrease in the outside diameter of the core ( 3 ) is gradually reduced from the large proximal end to the small distal end; i.e., the tapered part ( 11 ) decreases in diameter at a high rate at the proximal end, and decrease in diameter at a lower rate in the distal end than in the proximal end.

Owner:NOC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com