Friction material and method of manufacturing the same

A technology of friction materials and friction modifiers, applied in friction linings, mechanical equipment, etc., can solve problems such as difficult handling, and achieve the effects of easy handling, high friction coefficient and wear resistance, and improved attenuation characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

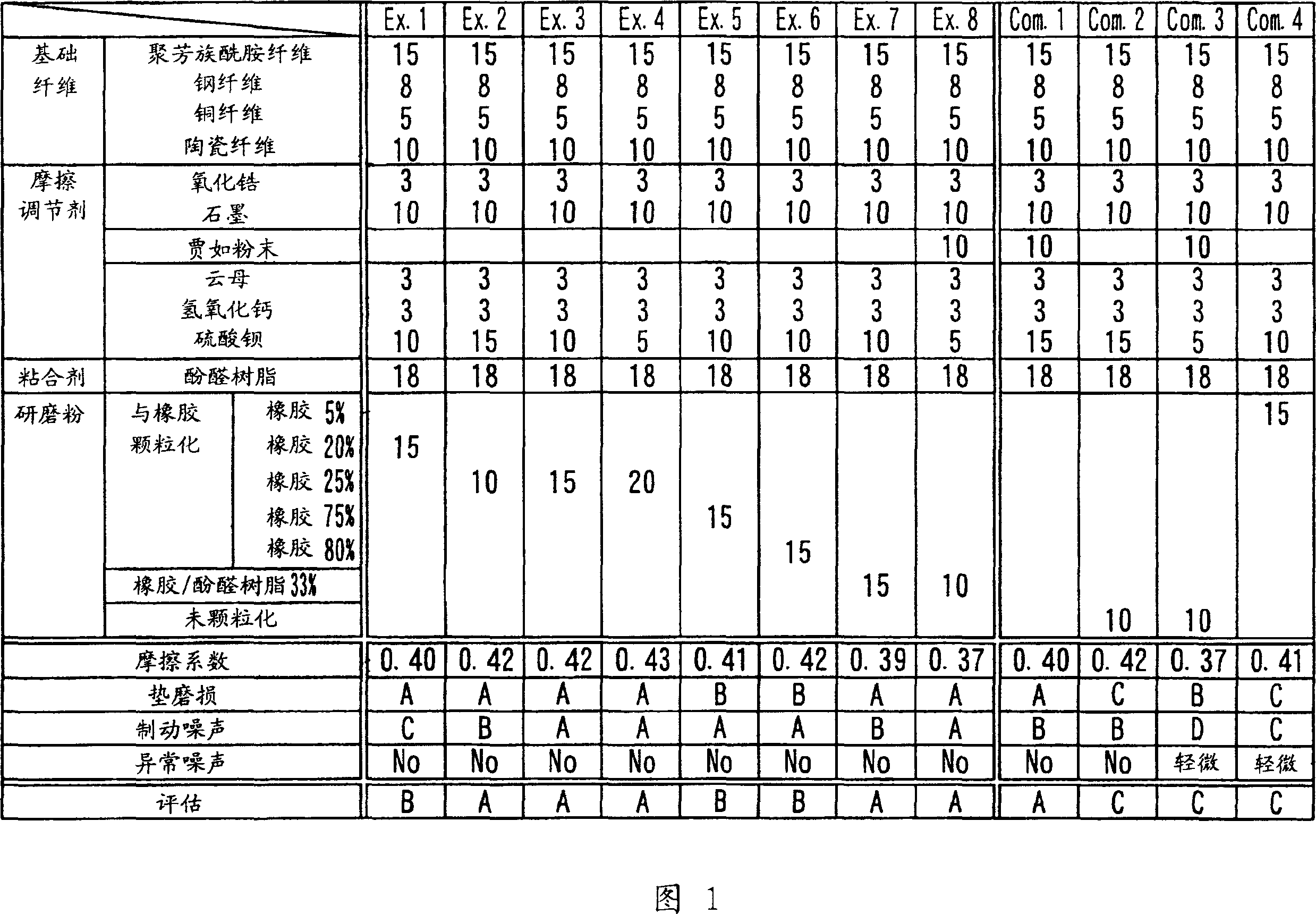

[0039] The enlarged powder in Example 1 included a rubber content of about 20%, or a ground to rubber weight ratio of 80:20. The enlarged powder accounts for about 15% of the volume of the friction material.

[0040] SBR (a product of Asahi Kasei under the trade mark Tafdene 2000) and BR (a product of Asahi Kasei under the trade mark Diene NF35R) were used as the rubber to bind the ground powder. The enlarged powder is obtained by kneading 70 parts by weight of SBR, 30 parts by weight of BR, 5 parts by weight of zinc white, 2 parts by weight of stearic acid, 0.5 parts by weight of sulfur, 3 parts by weight of vulcanization catalyst and 400 parts by weight of grinding powder Obtained in a pressure kneader. The enlarged powder was passed through a pan granulator (Fuji Paudal) and a rotary granulator (Horai) to form pellets with a diameter of 1-2 mm.

[0041] Then, the base fiber, friction modifier, binder, and enlarged powder of mill powder shown in FIG. 1 were mixed in a dry ...

example 5

[0044] The rubber content of the oversized powder in Example 5 was about 75%, or a weight ratio of ground powder to rubber of 25:75. More specifically, the enlarged powder was obtained by replacing 400 parts by weight of Example 1 with 33 parts by weight of ground powder. The abrasive dust in this example may comprise about 15% by volume of the friction material. Example 5 was produced in the same manner as Example 1.

example 6

[0045] The rubber content of the oversized powder in Example 6 was about 80%, or a weight ratio of ground powder to rubber of 20:80. More specifically, an enlarged powder was obtained by replacing the 400 parts by weight of Example 1 with 25 parts by weight of ground powder. In this example, the enlarged powder may comprise about 15% of the volume of the friction material. Example 6 was produced in the same manner as Example 1.

[0046] The enlarged powder in each of Examples 7 and 8 contained about 33% rubber and phenolic resin, or a 67:33 weight ratio between ground powder and rubber and phenolic resin mixture. Phenolic resin (Sumilite Resin PR310 from SumitomoBakelite) was added to the raw material as granules when they were granulated to obtain the enlarged powders in Examples 7 and 8. The enlarged powder may comprise about 15% or 10% of the volume of the friction material. Examples 7 and 8 were produced in the same manner as Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com